CHEFOOK 029801 FOX AUTO Instruction Manual

20

AUTHORISED RETAILER

AUTOMATIC MEAT TENDERISER

029801 FOX AUTO

USER AND MAINTENANCE INSTRUCTIONS

Ed. 002 05/2021

2 19

English

7.4 - WEEE (Waste Electrical and Electronic Equipment) regulations

Pursuant to Art. 13 of Italian Legislative Decree No. 151 of 25 July 2005

“Implementation of Directives 2002/95/EC, 2002/96/EC and 2003/108/EC

relating to the reduced use of hazardous substances in electrical and

electronic devices, and to waste disposal”.

The crossed-out wheelie bin symbol on the equipment or on its packaging

indicates that the product must be disposed of separately from other waste at the

end of its useful life.

The separate waste collection of this device at the end of its life is organised and

managed by the manufacturer. The user who wishes to dispose of this device

must contact the manufacturer and follow the given instructions to ensure that the

separate waste collection procedure is observed at the end of the equipment’s

useful life.

The correct disposal of the device for the subsequent recycling, management and

treatment of its parts in an environment-friendly way helps to prevent possible

adverse effects on the environment and promotes the reuse and/or recycling of its

constituent materials.

Unlawful disposal of the product by the user shall imply the application of

administrative penalties under current law.

18

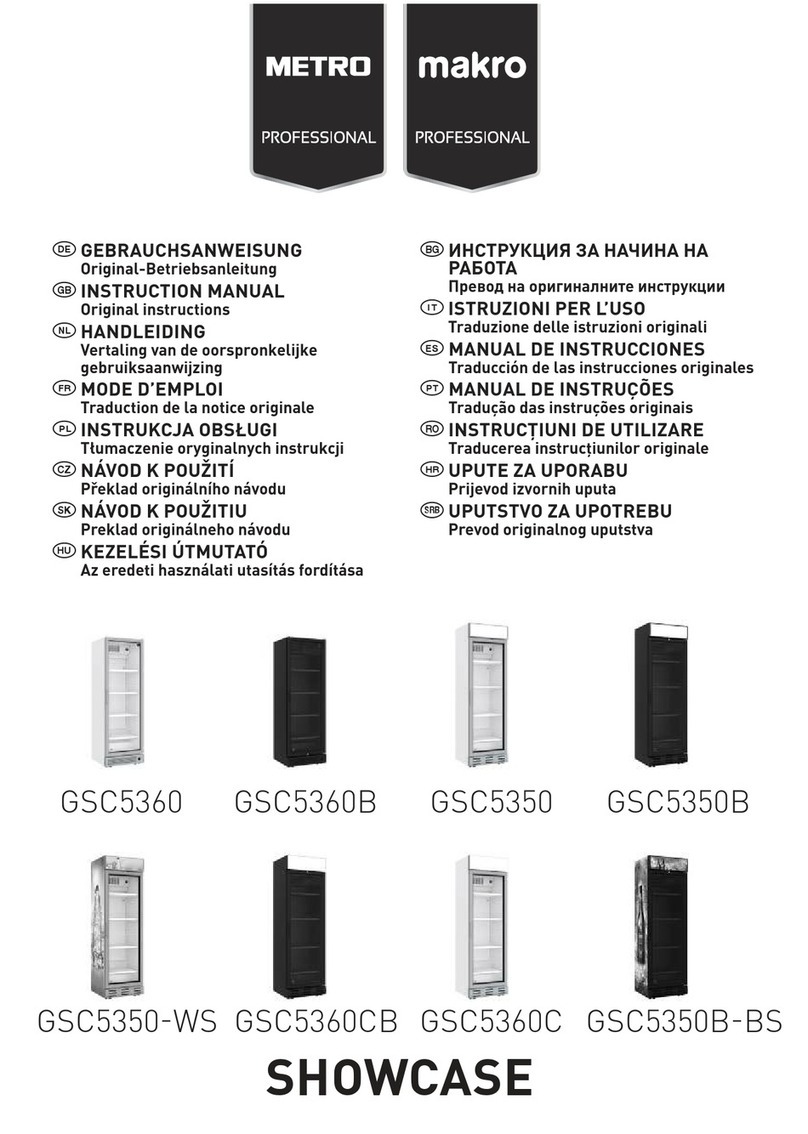

7.3.2 - Removing the blade pack (Fig. 7.2.2)

To remove the blade pack, proceed as follows:

- Wear Kevlar safety gloves that meet accident-

prevention criteria.

