Chlorine Tech Services CTS-IB-PPE-01 User manual

INSTRUCTION BOOKLET

(CTS-IB-PPE-01)

SELF-CONTAINED BREATHING

APPARATUS (SCBA)

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 2

TABLE OF CONTENTS

1. SAFETY REGULATIONS........................................................................................3

1.1. Correct Use......................................................................................................3

1.2. Liability Information........................................................................................3

2. THE SCBA ARRANGEMENTS...............................................................................3

2.1. Schematic ........................................................................................................3

2.2. Workings of the SCBA....................................................................................4

2.3. Air Consumption.............................................................................................5

2.4. Basic Unit –Backplate, pneumatic system without second connector ......5

2.5. Pressure Reducer............................................................................................6

2.6. The Demand Valve ..........................................................................................7

2.7. Medium Pressure Hose...................................................................................7

2.8. High Pressure Hose ........................................................................................8

3. USE.........................................................................................................................8

3.1. Mounting cylinder ...........................................................................................8

3.2. Connecting cylinder........................................................................................8

3.3. Donning (putting on) the SCBA......................................................................9

3.4. Doffing (taking off) the SCBA.......................................................................12

4. MAINTENANCE INSTRUCTIONS.........................................................................13

5. CLEANING............................................................................................................14

6. STORAGE.............................................................................................................14

7. TECHNICAL SPECIFICATIONS ...........................................................................14

8. ACKNOWLEDGEMENTS......................................................................................14

Read and understand the respective instructions for

use for each Device before using the equipment.

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 3

1. SAFETY REGULATIONS

1.1. Correct Use

This Self-contained Breathing Apparatus - referred to hereafter as SCBA - is self-

contained open-circuit compressed air apparatus operating independent of the

ambient air.

Breathable air according to EN 12021 is supplied to the user from a compressed air

cylinder via a pressure reducer, a lung governed demand valve and a full-face mask

(Refer to Instruction Booklet Full-Face Mask). The exhalation air is released directly

into the ambient atmosphere.

It is imperative that this instruction booklet be read and observed when using the

product. In particular, the safety instructions, as well as the information for the use

and operation of the product, must be carefully read and observed.

Furthermore, the applicable national regulations applicable in the user’s country

must be taken into account for safety use.

Alternative use, or use outside this specification will be considered as non-

compliance. This also applies especially to unauthorized alterations to the product

and to commissioning work that has not been carried out by authorized persons.ER

This product is supporting life and health. Inappropriate use, maintenance or

servicing may affect the function of the device and thereby seriously compromise

the user's life. Before use the product operability must be verified. The product must

not be used if the function test is unsuccessful, it is damaged, a competent

servicing/maintenance has not been made, or if genuine spare parts have not been

used.

1.2. Liability Information

Chlorine Tech Services accepts no liability in cases where the product has been

used inappropriately or not as intended. The selection and use of the product are

the exclusive responsibility of the individual operator. Product liability claims,

warranties also as guarantees made by the manufacturer with respect to the product

are voided, if it is not used, serviced or maintained in accordance with the

instructions in this instruction booklet.

