APPLICATION

The meter is designed for use with compressed air and nitro-

gen. If the meter will be used at pressures below 15 psig,

consult CDI about velocity limitations. The air must be free of oil,

dirt that could foul the probes, and suspended water droplets. In

a compressed-air application, the meter should be installed

downstream of a dryer. Each meter is calibrated for a specic

size and type of pipe. If a meter will be used in a type or size of

pipe that is not listed, consult CDI about a special calibration.

The meter is not to be used in safety or life-support applica-

tions. It should not be used as a sole means of determining

required capacity of air compressors and related equipment.

The meter must not be used in hazardous locations.

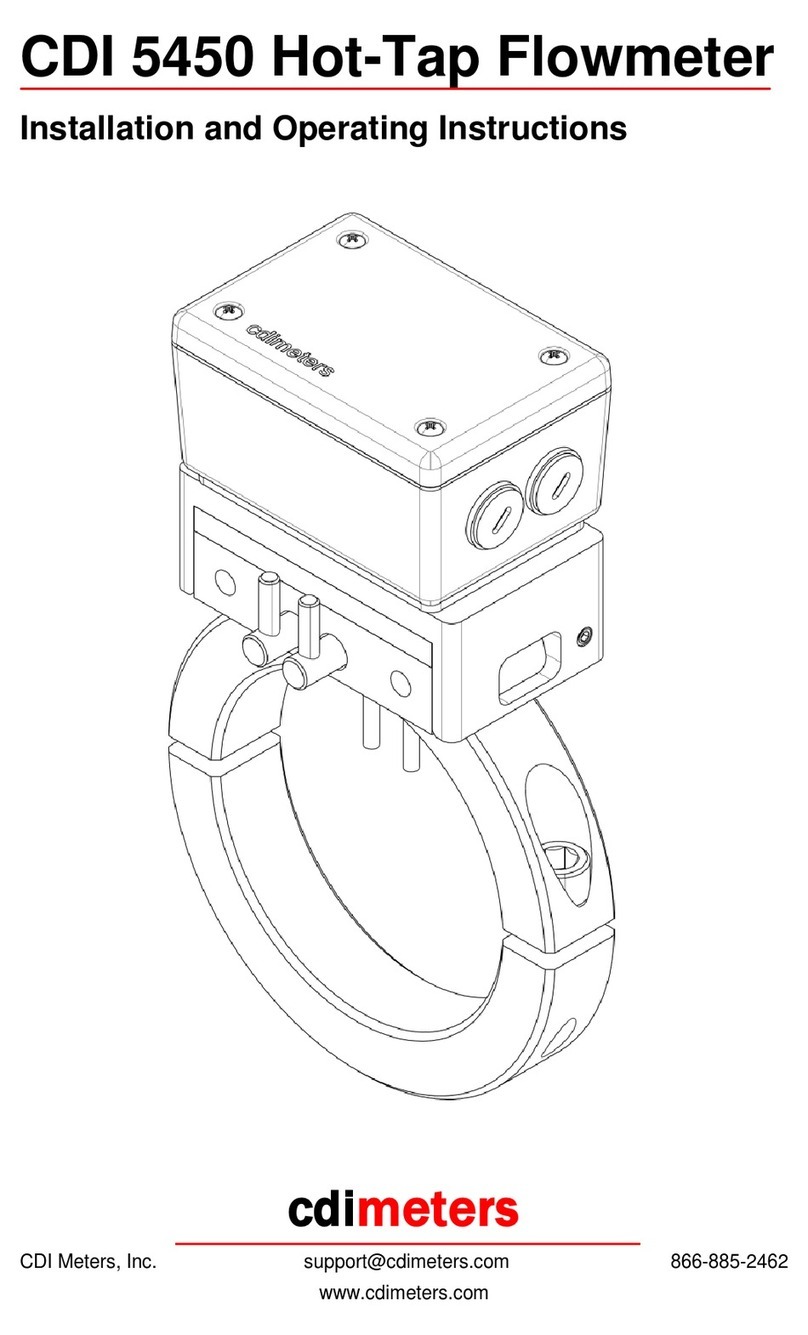

INSTALLATION

Drilling the holes to install the meter will release some metal

shavings into the pipe. When planning the installation, make sure

that all downstream equipment is protected by lters, or take

other precautions to ensure that shavings do not reach critical

equipment or get blown out in a way that could cause injury.

