cetoni neMESYS User manual

Original Setup and Operating Manual 2.01 –May 2015

neMESYS OEM

Hardware Manual

2neMESYS Hardware Manual

The information and data contained in this document are subject to change

without prior notice. No part of this document may be copied or transmitted

without the express consent of cetoni GmbH, irrespective of the means used for

this purpose –electronic or mechanical. The general terms of cetoni GmbH

apply. Agreements deviating from these terms must be made in writing.

Copyright © cetoni GmbH –Automation and Microsystems. All rights reserved.

neMAXYS Hardware Manual 3

Software License

The software and the supplied documentation are copyrighted material. By

installing the software you accept the terms of the licensing agreement.

License Agreement

cetoni GmbH grants the buyer the simple, non-exclusive and non-transferrable

right to use the software on a single computer or networked computer system

(LAN). Copying or any other duplication of the entire software or parts thereof or

mixing and connecting it with other software products is expressly prohibited.

For backup purposes the buyer may create a single copy of the software. Cetoni

GmbH reserves the right to alter, develop, improve or replace the software.

Cetoni is not obligated to inform the buyer with respect to modifications, new

developments or improvements or to supply them to him. Cetoni does not

legally warrant any particular software properties. Cetoni is not liable for any

damage, unless it is caused willfully or due to gross negligence on the part of

cetoni GmbH or its agents. Any liability for indirect, incidental or consequential

damage is excluded.

4neMESYS Hardware Manual

cetoni GmbH

Wiesenring 6

D- 07554 Korbussen

Germany

Tel.: +49 (0) 36602 338-0

Fax: +49 (0) 36602 338-11

E-Mail: [email protected]

