CHESTER Voyager Lathe User manual

Warning!

1. Read and understand the entire instruction manual before attempting to

assemble or operate the machine.

2. This lathe has been designed and is intended to be used by trained and

experienced personnel only. If you are not familiar with the correct and safe

operation of a lathe, do not operate this machine until you have been properly

trained.

3. Always wear approved safety glasses/face shields when using this machine.

4. Ma e certain the machine has been properly grounded.

5. Before operating the machine, remove ties, rings watches and other jewellery,

rollup sleeves above the elbows, remove loose clothing and confine long hair.

Do not wear gloves.

6. Keep the floor around the machine clean and free from scrap material, oil and

grease.

7. Keep the machine guards in place at all times when the machine is in use, if

they are removed for maintenance purposes, use extreme caution and replace

the guards immediately.

8. Do not over reach, maintain a balanced stance at all times so that you do not

fall or lean against cutting tools or the moving parts.

9. Ma e all machine adjustments or maintenance when the machine has been

unplugged from the power supply.

10. Do not force a tool or attachment to do a job which it was not designed for.

11. Replace any warning labels if they become damaged or obscured.

12. Ma e sure that the power switch is in the off position before connecting the

machine to the power supply.

13. Give your wor your undivided attention at all times, loo ing around,

continuing a conversation and general “horse-play” are careless acts that can

result in serious injury.

14. Keep visitors a safe distance from the wor area.

15. Use recommended accessories, using unsuitable accessories can be

hazardous.

16. Ma e a habit of chec ing to see that eys and adjusting wrenches are

removed before turning the machine on.

17. Never attempt any operation or adjustment if the procedure is not understood.

18. Keep fingers away from any rotating parts and cutting tools while in operation.

19. Keep the belt guard in place and in wor ing order.

20. Never force the cutting action.

21. Do not attempt to adjust or remove tools during operation.

22. Always use identical replacement parts when servicing the machine.

23. Always use eep cutting tools sharp.

24. Never operate or allow the machine to be operated by personnel under the

influence of alcohol or drugs.

25. Failure to comply with the above warnings may cause serious injury.

2

Contents

Warnings!

1. Specifications

2. Uncrating and Cleaning

3. Chuck Preparation

4. Lubrication

. Coolant Preparation

6. Electrical Connections

7. General Description

8. Controls

9. Break-In Procedure

10. Operation

11. Adjustments

12. Removable Gap

13. V-Belts

14. Aligning the Tailstock to Headstock

1 . Foundation Plans

16. Parts List and Drawings

3

1. Specifications

Swing Through the Gap 508mm

Distance Between Centres 1000mm

Hole Through Spindle 40mm

Spindle Nose D1-4

Taper in Spindle Nose MT5

Spindle Taper Adaptor MT3

Number of Spindle Speeds 12

Range of Spindle Speeds 40-1800rpm

Number of Longitudinal and Cross Feeds 42

Range of Longitudinal Feeds (mm/rev) 0.043-0.653

Range of Cross Feeds (mm/rev) 0..024-0.359

Number of Inch Threads 28

Range of Inch Threads 4-56TPI

Number of Metric Threads 37

Range of Metric Threads 0.4-7mm

Toolpost Type 4-Way

Maximum Tool Size 16x16mm

Maximum Compound Slide Travel 88mm

Maximum Cross Slide Travel 170mm

Maximum Carriage Travel 950mm

Tailstoc Spindle Travel 120mm

Diameter of Tailstoc Spindle 45mm

Taper in Tailstoc Spindle MT3

Overall Dimensions

1900x710x1170m

m

Net Weight 1200Kg

Gross Weight 1300Kg

4

2. Uncrating and Cleaning

1. Remove the crate from around the lathe carefully.

2. Unbolt the lathe from the shipping crate base.

3. Choose a suitable location for the lathe that is dry, is well lit and that has

enough room around to be able to perform maintenance to the entire machine.

