5. OPERATION

5.1. HOW THE UNIT FUNCTIONS

5.1.1. The infrared thermometer measures the surface temperature of an object. The unit’s optics sense emitted, reflected and transmitted

energy which is collected and focused onto a detector. The unit’s electronics translate the information into a temperature reading which

appears on the LCD display. The laser is for aiming purposes only and plays no part in the temperature measurement.

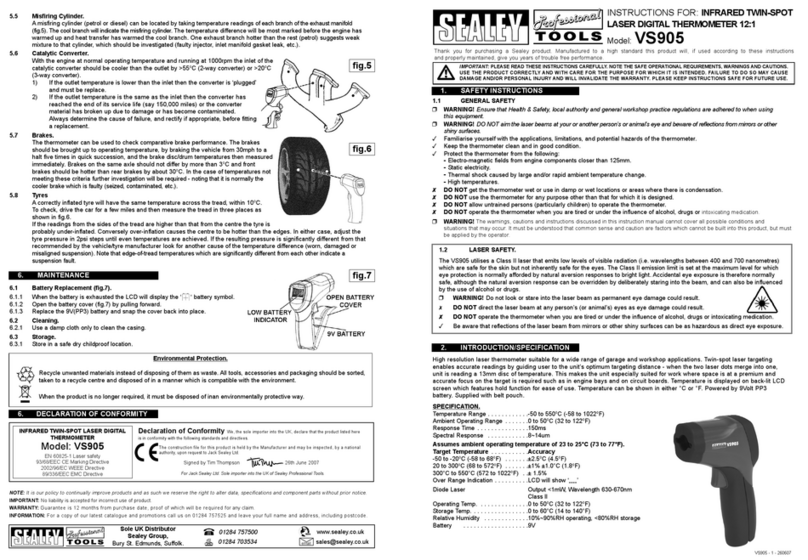

5.2. FIELD OF VIEW (FIG.5)

5.2.1. The units field of view is 12:1. This means that if the unit is positioned 300mm from the target the diameter of the object under test

must be at least 38mm. As a general rule make sure that the target is larger than the relevant spot size. The smaller the spot size the

closer you should be to the target. When accuracy is critical, make sure that the target is twice as large as the spot size.

5.3. EMISSIVITY

5.3.1. Different materials and surfaces have different energy emitting characteristics (emissivity) but most organic materials and painted or

oxidised surfaces are similar in this respect and the thermometer is designed to give correct readings for these materials and surfaces

(Emissivity 0.95). To maintain accurate measurement, shiny or polished metal surfaces should be covered in masking tape or

matt black paint before using the thermometer. Allow time for the tape/paint to attain the same temperature as the material beneath.

5.4. OBSTRUCTIONS

5.4.1. The thermometer cannot read the temperature of a target through glass or plastic sheet. It will only show the surface temperature of

the sheet. Similarly, steam, dust or smoke will result in erroneous readings.