2. THE SCBA ARRANGEMENTS

2.1. Schematic

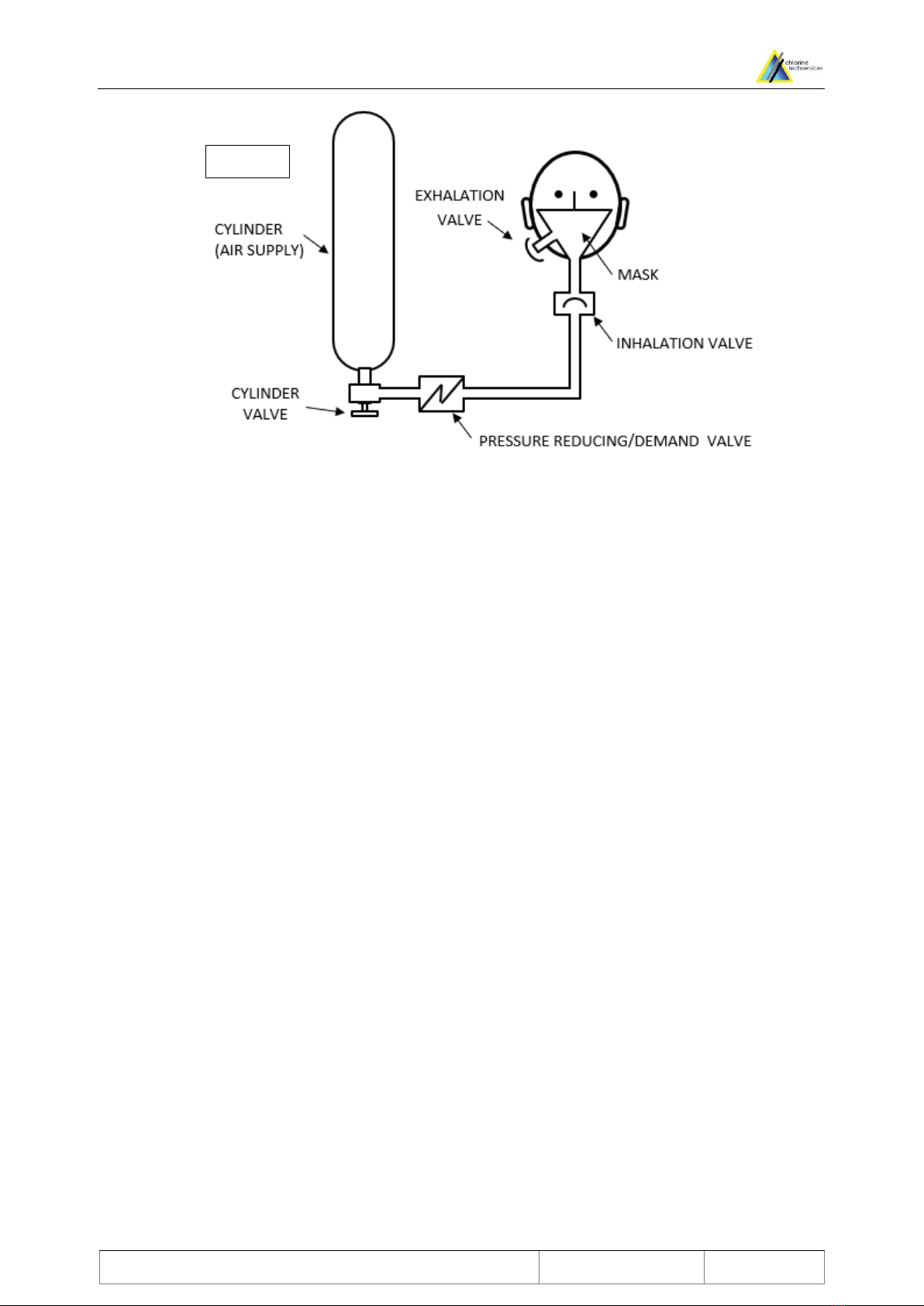

The equipment consists of:

•A cylinder containing air under pressure

•A harness to mount the cylinders on the back of the person

•A respiratory system which has a means to reduce the pressure of air from the

cylinder and of supplying the wearer with air on demand

•A facemask attached to a demand valve which maintains a positive pressure

inside the mask at all times

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 4

2.2. Workings of the SCBA

2.2.1. The cylinders contain about 1240 litres of compressed air at 300 bar. This gives the

wearer around 30 minutes of air supply for full usage or about 20 minutes for working

conditions (person breathes heavily during work hence there is more consumption of air

and that is why the time is lesser).

2.2.2. The reducing valve reduces the pressure by about 4 bars which is further reduced by the

demand valve which is attached to the mask.

2.2.3. The demand valve is the one that supplies the air to the wearer when inhaling.

2.2.4. The exhalation valve releases the air from the facemask.

2.2.5. When the air left inside the apparatus will last about 10 minutes (50-55 bar pressure), a

warning whistle is sounded continuously till the cylinder gets emptied. The start of this

whistle is an indication for the wearer to move out of the space he’s in to fight fire or

whatever purpose it is used for.

