cdimeters

www.cdimeters.com

Using the Outputs

The milliamp output is scaled so that four milliamps corresponds to zero flow and

20 milliamps corresponds to the range of the meter indicated on the data sheet.

The meter will display the milliamp full-scale value for a few seconds on startup.

It will also display it if the button on the main (lower) circuit board is pressed

twice.

The pulse output generates a square wave signal, sending one pulse for each

cubic foot of air that passes through the meter. The LED blinks with the pulse

output. At zero flow it may be on or off. The pulse output can be configured as a

threshold output, and the scaling of both the pulse output and the milliamp output

can be changed, using the optional configuration cable.

Using the Display

Pressing a button indicated by a circle on the front of the meter cycles the display

through four display options: rate, daily usage, cumulative usage and units of

measure, the last indicated by a digit: (0) for scfm, (1) for m

3

/min and (2) for

m

3

/hr. The cumulative values are indicated in thousands of cubic feet or cubic

meters. Holding the button pressed in either of the cumulative modes (daily

usage or cumulative usage) will reset that value to zero. The display normally

defaults to the rate display, but this can be changed, as can the units of measure

and the decimal point location in the cumulative modes. Please refer to

information on configuring the display.

Maintenance

If oil or dirt accumulates on the probes, the meter will read low. For this reason,

we recommend cleaning the probes from time to time. To clean the probes, wipe

them with a cloth dampened with alcohol or a similar degreaser. It may be found

that the system is clean enough that cleaning is not needed.

CDI warrants solely to the buyer that the Model 5400 Flowmeter shall be free from

defects in materials and workmanship, when given normal, proper and intended

usage, for three years from the date of purchase. During the warranty period, CDI will

repair or replace (at its option) any defective product at no cost to the buyer. The

foregoing warranty is in lieu of any other warranty, express or implied, written or oral

(including any warranty of merchantability or fitness for a particular purpose). CDI’s

liability arising out of the manufacture, sale or supplying of the flowmeter, whether

based on warranty, contract, tort or otherwise, shall not exceed the actual purchase

price paid by the buyer, and in no event shall CDI be liable to anyone for special,

incidental or consequential damages.

©

2014 CDI Meters, Inc. 10.14

CDI 5400 Flowmeter Rev. 3

Installation and Operating Instructions

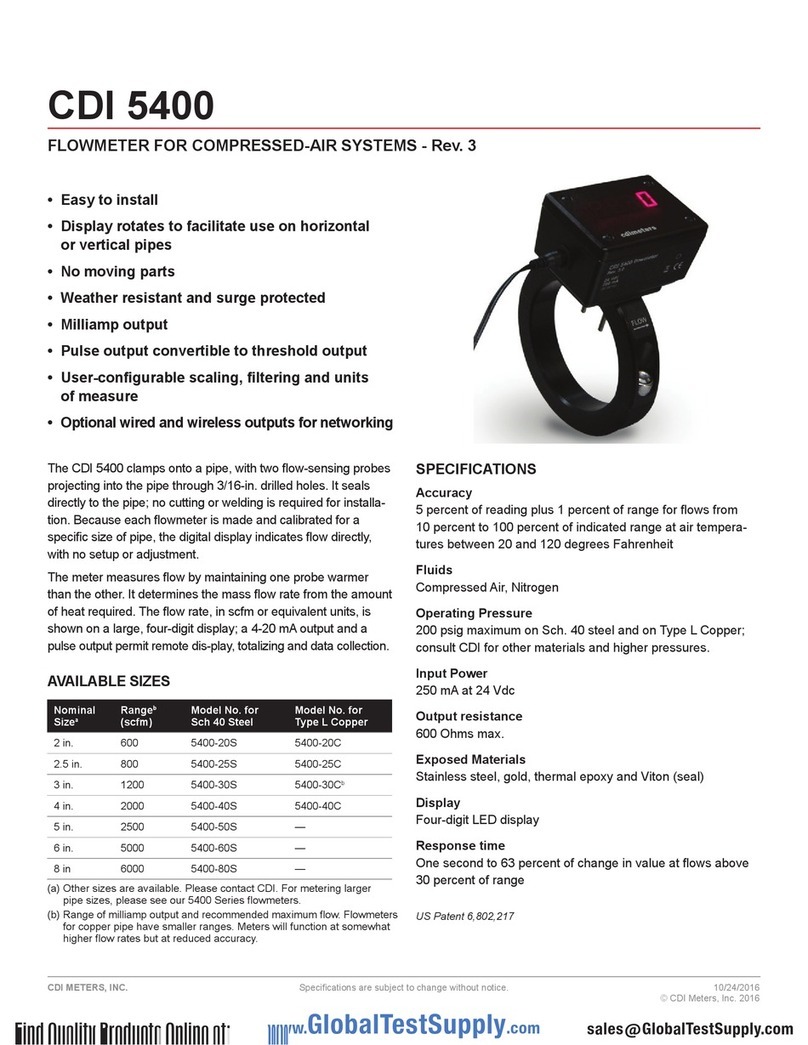

Limitations and Cautions

CDI 5400 flowmeters are not for use in hazardous areas or on pipes containing

gasses other than air or Nitrogen. They are not designed for installation under

pressure and they are not for use in control or safety applications. High-pressure

seals are required for all applications above 200 psig (14 barg). Contact CDI

about pressure limitations for applications above 200 psig on Type L or heavier

Copper and Sch. 40 or heavier steel pipe, and for all applications on other types

of pipe. The temperature compensation of the meters is suitable for use from 20

to 120°F (-7 to 49°C). The meters may be applied, at reduced accuracy, at

temperatures up to 150°F (66°C).

Locating the Meter

For accurate and reliable readings, the meters must be installed with adequate

straight pipe upstream, and, in compressed-air applications, they must be

installed downstream of a dryer.

Select a location with a straight run of pipe upstream equal to at least twenty

times the pipe diameter. If the meter is downstream of something that could

distort or concentrate the flow, such as a sweep elbow, a partially-closed valve,

an increase in pipe size or a hose, the run of pipe should be as long as possible;

thirty times the diameter at a minimum. Three diameters of straight downstream

piping is sufficient, unless the meter is immediately upstream of something that

would restrict the flow, such as a valve. If possible, locate and orient the meter

for good visibility from the plant floor.

The meters may, when necessary, be installed outdoors. For best visibility, avoid

direct sunlight.

Preparing the Holes

When the holes are drilled, metal shavings will enter the pipe. Make sure that

filters or other provisions are present downstream to prevent shavings from

damaging equipment or product or being blown out and causing injury.

For the larger size meters, the drill guide is a half ring with two drill bushings

mounted in it. Secure this half ring in place by bolting it to the back half ring that

came with the meter. For the smaller meters, the drill guide is an aluminum block

with two drill bushings. Secure this block to the pipe with a C clamp, a band

clamp or a chain clamp. A universal drill guide, similar to the small drill guide, is

also available; it can be used with all 5400 meter sizes.

Before starting to drill the holes, make sure that the air pressure is completely

bled down. With the drill guide firmly clamped to the pipe, drill the holes, using