CHESTER Cobra Mill User manual

Contents

1. Introduction 2

2. Health&Safety 35

3. MachineSpecification 67

4. Operation 89

5. Controls 10

6. PartDiagrams&Lists 1113

7.CircuitDiagram 1415

8. GuideToMilling 16

ChesterUKCobraMill

1

Introduction

ChesterUKLimitedisaspecialistcompanythathasbeensupplyingthemachinetoolindustryfor

over15years.TheChesterUKHeadOfficecomprisesofa30,500sq.ftfactorycompletewithofficesand

a showroom. Specialisingin conventional machine tools, Chester has built a reputation for quality and

reliability,whichishighlyregardedinthemachinetoolindustryandthemodelengineeringmarket.

Thereareseveral divisionswithinthecompany;Export,Education, ModelEngineering &UKSales,all

withdedicatedsalespersonnelwhoaretrainedtoansweryourquestions.

When buying from Chester you can be assured of a complete backup service with mechanical and

electricalengineersthatareavailabletogiveadviceifrequired.

StockisalargepartofanybusinessandChesterhavealwaysinvestedsubstantiallyinbuildingalarge

quantity of machines and spares, ready to satisfy customer requirements. Chester UK has one of the

largest stocks ofconventionalnew machines andaccessories within Great Britain. Pleasetake time to

visitourwebsite: www.chesteruk.net

ChesterUKCobraMill

2

Health&Safety

Aswithallmachinerytherearecertainhazardsinvolvedwiththeoperationanduseofthelathe.

Using the machine with respect and caution will considerably lessen the possibility of person injury.

However, if normal safety precautions are overlooked or ignored, personal injury to the operator may

result.

Thismachinewasdesignedforcertainapplicationsonly.Westronglyrecommendthatthemachineisnot

modified,and/orusedforanyapplicationotherthanwhichitwasdesigned.Ifyouhaveanyquestions

relativetoitsapplicationdonotusethemachine,untilyouhavefirstbeenincontactwithChester

UK.

The lathe may not arrive with a power socket or plug. In the event of this happening, please inform

ChesterUKonTel:(01244)531631.

Safetyrulesforalltools

User

1. Wearcorrectapparel

Nolooseclothing,gloves,rings,braceletsor otherjewellerytoget caughtinmovingparts.Non

slipfootwearisrecommended.Wearprotectivehaircoveringtocontainlonghair.

2. Alwaysweareyeprotection

Refer to ANSLZ87.1 standard for appropriate recommendations. Also use face and / or a dust

maskifthecuttingoperationisdusty.

3. Don’toverreach

Keepaproperfootingandbalanceatalltimes.

4. Neverstandonatool

Seriousinjurycouldoccurifthetoolistippedorifthecuttingtoolisaccidentallycontacted.

5. Neverleavethetoolrunningunattended

Turnpoweroff.Leavetooluntilitcomestoacompletestop.

6. Drugs,alcoholandmedication

Donotoperatethetoolwhileundertheinfluenceofdrugs,alcoholoranymedication.

7. Makesurethetoolisdisconnectedfromthepowersupply

Whilemotorisbeingmounted,connectedorreconnected.

8. Always

Keephandsandfingersawayfromanymovingparts.

9. Stop

Themachinebeforemovingchips.

10.Shutoff

Powerandcleanthelatheandworkareabeforeleavingthemachine.

Useofthemachine

1. Removeadjustingkeysandwrenches

Form a habit of checking to see that keys and adjusting wrenches are removed from the tool

beforeturningit‘on’.

2. Don’tforcethetool

Itwilldothejobbetterandbesaferattherateforwhichitwasdesigned.

3. Usetherighttool

Don’tforcethetoolorattachmenttodoajobforwhichitwasnotdesigned.

4. Securework

Useclampsoravicetoholdworkwhenpractical.It’ssaferthanusingyourhands,andfreesboth

tooperatethemachine.

ChesterUKCobraMill

3

5. Maintaintoolsintopcondition

Keeptoolssharpandcleanforthebestandsafestperformance.Followinstructionsforlubricating

andchangingaccessories.

6. Userecommendedaccessories

ConsultChesterUKforrecommendedaccessories.Theuseofimproperaccessoriesmaycause

hazards.

7. Avoidaccidentalstarting

Makesuretheswitchisinthe‘OFF’positionbeforeplugginginpowercord.

8. Stop

Themachinebeforeputtingmaterialinthevice.

9. Always

Havestockfirmlyclampedinthevicebeforestartingthecut.

10. Groundalltools

If the tool is equipped with a threeprong plug, it should be plugged into a threehole electrical

receptacle.Ifanadapterisusedtoaccommodateatwoprongreceptacle,theadapterplugmust

beattachedtoaknownground.Neverremovethethirdprong.

Adjustment

Make all adjustments with the power off.When assembling follow the manuals instructions, this

willensurecorrectinstructionandasafestructure.

Workingenvironment

1. Keeptheworkareaclean

Clutteredareasandbenchesinviteaccidents.

2. Don’tuseinadangerousenvironment

Don’tusepowertoolsindamporwetlocations,orexposetorain.Keeptheworkareawelllit.

3. Keepchildrenetcatasafedistance.

Allchildrenetcshouldbekeptatasafedistancefromtheworkarea.

4. Don’t

Install&usethismachineinanexplosivedangerousenvironment.

Maintenance

1. Disconnect

Machinefromthepowersourcewhenmakingrepairs.

2. Checkdamagedparts

Beforefurtheruseofthetool,aguardorotherpartthatisdamagedshouldbecarefullycheckedto

ensure that it would operate properly and perform its intended function check for alignment of

movingparts,bindingofmovingparts,breakageofparts,mountingandanyotherconditionsthat

may affect its operation. A guard or other part that is damaged should be properly repaired or

replaced.

3. Disconnecttools

Beforeservicingandwhenchangingaccessoriessuchasbladesbits,cutters,etc.