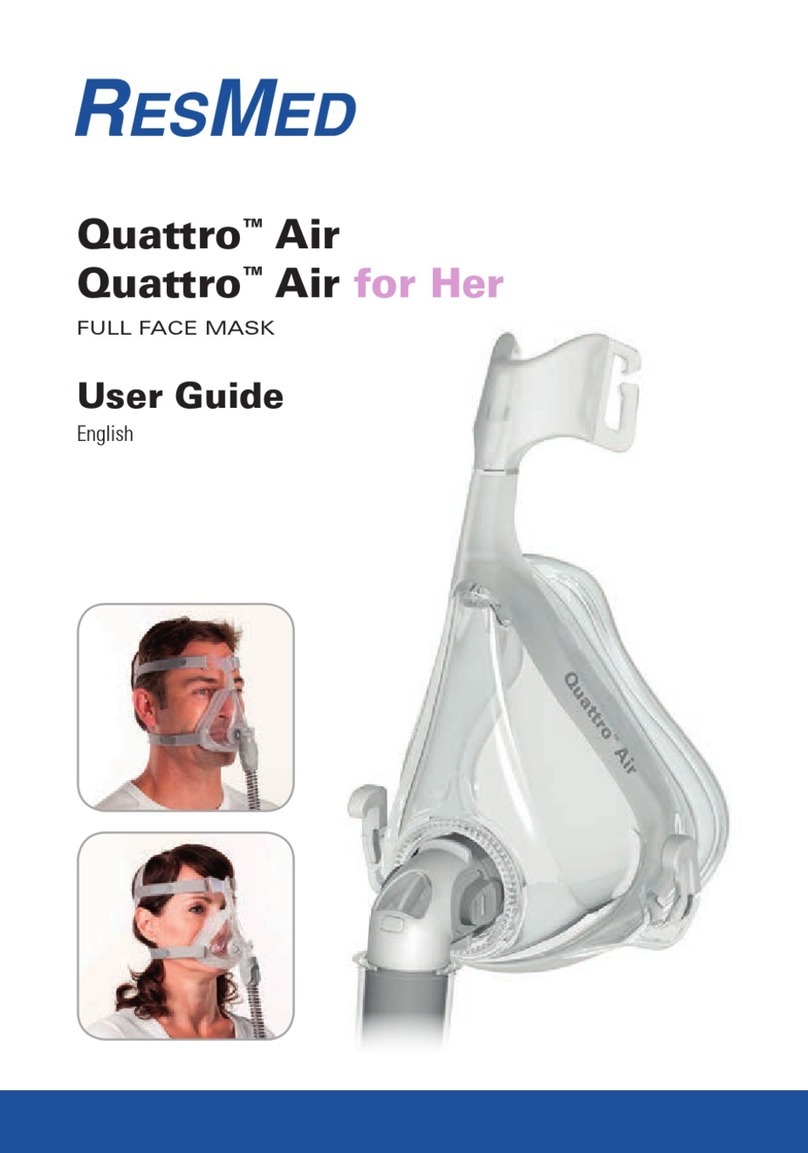

2.2.6. The face mask is of soft moulded nature rubber and five adjustable head straps

and a neck strap. It has a foam filled or air cushion seal and a full vision visor.

For correct positioning of the mask, the straps should be tightened in the

sequence where the first two lower (chin) straps then the middle pair (cheek

straps) and finally the head strap is tightened. Care should be taken to not over

tighten them causing discomfort to the wearer. The mask is made of rubber and

plastic with a shatterproof visor. It has an exhalation port with a speech

diaphragm and a nose guard.

2.2.7. The wearer should have a good, clear field of vision through the visor.

2.2.8. A gauge is provided, clipped or attached to the harness that carries the cylinder

and it monitors the pressure within the cylinder. It is positioned to be visible to the

wearer.

2.2.9. Spare cylinders must be provided for each set of breathing apparatus.

2.2.10. In case that the facemask is dislodged in a toxic atmosphere, the wearer should

hold his breath and position the mask correctly. Any inlet of such toxic air can be

highly dangerous.

Fig. 1

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 5

2.3. Air Consumption

Approximate consumption by a person is as follows:

Degrees of work

Air consumption

(litres/minute)

Duration of cylinder in

minutes (1200 litres

capacity in minutes)

Duration of cylinder in

minutes (1800 litres

capacity in minutes)

Resting

8-12

150-100

225-150

Light Work

12-20

100-60

150-90

Moderate Work

20-40

60-30

90-45

Heavy Work

40-60

30-20

45-30

Nominal Working Duration =

(Fully Charge Cylinder Capacity) –10

40

We subtract 10 as 10 minutes is when the alarm starts ringing and it is a safe

period which must be taken into account. So, a 1200 litres cylinder will last for

1200/40 = 30 minutes minus the 10 = 20 minutes.

Nervousness and excitement can cause an increased demand of oxygen and a

proportionate increase of respiration rate.

2.4. Basic Unit –Backplate, pneumatic system without second connector

8

6

7

10

9

11

0

1

2

3

4

14

0

12

0

13

0

15

3

5

Fig. 2

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 6

Fig. 2 Basic Unit Parts

1. Back Plate

9. Tightening Straps

2. Shoulder Strap

10. Waist Belt

3. Cylinder Strap

11. Alarm Whistle

4. Cylinder Strap Buckle

12. Pressure Reducer Support

5. Medium Pressure Hose

13. Pressure Reducer

6. Demand Valve

14. Demand Valve Holder

7. High Pressue Hose

15. Chest Strap

8. Pressure Gauge

The basic breathing apparatus is made up of back plate, shoulder strap, reducer,

medium pressure hose, high pressure hose, pressure gauge and demand valve.

Back plate is designed to use symmetrical plastic handles for convenient movement

of device. Reducer is mounted under the back plate. Cylinder bracket is mounted in

the guide groove at the upper part of back plate. Lengths of waist belt and shoulder

strap can be adjusted. Material of the back plate is fibre reinforced material.

Materials of the shoulder strap and waist belt are flame-resistant polyester webbing,

flame-resistant fabric and flame-resistant padding material. Wide shoulder padding

and waist protective padding make the wearing very comfortable. The metal on the

back plate, straps and waist belt are made of stainless steel, are not easily rusted.

