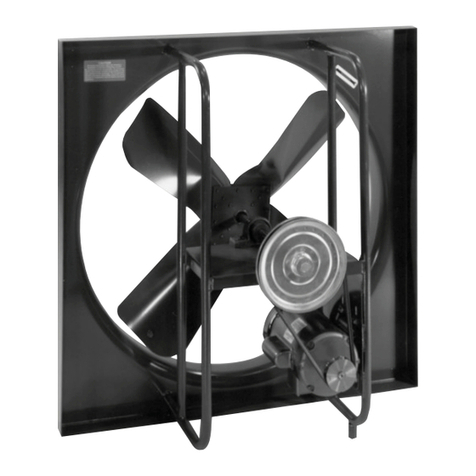

AIB BELT DRIVE TUBEAXIAL FANS

PRODUCT SPECIFICATION GUIDE

1.0 GENERAL

A. Fans shall be model AIB Belt Drive Tubeaxial Fans, as manufactured by Continental Fan Manufacturing Inc.,

of Buffalo, NY, and of the size and capacity as indicated on the drawings and fan schedule.

B. Fans shall be rated and tested in accordance with ANSI/AMCA Standard 210-99.

C. All motors and electrical components shall conform to NEMA standards.

2.0 FAN HOUSING

A. Fan housing shall be constructed of heavy gauge steel and welded angle ring flanges.

B. Fan motor base shall be adjustable, and be located on the exterior of the fan housing.

C. Fan belt tube shall be completely sealed, and shall isolate the bearings from ambient and/or contaminated airstreams.

D. Fan housing and motor base shall be coated with an air dried gray enamel finish.

3.0 FAN IMPELLER

A. Axial impeller shall be constructed of spark resistant, die cast aluminum airfoil shaped blades secured to a die

cast aluminum hub assembly.

B. Axial impeller blades shall be of adjustable pitch construction with multiple hub-to-blade arrangements to max-

imize air performance. Blade pitch angles shall be factory set.

C. Axial impeller hub shall be designed to incorporate a split taper bushing, and be keyed directly to motor shaft.

4.0 FAN MOTOR AND DRIVE

A. Motor shall be TEFC industrial duty and conform to NEMA standards.

B. Motor shall be of voltage, horsepower, RPM and enclosure as indicated on the fan schedule.

C. Fan sheaves shall be cast iron and appropriately sized and aligned.

D. Fan belts shall be static conducting, plus oil and heat resistant.

E. Fan shaft shall be steel, turned, ground and polished.

F. Fan shaft bearings shall be lubricated, self-aligning ball type in cast iron pillow block mounts with external

grease fittings.

5.0 OPTIONAL FAN ACCESSORIES

A. Where indicated, fan shall be provided with the following optional accessories:

• Guards • Protective coatings for fan housing

- Propeller side - Epoxy

- Motor side - Eisenheiss

• Mounting brackets • Motors

- Horizontal - Explosion proof

- Vertical - Special duty

• Mounting legs • 304 stainless steel construction

• Inspection door • 316 stainless steel construction

• Companion flanges • AMCA spark resistant construction

• Motor cover and/or belt guard • Variable pitch sheaves

6.0 FAN TESTING

A. Axial impeller shall be balanced and mounted in fan assembly.

B. Fan assembly shall be run and tested prior to shipment.

C. A test report shall be maintained on file for each individual fan.

3