5.5. OPERATING THE THERMOMETER

5.5.1. Hold the meter by its handle grip and point it towards the surface to be measured.

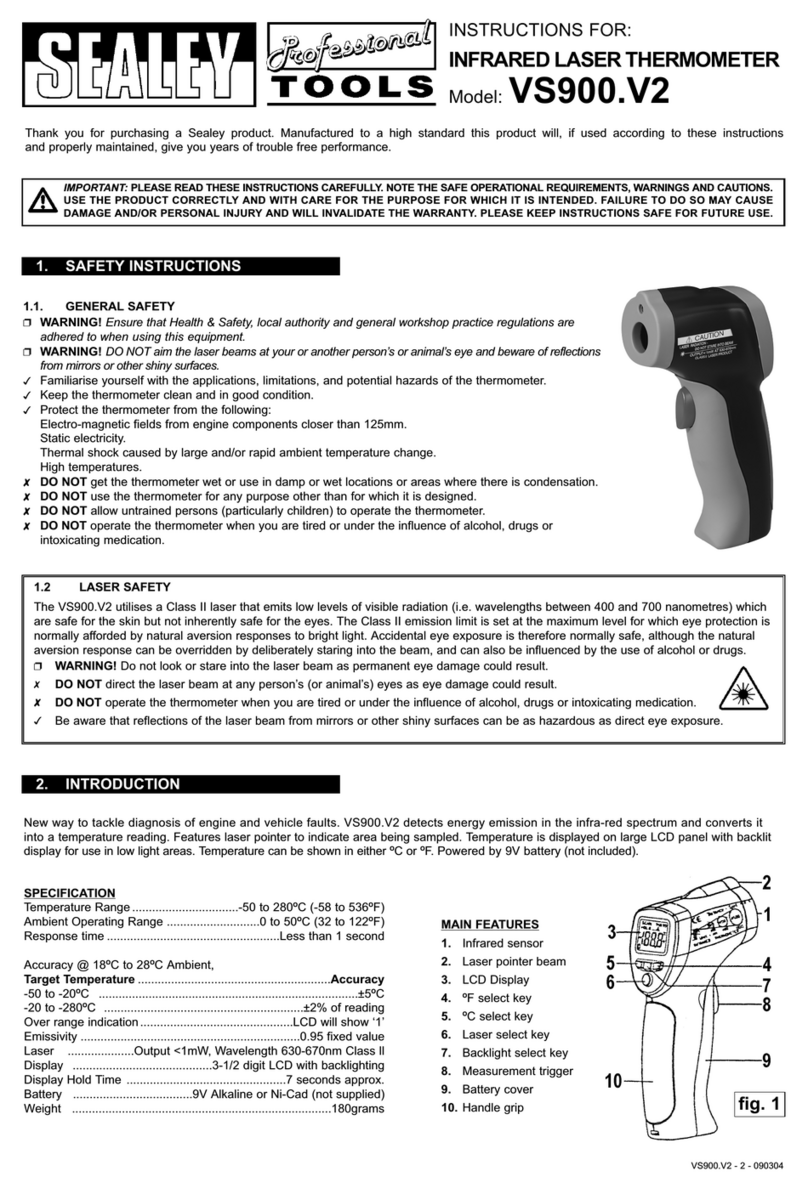

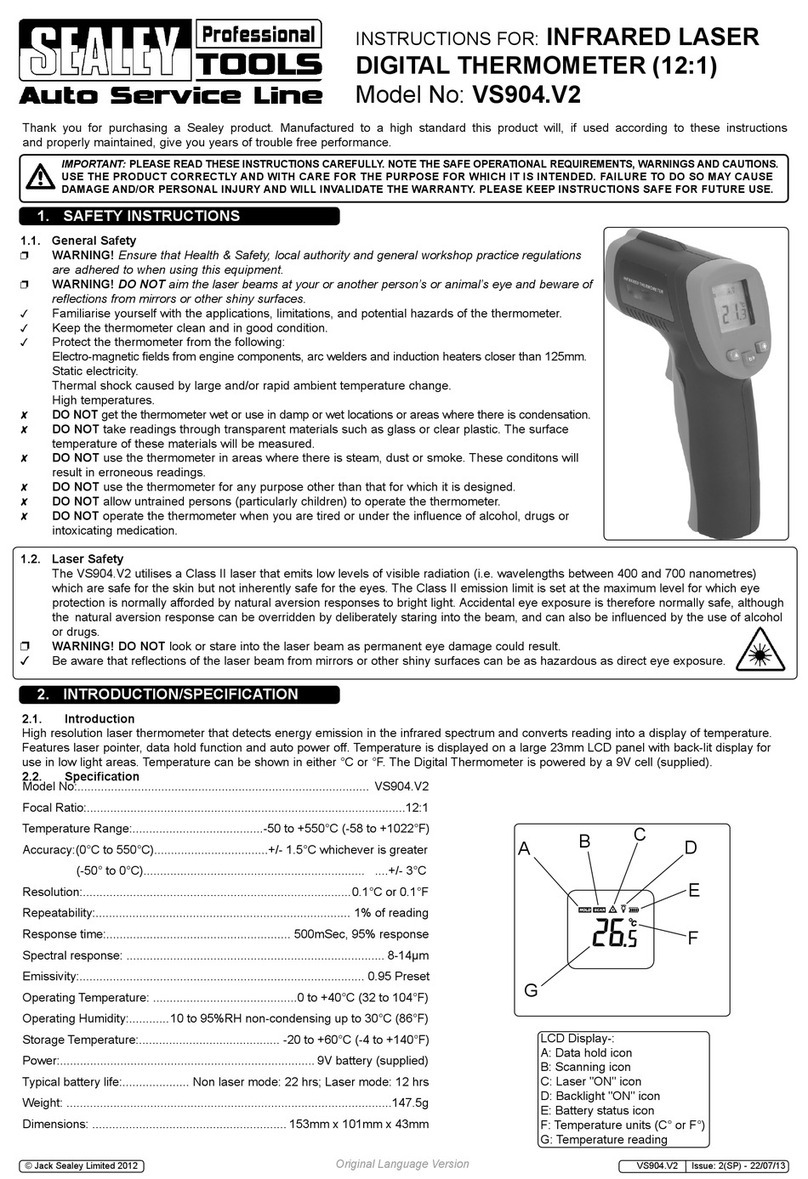

5.5.2. Pull and hold the trigger (fig.4.1) to turn the meter on and begin measuring. The Scanning icon (fig.3.F) and the Temperature Reading

(fig.3.A) will show on the LCD display.

5.5.3. Whilst using the thermometer the following functions can be used:

a) Push the Laser/Backlight button (fig.4.2) to turn on the laser

pointer. When the laser is ‘on’ the Laser On icon (fig.3.C) will

appear on the LCD display. Aim the beam approximately 16mm

above the point of test. (To turn the pointer ‘off’ press the Laser/

Backlight button again.)

b) Select the temperature units using the Temperature Unit

Switch (fig.4.7).

c) Push the Laser/Backlight button (fig.4.2) to turn on the LCD

display backlight for a 10 second period.

5.5.4. Once the trigger has been released the information on the LCD

display will remain for 30 seconds before the unit automatically

switches off. (Whilst the information remains on the LCD display

the Data Hold icon (fig.3.G) will be displayed).

5.6. LOCATING A HOT SPOT (FIG.6)

5.6.1. To find a hot spot aim the thermometer outside the area of interest,

then scan across with an up and down motion until you locate a

hot spot.

6. APPLICATIONS

WARNING! When working on vehicle systems, take all the precautions necessary to ensure the safety of yourself and others - always

refer to vehicle manufacturer’s handbook/service manual. The purpose of this tool dictates that it will be used close to very hot equipment

and therefore extreme care should be exercised.

6.1. AIR CONDITIONING

6.1.1. With the air conditioning set to maximum cooling, the temperature of the output air should be at least 15°C colder than the outside

ambient once the system has stabilised. DO NOT place the thermometer directly in the cold air stream (thermal shock) but rather hold it

to one side and take the temperature of the air duct. If the air temperature differential is less than 15°C have the A/C system checked.

6.2. HEATER