4. Toprevent

Thecorrosionofmachinedsurfaceswhenasolubleisusedascoolant,payparticularattentionto

wipingdrythesurfaceswherefluidaccumulatesanddoesnotevaporatequickly,suchasbetween

themachinebedandvice.

ChesterUKCobraMill

4

SafetyDevice

1. Interlockswitchonpulleycover.Assoonasthepulleycoverisopen,themachinewillcometo

a stop with the function of this switch. Do not remove this switch from the machine for any

reason,andcheckit’sfunctionfrequently.

2. Interlockswitchoncuttingarea.Assoonasthepulleycoverisopen,themachinewillcometo

a stop with the function of this switch. Do not remove this switch from the machine for any

reason,andcheckit’sfunctionfrequently.

ChesterUKCobraMill

5

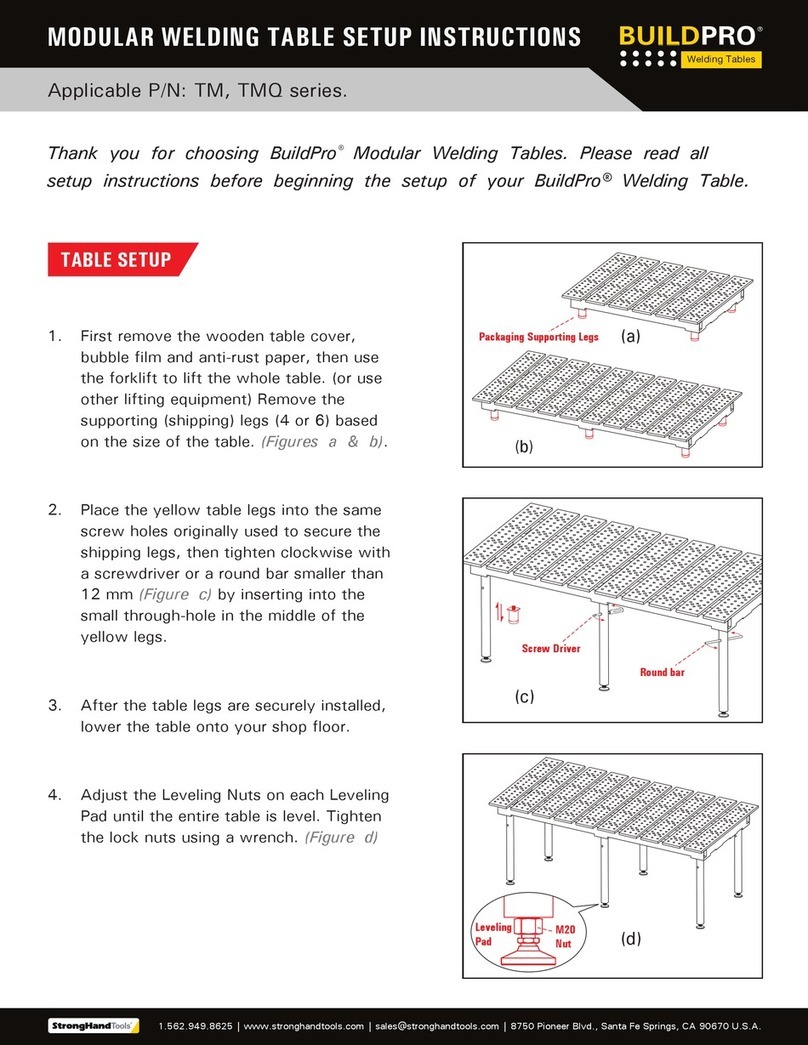

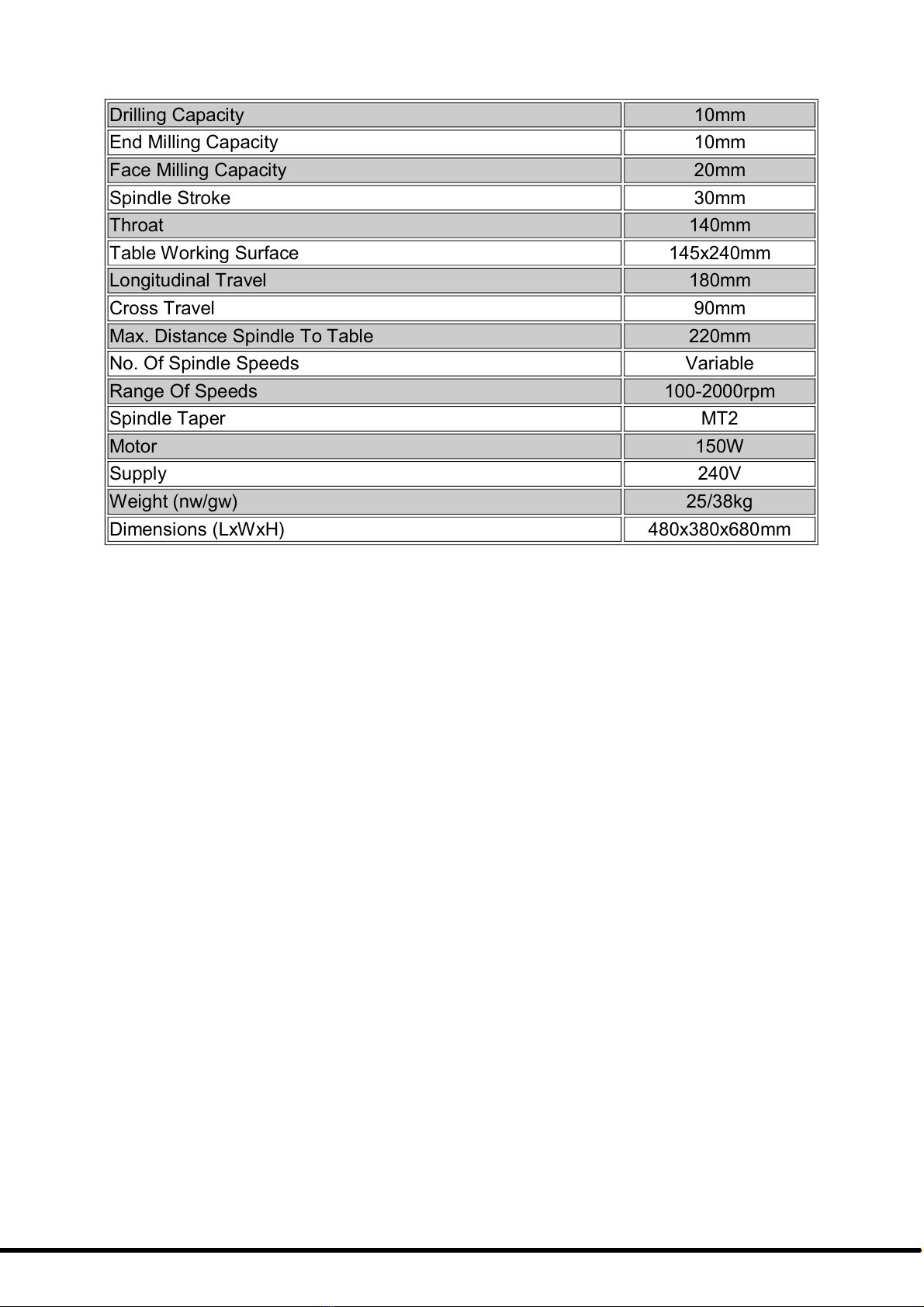

MachineSpecification

DrillingCapacity 10mm

EndMillingCapacity 10mm

FaceMillingCapacity 20mm

SpindleStroke 30mm

Throat 140mm

TableWorkingSurface 145x240mm

LongitudinalTravel 180mm

CrossTravel 90mm

Max.DistanceSpindleToTable 220mm

No.OfSpindleSpeeds Variable

RangeOfSpeeds 1002000rpm

SpindleTaper MT2

Motor 150W

Supply 240V

Weight(nw/gw) 25/38kg

Dimensions(LxWxH) 480x380x680mm

ChesterUKCobraMill

6

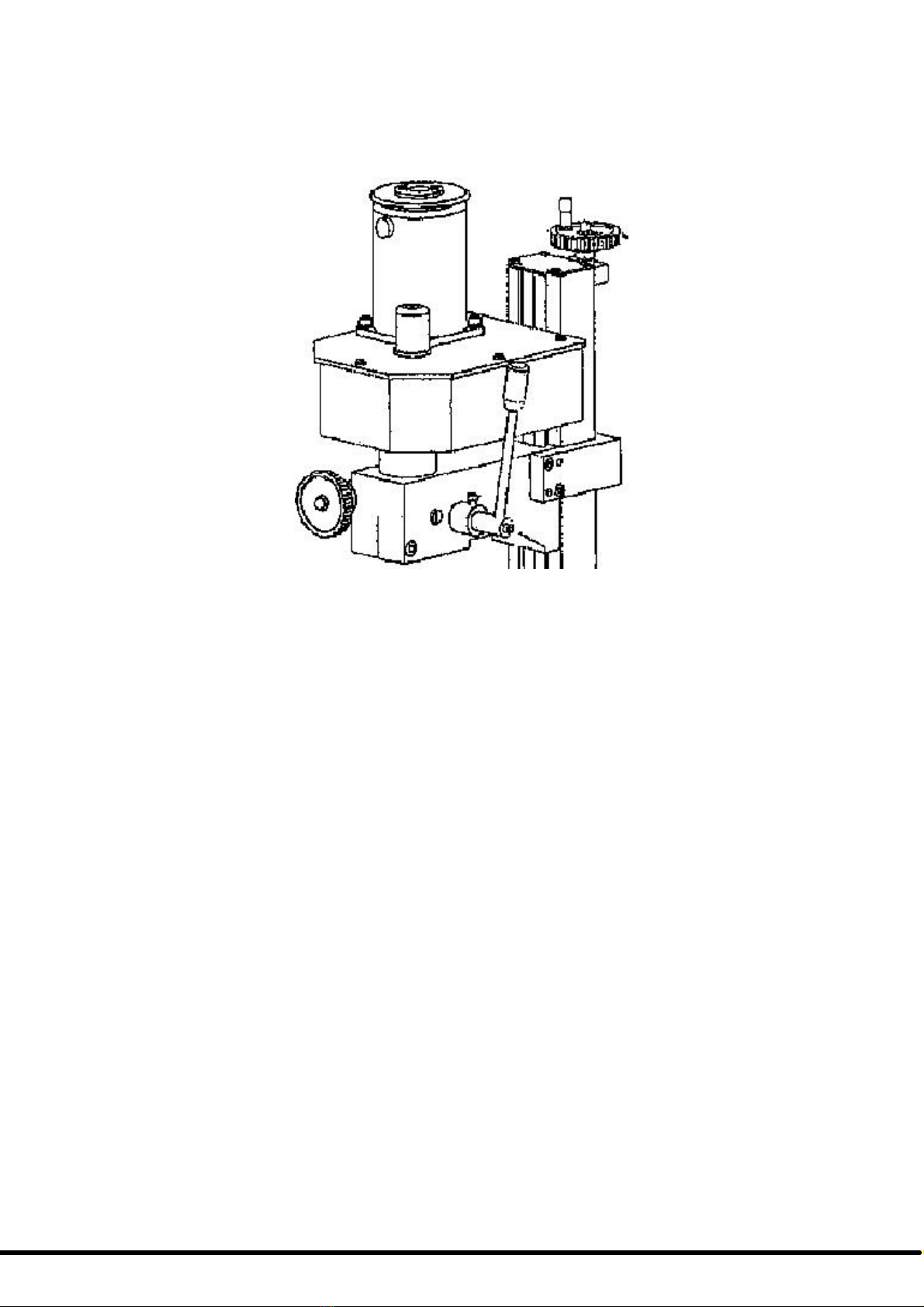

Features

1.Forward/Off/ReverseSwitch 2.VariableSpeedControlKnob 3.FuseBox

4.PowerLight(Green) 5.YellowLight(only110V) 6.HighLowChangeKnob

7. 8.FineFeedingHandwheel 9.

