SKU 95668 For technical questions, please call 1-800-444-3353 PAGE 7

26. Use the right tool for the job. Do not attempt to force a small tool or

attachment to do the work of a larger industrial tool. There are certain

applications for which this tool was designed. It will do the job better and more

safely at the rate for which it was intended. Do not modify this tool, and do not

use this tool for a purpose for which it was not intended.

27. WARNING! Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities, contain chemicals known (to the State of

California) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are: lead from lead-based paints, crystalline silica

from bricks and cement or other masonry products, arsenic and chromium from

chemically treated lumber. Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equipment, such as

those dust masks that are specially designed to lter out microscopic particles.

(California Health & Safety Code 25249.5, et seq.)

28. WARNING! People with pacemakers should consult their physician(s)

before using this product. Operation of electrical equipment in close proximity to

a heart pacemaker could cause interference or failure of the pacemaker.

SAVE THESE INSTRUCTIONS

29. WARNING! The warnings, precautions, and instructions discussed in this

manual cannot cover all possible conditions and situations that may occur. The

operator must understand that common sense and caution are factors which cannot

be built into this product, but must be supplied by the operator.

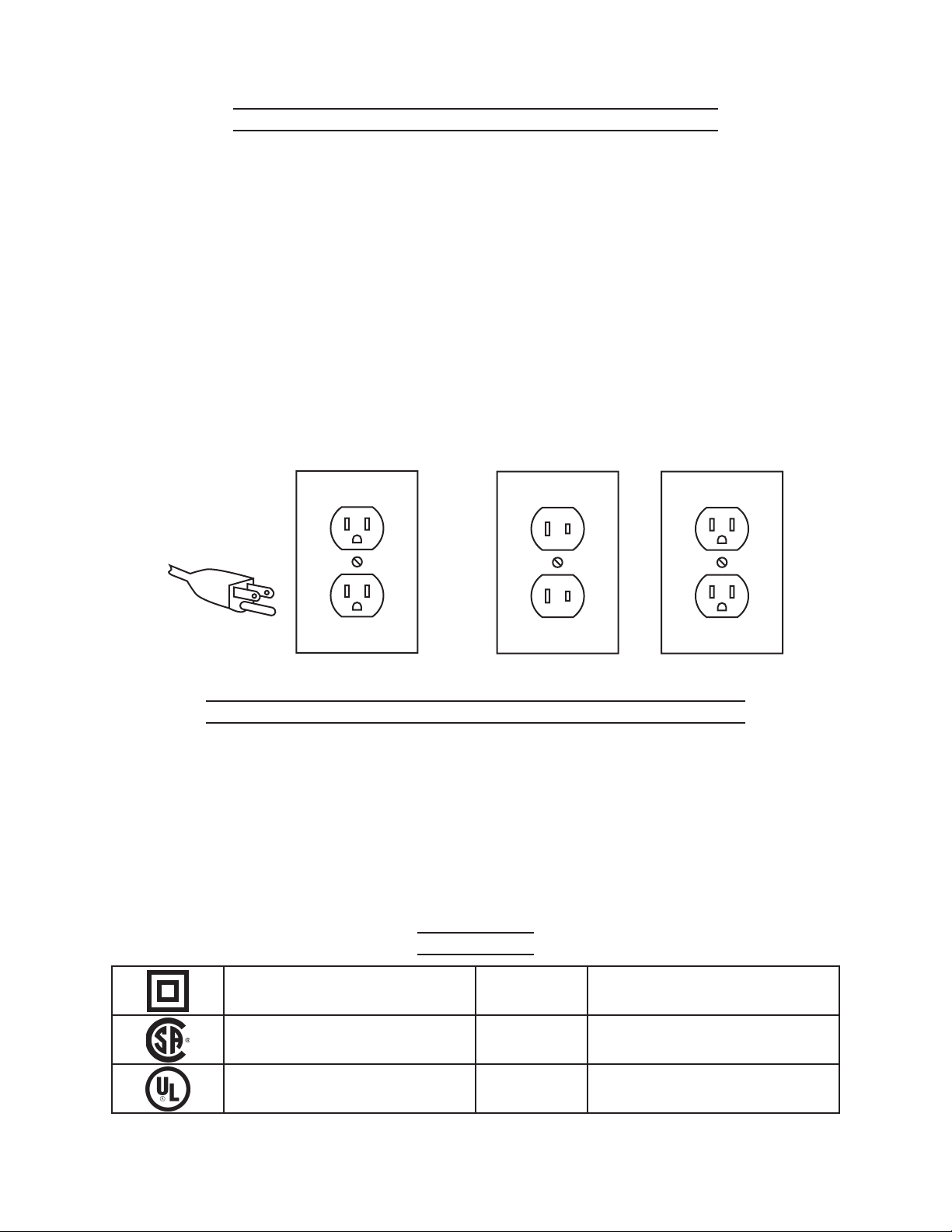

GROUNDING

Improperly connecting the grounding wire can result in

electric shock.

Checkwithaqualiedelectricianifyouareindoubtasto

whether the outlet is properly grounded. Do not modify

the power cord plug provided with the tool. Never remove

the grounding prong from the plug. Do not use the tool if

the power cord or plug is damaged. If damaged, have it

repaired by a service facility before use. If the plug will not

ttheoutlet,haveaproperoutletinstalledbyaqualied

electrician.

WARNING