Internet: www.cetoni.de

neMESYS Manual - Content 5

1. Overviews and Indexes

1.1. Content

1. Overviews and Indexes................................................................... 5

1.1. Content.................................................................................................... 5

1.2. Revision History....................................................................................... 8

2. Introduction ................................................................................... 9

2.1. Preface..................................................................................................... 9

2.2. Symbols and Keywords............................................................................ 9

3. Basic Information ......................................................................... 10

3.1. Standards and Guidelines...................................................................... 10

3.2. Intended Use ......................................................................................... 10

3.2.1. General Description of the Component................................................ 10

3.2.2. Proper Use............................................................................................. 11

3.2.3. Reasonably foreseeable Misuse............................................................ 11

3.2.4. Safety Measures.................................................................................... 11

3.2.5. Measures for safe Setup ....................................................................... 13

3.2.6. Safe Operation Measures...................................................................... 13

3.2.7. Condition of Devices ............................................................................. 14

3.3. Warranty and Liability ........................................................................... 14

4. Technical Data .............................................................................. 16

4.1. Performance Data ................................................................................. 16

4.2. Dimensional Drawing of Pump.............................................................. 18

4.3. Standard Valve ...................................................................................... 19

4.4. Dimensional Drawing of Valve .............................................................. 19

4.5. Dosing Performance .............................................................................. 20

5. Transport and Storage .................................................................. 21

6neMESYS Manual - Content

5.1. Transport ............................................................................................... 21

5.2. Maintenance and Care .......................................................................... 21

6. Hardware Operation .................................................................... 22

6.1. Installing a Syringe................................................................................. 22

6.2. Fluidic / Valve ........................................................................................ 25

6.3. Removing Valves ................................................................................... 27

7. Electrical Interfaces ...................................................................... 29

7.1. Overview ............................................................................................... 29

7.2. Power Supply (J1 / J2) ........................................................................... 30

7.2.1. Pin Assignment...................................................................................... 30

7.2.2. Technical Data....................................................................................... 30

7.3. CAN Interface (J3 / J4) ........................................................................... 32

7.3.1. Pin Assignment...................................................................................... 32

7.3.2. Technical Data....................................................................................... 32

