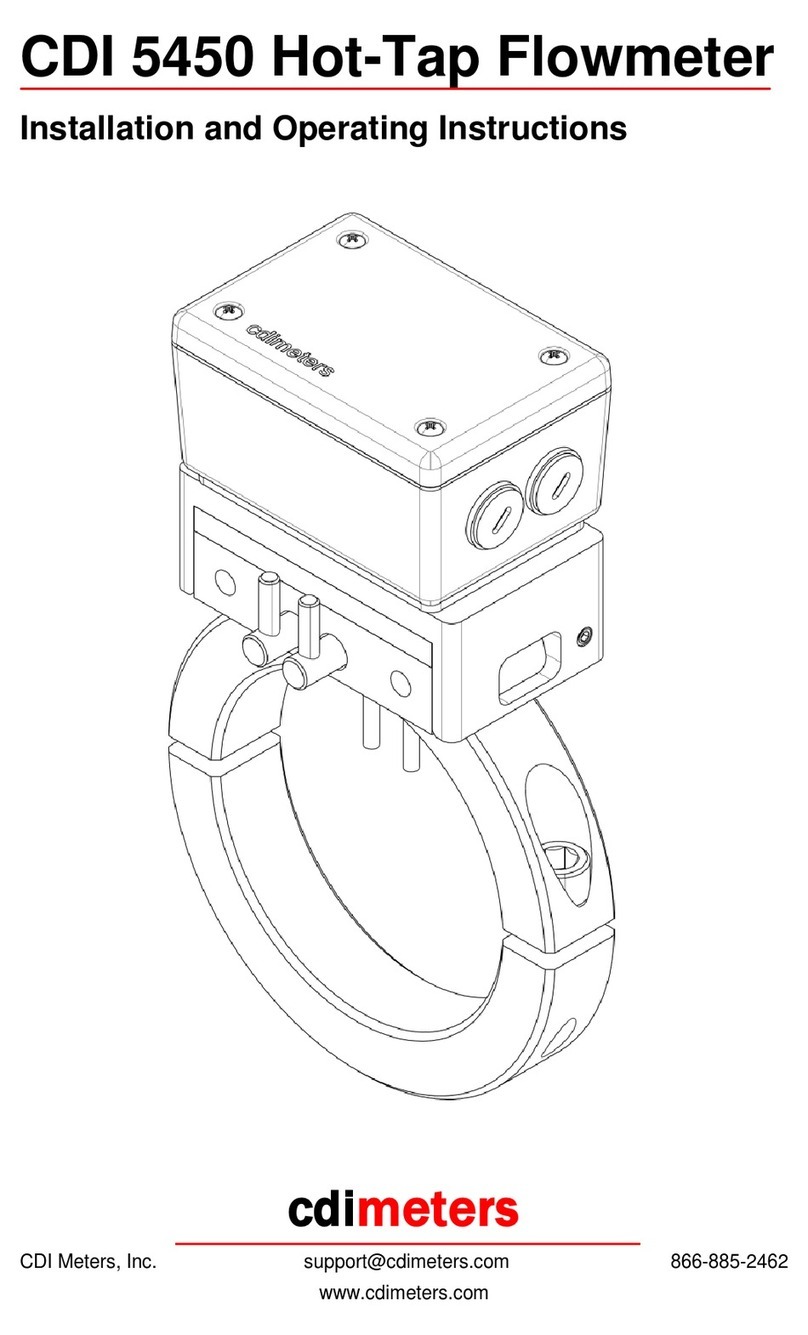

Installing the Meter

Make sure the probes are clean. If there is any oil or dirt on them, clean them

with alcohol or a similar degreaser. If the housing must be rotated to suit the

installation, loosen (do not remove) the two small cap screws in the plate

beneath the housing, rotate the housing, and tighten the screws. Insert the

probes into the holes in the pipe, with the flow arrow pointing in the direction of

flow. Tighten the screws carefully, alternating screws, so that the two sides of the

collar are pulled together evenly. If the LED display is upside down, remove the

cover of the meter, rotate it and the display panel 180 degrees, and reinstall the

cover. If the yellow caution label is not visible, apply the extra caution label from

the bag of parts in a visible location.

Wiring the Meter

POWER

Either use the 18-Volt dc wall-plug supply provided with the meter, or connect a

24-Volt dc supply to the DC- and DC+ terminals. The DC- terminal is connected

to the pipe on which the meter is mounted.

REMOTE DISPLAY

If you are using Summing Remote Display, connect the DC-, DC+ and display

terminals in the display to the corresponding terminals in the meter. The meter

may be powered from the remote display if the connecting cable is 22 gauge or

larger and the distance is no greater than 60 feet.

MILLIAMP OUTPUT

The mA- and mA+ terminals are optically isolated from the remainder of the

circuit and may be wired as part of an externally-powered loop. When this is

done, the jumper that is supplied with the meter must be removed. If you use an

external supply, be sure that it has sufficient voltage to overcome an 8.2 Volt

drop within the meter in addition to any other voltage drops in the loop. Powering

the milliamp circuit from an external supply does not provide power to the meter

itself. The meter must be powered from its wall-plug supply or a separate 24 Volt

dc supply.

Alternatively, the meter’s supply may be used to power the milliamp signal.

Leave the jumper in place from the DC+ terminal to mA+. Wire from the mA-

terminal to the positive side of the external receiver and from the negative side of

the external receiver to the DC- terminal. Power the meter from its wall-plug

supply or a 24V dc supply. Note that the DC- terminals are connected to the pipe

on which the meter is mounted.

©Copyright 2006 - 2010 CDI Meters, Inc. 07.10

PULSE OUTPUT

The pulse output is an open-drain output, that is, a transistor switch connected to

the meter’s negative supply. To use the output, connect it to an input of the

receiving device (usually a counter or PLC) and connect a pullup resistor from

that input to a positive supply suitable for the receiving device. Also connect the

negative supply terminal of the meter to the negative supply of the receiving

device. If an isolated relay contact is required, install the CDI 5200-IPO isolated

pulse output and wire it to the receiving device.

SERIAL COMMUNICATION OPTION

The RS-485 signal used with the Serial Communication option is wired to the

special Serial Communication display board. The two threaded openings in the

meter enclosure permit the signal to be wired from meter to meter without

external splices. Please refer to the data sheet for the Serial Communication

option.

Using the Outputs

The milliamp output is scaled so that four milliamps corresponds to zero flow and

20 milliamps corresponds to a flow rate that is above the calibrated range. The

flow rate that corresponds to 20 milliamps is displayed for a few seconds each

time the meter is powered up.

The pulse output generates a square wave signal, sending five pulses for each

cubic foot of air that passes through the meter. The LED blinks with the pulse

output. At zero flow it may be on or off.

Maintenance

If oil or dirt accumulates on the probes, the meter will read low. For this reason,

we recommend cleaning the probes from time to time. To clean the probes, wipe

them with a cloth dampened with alcohol or a similar degreaser. It may be found

that the system is clean enough that cleaning is not needed.