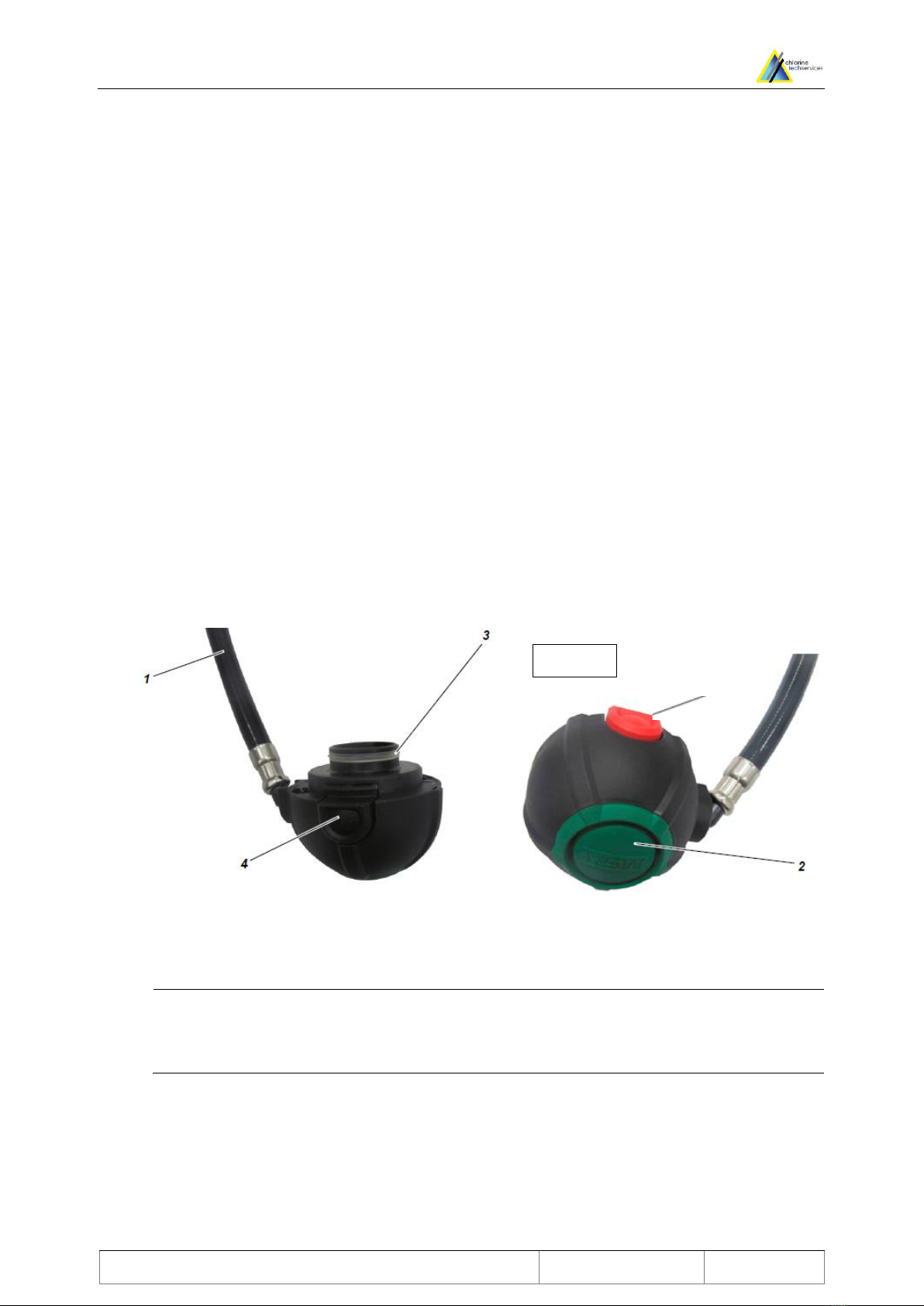

2.5. Pressure Reducer

1. High Pressure Hose

5. Cylinder Connector

2. Medium Pressure Hose

6. Alarm Whistle

3. O-ring

7. Safety Pressure Valve

4. Hand Wheel

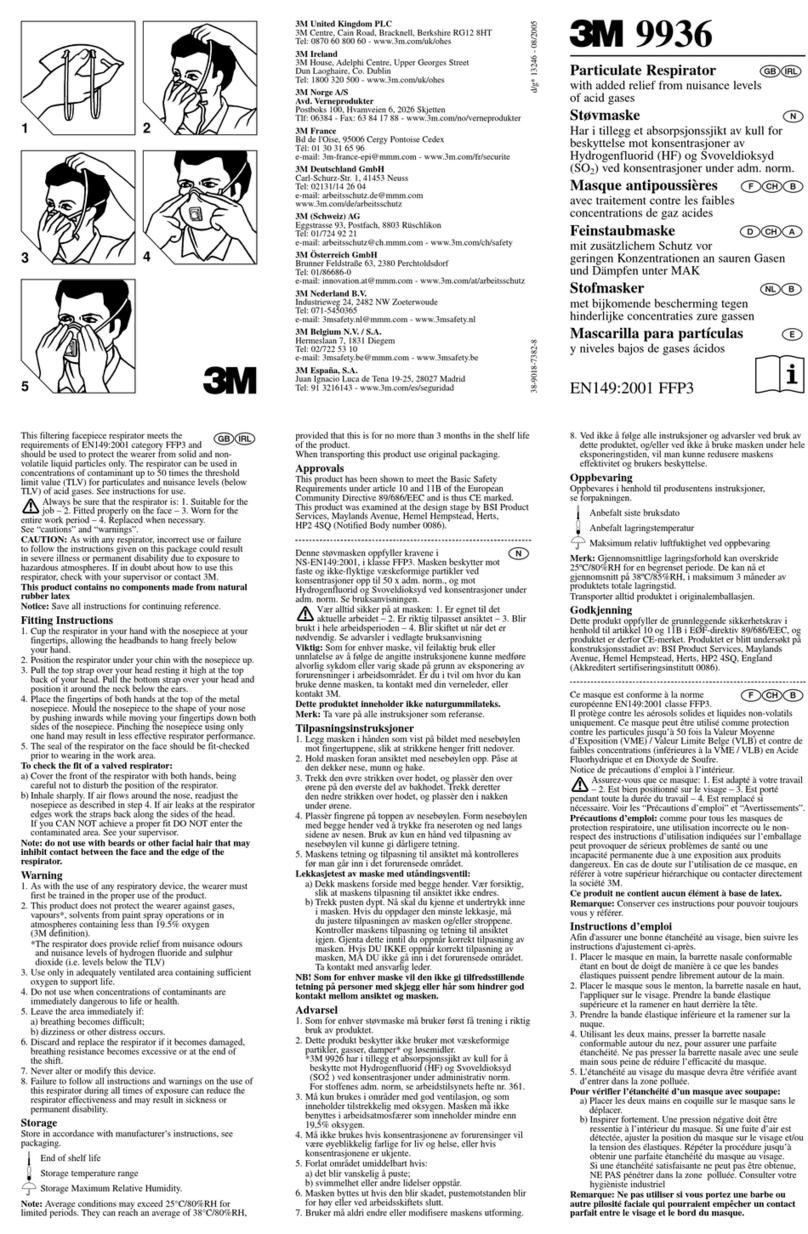

WARNING

Once the air releasing phenomenon by the safety pressure release valve of the

reducer is noticed, withdraw from the working place immediately and stop using this

breathing apparatus. Send it to authorized service centres for inspection and repair.

It can only be used after all trouble removed. It’s forbidden to adjust any parts in the

reducer by user. The breathing apparatus must be sent back to an authorized

service centre for repair if any failure occurs. It is no allowed to disassemble the

reducer by the user. Don’t damage the seal surface when replacing the seal O ring

on the high-pressure connection.

Fig. 3

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 7

The reducer is mounted in the lower area of the back plate. It reduces pressure of

the high-pressure air from the cylinder to mid pressure at about 7 bar. The air is

delivered through medium pressure hose to demand valve, reduce the pressure

again and then used by the user. Turn the hand wheel and connect the cylinder

connector with the cylinder. Once the cylinder valve is opened, the user can view

the pressure indication from the pressure gauge as which is connected to the high-

pressure hose. A pressure alarm device is equipped in the reducer. When the

pressure of the cylinder is lowered to 55 ± 5 bar, it will give off audible alarm signal

≥ 90 dB. The alarm device will not be dependent on the ambient air when alarm

device gives an alarm, so the alarm device will not lose its function even if in high

humid atmosphere or under sprinkle water, or even in very low temperature. In

addition, the air consumed for the alarm device’s alarm is ≤ 5 L/min.

There is also a safety release valve, which is set to about 11 bar, in case there is

anything wrong and the medium pressure rises, the valve will be opened, release

the over pressure to guarantee the performance of the demand valve.

2.6. The Demand Valve