For best accuracy, the meter should be installed with at least

20 diameters of straight pipe upstream and three diameters

downstream. Avoid installing the meter down-stream of any

item that could distort or concentrate the ow, such as a

partially-closed valve, a regulator, a lter or moisture separa-

tor, two closely-spaced elbows in different planes, a

long-radius elbow or a curved hose. Allow at least 30 diame-

ters of straight pipe between any such item and the meter. If

a valve or other restriction will be immediately downstream of

the meter, provide at least ve diameters downstream. Select

a location that meets these requirements and also provides

good visibility from the plant oor. If this is not possible,

consider using the remote display discussed below.

To install the meter, rst shut off the supply of air to the pipe

where the meter will be mounted and allow the pres-sure to

bleed down. Clamp the drill guide rmly to the pipe, orienting

it for best visibility of the meter. Drill the two holes and remove

any resulting burrs from the outside of the pipe. Make sure

the outside surface of the pipe is clean and smooth.

Before mounting the meter on the pipe, orient the display

relative to the ring for best visibility. The display and cover can

be removed and rotated 180 degrees relative to the meter

housing, and the meter housing can be rotated 90 degrees

relative to the ring, using screws behind the housing.

Next remove the back half of the ring, insert the probes into

the holes in the pipe with the ow arrow pointing in the proper

direction, and re-assemble the rings. Tighten the cap screws

rmly and evenly so that the gaps between the halves of the

rings are about equal on both sides of the pipe.

MILLIAMP AND PULSE OUTPUTS

The meter has an isolated, unpowered, milliamp output. The

meter is shipped with a jumper in place to power the output

from the instrument’s dc supply. With the jumper in place, the

meter will source a dc signal. The pulse output is an open

collector, referenced to the instrument ground. For applica-

tions in which a contact-closure output is required, the

isolated pulse output (CDI 5200-IPO) should be used. It

installs inside the meter. The pulse output can be made into a

threshold output by using the optional conguration cable.

DISPLAY CONTROL AND CONFIGURATION

The display can be cycled through rate, daily usage and cumula-

tive usage using a button indicated by a circle on the front of

the meter. The same button can be used to select a default

display option, reset totals and select units of measure. Please

refer to the conguration instructions enclosed with the meter.

METER CONFIGURATION

Several parameters of the meter’s conguration can be

changed by the user using an optional conguration cable

and software available from CDI. These parameters include

milliamp scaling, pulse scaling, conversion from pulse out-put

to threshold output, ltering (smoothing) of the output, pipe

inside diameter, and pressure compensation for high-pres-

sure applications. For most applications, none of these

parameters need to be changed.

POWER SUPPLY

Each meter is furnished with a wall-plug dc supply for 110 V to

230 Volt AC main with a 6-foot (1.5 M) cable plus a 14-foot (4.2

M) extension cable. Prongs for Australian, European, UK and US

outlets are provided, as appropriate. The meter may alternatively

be hard wired to a 24-Volt dc sup-ply. Eighteen-Volt supplies

furnished with some earlier CDI owmeters must not be used.

DRILL GUIDE

For pipe sizes three inches and larger, the drill guides are

half rings that bolt to the back halves of the meter rings (CDI

5400-XX-DG). For the two- and 2-1/2 inch sizes, a single drill

guide is used (CDI 5400-S-DG). There is also a universal drill

guide (CDI 5400-U-DG) for all 5400 sizes. Each of the drill

guides is furnished with a 3/16 inch drill bit and a hex wrench.

Please note that the 5200-DG drill guide cannot be used with

the 5400-series owmeters.

LIMITED WARRANTY

CDI warrants solely to the buyer that the Model 5400 Flowmeter

shall be free from defects in materials and workmanship, when

given normal, proper and intended usage, for three years from

the date of purchase. During the warranty period, CDI will repair

or replace (at its option) any defective product at no cost to the

buyer. The foregoing warranty is in lieu of any other warranty,

express or implied, written or oral (including any warranty of

merchantability or tness for a particular purpose). CDI’s liability

arising out of the manufacture, sale or supplying of the owme-

ter, whether based on warranty, contract, tort or otherwise, shall

not exceed the actual purchase price paid by the buyer, and in

no event shall CDI be liable to anyone for special, incidental or

consequential damages.

CDI METERS, INC. 06/13/2016

© CDI Meters, Inc. 2016

Specications are subject to change without notice.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com