10.WorkTable 11.CrossFeedHandwheel 12.LongitudinalFeedHandwheel

13.Handle 14.LiftingHandwheel 15.DCMotor

ChesterUKCobraMill

7

Operation

InstallationOfTheTaperedShank

1. Disconnectfromthemainpowersupply,beforeyoureplacethecutter.

2. Removetheprotectivecover(a).

3. Wipethespindlesleeveandtapershank.

4. Putthetapershank(i)intothespindlesleeve.Mattthecutterwithanoilcloth.

5. Usea#14openendwrench(c),turningthespindledrawbar(clockwise)(b),inordertosecure

thetaperedshank.

6. Pulloutthefixingpin

7. Installtheprotectivecover(a).

RemovalOfTheTaperedShank

1. Disconnectfromthemainpowersupply,beforeyoureplacethecutter.

2. Removetheprotectivecover(a).

3. Usea#14openendwrench(c),toloosenthespindledrawbar(counterclockwise)(i),inorder

toremovethetaperedshank.

4. Knockthetapershank(i)(gentlywithaplastichammer)toloosenitinthespindlesleeve.

5. Mattthecutterwithanoilcloth.

6. Installtheprotectivecover(a).

ChesterUKCobraMill

8

TravelAdjustment

Theliftinghandlecanbeusedtocontrolthetravellingofthespindlebox.

1. Loosenthescrewinsidethespindlebox.

2. Rotationoftheliftinghandlewillmovethespindleboxupordown.

FineFeeding

Tooperatethefinefeed,pushtheclutchleverin.Thiswillenablethehandwheelforthefinefeed.

MitreWedgeAdjustment

Inthelongtermwearwilloccuronthedovetail.Thiswillcauseinaccuracythatcanbeeliminatedby

adjustingthemitrewedge(adjustingthedovetailgibstrip).Adjustingthescrewslidesthetaperedstripto

reducethegapandrestoreaccuracyofthemill.

Thefollowingadjustmentsarepossible:

1. Base&YAxisCrossSlide.

2. XAxisCrossSlide&WorkTable

3. MillHeadSeat&VerticalColumn.

4. MillHead&Spindle.

TheWayToAdjust

1. Loosenthelockednuts.

2. Adjust the foremost pressure of the mitre wedge by locked nut. If necessary, loosen all the

adjustingscrewstothesame.

3. Tightenand loosen the adjusting screws, also keeping the pressure of each adjusting screw

thesame.

4. Tightenthelockednutuniformly.

5. Whenthenutislocked,pleaseusethe#3interiorhexagonalwrenchtofixtheadjustingscrew

fromrotating(thiswillcauseanunbalanceinthepressure).

6. Please adjust the middle portion first and then go to toward the interior from two sides

uniformlywhileyouareadjustingthescrewinordertoensureuniformpressure.

ChesterUKCobraMill

9

Controls

InitialStart

Set the HIGH / LOW range lever to low. Connect to the power supply. Select FORWARD, using the

FORWARD/OFF/REVERSESwitch(A)onthemaincontrolPanel,thenthepowerlamp(B)lights.

SwitchontheCobraMillbyslowlyturningtheVariableSpeedControlKnob(C)clockwise.

Thespeedwillincreaseprogressivelythefurthertheknobisturned.

Runforatotalof5minutes;graduallyincreasethespindlespeedtoitsmaximum.Runattopspeedforat

least2minutesattopspeedbeforestopping.

Checkthatallcomponentsaresecure,workingfreelyandcorrectly.

CheckthattheCobraMillismountedsecurely.

RepeattheprocedureataHIGHspeedsetting.

Caution

NeverattempttochangefromaHIGHtoaLOWspeedwhilstthemachineisrunning.

StartingUnderNormalConditions

1. Takeallthenecessaryprecautionspreviouslystated,andensuretheworkpieceisfixedfirmly.

2. Selectanappropriatespeedlevel.

3. SelecttheFORWARD/off/REVERSEtoaFORWARDorREVERSEposition.

4. Proceedtostartthemachineasdescribedabove.

5. Whilstnotinuse,switchoffanddisconnectfromthepowersupply.

Notice

When using 100~120v power, the socket will have to have a auto overload protective function. If the

feedistofast,orthedrillingistoodeep,theCobraMillwillstopworkingandayellowlight(behindthe

fuselage)willlightup.ByturningtheVariableSpeedcontrolknob(D)andthenturnonagain,theCobra

willnowworkagainandtheyellowlampwilloffautomatically.