- Loosen the two knobs (2) fastening the scraper

and remove them.

- Grip the scraper (3) (from in front of the

machine) and pull it towards yourself until it

slides off.

- Loosen the two knobs on the slide (4).

- Grip the blade pack (5) with both hands from the

sides.

- Turn it with the blade tips towards yourself by

levering it on the fixing point, detach it and pull it

out.

7.3.3 - Removing the chopping board

(Fig. 7.2.3)

From the front of the machine grip the handle of

the chopping board (7) and pull it towards yourself

by sliding the board along the slit on the base.

Move it slightly to make the pin come out of the

hole and extract the chopping board.

3

Fig. 7.2.2

4

2

5

Fig. 7.2.3

6

7

3

English

CONTENTS

1. Delivery and warranty 4

1.1 Introduction

1.2 Storing and using this manual

1.3 Warranty

1.4 Machine description

1.5 Intended use

1.6 Improper use

1.7 Specific equipment details

1.7.1 Warning and danger signs

1.8 Guards and safety devices

1.9 Work position

2. Technical specifications 9

2.1 Main parts

2.2 Technical characteristics

2.3 Machine dimensions and weight

2.4 Noise level emitted

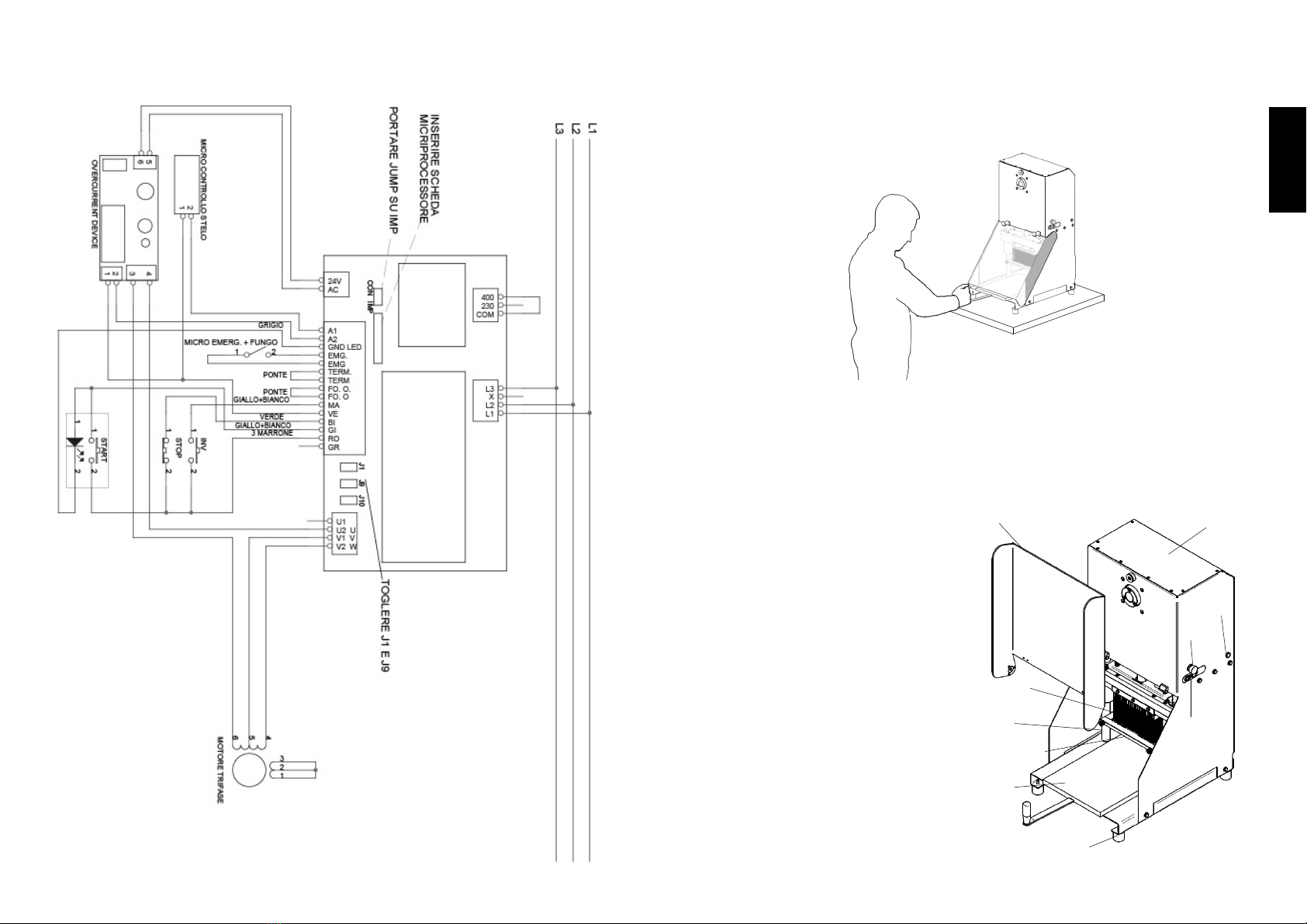

2.4 Wiring diagrams

2.4.1 Single-phase wiring diagram

2.4.2 Three-phase wiring diagram

3. Controls and indicators 13

3.1 List of controls and indicators

4. Factory testing, shipping, delivery and installation 13

4.1 Factory testing

4.2 Delivery and handling

4.3 Installation

4.3.1 Installation

4.3.2 Disposal of packaging

4.3.3 Handling the machine

4.4 Electrical connections

4.4.1 Three-phase machine

4.4.2 Single-phase machine

5. Start-up and shutdown 15

5.1 Verification of the correct electrical connection

5.2 Verification of the presence and efficiency of guards and safety devices

5.3 Verification of the efficiency of the emergency stop button