4. Place two steel rods or pipes (of sufficient strength) into the four holes (A, Fig

1) of the lathe stand. Place slings around the rods (ma e sure that they are of a

sufficient capacity). DO NOT lift by the spindle. Use a crane to list the machine

and slowly raise the lathe from the base, ma e sure that the lathe is balanced

before moving.

Fig 1

5. To avoid twisting the bed, the lathes location must be absolutely flat and level,

use an engineer’s precision level on the beds ways in both the longitudinal and

cross directions. Levelling pads have been included with the machine, use these

and the levelling screws to adjust the level of the machine. The lathe must be

level to be accurate.

6. Clean the anti-rust oil from the surfaces of the machine with a mild

commercial solvent or erosene. Do not use paint thinner, gasoline or lacquer

thinner as these will damage the painted surfaces. Once the surfaces have been

cleaned apply a thin layer of machine oil to protect the bare metal surfaces from

rust.

7. Open the end gear door, clean all of the components and the coat the gears

with heavy oil or non-slinging grease, close the door before use.

5

3. Chuck Preparation

Note: Before removing the chuc form the spindle, place a wooden bloc across the

guideways under the chuc .

1. Support the chuc while turning the three camloc s ¼ turn counter-cloc wise

with the chuc ey.

2. Carefully remove the chuc from the spindle and place it onto an adequate

wor surface.

3. Inspect the camloc studs and ma e sure that they have not become crac ed

or bro en during transport. Clean all of the parts thoroughly and clean the

spindle and camloc s to ensure that the chuc mates with the spindle securely.

4. Cover the chuc jaws and scroll inside the chuc with a thin layer of oil, cover

the spindle, cam loc s and the chuc body with a light film of heavier oil.

5. Lift the chuc up to the spindle nose and press onto the spindle. Tighten the

chuc in place by turning the camloc s ¼ turn cloc wise, the index mar (A, Fig

2) on the camloc should be between the two indicator arrows (B, Fig 2). If the

index mar is not between the two arrows, remove the chuc and adjust the

camloc studs by either turning out one full turn (if the cam will not engage) or

turning in one full turn (if the cams turn beyond the indicator mar s).

6

Lubrication

Caution! The lathe must be kept well lubricated at all times and all reservoirs

filled to their operating levels before starting the machine. Failure to comply

may cause serious damage to the lathe!

1. Headstoc : The oil must be filled to the indicator mar on the oil sight glass

(A, Fig 3). The oil can be poured into the headstoc once the plug (D, Fig 3) has

been removed. To drain the oil from the headstoc , unscrew the drain plug (A,

Fig 4) with an 8mm Allen ey, drain the oil completely and tighten the drain plug

bac into place. Drain and replace the oil in the headstoc after first month of

operation, then every 12 months.

Fig. 3

2. Gearbox: The oil must be filled to the indicator mar on the oil sight glass (A,

Fig 3). The oil can be poured into the gearbox once the plug (C, Fig 5) has been

removed. To drain the oil from the gearbox, unscrew the drain plug (A, Fig 5)

with an 8mm Allen ey, drain the oil completely and tighten the drain plug bac

into place. Drain and replace the oil in the gearbox after first month of operation,

then every 12 months.

7

Fig. 5

3. Apron: The oil must be filled to the indicator mar on the oil sight glass (A, Fig

6). The oil can be poured into the apron once the plug (B, Fig 6) has been

removed. To drain the oil from the apron, unscrew the drain plug with an 8mm

Allen ey, drain the oil completely and tighten the drain plug bac into place.

Drain and replace the oil in the apron after first month of operation, then every 12

months.

Fig 6

4. Leadscrew/Feed Rod: Lubricate the

ball oiler (A, Fig 7) on the

leadscrew/feed rod brac et once daily.

5. Tailstoc : Lubricate the two ball

oilers (B, Fig 7) once daily.