ChesterUKCobraMill

10

PartDiagrams&Lists

ChesterUKCobraMill

11

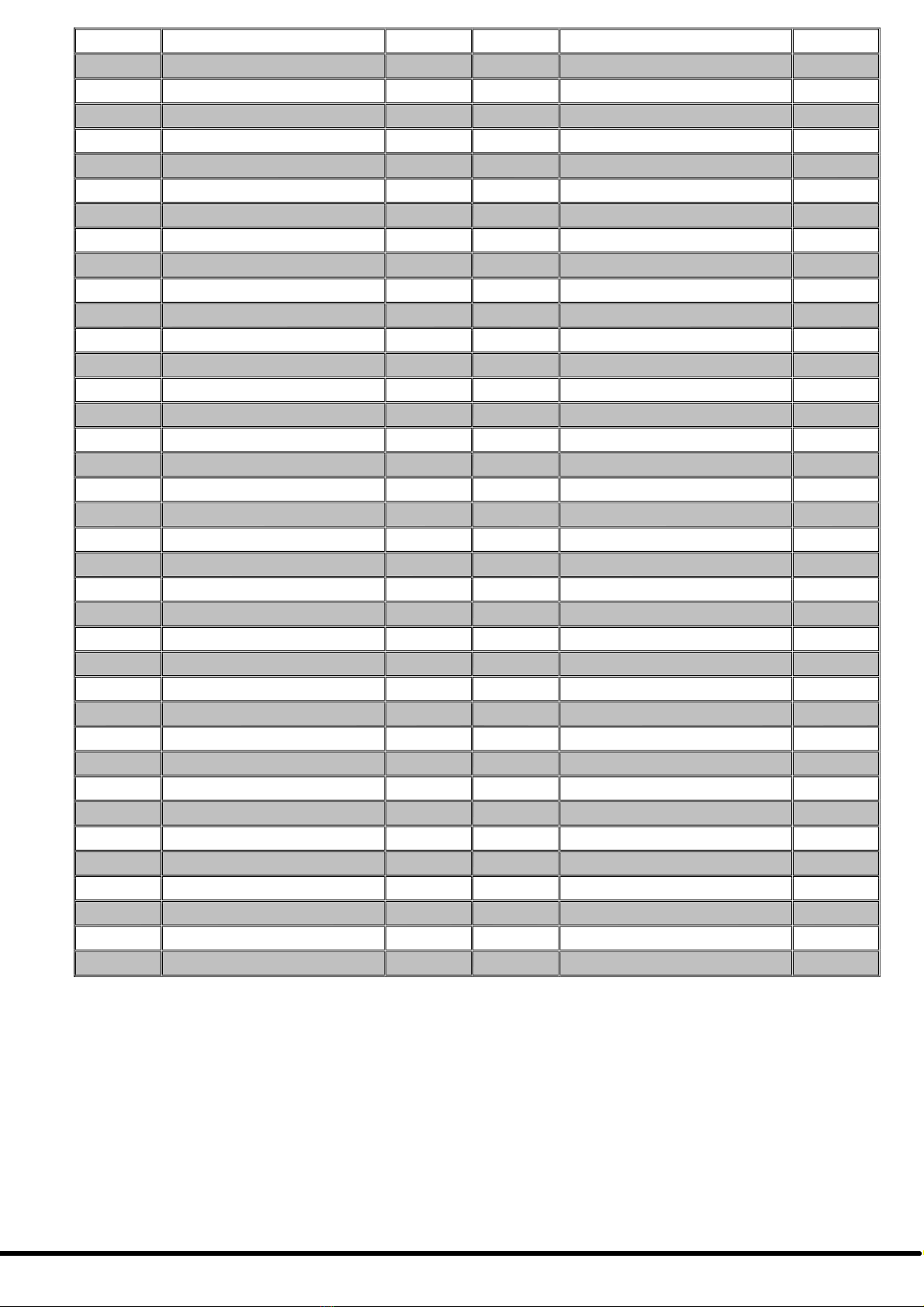

No. Description Q'ty No. Description Q'ty

1 ScrewM4x12 2 38 Shiftshaft 1

2 Coverforthemotor 1 39 Key4x8 1

3 ScrewM6x12 3 40 Key4x12 1

4 Springwasher6 3 41 Changegear 1

5 Washer6 3 42 Dialfork 1

6 DCmotor 1 43 Flangelining 2

7 Roundkey 1 44 Checkring21 1

8 Checkringforshaft8 2 45 Spacer 1

46 Variablespeedcontrolknob 1

10 Motorgear 1 47 Springpin2x12 1

11 Safetycover 1 48 Wedge 1

12 ScrewM4x6 1 49 ScrewM5x18 4

13 ScrewM4x8 4 50 NutM5 4

14 Washer4 4 51 Handle 1

15 Upcover 1 52 PinA3x12 1

16 Sleevesupportplate 1 53 Jointshaft 1

17 ScrewM6x5 1 54 ScrewM5x18 1

18 Compressionspring 1 55 Jointscrew 1

19 Steelball5 1 56 Wormbase 1

20 Gearbox 1 57 Helicalgear 1

21 Spindlesleeve 1 58 Spacer 1

22 ScrewM6x14 2 59 PinA3x18 1

23 Bearing619052E 2 60 Key2x18 1

24 Spindlebox 1 61 Wormshaft 1

25 Checkringforhole38 2 62 Dial 1

26 Springseatring 1 63 Dampspring 1

27 Compressionspring 1 64 Handwheel 1

28 Roundnutstopgasket 1

29 RoundnutM24x1.5 1

30 Spindlegear 1 67 Washer6 4

31 Spacer 1 68 TopnutM6 4

32 Spindlegear 1 69 ScrewM6x20 1

33 Checkringforshaft20 1

34 Powdermetallurgybearing 2 71 ScrewM4x20 2

35 Gear 1 72 ScrewM4X18 8

36 Checkringforshaft10 1 73 NutM4 8

37 Changegear 1 74A Base 1

ChesterUKCobraMill

12

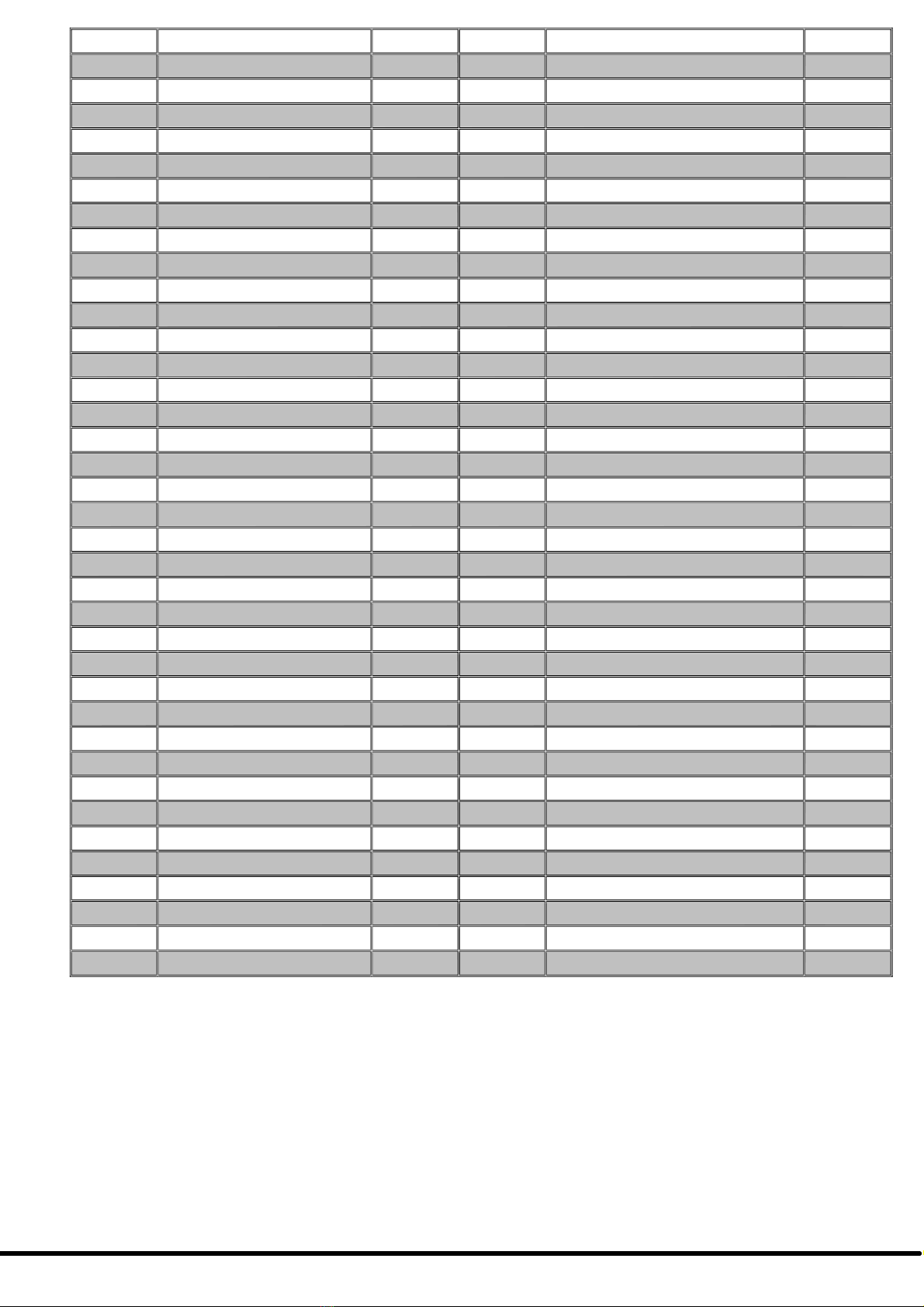

No. Description Q'ty No. Description Q'ty

75 ScrewM6x20 2 119 Diallabel 1

77 Lockscrew 1 120 Electricitybox 1

78 Spindle 1 121 PCBoard 1

79 Key4x28 1 122 Powerindicatorlight 1

84 ScrewM8x50 1 123 Fusebox 1

85 Fixscrew 1 124 Metachoresisswitch 1

