INST.No.INE-510-P6

-C1-

1. Introduction.............................1

1.1 General ................................................... 1

2. Model........................................1

2.1 Model...................................................... 1

2.2 Belongings.............................................. 1

2.3 Accessories Model.................................. 2

3. Names and functions of

component parts.................3

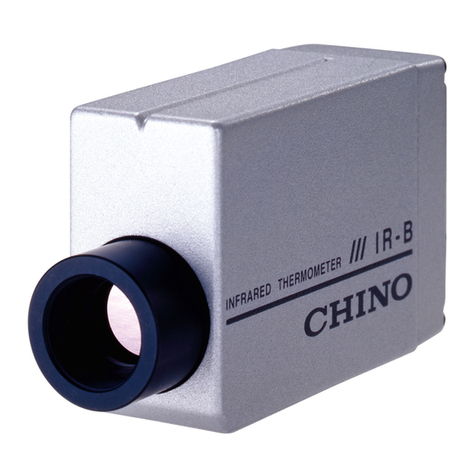

3.1 Overview ................................................ 3

3.2 Serial No. Label...................................... 3

4. Installation...............................4

4.1 Precautions in Installation ...................... 4

4.2 Installation.............................................. 5

4.3 Measuring distance and measuring

diameter ....... 6

4.4 Targeting................................................. 9

4.4.1 Telescope (Model : IR-ZYTS)............. 9

4.4.2 Laser pointer (MODEL : IR-ZYLZ1) 10

5. Connections and wirings...... 11

5.1 Connections and wirings ...................... 11

5.1.1 Connection of the exclusive cable

IR-ZYRC to IR-SA............ 11

5.1.2 Connection of the exclusive cable

IR-ZYRC to IR-GZ............ 11

6. Operation...............................12

6.1 Self-diagnostic function........................ 12

7. Maintenance and check........13

7.1 Periodical checking… .......................... 13

7.2 Trouble shooting................................... 13

7.2.1 Measuring value not displayed or

displayed lower.......... 13

7.2.2 Measuring value displayed higher..... 13

7.2.3 Display fluctuated.............................. 13

8. Reference................................14

8.1 Emissivity table .................................... 14

8.1.1 Emissivity table (= 0.65µm)........... 14

8.1.2 Emissivity table (= 0.9µm).............. 15

8.1.3 Emissivity table (= 1.55µm)............ 15

8.1.4 Emissivity table (=2.0µm) ............. 16

9. General specifications...........17

9.1 Thermometer ........................................ 17

9.2 IR-SAIN, IR-SASN .................... 18

Outside dimensions.................... 18

9.3 Accessories outside dimensions ........... 18

9.3.1 Installation fittings

(MODEL : IR-ZYHAW :

BELONGINGS)................. 18

9.3.2 Connection cable

(MODEL : IR-ZYRC)........................ 18

9.3.3 Telescope (MODEL : IR-ZYTS) ....... 19

9.3.4 Laser pointer (MODEL : IR-ZYLZ1) 19

9.3.5 Fitting (MODEL : IR-ZYHG1).......... 19

9.3.6 Fitting (MODEL : IR-ZYHG2).......... 20

9.3.7 Universal head (MODEL : IR-ZMSS)20