Fig. 7

6. Cross Slide: Lubricate the four ball oilers (A, Fig 8) once daily

8

7. Compound Rest: Lubricate one ball

oiler (B, Fig 8) once daily

8. Carriage: Lubricate the four ball

oilers (D, Fig 8) once daily

Fig. 8

9

Coolant Preparation

Caution! Follow the manufactures recommendations for use, care and

disposal.

Remove the rear access cover on the tailstoc end and ma e sure that the coolant

tan has not shifted during transport and is properly located under the recovery

chute.

Fig 9.

Pour three gallons of coolant mix into the chip pan and, once the power has been

connected, turn on the coolant pump and chec to see that the coolant is cycling

properly. Once this has all been chec ed, secure the coolant door bac onto the

stand.

Electrical Connections

Warning! All electrical connections must be completed by a qualified

electrician! Failure to comply may cause serious injury and/or damage to the

machinery and property!

Lathe Power Source Junction Box: Remove the cover. Run the main power through

the strain relief bushing and attach the ground, followed by the power leads.

Replace the cover.

Main Power Switch: Located on the rear of the machine. Turns the power to the

machine on and off.

Ma e sure that the lathe is properly grounded.

To ensure that the lathe has been connected correctly, pull up the forward/reverse

lever, the spindle should rotate in a counter-cloc wise direction when viewed from

the tailstoc . If the spindle rotates cloc wise, turn the power off and change any two

10

of the phases into the machine before re-connecting the power and restarting the

machine.

Warning! Disconnect the machine from the power source, failure to do so may

cause serious injury!

Main Motor: Change the wires according to the diagram on the inside of the motor

junction box.

Coolant Pump: Open the access panel on the base at the tailstoc end and change

the wires in the coolant pump junction box as per the diagram on the inside of the

junction box.