5.4 Machine start-up

5.5 Machine shutdown

6. Using the machine 16

6.1 Safety instructions

6.2 Using the machine

7. Maintenance 17

7.1 Safety instructions

7.2 Lubrication

7.3 Cleaning the machine

7.3.1 Removing the plexiglass cover (Fig. 7.2.1)

7.3.2 Removing the blade pack (Fig. 7.2.2)

7.3.3 Removing the chopping board (Fig. 7.2.3)

7.4 WEEE (Waste Electrical and Electronic Equipment)

8. Malfunctions and remedies 20

8.1 Malfunctions: causes and remedies

4

1 - Delivery and warranty

1.1 - Introduction

CAUTION!

The symbols used in this manual draw the reader’s attention to points and

operations that are hazardous to the operator’s personal safety or that risk

damaging the machine.

Do not use the machine unless you have read and properly understood these

notes.

CAUTION!

For reasons of clarity, some of the illustrations appearing in this manual show the

machine or parts of it with its panels or guards removed.

Never use the machine in this condition; only use it when it is fully equipped with

the guards and in good working order.

The manufacturer forbids the reproduction, even partial, of this manual or the use

of its contents for purposes other than those expressly allowed.

Any breach in this regard shall be punishable by law.

1.2 - Storing and using this manual

This manual uses text and illustrations to familiarise users with the machine and

explain the instructions and essential criteria for its transport, handling, use and

maintenance. Read this manual carefully before using the machine. Store this

manual with care near the machine so that it can be readily available for future

reference.

If the manual is lost or damaged, you can request a copy from your dealer.

If you sell the machine, report the new owner's identification and address to the

manufacturer.