86 Gearshaft 1 125 Forward/reverseswitch 1

87 Handleshaft 1 126 Electricitylabel 1

88 Longhandlesleeve 1 127 ScrewST2.9x6.5 4

89 Springpin3x12 2 128 Powerline 1

90 Markshowsleeve 1 129 Cautionlabel 1

91 ScrewM5x8 2 130 Spindleaxislabel 1

92 ScrewM6x20 4 *131 Technicalparameterlabel 1

93 Pin6x26 2 *132 Drillchuck 1

94 Nutblock 1 *133 InsideSixhomWrenchS:3,6 1

95 Liftingscrew 1 *134 DoubleendWrench:5.5*,8*10 1

96 Screwsupport 1 *135 RoundnutWrenchD=3842 1

97 Handwheel 3 *136 Oilcan 1

98 Handlebolt 3 *137 Fuse 1

99 Handlesleeve 3 *138 Tapershank 1

100 Key3x10 3 *139 Chuckkey 1

101 Coverboard 1 *140 Tnut 4

102A Fuselage 1 141 Crossscrew 1

103 Screw 4 142 Crosswedge 1

105 Worktable 1 143 Connectplatesupport 1

107 Dampspring 2 144 Connectflange 1

108 Dial 2 145 Roundclampplate 1

109 ScrewM6x16 4 146 Scale 1

110 Screwbase 2 147 Finger 1

111 Lengthwaysscrew 2 148 ScrewM6*6 1

112 ScrewM4x8 4 149 ScrewM8*25 4

113 Screwnut 2 150 ScrewM6*25 2

114A Saddle 1 151 Labelrivet2*3 2

115 Wedge 2 152 Pin6*35 2

116 Changespeedlabel 1

117 Jointlabel 1

118 0positionlabel 2

ChesterUKCobraMill

13

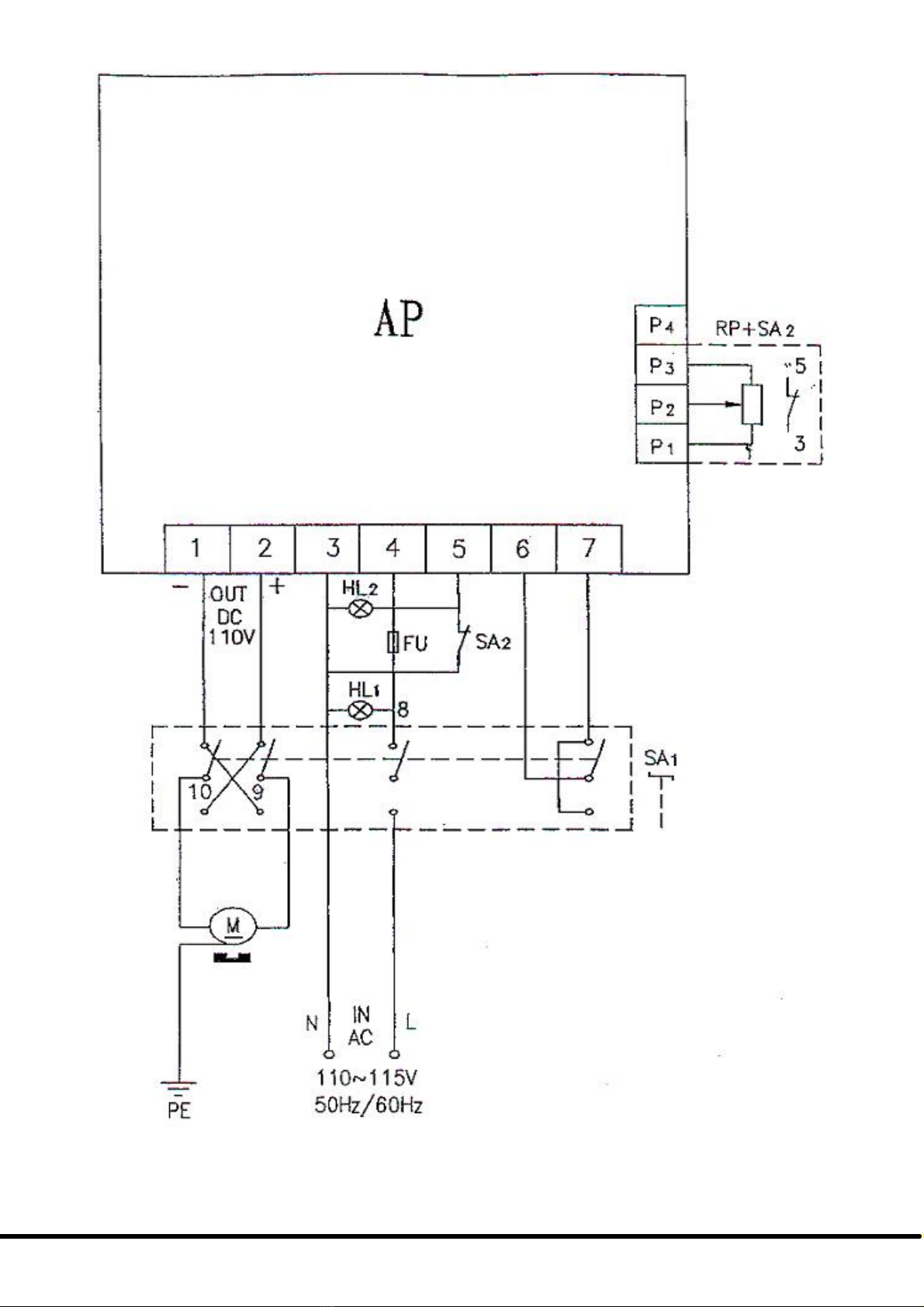

CircuitDiagram

220~240V/5060Hz

ChesterUKCobraMill

14

100~120V/5060Hz

ChesterUKCobraMill

15

GuideToMilling

Contents

1. Introduction

2. TypesofMillingMachine

2.1HorizontalMillingMachine

2.2VerticalMillingMachine

3. CuttingTools

3.1CuttingToolsforHorizontal

MillingMachine

3.2CuttingToolsforVertical

MillingMachine

4. IndustrialApplications

5. MillingProcesses

5.1SpindleSpeed

5.2FeedRate

5.3DepthofCut

5.4DirectionofCutterRotation

6. TypicalMillingOperations

6.1PlainMilling