General Description

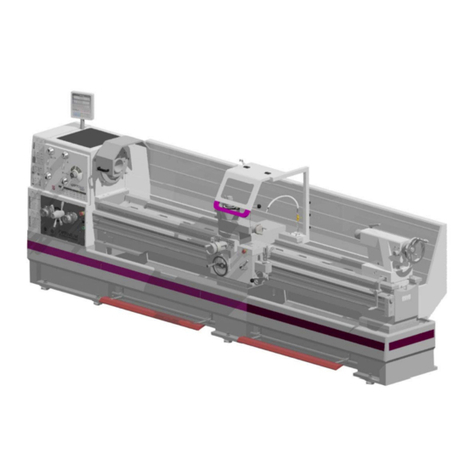

Lathe Bed

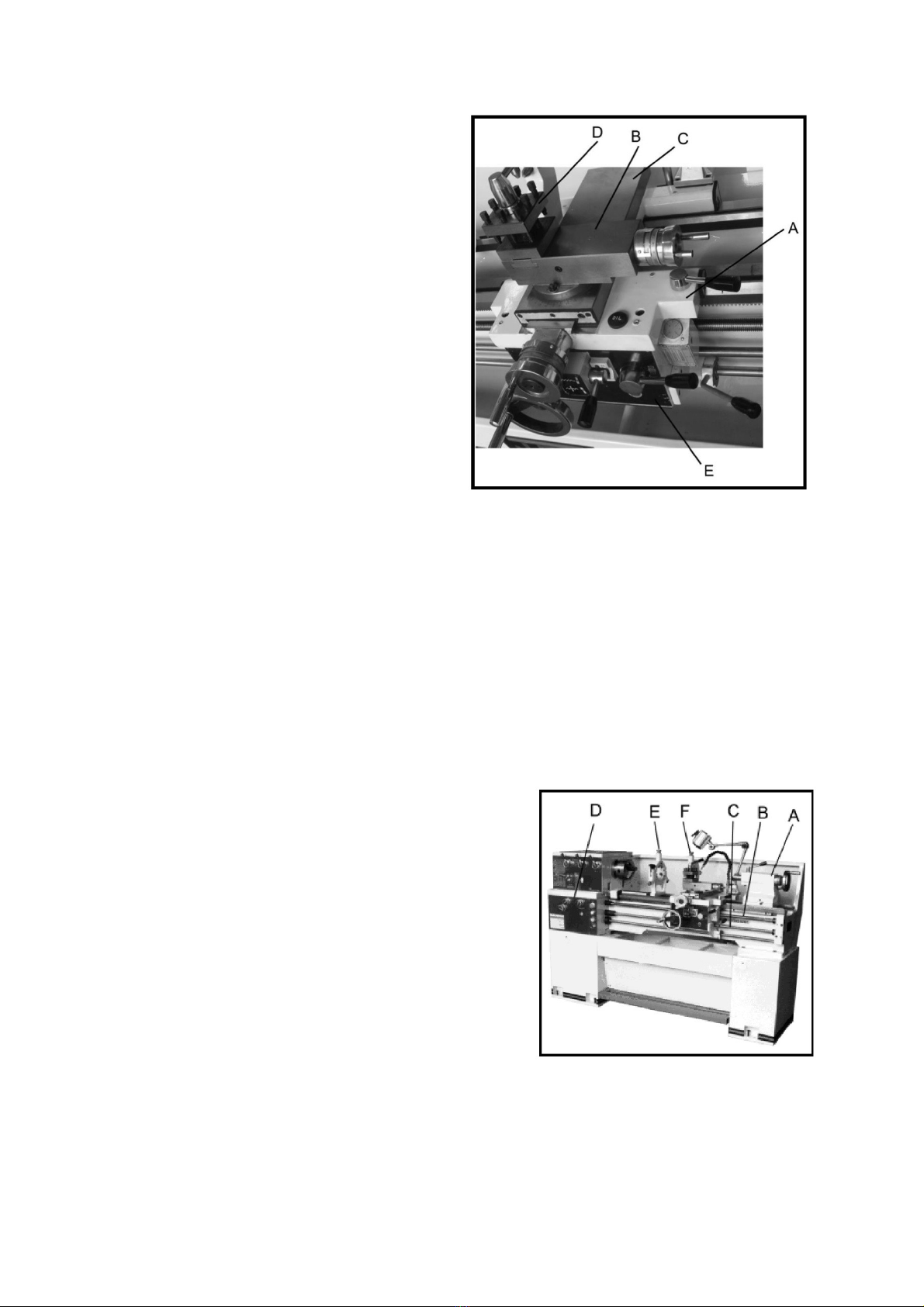

The lathe bed (A, Fig 10) is made of high

grade cast iron, by combining high chee s

with strong cross ribs, a bed with low

vibration and high rigidity is realized. Two

precision ground vee slideways, reinforced

by heat hardening and grinding are an

accurate guide for the carriage and

headstoc . The main drive motor is

mounted in the stand below the

headstoc .

Fig 10.

Headstock

The headstoc (B, Fig 10) is cast from high grade, low vibration cast iron. It is bolted

to the bed by four screws with two adjusting screws for alignment. In the head, the

spindle is mounted on two precision taper roller bearings. The hollow spindle has

Morse Taper #5 with a 1½” bore.

11

Carriage

The carriage (A, Fig 11) is made from

high quality cast iron, the sliding parts

are ground smooth. The cross-slide is

mounted on the carriage and moves on a

dove tailed slide which can be adjusted

for play by adjusting the gibs.

The compound slide (B, Fig 11) is

mounted on the cross slide (C, Fig 11)

and can be rotated through 360°. The

top slide and the cross-slide travel in a

dovetail slide and have adjustable gibs.

The four-way tool post is fitted on the top

slide.

Fig 11.

Four-Way Tool Post

The four-way tool post (D, Fig 11) is mounted on the top slide and allows a maximum

of four tools to be mounted simultaneously. Remember to use a minimum of two

clamping screws when installing the cutting tool.