The demand valve is a lung governed demand valve for a compressed air breathing

apparatus. It is connected between compressed air supply and full-face mask and

controls the inhaled and exhaled air. The demand is not an independent breathing

apparatus. It must be used exclusively mounted on a full-face mask. The demand is

not suitable for underwater diving.

1. Medium Pressure Hose

3. Port of Mask

5. LDV Button

2. Exhaust Button

4. Operating Button

Don’t push operating button and exhaust button at the same time. Don’t press

down the red and black button during the use, because pushing both buttons

can disconnect the demand valve from the mask.

The outer housing of the demand valve is made of high strength engineering plastic

to endure possible collision. The demand valve must be used with full mask.

2.7. Medium Pressure Hose

The explosion pressure for medium pressure hose is not less than four times of the

reducer output pressure. Connection of the medium pressure hose with the demand

Fig. 4

5

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 8

valve is flexible and swivelling, which can automatically fit head movement of the

operator.

2.8. High Pressure Hose

A high-pressure gauge is connected with the high-pressure hose. The pressure

gauge surface is luminescent, so the pressure display can be viewed clearly even

in the dark. Connection of the pressure gauge and the high-pressure hose is

swivelling and canturn in 360°, this makes easy for the operator to view the pressure

gauge at any position.

There is a small hole in the high-pressure hose, which is safety hole. In case there

is leak from the high-pressure hose, air will be released from the small safety hole,

thus to avoid the high-pressure hose from exploding.

3. USE

The device can be used only after fully maintained and tested. If malfunctions or

defects were found before using, do not use the device. Prevent the respirator

from sharp objects and prevent it from collision with any objects during the use.

The device shall be checked and repaired by MSA authorized service centre.

WARNING

3.1. Mounting cylinder

(1) Insert the cylinder into the cylinder

strap (In this picture it only shows a

composite cylinder).