The manual reflects the state of knowledge at the time of sale of the machine, and

cannot be considered inadequate in the light of more recent experience and

updates. The manufacturer reserves the right to update the products and manuals

without being obliged to update previous products and manuals, except in

exceptional circumstances. In case of doubt, contact your local service centre or

the manufacturer.

The manufacturer is committed to continuously improving its products. For this

reason, the manufacturer welcomes any reports or proposals geared towards

improving the machine and/or the manual. The machine is delivered to the

customer with the warranty conditions applicable at the time of sale.

Please contact your dealer for any further information.

1.3 - Warranty

The user is not authorised to tamper with the machine in any way.

Contact your dealer if you encounter any anomalies.

Any attempt to dismantle, modify or tamper with any part of the machine by the

user or unauthorised personnel will immediately void the Declaration of

Conformity drawn up pursuant to Directive 2006/42/EEC and the warranty, and

17

English

7 - Maintenance

7.1 - Instructions

CAUTION!

Maintenance and cleaning must always be carried out with the machine at a

standstill and disconnected from the mains power supply.

Always keep the maintenance zone clean and dry.

Do not allow unauthorised persons to intervene on the machine.

Parts and tools must be replaced using original spare parts at authorised service

centres.

The blade pack must be handled while wearing Kevlar safety gloves that meet

accident-prevention criteria.

The machine is not designed to operate inside a cold room: this could

seriously damage the electrical components sensitive to condensate (which

forms at low temperatures) and also alter the viscosity of the grease and/or

lubricating oil in the gearbox housed inside it, jeopardising the machine’s

correct operation and causing potential failures.

7.2 - Lubrication

The shaft and the sliding rods should be greased using vaseline grease for

improved sliding of the slide.

7.3 - Cleaning the machine

CAUTION!

Disconnect the machine from the mains power supply before cleaning it.

Do not clean the machine using a water jet.

Only use non-toxic detergents specifically formulated for cleaning components

used with foodstuffs.

The blades are made of grade AISI 420 steel and may rust if they are not dried

after washing them.

The blade pack must be handled while wearing Kevlar safety gloves that meet

accident-prevention criteria.

7.3.1 - Removing the plexiglass cover (Fig. 7.2.1)

To remove the plexiglass protection, proceed as follows:

- Grip the cover (1) and lift it until it lies vertical.

- Slide the cover off the pins towards the left.

Fig. 7.2.1

1

16

6 - Using the machine

6.1 - Instructions

CAUTION!

Only authorised personnel may intervene on the machine.

Before using the machine, the operator must ensure that all guards are in place

and that the safety devices are present and working efficiently.

If this is not the case, switch the machine off and contact the maintenance

supervisor.

The product to be tenderised must have the right size so that it fits beneath the

scraper and must not protrude from the chopping board.

The blade pack must be handled while wearing Kevlar safety gloves that meet

accident-prevention criteria.

CAUTION! The product to be tenderised must have a maximum height

of 10 cm and must not protrude from the chopping board.

6.2 - Using the machine

-Verify that the supply voltage matches the value shown on the rating plate.

-Make sure that the product to be tenderised does not have any rind, bones or

nerves that can ruin the blades.

-Open the front panel and place the product on the chopping board.

-Close the front panel and start the machine by pressing the ON button. The

blade pack will start moving.

-Grip the handle of the chopping board and move it forward and back along the

slit on the chopping board. Thanks to the sliding pin located under the chopping

board, the latter can be shifted forward and back, but also turned to the right and

left. By moving in this way the blades can tenderise the entire product.

-Switch the machine off using the OFF button: the blade pack will return to its

initial position and the machine will stop.

-Extract the tenderised product.

5

English

relieves the manufacturer of any liability for damages deriving from such action.

The manufacturer is also relieved of all liability for the consequences of:

-incorrect installation;

- improper use of the machine by inadequately trained personnel;

- use of the machine in breach of local regulations;

-lack of or negligent maintenance;

-use of non-original spare parts, not specified for the model in question;

-total or partial failure to follow the instructions.