6.2EndMilling

6.3GangMilling

6.4StraddleMilling

7. MillingSetUp

7.1ViceAlignment

7.2WorkHoldingMethod

8. Safety

1.Introduction

Millingmachineisoneofthemostversatileconventionalmachinetoolswithawiderangeofmetal

cuttingcapability.Manycomplicatedoperationssuchasindexing,gangmilling,andstraddlemillingetc.

canbecarriedoutonamillingmachine.

Thistrainingmoduleisintendedtogiveyouagoodappreciationonthetypeofmillingmachinesand

thevarioustypesofmillingprocesses.Emphasisisplacedonitsindustrialapplications,operations,and

theselectionofappropriatecuttingtools.

Oncompletionofthismodule,youwill

acquiresomeofthesetechniquesfromthe

trainingexercisesasillustratedinfigure1.

However,togainmaximumbenefit,you

arestronglyadvisedtomakeyourself

familiarwiththefollowingnotesbefore

undertakingthetrainingactivities,andto

haveagoodinteractionbetweenyourself

andthestaffinchargeofyourtraining.

Assessmentofyourtrainingwillbebased

onacombinationofyourskillandattitude

ingettingtheworkdone.

Figure1.MillingProducts

2.TypesofMillingMachine

Mostofthemillingmachineareconstructedof¡¥columnandknee¡¦structureandtheyareclassified

intotwomaintypesnamelyHorizontalMillingMachineandVerticalMillingMachine.Thename

HorizontalorVerticalisgiventothemachinebyvirtueofitsspindleaxis.Horizontalmachinescanbe

furtherclassifiedintoPlainHorizontalandUniversalMillingMachine.Themaindifferencebetweenthe

twoisthatthetableofanUniversalMillingMachinecanbesetatanangleforhelicalmillingwhilethe

tableofaPlainHorizontalMillingMachineisnot.

2.1.HorizontalMillingMachine

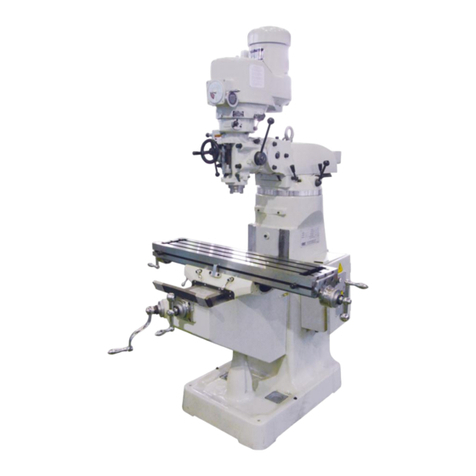

Figure2showsthemainfeaturesofaPlainHorizontalMillingMachine.