7.3.3. Connecting neMESYS to CAN bus line CiA DS-102................................ 32

7.4. RS-232 Connection (J5) ......................................................................... 33

7.4.1. Pin Assignment...................................................................................... 33

7.4.2. Technical Data....................................................................................... 33

7.4.3. Connecting neMESYS to a PC ................................................................ 34

7.5. Signal Connection (J6) ........................................................................... 35

7.5.1. Pin Assignment...................................................................................... 35

7.5.2. Analog Input 1 and 2 (Pin 1 and 2)........................................................ 36

7.5.3. Digital Inputs 1 and 2 (Pin 3 and 4) ....................................................... 36

7.5.4. Digital Input 7 (Pin 5)............................................................................. 38

7.5.5. Digital Output 1 and 2 (Pin 6 and 7)...................................................... 39

7.5.6. Digital Output 5..................................................................................... 41

7.6. CAN-Bus Termination............................................................................ 43

7.7. Switching the integrated Valve ............................................................. 43

8. Cable Set ...................................................................................... 45

8.1. Power Cable .......................................................................................... 45

8.2. Power Connection cable ....................................................................... 45

8.3. CAN Cable (terminated DSub socket) ................................................... 46

neMESYS Manual - Content 7

8.4. CAN Cable (DSub plug) .......................................................................... 47

8.5. CAN Connection Cable........................................................................... 47

8.6. CAN Terminator..................................................................................... 48

8.7. RS232 Cable (DSub socket).................................................................... 49

8.8. USB-to-CAN Adapter ............................................................................. 49

9. Setup & Cable Connection............................................................ 51

9.1. Mechanical Setup .................................................................................. 51

9.2. Introduction to Cable Connection......................................................... 51

9.3. Step 1 –Connecting the Power Cable ................................................... 51

9.4. Step 2 –Data Connection...................................................................... 52

9.4.1. Introduction........................................................................................... 52

9.4.2. Data Connection through CAN.............................................................. 52

9.4.3. Data Connection through RS232........................................................... 53

9.5. Step 3 –Power Supply of additional Modules ...................................... 53

9.6. Step 4 –Data Connection to additional Modules ................................. 53

9.7. Step 5 –CAN Bus Termination .............................................................. 53

10. Disposal ...................................................................................... 55

8neMESYS Manual - Content

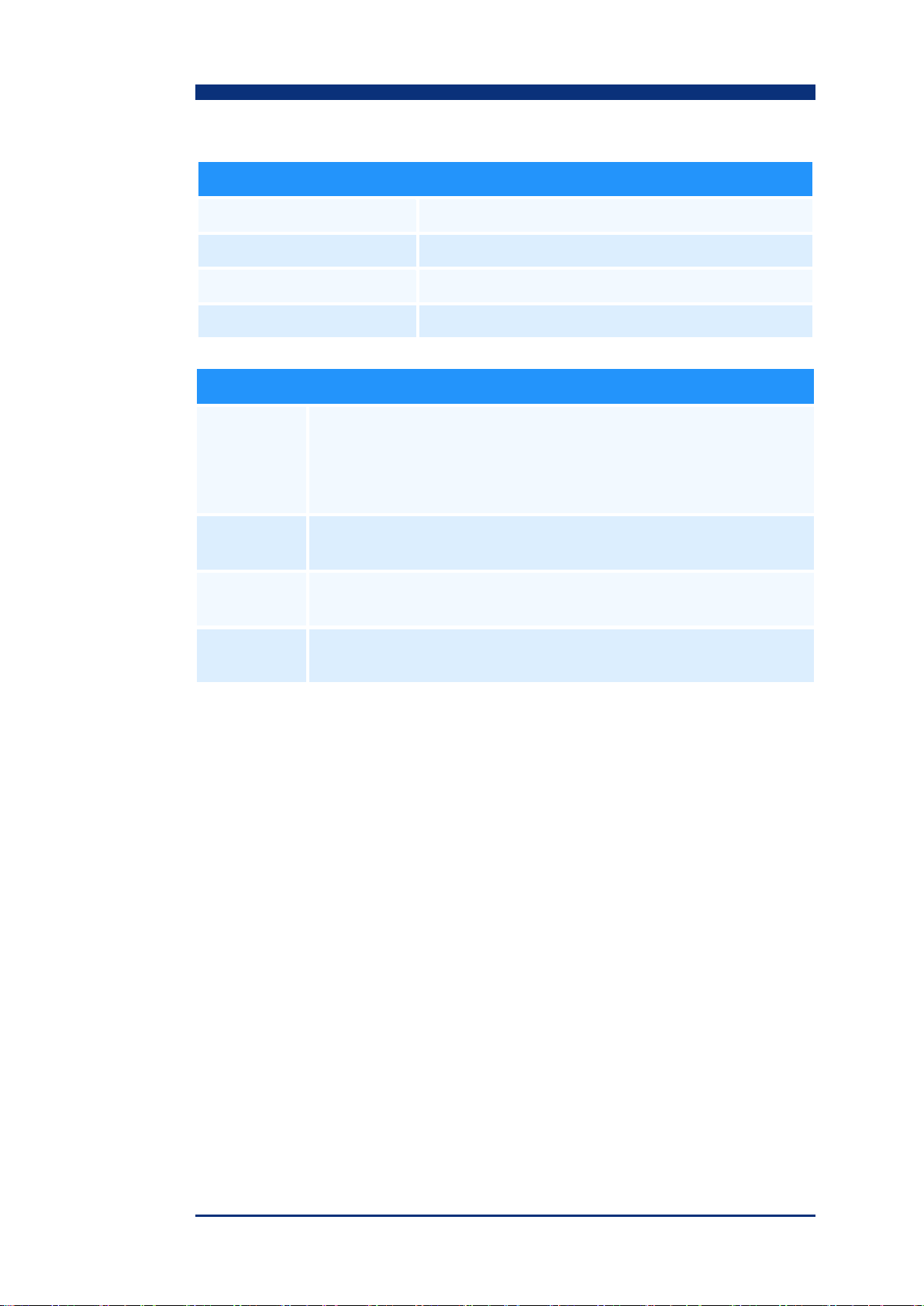

1.2. Revision History

Rev

Date

Modification

1.03

17.08.2010

Creation of Manual

2.00

09.01.2015

Revision for new Hardware

2.01

30.03.2015

RS232 cable modified (DSub jack instead of plug)

Added logic table for valve switching

neMESYS Manual - Introduction 9

2. Introduction

2.1. Preface

Thank you for purchasing a cetoni product. With this manual we would like to

support you in using the device. For additional questions or comments please

feel free to contact us directly.