(2) Erect the cylinder and the back plate

(3) Align the cylinder valve outlet centre

with the reducer hand wheel centre.

(4) Turn the hand wheel, to connect the

reducer with the cylinder.

(5) Not to make it too tight, just hand-tight.

(6) Don’t use any tools.

3.2. Connecting cylinder

(1) Place compressed air breathing apparatus horizontally so that the back face

is on top.

(2) Check gasket on pressure reducer for proper condition.

(3) Open cylinder buckle on the cylinder strap eliminating any tension and

extend the strap.

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 9

(4) Push compressed air cylinder through the cylinder strap with the cylinder

valve toward the pressure reducer, so that it lies on the central support.

(5) Thread cylinder valve onto pressure reducer, if necessary, bring the

compressed air breathing apparatus with valve up into a vertical position.

(6) Tighten cylinder strap by pulling the free end.

(7) Check position of compressed air cylinder, retighten if necessary.

(8) Push cylinder buckle down until it catches.

(9) Fasten end of the cylinder retaining strap onto Velcro strip.

(10) Briefly open cylinder valve and check for escaping air, retighten if necessary.

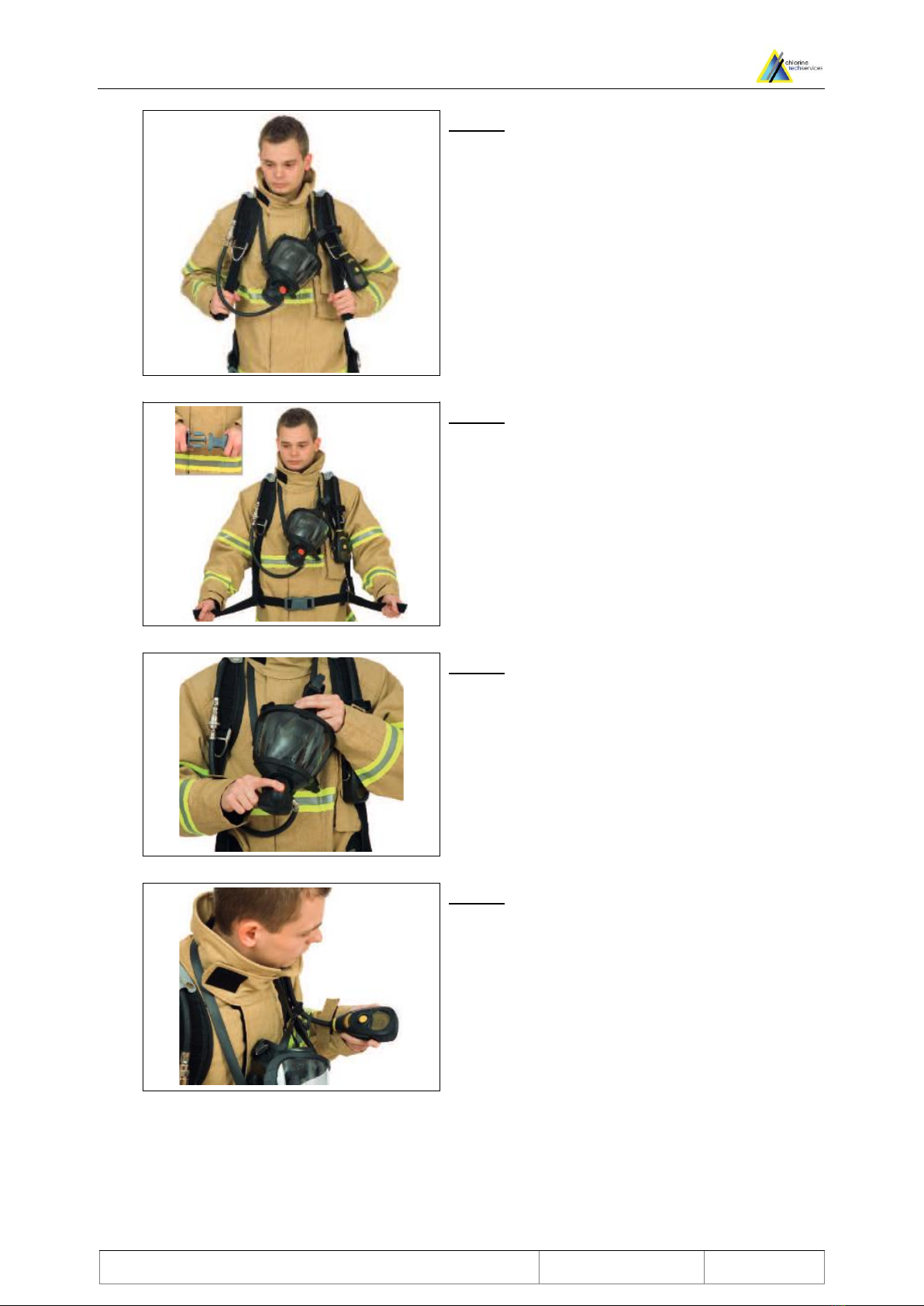

3.3. Donning (putting on) the SCBA

Step 1

•Place the SCBA in front of you with the

cylinder facing down and the cylinder

valve away from you

•Fully open the shoulder straps and waist

belt

•Lay the shoulder straps and waist belt

out to prevent them from tangling

•Check all components of the device for

defects and malfunctions

Step 2 (Overhead Method)

•Grasp the carrying frame of the backplate

with both hands

•Carefully lift the SCBA over and behind

your head

•Your elbows must go through the

shoulder harness straps.

