4

Ilcircuitodisaldaturanondeveesserepostodeliberatamente a

contattodirettoo indiretto conilconduttorediprotezionesenon

nelpezzodasaldare.

Se il pezzo in lavorazione viene collegato deliberatamente a

terraattraversoil conduttore diprotezione,ilcollegamentodeve

essereilpiùdirettopossibile ed eseguitoconunconduttore di

sezione almeno uguale a quella del conduttore di ritorno della

corrente di saldatura e connesso al pezzo inlavorazione

nello stesso punto del conduttore di ritorno utilizzando il

morsettodelconduttorediritornooppure utilizzandoun secondo

morsetto di massa posto immediatamente vicino.

Ogni precauzione deve essere presa per evitare correnti

vagantidisaldatura.

Scegliere, mediante la manopola F, la corrente di taglio in

funzionedellospessoredatagliareseguendoleseguentiindica-

zioni:

Alluminio: 3 ÷ 4 mm 40 ÷ 50A

8 ÷10 mm 80 ÷ 90A

15 ÷18 mm 110 ÷ 120A

22 ÷25 mm 150A

Acciaioinossidabile fino a 5 mm 40 ÷ 50A

Acciaio dolce fino a20 mm 80 ÷ 90A

fino a30 mm 110 ÷ 120A

fino a40 mm 150A

La macchina è dotata di regolazione continua della corrente di

taglio, per cui l'utilizzatore può ricercare il corretto valore in

funzione delle condizioni di taglio.

Valoridicorrentepiùaltidiquelliindicatinonpregiudicanoilbuon

funzionamentodellamacchinaodellatorciae,avoltepossono

migliorarelaqualitàdeltagliopoichèriduconolescoriesuibordi

del pezzo.

Il diametro del foro dell'ugello della torcia è funzione della

corrente di taglio e, così come anche indicato sul pannello

frontaledella macchina,deve essere:

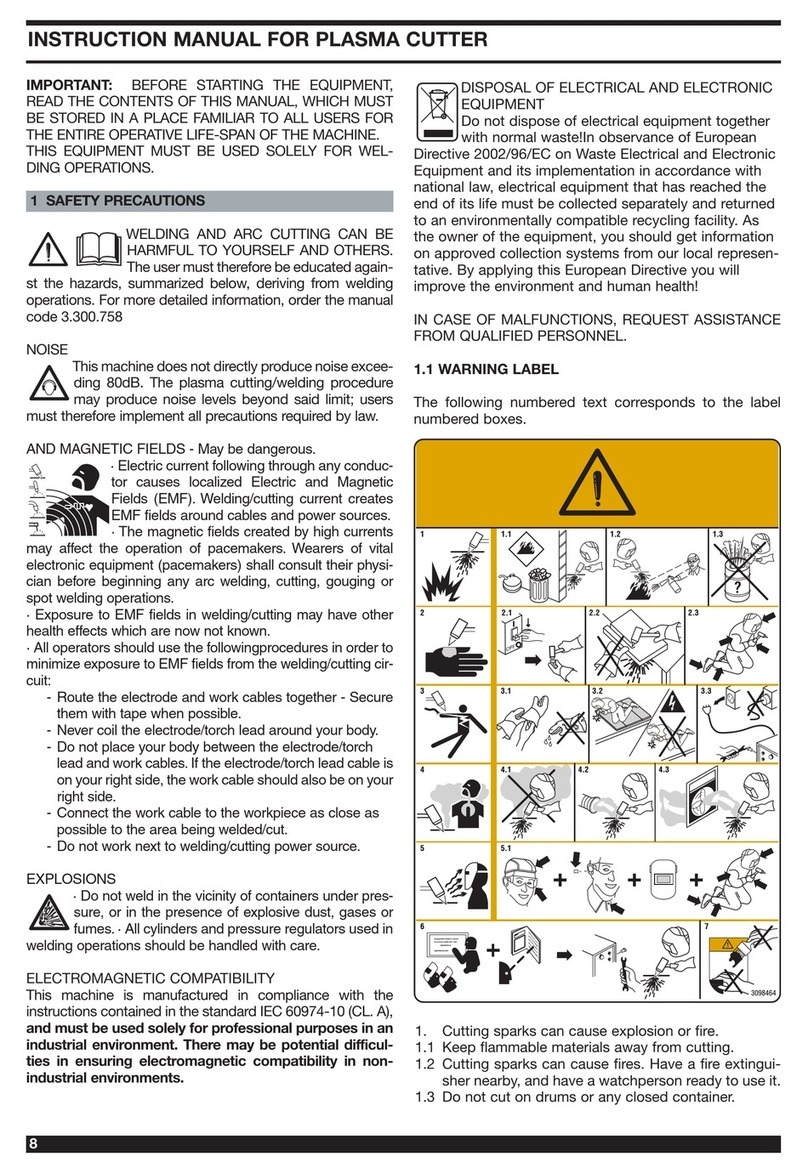

Con 20/50A ugello ø 1.1 mm standard o lungo

40/90A ugello ø 1.3 mm

80/130A ugello ø 1.6 mm

120/150A ugello ø 1.8 mm

Concorrentiditaglio da20a 50Aeugello ø1.1mm standardo

lungo è possibile lavorare a contatto, cioè con l'ugello diretta-

menteinappoggioalmateriale datagliare.