1.4 - Machine description

The meat tenderiser you have purchased is a straightforward, compact machine

guaranteeing powerful operation and efficient performance.

-Since the product must be used with food products, all components that can

come into contact with it have been carefully chosen to guarantee the utmost

hygiene.

-The chopping board is made of stainless steel and can be easily removed for

guaranteeing maximum hygiene and facilitating cleaning operations.

-The blade pack is made of grade AISI 420 steel and can be easily removed to

ensure long-lasting operation and maximum hygiene.

-Electronic control of the absorption for monitoring the forward movement of the

shaft.

-Ventilated motors offering the following advantages:

extremely constant performance and long motor life;

longer actual work time thanks to fewer interruptions;

low level of heating so that the meat stays constantly fresh and unaltered.

This equipment conforms to the essential safety and health requirements set out in

Directive 2006/42/EC and to the requirements of Directives 2014/30/EU, 2014/35/

EU, 2006/42/EC, 2011/65/EU (RoHS) and Regulation (EC) 1935/2004.

If any accident occurs, the manufacturer shall not be held liable if the machine has

been modified, tampered with, had its safety guards removed or is used for

purposes other than the intended use specified by the manufacturer.

1.5 - Intended use

The machine was designed and manufactured for tenderising slices of meat.

It must be used in a professional setting by qualified operators who have read and

understood this manual. Use the machine exclusively when it is securely placed on

a solid worktable.

1.6 - Improper use

The machine must only be used for its intended purposes; in particular:

- Do not use the machine for tenderising food products other than meat.

- Do not use the machine unless it has been properly installed with all its guards in

good working order and correctly fitted, to prevent the risk of serious injury.

- Do not use or store the machine inside a cold room: this could seriously damage

the electrical components sensitive to condensate (which forms at low

temperatures) and also alter the viscosity of the grease and/or lubricating oil in

6

the gearbox housed inside it, jeopardising the machine’s correct operation and

causing potential failures.

- Do not access any of the electrical components without having first disconnected

the machine from the mains power supply: risk of electric shock.

- Do not process products that are too large to be fully contained under the blade

pack.

- Do not wear clothing which does not comply with safety regulations. Consult

your employer for information on the applicable safety regulations and the

personal protective equipment to be worn.

- Do not start the machine if it has a fault.

- Before using the machine, make sure that any potentially hazardous conditions

have been adequately eliminated. If you notice anything unusual in its operation,

shut down the machine and inform the maintenance supervisors.

- Do not allow unauthorised persons to work on the machine.

In case of injury caused by electric shock, the first thing to do is to detach the

injured person from live conductors (as the person will probably be unconscious).

This is highly hazardous.

In this instance, the injured person is also a live electrical conductor; touching them

directly would mean suffering electric shock.

It is advisable to disconnect the contacts directly from the line’s power supply

valve; should this not be possible, move the victim away using insulating material

(wooden or PVC sticks, fabric, leather, etc.).

First-aid medical assistance should be requested promptly and the injured person

should be taken to hospital.

1.7 - Specific equipment details

Citing the “Model”, “Serial number” and “year of manufacture” of the machine

will help our technical assistance service to respond to your requests rapidly and

effectively. We recommend specifying the machine model and serial number

whenever you contact the technical assistance service.

This information appears on the rating plate shown in Fig. 1.7.1. As a reminder, we

suggest writing the data of the machine you have purchased in the table below:

Machine Model………………………..

Serial number…………………………

Year of construction…………………

Type……………………………………

15

English

5 - Start-up and shutdown

5.1 - Verification of the correct electrical connection

- Connect the plug to the mains power supply.

-Set the residual-current switch to “I”.

-Press the ON button. The blade pack will start moving down and up.

5.2 - Verification of the presence and efficiency of guards and safety

devices

1 - With the machine running, open the front

panel “1” Fig. 5.2.1. The machine must stop

instantly.