Apron

The apron (E, Fig 11) is mounted to the carriage. The apron has a half nut fitted, the

half nut gibs can be adjusted from the outside and can be engaged by the use of a

lever. The quic travel of the apron is accomplished by means to a bed mounted

rac and pinion and operated by a handwheel on the front of the apron.

Tailstock

The Tailstoc (A, Fig 12) slides on a V-way and

can be loc ed at any location by a clamping

lever. The tailstoc has a heavy duty spindle with

a Morse taper #3.

Leadscrew and Feed Rod

The leadscrew (B, Fig 12.) and feed rod (C, Fig

12) are mounted on the front of the machine bed.

They are connected to the gearbox at the left for

automatic feed and lead and are supported by

bushings on both ends, they are equipped with

brass shear pins.

Gearbox

12

The gearbox (D, Fig 12) is made from high quality cast iron and is mounted to the left

side of the machine bed.

Steady Rest

The steady rest (E, Fig 12) serves as a support for shafts on the free tailstoc end.

The steady rest is mounted on the bed way and secured below with bolt, nut and

loc ing plate. The sliding fingers require continuous lubrication at the contact points

with the wor piece to prevent premature wear.

To set the steady rest:

1. Loosen the three hex

screws

2. Loosen the nurled

screw and open the sliding fingers until the steady rest can be moved with its

fingers around the wor piece. Secure the steady rest into position.

3. Set the fingers snugly

to the wor piece and secure the three hex soc et screws. The fingers should be

snug but not overly tight. Lubricate the sliding points with heavy oil.

4. After prolonged use,

the fingers will show wear, re-mill or file the tips of the fingers.

Follow Rest

The travelling follow rest (F, Fig 12) is mounted on the saddle and follows the

movement of the turning tool. Only two fingers are required as the place of the third

is ta en by the turning tool. The follow rest is used for turning long and slender

wor piece, it prevents the wor piece from flexing due to the pressure created by the

cutting tool.

The sliding fingers are set in a similar fashion to the steady rest, snug but not overly

tight. Always use a heavy oil to lubricate the contact point.

