INST.No.INE-508-P0

-3-

The detector unit is a single-color narrow-band radiation thermometer using the detecting element

of PbSe (4.0μm measuring wavelength). Its drive power is supplied from the relay box. By

scanning the measuring area optically by the hexahedron rotary mirror, it measures

unidirectional temperature patterns of an object and transmits the measured temperature as the

electric signal of 0 to 1mADC to the relay box.

In the relay box, the electric signal of 0 to 1mADC is converted to 0 to 5VDC that is transmitted

to the high-speed display/processing unit.

It measures temperature with the wide scanning angle of 50° and the high scanning speed is as

fast as 50 times/second.

2 kinds of connection types of the connector connection and the terminal connection are

available. The connection type of your detector unit has been selected by your ordering

specification.

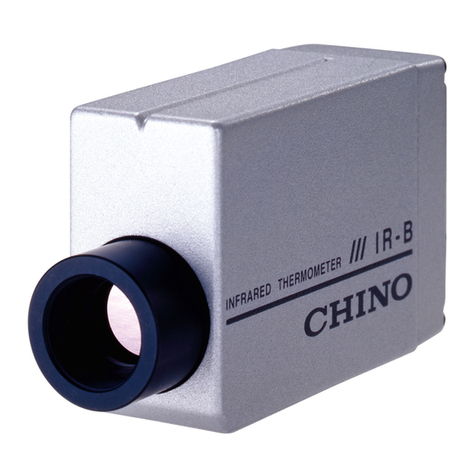

3.1 Names and functions of parts

Names Functions

Detector unit Functions of an optical system, electric circuits, etc.

required for a detector unit are built-in.

Measurement window

This window is for taking the radiant energy from a

measuring area into the detector unit.

It is required to always keep it clean.

Distance setting axis

This axis is for bringing the detector unit into focus on

a measuring area.

While looking through a setting distance display

window, turn this axis with a flathead screwdriver to

adjust the measurement distance on a marker.

Setting distance display window The measurement distance set by the distance setting

can be confirmed.

Connector

(For connector connection type)

This connector is for the connecting cable between the

detector unit and the relay box.

Terminal board

(For terminal connection type)

This terminal board is for the connecting cable between

the detector unit and the relay box.

Detector unit fixing hole

This hole is for fixing the detector unit in place.

With 2 pieces of M20 bolts, fix the unit to a mounting

angle, a mounting plate, etc.

When the protective case is used, fix the unit by

inserting 2 guide supports through the fixing holes.

3. Detector unit

Setting distance

display window Measurement

window

Connector

Terminal board

Distance setting axis

Detector unit fixing hole