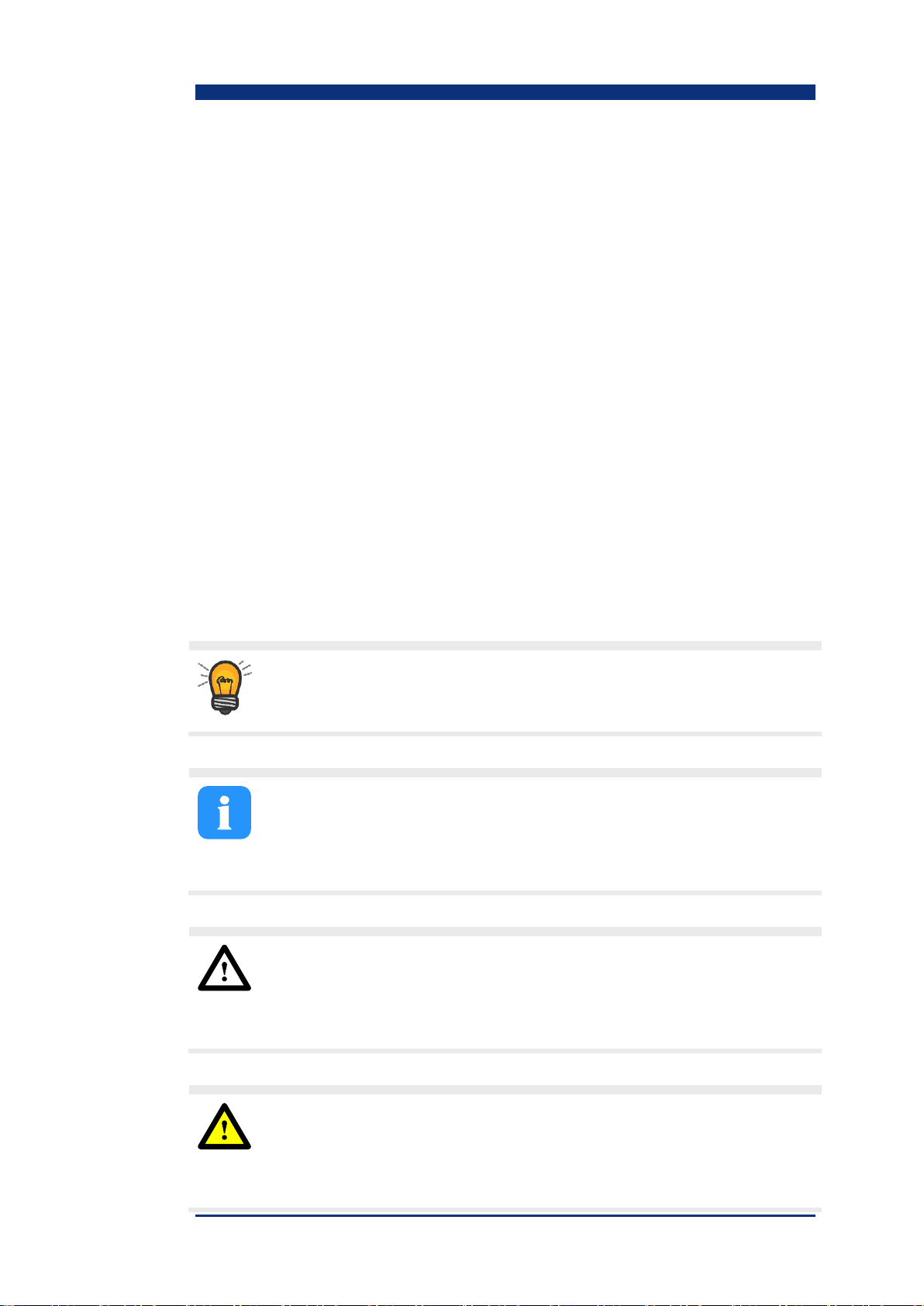

2.2. Symbols and Keywords

This manual uses the following symbols, intended to help you navigate the

document:

TIP

User tips and useful information to simplify the use of the software.

IMPORTANT

Important information and additional, particularly useful information.

This symbol does not refer to dangerous or hazardous situations.

CAUTION

This symbol signifies a potentially hazardous situation. Failing to avoid it

may cause damage to the product or its environment.

WARNING

This symbol signifies a potentially dangerous situation. Failing to avoid

it may cause light or insignificant injury or material damage.

10 neMESYS Manual –Basic Information

3. Basic Information

3.1. Standards and Guidelines

neMESYS OEM-modules conform to the basic health and safety requirements

stipulated by the 2006/42/EC machine directive. The modules are incomplete

machines according to the 2006/42/EC machine directive and intended for

installation into a machine. According to the directive they do not bear the CE

mark.

Integrating the modules into a machine may cause additional risks. It is

imperative that you conduct a risk evaluation of your machine with the

integrated modules and take any safety measures necessary.

IMPORTANT

Please note that you may not use neMESYS OEM-modules until the

machine or plant into which the modules are integrated complies with

the 2006/42/EC machine directive and the declaration of conformity in

attachment II A has been issued.

3.2. Intended Use

3.2.1. General Description of the Component

neMESYS devices are syringe pumps. They enable emptying and filling of syringes

through a linear relative movement between a syringe holder and a piston

holder.

The OEM-module is not a complete machine as defined by the machine directive,

but an incomplete machine intended for installation into another machine or

neMESYS Manual –Basic Information 11

plant. Please refer to the information provided in chapter 9 of this manual with

respect to installation and cable connection.

3.2.2. Proper Use

The neMESYS syringe pump system is intended for high-precision and pulsation-

free dosing of fluids in a range from nanoliters to milliliters per second.

Depending on the device being used, pressures in excess of several hundred bar

may be reached. The devices are typically used in a lab-like environment.

3.2.3. Reasonably foreseeable Misuse

Using the devices in applications other than the ones intended for them may

create dangerous situations and must be avoided.

WARNING

The devices must not be used as medical devices or for medical

purposes.

3.2.4. Safety Measures

Operator safety and failure-free operation of the devices can only be guaranteed

when using original equipment parts. Only original accessories may be used.

Warranty claims are void if damage was caused by using third-party equipment

or third-party material.

The devices were developed and designed in such way as to largely rule out

dangers, if used properly. Nevertheless, you should observe the following safety

measures to rule out any residual danger.

cetoni GmbH would like to point out the operator’s responsibilities when

using the device. Local laws and regulations relevant to using this device must

be observed. In the interest of a safe work process the operator and user of

the device is responsible for observing all relevant laws and regulations.

The devices must not be used as medical products or for medical purposes.

12 neMESYS Manual –Basic Information

The device is designed and approved for operation in systems governed by

article 4 section 3 or the pressurized devices directive 2014/68/EU. This

means that he devices may not exceed a maximum volume of 1 liter. When

using group 1 fluids according to article 13 of the pressurized systems

directive 2014/68/EU, the maximum allowable system pressure is 200 bar. It

is 1000 bar for group 2 fluids. If the “Technical Data” section stipulates

different product-specific maximum pressure values, such values must be

observed. Particular attention must be paid to not exceeding the pressure

range of the respective sensor. The information provided in the “Technical

Data” section with respect to the maximum operating temperature must be

observed. cetoni GmbH is not liable for potential impacts caused by the user

extending the system with peripheral devices in a way that causes one or both

of these values to be exceeded. The operator is responsible for becoming

acquainted with the aforementioned pressurized systems directive and

observing applicable stipulations.

