AAFFKKFFLLAANNGGEEFFAANN

PPRROODDUUCCTTSSPPEECCIIFFIICCAATTIIOONNGGUUIIDDEE

11..00GGEENNEERRAALL

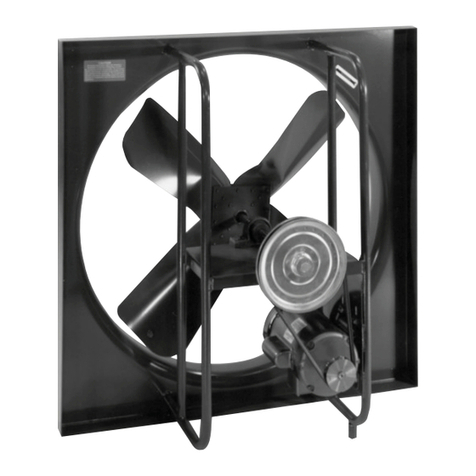

A. Fans shall be model AFK Flange Fans, as manufactured by Continental Fan Manufacturing Inc., of Buffalo,

NY, and of the size, capacity and flow direction as indicated on the drawings and fan schedule.

B. Fans shall be rated and tested in accordance with ANSI/AMCA Standard 210-99.

C. All motors and electrical components shall conform to NEMA standards.

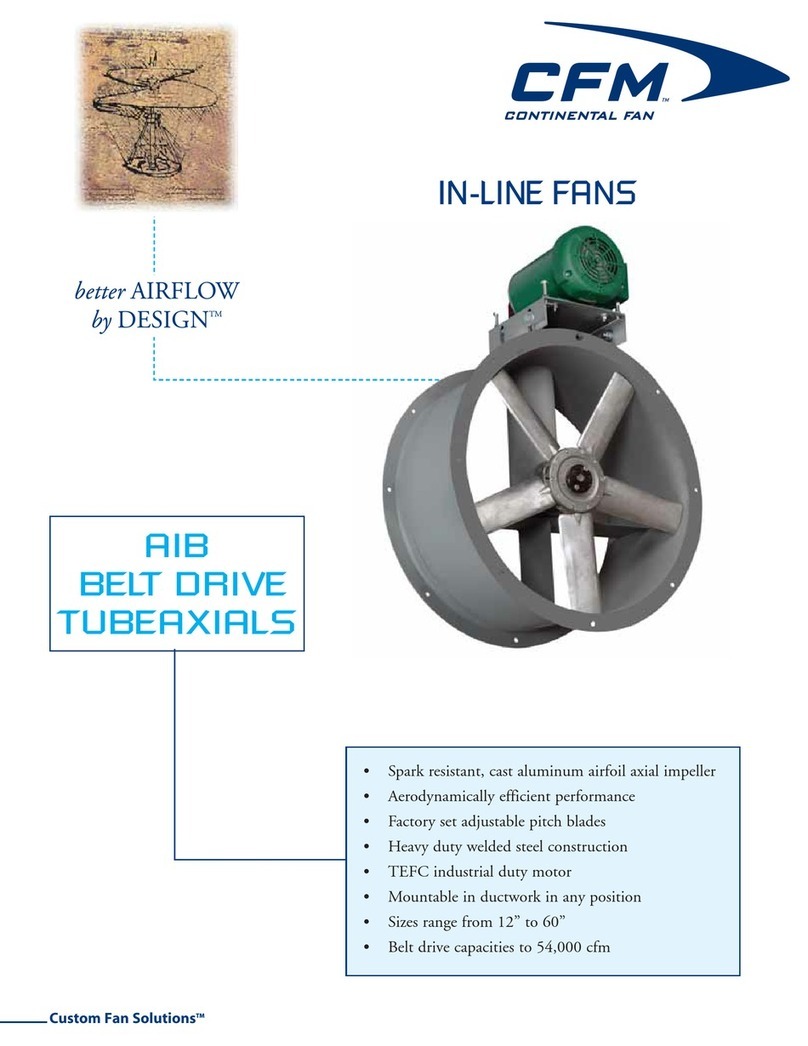

22..00FFAANNHHOOUUSSIINNGG

A. Fan housing shall be constructed of rolled and continuously welded heavy gauge steel.

B. Inlet and outlet flanges shall be integrally formed to ensure concentricity and alignment of the flanges.

C. Adjustable motor base shall be constructed from heavy gauge steel and bolted to the flange.

D. Fan housing and motor base shall be coated with baked polyester powder coat finish.

33..00FFAANNIIMMPPEELLLLEERR

A. Axial impeller shall be constructed of spark resistant die cast aluminum airfoil shaped blades secured

to a die cast aluminum hub assembly.

B. Axial impeller blades shall be of adjustable pitch construction with multiple hub-to-blade arrangements

to maximize air performance. Blade pitch angles shall be factory set.

C. Axial impeller hub shall be designed to incorporate a split taper bushing, and be keyed directly to drive shaft.

44..00FFAANNMMOOTTOORRAANNDDDDRRIIVVEE

A. Motor shall be TEFC industrial duty and conform to NEMA standards.

B. Motor shall be of voltage, horsepower, RPM and enclosure as indicated on the fan schedule.

55..00OOPPTTIIOONNAALLFFAANNAACCCCEESSSSOORRIIEESS

A. Where indicated, fan shall be provided with the following optional accessories:

• Mounting panel

• AMCA spark resistant construction

• Motor side guard

• Reverse flow construction

• Propeller side guard

• Special materials

• Special coatings

• Housing yoke with mounting bracket

• Motors

- Explosion proof

- Special duty

66..00FFAANNTTEESSTTIINNGG

A. Axial impeller shall be balanced and mounted in fan assembly.

B. Fan assembly shall be run and tested prior to shipment.

C. A test report shall be maintained on file for each individual fan.

3