2 - With the machine running, press the

mushroom-head emergency button “2” Fig

5.2.1.

The machine must stop instantly.

3 - Check that the stainless steel casing “4” Fig

5.2.1 is intact and rigidly fastened.

5.3 - Verification of the efficiency of the emergency stop button

With the machine connected to the mains electricity and the accessory tool

moving, press the OFF button (Ref. 5 Fig. 5.2.1).

The blade pack must return to its initial position and the machine must stop.

5.4 - Machine start up

To start the machine, simply press the ON button (Ref. 6 Fig. 5.2.1). Start the

machine only after properly connecting the plug to the mains power supply.

5.5 - Machine shutdown

To stop the machine, simply press the OFF button (Ref. 5 Fig. 5.2.1). The blade

pack will return to its initial position and the machine will stop.

Fig. 5.2.1

1

4

2

6

5

14

Remove the cellophane wrapping and any other packaging present inside.

4.3.2 - Disposing of packaging material

The packaging materials (cardboard, nylon, wood, etc.) can be regarded as solid

urban waste, which means that they can disposed of freely.

If the machine is delivered to a country where special regulations apply, dispose of

the packaging accordingly.

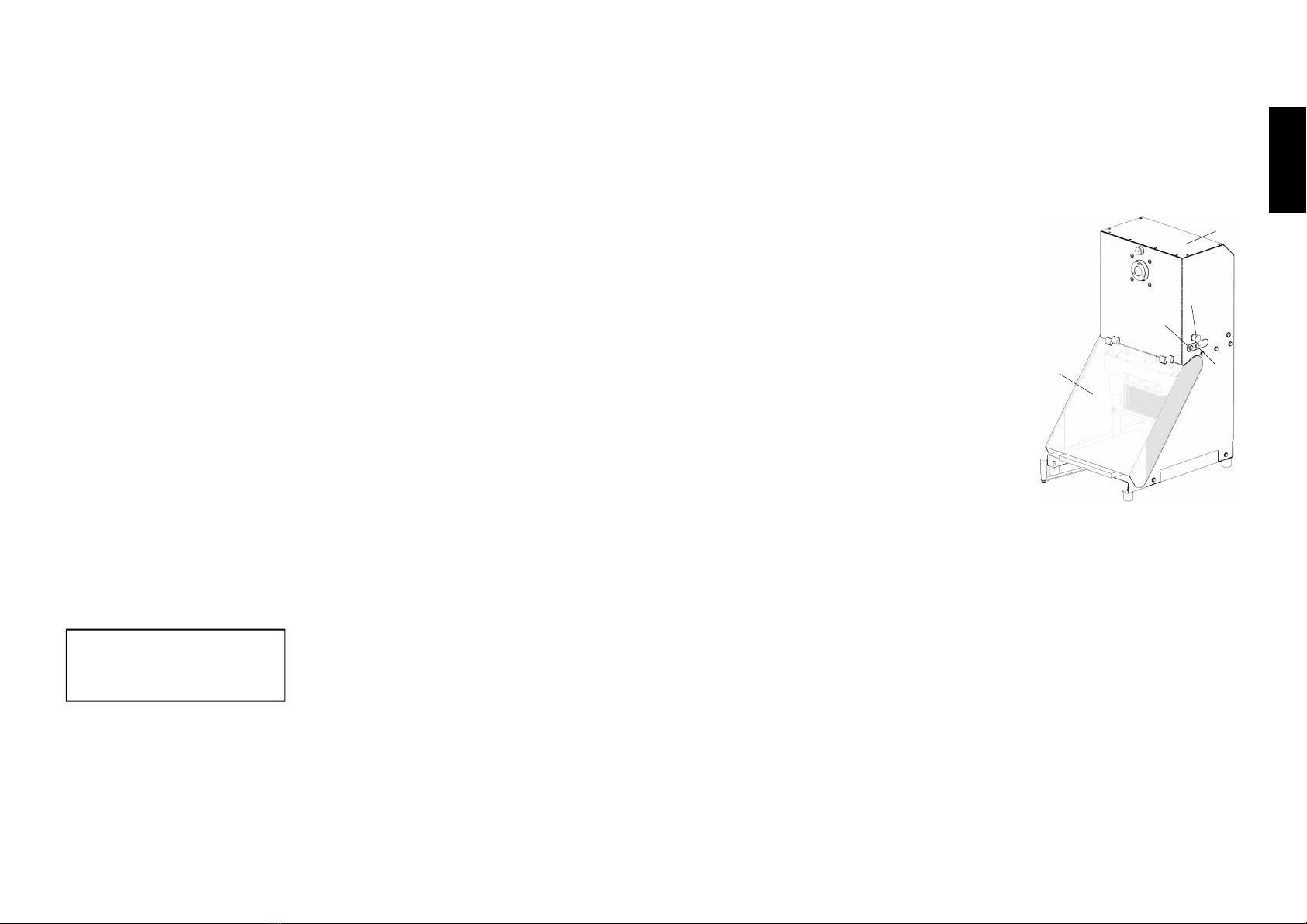

4.3.3 - Handling the machine

Lift the machine up using a forklift truck with adequate

load-bearing capacity.

Check the stability and position of the load on the forks,

particularly along uneven, slippery or inclined surfaces.

When moving the load, keep it as low as possible in

order to ensure better stability and visibility. Widen the

forks on the forklift truck in order to stabilise the load as

much as possible.

At least two operators are required to move the

machine manually.

4.4 - Electrical connections

CAUTION!

Check that the power supply line has the same specifications as those shown on

the machine’s rating plate. All interventions must be carried out solely by

specialised personnel expressly authorised by the relevant supervisor. Make the

connection to a power line equipped with an efficient earthing socket.

4.4.1 - 380 V-50 Hz three-phase machine

and 220 V-50 Hz three-phase machine