6.2.1. With the engine running, and at normal operating temperature, A/C ‘off’ and heater controls ‘on’ measure the temperatures of the heater

inlet and outlet hoses/pipes at the engine compartment bulkhead. The outlet hose/pipe should be approximately 10°C cooler than the

inlet. If the differential is significantly more than this the flow through the heater core is restricted and the system should be investigated.

6.3. RADIATOR

6.3.1. When the engine is running at normal operating temperature, there should be an even temperature drop between the radiator inlet and

outlet. Check the whole radiator surface for any ‘cold’ spots which would indicate a blockage.

6.4. THERMOSTAT

6.4.1. Under normal operation the thermostat will open as the engine reaches operating temperature, releasing hot coolant into the hose linking

the thermostat housing to the radiator.

6.4.2. Use the thermometer to monitor the hose temperature, adjacent to the thermostat housing, as the engine warms up to operating

temperature (85°C-105°C).

6.4.3. If the hose temperature abruptly and quickly increases, the thermostat is functioning correctly.

6.4.4. If the temperature increases gradually and does not reach operating level, the thermostat has failed in the open condition (or is missing).

6.4.5. If the temperature does not rise at all the thermostat has failed in the closed condition or coolant is not flowing for some other reason (air

lock, pump failure etc.) and further investigation is required.

6.4.6. A fluctuating temperature indicates a weak thermostat spring or air in the system.

6.5. MISFIRING CYLINDER (FIG.7)

6.5.1. A misfiring cylinder (petrol or diesel) can be located by taking temperature readings of each branch of the exhaust manifold.

6.5.2. The cool branch will indicate the misfiring cylinder. The temperature difference will be most marked before the engine has warmed up and

heat transfer has heated the cool branch.

6.5.3. One exhaust branch hotter than the rest (petrol) suggests weak mixture to that cylinder, which should be investigated (faulty injector, inlet

manifold gasket leak, etc.).

g.6

VS907 Issue 3 (HF) 05/10/18

Original Language Version

© Jack Sealey Limited