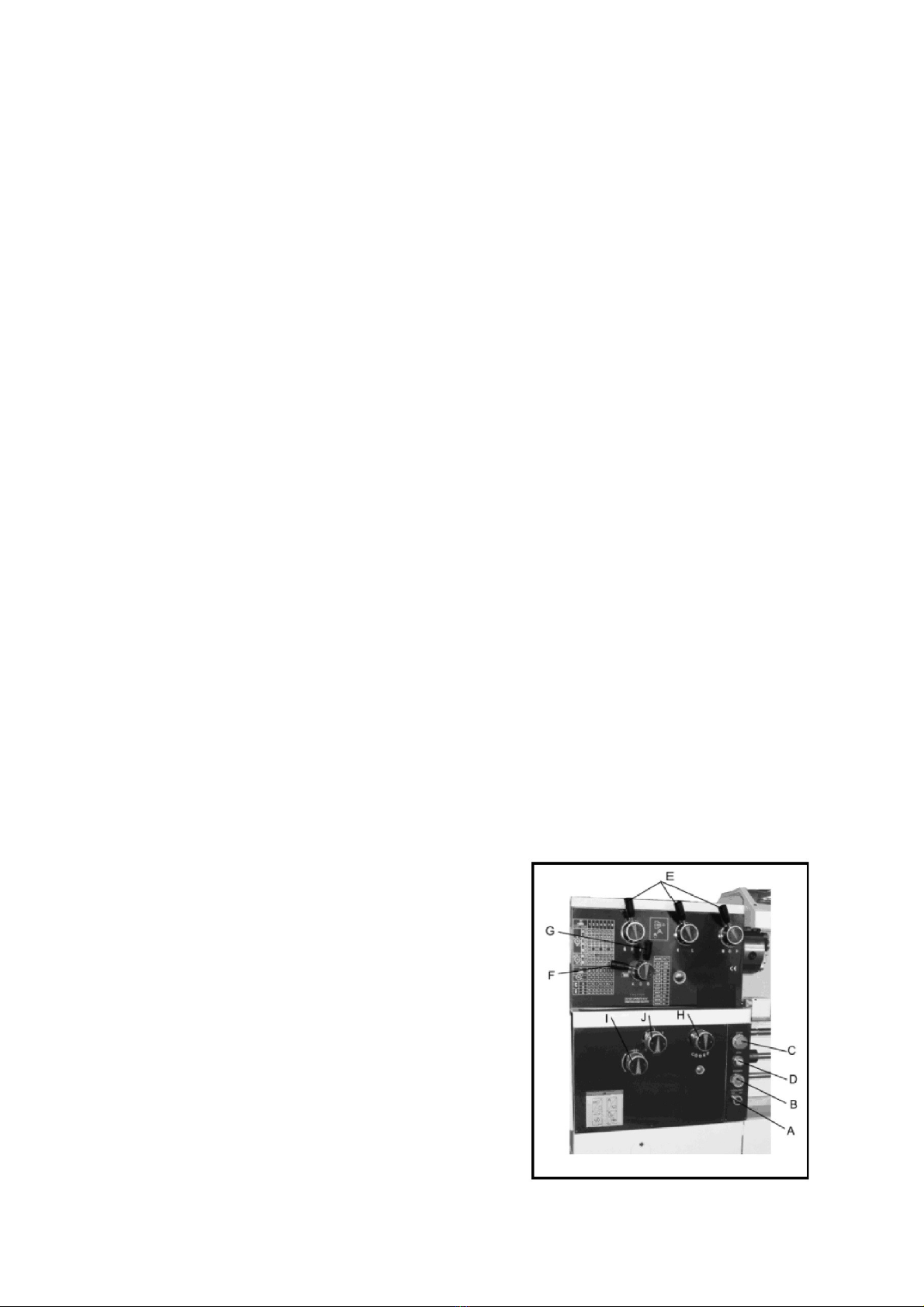

Controls

1.

Control Panel – located on the front of the

gearbox

A. Coolant On/Off Switch (A, Fig 13), turns

the coolant on and off.

B. Power Indicator Light (B, Fig 13), will

illuminate when the lathe has power.

C. Emergency Stop Button (C, Fig 13), press

to stop all of the machine functions.

Caution – lathe will still have power, twist

the button to re-set.

13

D. Jog Switch (D, Fig 13), press and release immediately to advance the spindle

position.

2. Headstoc Gear

Change Levers (E, Fig 13) – located on the front of the headstoc , move the

levers according to the speed chart for the desired speed setting.

3. Leadscrew/Feed Rod

Direction Lever (F, Fig 13) – Located on the front of the headstoc , Moving the

lever up will allow the carriage tot travel in the direction of the tailstoc ; moving

the lever down will allow the carriage to move in the direction of the headstoc

when the spindle is rotating in either direction.

Do not move the lever whilst the machine is running.

4. Feed/Leadscrew

Selector Lever (G, Fig 13) – located on the front of the headstoc , used when

setting up for threading or feeding.

Caution: in the “A” position, never run the lathe at speeds higher than 650rpm.

5. Feed/Leadscrew

Selector Lever (H, Fig 13) – located on the front of the gearbox and is used when

setting up for feeding and threading. Positions “F” and “D” are for the feed rod.

Position “E” and “C” are for the feed screw. Position “0” is neutral.

6. Loc Knob (I, Fig 13) –

Located on the front of the gearbox. When the nob is in the six o’cloc position,

the feed/leadscrew selector lever (J, Fig 13) can be adjusted. With the nob in

the 12 o’cloc position, the same lever will be loc ed.

7. Feed/Leadscrew

Selector Knob (J, Fig 13) – located on the front of the gearbox, it is used when

setting up for feeding and threading.