•Slide the backplate down your back and

grasp the shoulder harness straps as the

unit slides down the middle of your back

Step 2 (Coat-style Method)

•Fully extend all straps

•If using the coat-style method of donning,

grasp the shoulder harness straps at the

padding

•Place the SCBA over one shoulder

•Then the other harness over the

remaining shoulder

•SCBA must rest in middle of back

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 10

Step 3

•Place the face mask, via strap, around

neck

•Grasp the ends of the pull-down

adjustment shoulder straps

•Pull the straps downwards towards your

hips until waist belt pad aligns with hips

•Adjust the SCBA into position (top of

cylinder should be neck high)

Step 4

•Connect waist belt buckle

•Pull adjusting straps (as shown) until

device is secure

•Adjust the waist (weight) belt to suit the

weight of the SCBA which should rest

comfortably on your hips

•Tuck strap loose ends into belt

Step 5

•Press RED LDV button (Fig 4) to switch

off positive pressure

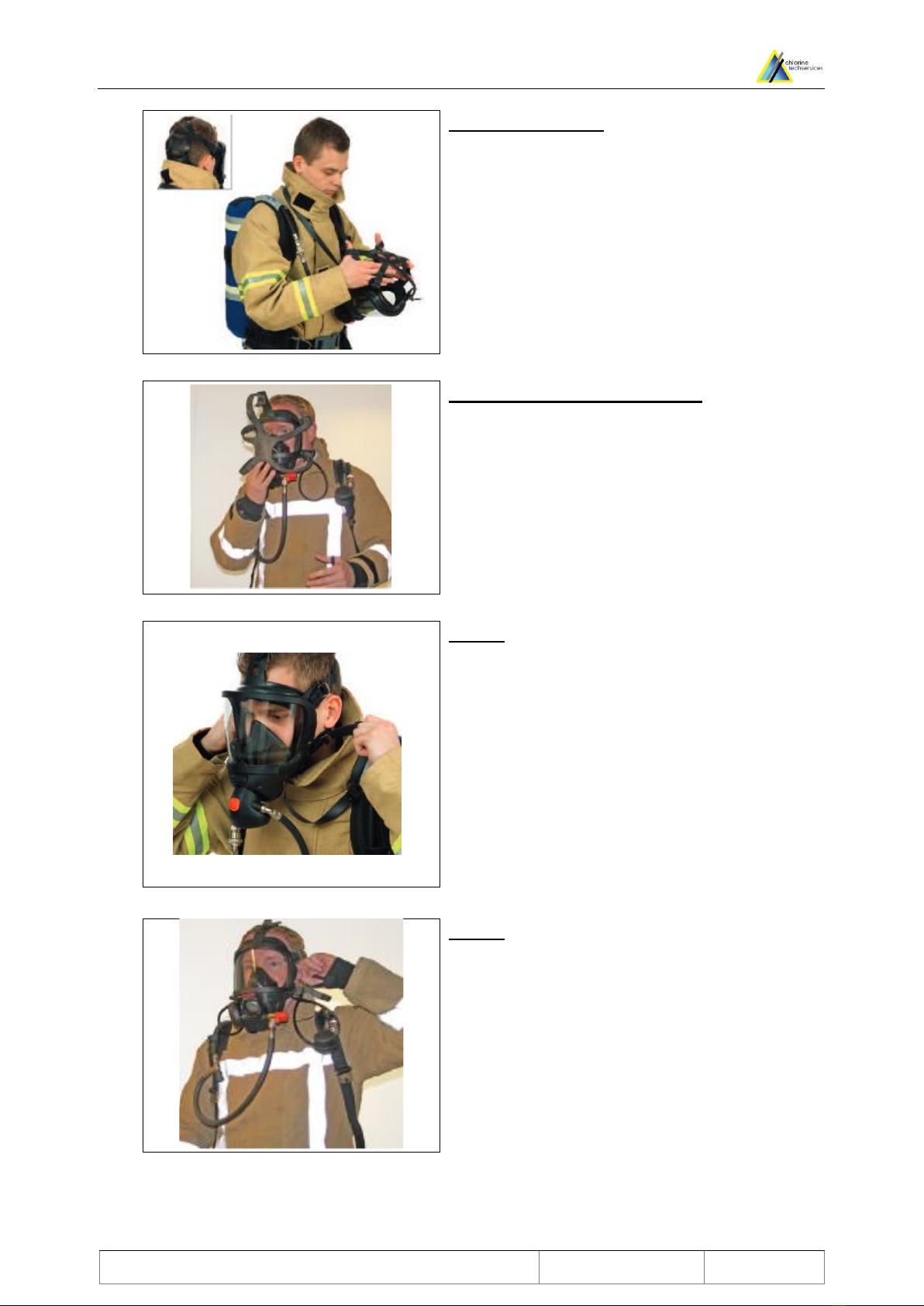

Step 6

•Fully open the cylinder valve (slowly) to

pressurise the system

•Check the pressure gauge (should read

between 250/300 bar)

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 11

Step 7 (Method 1)

•Holding the facemask as shown, place

over head with centre plate at the back

•Place chin in facemask chin cup

•Tighten chin (lower) straps

•Tighten cheek (upper) straps

•Tighten centre (head) strap if necessary.