In these configurations, the machine is supplied with a power cord with 4 x 1.5 mm

gauge.

This cord is connected to a three-phase plug with

three pins + earth. Attach the cord to the three-

phase power supply line by installing a 16 A

residual current circuit breaker in between.

4.4.2 - 220 V-50 Hz single-phase machine

In this configuration, the machine is supplied with a power cable with

3 x 1.5 mm gauge. This cable is connected to a single-phase plug

with three pins. Attach the cable to the 220 V-50

Hz single-phase power supply line by installing

a 16 A residual current circuit breaker in

between.

Consult the manufacturer for configurations

differing from those mentioned above. If the power cable needs to

be extended, use a cable of the same gauge as the original cable

installed by the manufacturer.

Fig. 4.3.1

7

English

CAUTION! Do not alter the data on the rating plate for any reason.

1.7.1 - Warning and danger signs (Fig. 1.7.2)

CAUTION!

Do not intervene on the electrical components when the machine is connected to

the mains power supply. You risk getting an electric shock.

Observe the warnings signalled by the signs. Failure to do so could lead to

personal injury.

Make sure that the signs are always present and legible.

If they are not, apply or replace them.

A = Machine model

B = Power supply

C = Motor power

D = Motor frequency Hz

E = Weight

F = Amperage

G = Year of construction

H = Serial N°

I = Manufacturer

L = Bar code

A

B C

D E

F G

H

I

L

Fig. 1.7.1

Fig. 1.7.2

8

1.8 - Guards and safety devices

CAUTION!

Before using the machine, make sure that its safety devices are properly

positioned and in good working order.

Check that they are present and work properly at the start of each shift. If not,

notify the maintenance supervisor.

(Fig. 1.8.1)

1 - Interlocked plexiglass cover

2 - Guard protecting the stainless steel mechanical moving elements

3 - Mushroom-head emergency button

CAUTION!

Do not tamper with the safety devices for any reason.

2

3

1

Fig. 1.8.1

13

English

3 - Controls and indicators

3.1 - List of controls and indicators

1 Start button:

Press to start the blade pack.