8.

Compound Loc (A, Fig 14) – This is a Hex

Soc et Screw located on the left side of the

compound slide. Turn cloc wise to loc and

counter-cloc wise to unloc .

9.

Carriage Loc (B, Fig 14) – The loc handle is

located on the top of the carriage, turn it

cloc wise to loc the carriage and counter-

cloc wise to unloc the carriage.

Caution: The carriage must be unloc ed

before engaging automatic feeds to prevent causing damage to the lathe.

10. Longitudinal Traverse

Handwheel (D, Fig 14) – located on the apron assembly, rotate the handwheel

cloc wise to move the apron assembly towards the tailstoc , rotate counter-

cloc wise to move the apron assembly towards the headstoc .

14

11. Feed Selector (E, Fig

14) – located in the centre front of the apron, pushing the lever to the left and

dfown activates the cross feed function, pulling the lefer to the right and up

activates the longitudinal function.

12. Half-Nut Engagement

Lever (Thread Cutting) (F, Fig 14) – located on the frnt of the apron, move the

lever down to engage the half-nut and move bac up to disengage.

13. Cross Traverse

Handwheel (G, Fig 14) – located above the apron, rotate cloc wise or counter-

cloc wise to move the cross slide into position.

14. Compound Rest

Traverse Handwheel (H, Fig 14) – located on the end of the compound slide,

rotate the handwheel cloc wise or counter-cloc wise to move the compound slide

inot position.

15. Tool Post Clamping

Lever (J, Fig 14) – located on the top of the tool post, rotate counter-cloc wise to

loosen and cloc wise to tighten.

16.

Tailstoc Quill Clamping Lever (A, Fig 15) –

located on the tailstoc , rotate cloc wise to loc

the quill and counter-cloc wise to unloc .

17.

Tailstoc Clamping Lever (B, Fig 15) – located on

the tailstoc , lift the lever to loc the tailstoc into

position and push bac dow to release the

tailstoc .

18. Tailstoc Quill Traverse

Handwheel (C, Fig 15) – located on the tailstoc , rotate the handwheel cloc wise

to move the quill forward and counter-cloc wise to retract the quill.

19. Tailstoc Off-Set

Adjustment (D, Fig 15) – Two hes soc et cap screws located on the tailstoc

base are used to off-set the tailstoc for cutting tapers, loosening the one screw

whilst tightening the other will set the tailstoc into position.

20.

Foot Bra e (A, Fig 16) – located between the

stand pedestals, push the lever down to stop

the machine.

21.

Micro Carriage Stop (B, Fig 16) – located on

the bed, loosen the two hex soc et cap

screws underneath the body and slide along

the bed to the desired position. Re-tighten the

screws to hold in place.

15

22. Main Power Switch (not

shown) – located on the electrical box door on the rear of the lathe. Turns the

main power to the lathe on and off.

Break-In Procedure

During manufacture and testing, this lathe has been run in the low rpm range for

three hours.

To allow time for the gears and bearings to brea in and run smoothly, do not run the

lathe above 650rpm during the first six hours of operation and use.

Operation

Feed and Thread Selection

1.

Use the feed and thread chart found on

the gearbox faceplate table (A, Fig 17 and

thread tables in this manual).

2.

Move the levers (B, C, D, E and F, Fig 17)

to the required positions according to the

chart.

Change Gear Replacement

The 30T, 12T and 60T gears are installed in

the end gear compartment when delivered

from the factory. This combination will cover most inchfeeds and threads under

normal circumstances.

The 24T, 32T, 40T, 65T, 66T and 70T gears found in the toolbox are used with

different combinations as indicated on the feed and thread tables.

1. Disconnect the

machine from the power source.

2. Remove the end cover

on the left-hand side of the headstoc .

3. Loosen the nuts (A and

B, Fig 18)

4. Move the quadrant (C,

Fig 18) out of the way and hold in place temporarily by tightening the nut (A and

B).