Step 7 (Method 2 - preferred)

•Holding the facemask as shown

•Place chin in facemask chin cup and pull

head harness over the head

•Tighten chin (lower) straps

•Tighten cheek (upper) straps

•Tighten centre (head) strap if necessary.

Step 8

•First breathe will switch on LDV to positive

pressure mode

•Inhale and hold breath –there must be no

leak (audible)

•Breathe normally and expelled air should

pass free through exhalation valve

•Check supplementary air supply is

working by pressing centre button on LDV

–then release

Step 9

•Check that a strong air flow is heard

when two fingers are inserted between

the sealing edge and face

•Check that the pressure on the pressure

gauge reads full

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 12

Step 10 (Vacuum Test)

•Close the cylinder valve and breathe down

(slowly) the system

•The alarm whistle should sound at +/- 50

bar

•Continue breathing down the system

•Once empty, hold breath for 8 seconds –

the face mask should collapse and hold to

face (indicating a positive seal)

3.4. Doffing (taking off) the SCBA

Step 1

•Loosen the chin and cheek straps, by

pressing the buckles forward using your

thumbs

Step 2

•Reach under and pull the mask off

backwards over your head (do not pull on

the front port).

•Reset Demand Valve by pushing the

RED button (this will shut the air flow)

•Close the cylinder valve

•Vent system by pressing Exhaust Button

•Check that Pressure Gauge is on Zero

pressure

•Press Red Button to reset system

Step 3

•Extend waistbelt straps and open waist

belt buckle.

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 13

Step 4

•Lift shoulder strap buckles and open fully.

Remove facemask strap from neck and

remove apparatus from shoulders.

4. MAINTENANCE INSTRUCTIONS

Below is the requirement for the maintenance schedule for each part. Testing for

the mask and demand valve should be done on the complete set of the apparatus,

and cylinder pressure should not be lower than 250 bar.

Component

Maintenance Item

Minimum intervals for checking, maintenance and

repair

Before

use

After

use

Every

year

Every 3

years

Every 9

years

Demand

valve

Cleaning & disinfection

X

Check diaphragm

X

X

Replace diaphragm

X

Tightness check

X

X

X

Check closing pressure

X

X

Overhaul inspection

X

Reducer

Alarm device

X

X

X

Replace high pressure

seal

X

Full-function test

X

X

Overhaul inspection

X

Medium &

High-

pressure

parts

Appearance

X

X

X

Sealing properly

X

Cleaning

X

X

Pressure gauge

X

Breathing

device

Complete set cleaning

X

X

Function test, leak test

X

X

Completeness test

X

X

SELF-CONTAINED BREATHING APPARATUS (CTS-IB-PPE-01)

©Chlorine Tech Services (Pty) Ltd –CIPC Reg # 2018/101848/07

Rev # 01/2020/10/15

P a g e | 14

5. CLEANING

Contaminated apparatus after usage must be cleaned thoroughly. If necessary, wash

the back plate with warm water. For cleaning, disassemble the reducer from the

carrying plate (loosen the fixing screws) and disassemble the demand valve.

Do not immerse the reducer and demand valve into the water. The air for drying the

apparatus should be less than 60 °C. When cleaning, never to use any organic

solvent, such as nitro solution, alcohol, alcohol solution, gasoline, trichloroethylene,

etc. If there is too much dirt, the carry straps, including metal parts, could be machine-

washed with water not above 40 °C. Buckles should be well-inserted during washing.

After washing, hang them in a ventilated place for a naturally dry.

6. STORAGE

The apparatus should be stored in a clean, dry and well-ventilated place. Put the

apparatus into the package and keep it away from long-term exposure to sunshine,

heat radiation, electromagnetic field and devices that may produce ozone, electrical

spark or silent discharge device. Do not store the apparatus with oil, acid, alkali or

other corrosive substances, no heavy press on the apparatus.

7. TECHNICAL SPECIFICATIONS

High pressure connection: 300 bar

Medium pressure: 5 bar to 9 bar

Operating temperature: -30 °C to +60 °C

Alarm pressure: 55 ± 5 bar

8. ACKNOWLEDGEMENTS

8.1. MSA 2015 - Operating Manual - Self-contained Open-circuit Compressed Air

Breathing Apparatus

8.2. INTERSPIRO –User Manual

8.3. Dräger –Donning and Start-up Procedure

Table of contents