Theirfunctionsare:

a.Column

Thecolumnhousesthespindle,thebearings,

thegearbox,theclutches,theshafts,the

pumps,andtheshiftingmechanismsfor

transmittingpowerfromtheelectricmotortothe

spindleataselectedspeed.

b.Knee

Thekneemountedinfrontofthecolumnisfor

supportingthetableandtoprovideanupor

downmotionalongtheZaxis.

c.Saddle

Thesaddleconsistsoftwoslideways,oneonthe

topandoneatthebottomlocatedat90ºtoeach

other,forprovidingmotionsintheXorYaxesby

meansofleadscrews.

d.Table

Thetableismountedontopofthesaddleand

canbemovedalongtheXaxis.Ontopofthe

tablearesomeTslotsforthemountingof

workpieceorclampingfixtures.

e.Arbor

Thearborisanextensionofthespindlefor

mountingcutters.Usually,thethreadendofan

arborisoflefthandhelix.

Figure2.HorizontalMillingMachine

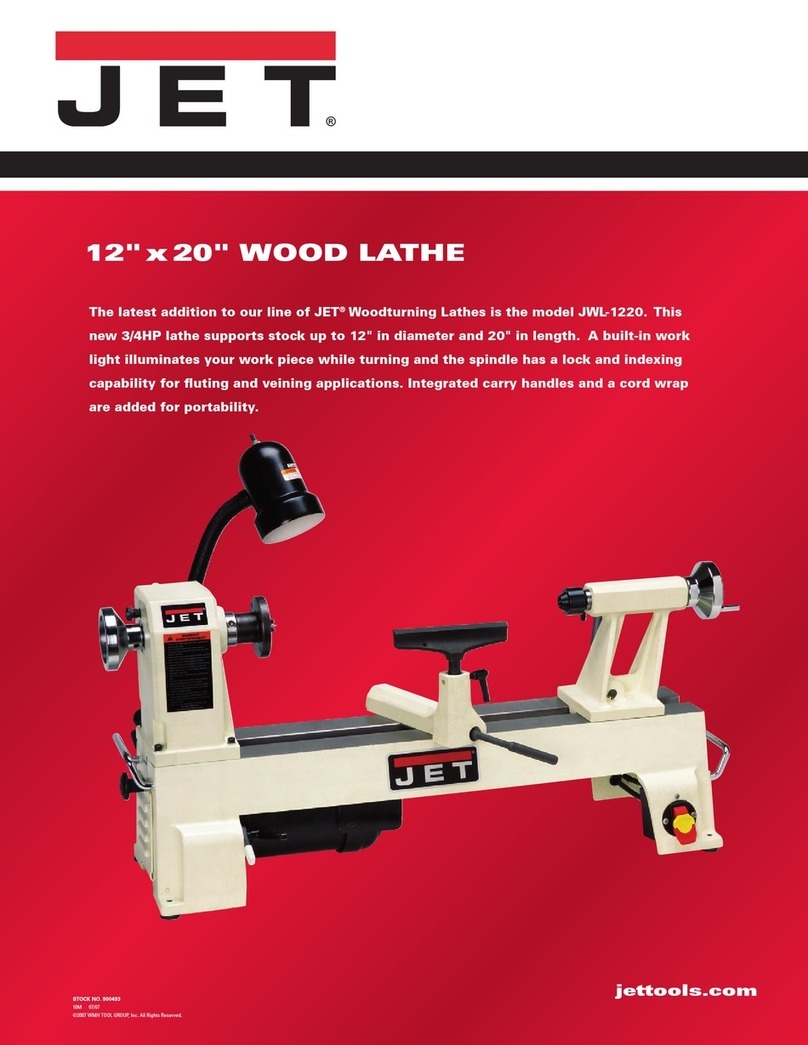

2.2.VerticalMi

llingMachine

Figure6.SlittingSaw

Note:Horizontalmillingcuttersarespecifiedbythename,thematerial,thewidth,thediameter,andthe

hubsizeofthecutter.

Example Sideandfacecutter,

HighSpeedSteel,

Cuttersize:10Xø100

Hubsize:ø25

3.2.CuttingtoolsforVerticalMilling

a.EndMills

Commonlyusedforfacing,slottingandprofilemilling.

Figure7.EndMill

b.RoughCutEndMills

Forrapidmetalremoval.

Figure8.RoughCutEndMill

c.SlotDrills

Forproducingpocketswithoutdrillingaholebeforehand.

Figure9.SlotDrill

d.FaceMillingCutters

Forheavycutting.

Figure10.FaceMillingCutter

Note:Mostverticalmillingcuttersareofendmilltypesandarespecifiedbythematerial,thediameter,

thelength,thehelicalangle,thetypesofshankandtheshankdiameter.Forfacemillingcutter,onlythe

diameterofthecutterandthetypesofcarbideinsertsarerequired.

Table of contents

Other CHESTER Lathe manuals

CHESTER

CHESTER Craftsman User manual

CHESTER

CHESTER Voyager Lathe User manual

CHESTER

CHESTER Crusader User manual

CHESTER

CHESTER DB8VS User manual

CHESTER

CHESTER CONQUEST SUPER LATHE User manual

CHESTER

CHESTER Crusader Deluxe Lathe User manual

CHESTER

CHESTER Crusader VS User manual

CHESTER

CHESTER DB7VS User manual

CHESTER

CHESTER Coventry Pro User manual

CHESTER

CHESTER CONQUEST SUPER User manual

Popular Lathe manuals by other brands

Hurco

Hurco TM6 Getting started

Scheppach

Scheppach DM600VARIO Translation of original instruction manual

WoodFast

WoodFast M305X instruction manual

Baileigh Industrial

Baileigh Industrial SR-5016 Operator's manual

AMMCO

AMMCO 7000 installation instructions

Record Power

Record Power DML36SH-CAM Original instruction manual