16

5.

Remove the hex soc et cap screws (D

and/or E, Fig18) depending on the which

gear is being changed.

6.

Install the new gear(s) and tighten into

place with a hex soc et cap screw.

7.

Loosen the nut (B, Fig 18) and move the

quadrant bac so that the teeth mesh on

the gears and tighten the nuts (A and B).

Caution:Ma e sure that the is a bac lash of

0.002” -0.003” between the gears, setting

the gears too tight will cause excessive noise and wear.

8. Close the door and

connect the machine to the power source.

Automatic Feed Operation and Feed Changes

1.

Move the forward/reverse selector (A, Fig

19) up or down depending on the required

direction.

2.

Set the selectors (A, B, C and D, Fig 20) to

the desired rate.

Note:for feeding, lever D will be set at “F” or

“D” depending on the desired feed rate.

Powered Carriage Travel

1. Push the lever (D, Fig

19) to the left and down to engage the cross feed.

2. Pull the lever to the

right and up to engage the longitudinal feed.

17

Thread Cutting

1.

Set the forward/reverse lever (A, Fig 19) up or

down depending on the desired direction.

2.

Set the selectors (A, B, C and D, Fig 20) to the

desired rate.

Note:for feeding, lever D will be set at “C” or “E”

depending on the desired thread.

3.

Push the lever (B, Fig 19) to the right.

4.

Engage the Half-Nut lever (C, Fig 19).

5. To cut inch threads,

use the feed and thread tables, the half nut lever and the threading dial are used

to thread in the conventional manner. The thread dial chart specifies at which

pointa thread can be entered using the threading dial.

6. To cut metric threads,

the half nuts must be left continually engaged once the start point has been

selected and the half nut is initially enaged (the thread dial cannot be used.

Metric Thread Table

18

Inch Lead and Feed Table

Compound Rest

19

The compound rest is located on top of the

cross slide and can be rotated around 360°.

Loosen the two soc et head cap screws (A, Fig

21) on the compound rest base. Use the

calibrated dial (B, Fig 21) below the rest to

assist the placement of the compound rest to

the desired angle.

Adjustments

After a period of time, wear in some of the

moving components may need to be adjusted:

Saddle

1.

Locate the four hex nuts found on the bottom

rear of the cross slide and bac the off one

full turn each.

2.

Turn each of the four set screws with a hex

wrench until a slight resistance is felt. Do not

overtighten these screws.

3.

Move the carriage with the handwheel and

determine if the drag is correct, readjust the

set screws as necessary to achieve the

desired drag.

4.

Hold the soce t set screw firmly with a hex

wrench and tighten the hex nut to loc the set screw in place.

5. Move the carriage

again and readjust if necessary.

Note: Over adjustment will cause excessive and premature wear of the gibs.

Cross Slide

If the cross slide is too loose, use the following procedure to tighten.

1. Loosen the rear gib

strip (not shown) approximately one turn.

2. Tighten the front gib

strip (B, Fig 22) a quarter turn. Turn the cross slide handwheel to see if the cross

slide is loose. If it is still loose, tighten the front screw a bit more and try again.

3. When the cross slide is

properly adjusted, tighten the rear gib strip.

Note: Over adjustment will cause excessive and premature wear of the gibs.

20

Table of contents

Other CHESTER Lathe manuals

CHESTER

CHESTER Coventry Pro User manual

CHESTER

CHESTER Crusader User manual

CHESTER

CHESTER CONQUEST SUPER LATHE User manual

CHESTER

CHESTER Crusader Deluxe Lathe User manual

CHESTER

CHESTER DB10VS User manual

CHESTER

CHESTER DB11VS User manual

CHESTER

CHESTER Centurion Series User manual

CHESTER

CHESTER Cobra Mill User manual

CHESTER

CHESTER CONQUEST SUPER User manual

CHESTER

CHESTER DB8VS User manual