Nell'art 946 PROF 122 la spia rossa S, sul pannello frontale,

seganalaildivietoditagliareacontatto.Questoavvienequando

la corrente di taglio regolata è superiore a 50 A.

Nellealtrecondizionièindispensabileutilizzareundistanziale(a

due punte Bo a molla Afig.8) per evitare di mettere a contatto

diretto l'ugello con il pezzo da tagliare.

Tenere una distanza di circa 4 mm con torcia per impiego in

automatico.

Premere il pulsante della torcia per accendere l’arco pilota.

Sedopo2o3secondinonsiiniziailtaglio,l’arcopilota sispegne

equindi,perriaccenderlo,premerenuovamenteilpulsante.

Quando èpossibilelatorciadeveesseretirata. Tirareèpiùfacile

che spingere. Tenere la torcia verticale durante il taglio.

Completato il taglio e dopo aver lasciato il pulsante, l’aria

continua ad uscire dalla torcia per circa 1'e30"perconsentire

alla torcia stessa di raffreddarsi. E’ bene non spegnere

l’apparecchioprima dellafine diquestotempo.

Nel casosidebbanoeseguireforiosidebbainiziareil tagliodal

centro delpezzosidevedisporrela torcia in posizioneinclinata

e lentamente raddrizzarla in modo che il metallo fuso non sia

spruzzato sull’ugello (vedi fig.4). Questa operazione deve

essere eseguita quando si forano pezzi di spessoresuperiore

ai 3 mm.

Nell'impiegoinautomatico(vedifig.5)tenerel'ugellodistante7/

8mmdalpezzoesepossibiledopoaverfattoilforoavvicinarlo

a c.a. 4 mm. Non forare spessori superiori a 10/12 mm. Per

Pneumatica:

Per evitare che la macchina lavori con pressione aria insuffi-

ciente.E'postasull’alimentazionedellatorcia edèevidenziata

dalla spia D(vedi fig.2).

Elettrica:

1) posta sul corpo torcia per evitare che vi siano tensioni

pericolose sulla torcia quando si sostituiscono l’ugello, il

diffusore,l’elettrodoo ilportaugello;

2)chemandainbloccolamacchinaquandol’elettrodoraggiunge

uno stato di usura tale da dover essere sostituito. Questa

funzioneèevidenziatadall’accensionedellaspiaE (fig.2).

3) che manda in blocco la macchina in caso di avaria di un

componentedipotenza.Questafunzioneèevidenziatadall'ac-

censione della spia R .

Per garantire l'efficenza di queste sicurezze:

• Non eliminare o cortocircuitare le sicurezze .

• Utilizzare solamente ricambi originali.

•Sostituire sempre con materiale originale eventuali parti

danneggiate della macchina o della torcia.

• Utilizzare solo torce CEBORA tipo P70 e P150.

• Non utilizzare la macchina senza i fascioni laterali ed il

coperchio.E'pericoloso perl'operatore elepersone che si

trovanonell’area di lavoroed impedisce alla macchinaun

raffreddamentoadeguato.

2 IMPIEGO

Primadell’usoleggereattentamentelenormeCEI26/9-CENELEC

HD 407 e CEI 26.11 - CENELEC HD 433 inoltre verificare

l’integrità dell’isolamento dei cavi.

Accendere l’apparecchio mediante la manopola A.Questa

operazionesaràevidenziatadall’accensionedellaspiaB.

Ilmotoventilatoredellamacchinaècomandatodauntermo-

stato, per cui parte solamente quando il generatore deve

essereraffreddato.

Nellemacchinedotatedipulsantediemergenzaportarelamano-

poladell'interruttoresuON;questaoperazione,evidenziatadall'ac-

censione della lampada mette la macchina in condizione di

"pronti". Spostando ulteriormente la manopola su START si

comandal'accensionechesicompletaconl'entratainfunzionedel

ventilatoreinternoallamacchina.LaposizioneSTARTdell'interrut-

toreèinstabilepercui,rilasciandolamanopola,essaritornanella

posizionediON.

Premendo il pulsante di emergenza durante il funzionamento la

macchinasiarrestaimmediatamenteritornandonellacondizione

di "pronti".

Dopoaveraccesolamacchina,premereperuntempobrevissimo

ilpulsantedellatorciapercomandarel'aperturadelflussodell'aria

compressa.

Nelletorceperimpiegoinautomatico,perpulsantetorciasiintende

ilpulsanteol'interruttorepostosulpantografochevacollegatoal

filo fornito attaccato alla torcia.

Verificare che, inquestacondizione, lapressioneindicatadal

manometroOsiadi5bar(0,5MPa),incasocontrarioaggiustarla

agendo sulla manopolaMdelriduttore, quindi bloccare detta

manopolapremendoversoilbasso.

Collegare la pinza del cavo di massa al pezzo da tagliare,

assicurandosi che ilmorsettoeilpezzosianoin buon contatto

elettrico in particolare con lamiere verniciate, ossidate o con

rivestimenti isolanti.

Non collegare la pinza al pezzo di materiale che deve essere

asportato.