2 Stop button: press to switch the machine off.

When pressed, the blade pack returns to its initial position and then the

machine switches off.

3 Mushroom-head emergency button: switches the machine off instantly.

To restart the machine, turn the button to unlock it.

CAUTION! If the machine seizes up due to jamming of the product, press the

reversal button on the machine’s right-hand side (see Fig. 2.1.1 Ref. 9). Pressing

this button will reverse the motor’s movement and the shaft will lift to free the

jammed product or the slide.

4 - Factory testing, shipping, delivery and installation

4.1 - Factory testing

The machine you have purchased has been tested at our plants to verify its correct

operation and proper adjustment. The tests were conducted using materials similar

to those processed by the user.

4.2 - Delivery and handling

All shipped material is carefully checked prior to being handed over to the shipping

agent. Unless otherwise agreed with the customer, the machine is wrapped in

nylon and screwed onto the pallet. It is then covered with cardboard, which is

strapped to the pallet. When you receive the machine, check the condition of its

packaging. If you notice any damage to the packaging, sign the delivery note with

the following note: “Goods accepted with reservation...” and the reason.

If you notice any damage to the components of the machine after opening the

package, report it to the shipping agent within three days from the date shown on

the documents.

4.3 - Installation

CAUTION! The installation area must be level and solid, and the area supporting

the machine must ensure that it is stable and safe. Moreover, the machine must be

placed where there is ample space around it, taking into account the dimensions

required for supporting it. This will facilitate manoeuvring during work phases and

ensure easy access for subsequent maintenance operations.

Provide adequate lighting around the tenderiser to ensure proper visibility for the

operator using it.

4.3.1 - Installation

Handle the package with a lift truck or similar equipment, since the machine is

delivered in a cardboard carton mounted to a pallet.

Remove the two straps fastening the cardboard box to the pallet.

Remove the cardboard.

Fig. 3.1.1

1 23

12

2.4.2 - Three-phase wiring diagram

9

English

1.9 - Work position

To optimise work with the machine, the operator should assume the position

shown in Fig. 1.9.1.

2 - Technical specifications

2.1 - Main parts

To aid comprehension of the manual, the main components of the machine are

listed below and shown in Fig. 2.1.1.

1. Removable plexiglass guard

2. Mushroom-head emergency stop

button

3. Grade AISI 304 steel machine body

4. POLYETHYLENE chopping board

5. Feet

6. Grade AISI 420 steel blade pack

7. POM-C scraper

8. Grade AISI 304 steel sliding rods

9. Reversal button

10. Machine controls

1

2

3

4

6

7

8

Fig. 2.1.1

9

5

10

Fig. 1.9.1

10

2.2 - Technical specifications

2.3 - Machine dimensions and weight

A B C D E F Net weight

mm mm mm mm mm mm kg

424 560 520 615 970 875 85

Motor Power supply Work area Blades

watt/hp Volt mm n°

1100/1,5 400V/50Hz 216x280x100 32

750/1 230V/50Hz 216x280x100 32

A

C

B

D F

E

Fig. 2.3.1

11

English

2.4 - Wiring diagrams

2.4.1 - Single-phase wiring diagram

Other CHEFOOK Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Omcan

Omcan BE-CN-2083-CSS instruction manual

Somerset

Somerset SDP-747 Operation manual

Chocolate World

Chocolate World Cw60 Use and maintenance manual

Rocam Losi

Rocam Losi TETI Instructions for assembly, installation, use and maintenance

Zoin

Zoin Danny DC120BSVB171VA Technical instructions

Omcan

Omcan FR-CN-0007W instruction manual

Falcon

Falcon E2962 User instructions

Lotus

Lotus LIBR.ISTR.TP70G Installation and operating instructions

Horizon Fitness

Horizon Fitness BOOK BINDER BQ-470 Important information

Diamond

Diamond ML20/B5-VV/R2 Technical instructions

GenLab

GenLab PRIME RANGE operating instructions

Wahl

Wahl KM CORDLESS 09596-200 Operation manual