Before each operation of the device the user has to ensure that the device is

functioning safely and is in proper condition.

The user must be familiar with the operation of the device and the software.

Before starting operation, the devices and wiring must be checked for

damage. Damaged wires and plugs must be replaced immediately.

Cables must be routed in such way as to rule out any trip hazards.

Do not touch moving parts on the devices during operation. There is a risk of

crushing.

neMESYS Manual –Basic Information 13

Operating the devices in an explosive environment or with explosive

substances is prohibited!

Make sure to wear safety goggles during installation work on the device or

when you work with corrosive, hot or otherwise dangerous substances.

Transport, storage or operation at temperatures below 0°C with water in the

fluid channels may cause damage to the devices.

3.2.5. Measures for safe Setup

Mechanical and electrical installation of pumps may only be done by skilled

personnel.

Make sure that all devices are installed in line with local laws and regulations.

Please note that, principally, the OEM-pumps cannot be considered fail-safe.

You have to ensure that a failing pump will not cause damage to your

application by employing suitable safety and monitoring measures.

Please note that you are not authorized to repair cetoni devices or

components.

Make sure that the power supply is not active and cannot be activated while

conducting installation or wiring work on the devices.

3.2.6. Safe Operation Measures

3.2.6.1 Electromagnetic Emissions

The neMESYS syringe pump system is designed for usage in any facility directly

connected to a public supply network that also supplies buildings used for

residential purposes.

14 neMESYS Manual –Basic Information

3.2.6.2 ESD-Discharge

Floors should be wood or concrete or covered with ceramic tiles. If floors are

covered with synthetic material, relative air humidity must be at least 30%.

3.2.6.3 Electrical Disturbances

Supply voltage quality should be equal to a typical business or hospital

environment.

3.2.6.4 Magnetic Disturbances

Power lines, including those of other devices, should not be placed near the

device or its cables. Mobile two-way radios should be kept at the minimum safe

distance from the device and its wiring.

3.2.7. Condition of Devices

Despite flawless workmanship, the devices may be damaged during operation.

Therefore, you should visually inspect the device components mentioned before

each use. Pay particular attention to crushed cables, damaged hoses and

deformed plugs. If you find any damage, please refrain from using the devices

and contact cetoni GmbH immediately. We will repair your devices as soon as

possible. Never attempt to repair a device yourself.

3.3. Warranty and Liability

The devices left our facilities in perfect condition and may only be opened by

cetoni GmbH. If a device is opened by an unauthorized person, all warranty and

liability claims shall be void, in particular those referring to personal injury.

The warranty period is 1 year from the day of delivery. Any work done on the

devices within this period shall not extend or renew the warranty.

cetoni GmbH assumes responsibility for its devices with respect to safety,

reliability and function only if installation, readjustment, changes, extensions and

neMESYS Manual –Basic Information 15

repairs are done by cetoni GmbH or an authorized party, and if the devices are

used in accordance with the user manual.

The neMESYS syringe pump system complies with the applicable safety rules and

standards. cetoni GmbH reserves all property rights for the relevant wiring,

processes, names, software and devices.

16 neMESYS Manual –Technical Data

4. Technical Data

4.1. Performance Data

Electrical Data

Supply voltage VCC (ripple < 10%)

24 VDC

Peak current draw at 24 VDC

0.6 A

Typical current draw at 24 VDC

0.3 A

Inputs

Analog input 1 (AI1)

resolution 11-bit 0 ... +5 V (Ri = 34 kΩ)

Analog input 2 (AI2)

resolution 11-bit 0 ... +5 V (Ri = 34 kΩ)

Digital input 1 (DI1)

+3 … +36 VDC (Ri = 12 kΩ)

Digital input 2 (DI2)

+3 … +36 VDC (Ri = 12 kΩ)

Digital input 3 (DI7)

+3 … +36 VDC (Ri = 12 kΩ)

Outputs

Digital output 1 (DO1)

open collector, max. 36 VDC (IL < 50 mA)

Digital output 2 (DO2)

open collector, max. 36 VDC (IL < 50 mA)

Digital output 3 (DO5)

push pull, max. 36 VDC (IL < 10 mA)

Interfaces

CAN

CAN_H (high); CAN_L (low)

max. 1 Mbit / s (standard 1 Mbit / s)

RS232

RxD; TxD

max. 115200 bit / s (115200 bit / s)

Mechanical Data

Weight

approx. 1100 g

Dimensions (L x W x H)

310 x 47 x 130 mm

Attachments

M3 screws

neMESYS Manual –Technical Data 17

Ambient Conditions

Operating Temperature

-10 … +45°C

Storage Temperature

-40 … +85°C

Air Humidity

Non-condensing 20 … 80 %

Sound power level

< 70 dB(A)

Connections

Power

supply

on device: two-row pin connector (2-pole type) Molex Mini Fit Jr

plug connector: two-row socket (2-pole type)

Molex Mini-Fit Jr. 39-01-2020

crimp contacts: crimp socket Molex Mini-Fit Jr.TM 444-76-1111 (AWG 18-24)

CAN

on device: 3-pole plug JST XARR-03V

plug connector: 3-pole socket JST XAP-03V-1

RS232

on device: 4-pole plug JST XARR-04V

plug connector: 4-pole socket JST XAP-04V-1

Signal

on device: 12-pole plug JST XARR-12V

plug connector: 12-pole socket JST XAP-12V-1

18 neMESYS Manual –Technical Data

4.2. Dimensional Drawing of Pump

neMESYS Manual –Technical Data 19

4.3. Standard Valve

Valve

Housing material

PEEK

Sealing material

FFKM (perfluoroelastomer)

Media temperature

0 to +50°C

Max. viscosity

21 mm²/s

Internal volume

approx. 45 µl

Max. pressure

3 bar

Rated width

0.6 mm

Fluidic connections

¼“ – 28 UNF

4.4. Dimensional Drawing of Valve

CAUTION

There is a danger of damaging the housing or sealing material.

Before using the valve for the first time, please check the chemical

compatibility of the media you want to use with the PEEK housing

material and the FFKM (perfluoroelastomer) sealing material.

output (normally open)

input (normally closed)

syringe

seals

PEEK

20 neMESYS Manual –Technical Data

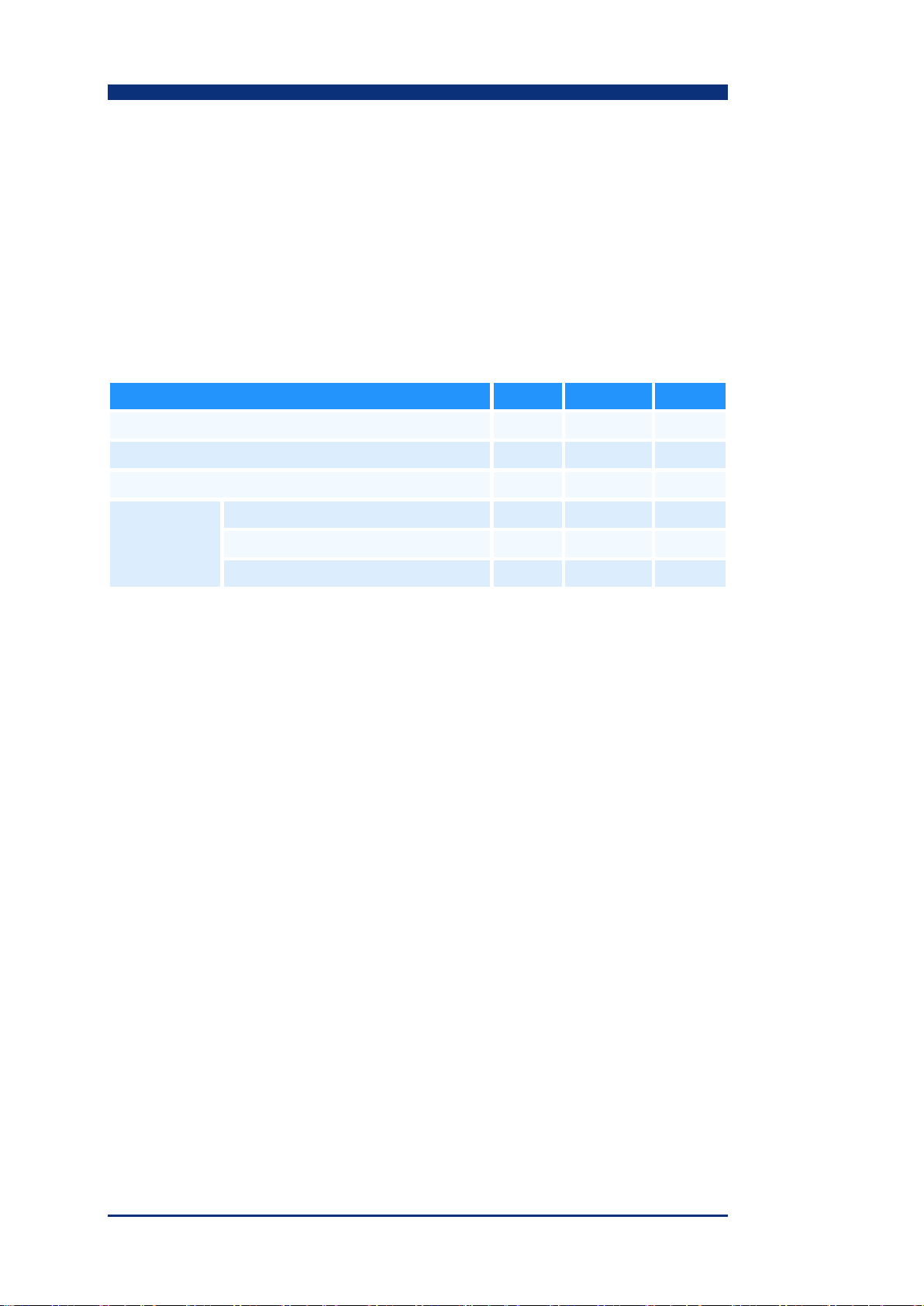

4.5. Dosing Performance

The following table provides an overview of the minimum and maximum dosing

speeds of the various gear configurations as well as the resulting flow rates,

using the example of a 1ml syringe with a 60 mm stroke.

Speeds and flow rates lower than those referred to as pulsation-free, will cause

dosing precision to decrease slowly.

Gear

w/o

14:1

29:1

Min. speed [µm/s]

0.065

0.065

0.065

Min. pulsation-free speed [µm/s]

14.648

1.042

0.502

Max. speed [mm/s]

89

6.33

3.06

1 ml syringe

with 60 mm

stroke

Min. flow [µl/min]

0.065

0.065

0.065

Min. pulsation-free flow [µl/min]

14.648

1.042

0.502

Max. flow [ml/min]

89

6.33

3.05

Other manuals for neMESYS

2

Table of contents

Other cetoni Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Phase Technologies

Phase Technologies 70Xi Quick installation guide

RBCBioscience

RBCBioscience MagCore Super Engineer in Training Manual

PerkinElmer

PerkinElmer Lambda 365 installation instructions

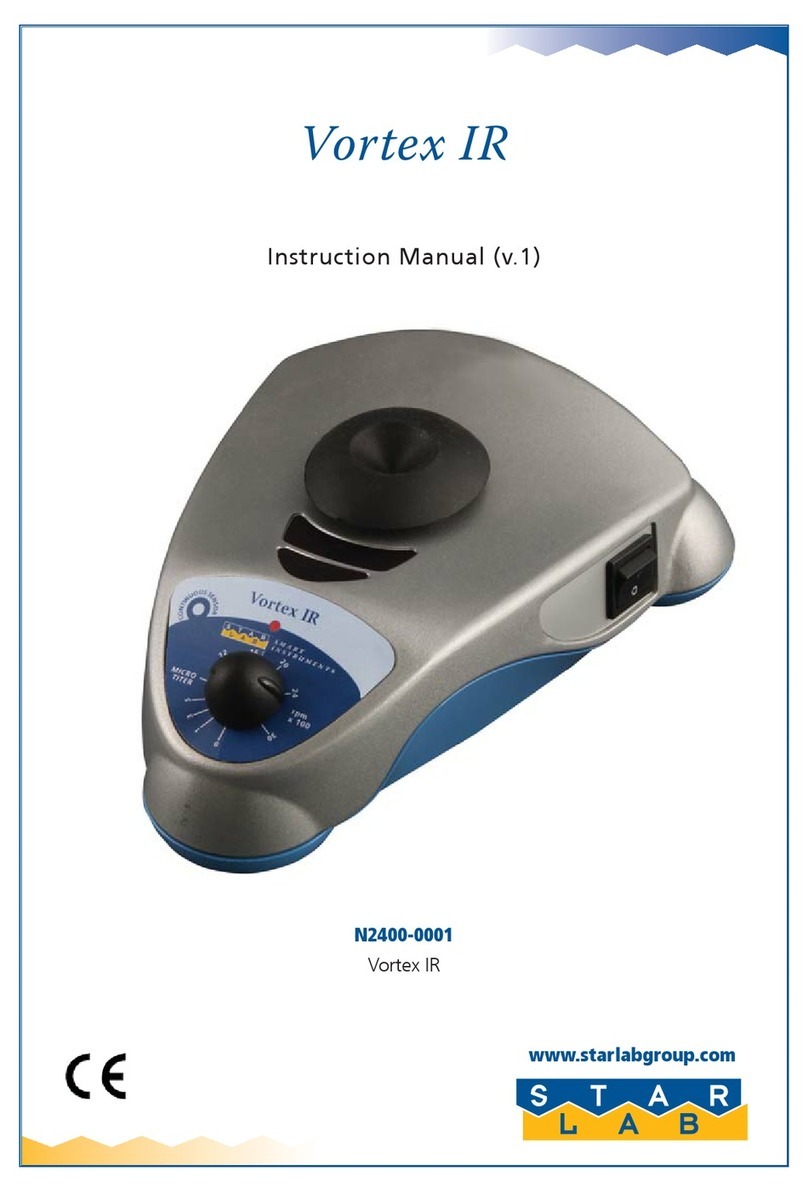

Star Lab

Star Lab N2400-0001 Vortex IR instruction manual

J.P. SELECTA

J.P. SELECTA APL-54 manual

Exor

Exor JSPOU0P1 installation guide

J.P. SELECTA

J.P. SELECTA DIGITAL-S instruction manual

Cooper Surgical

Cooper Surgical K-Systems R65 user manual

PerkinElmer

PerkinElmer Lambda 365 installation instructions

TAN Bead

TAN Bead Maelstrom 4810 user manual

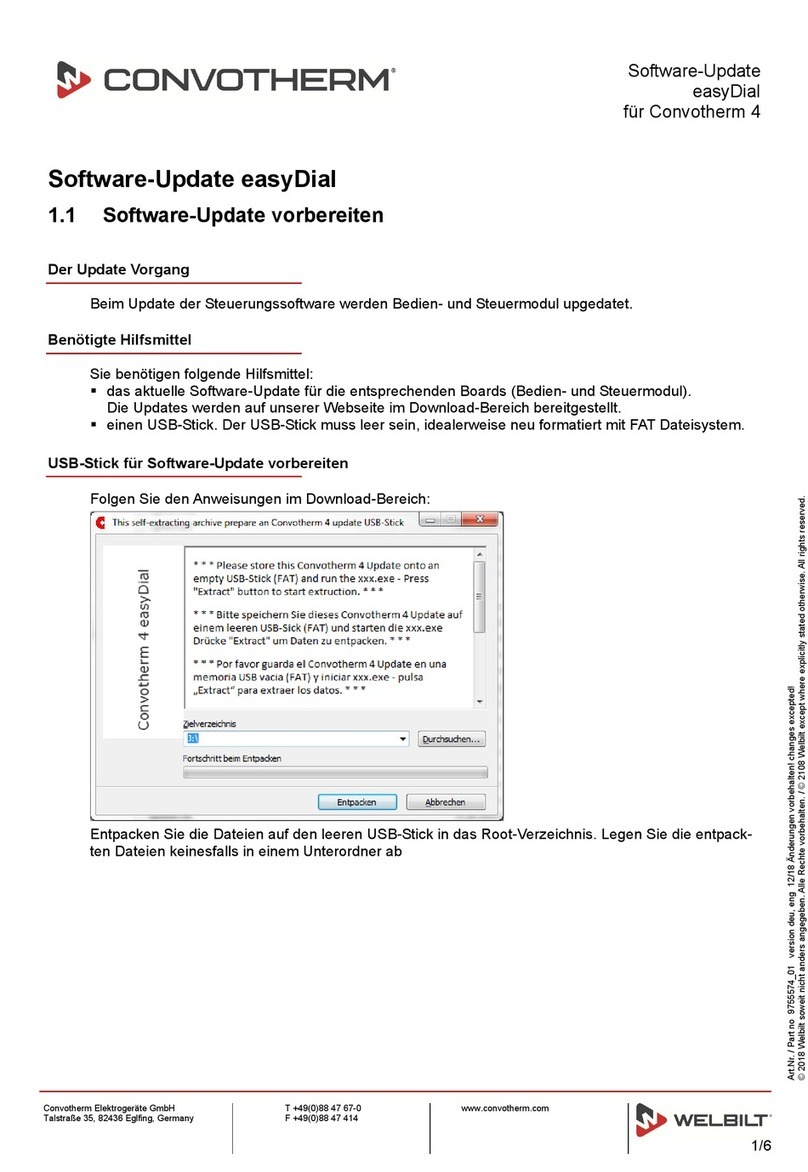

Welbilt

Welbilt Convotherm easyDial Update manual

Tripp Lite

Tripp Lite NPOEI-60W-1G quick start guide