12 13

SAFETY PRECAUTIONS:

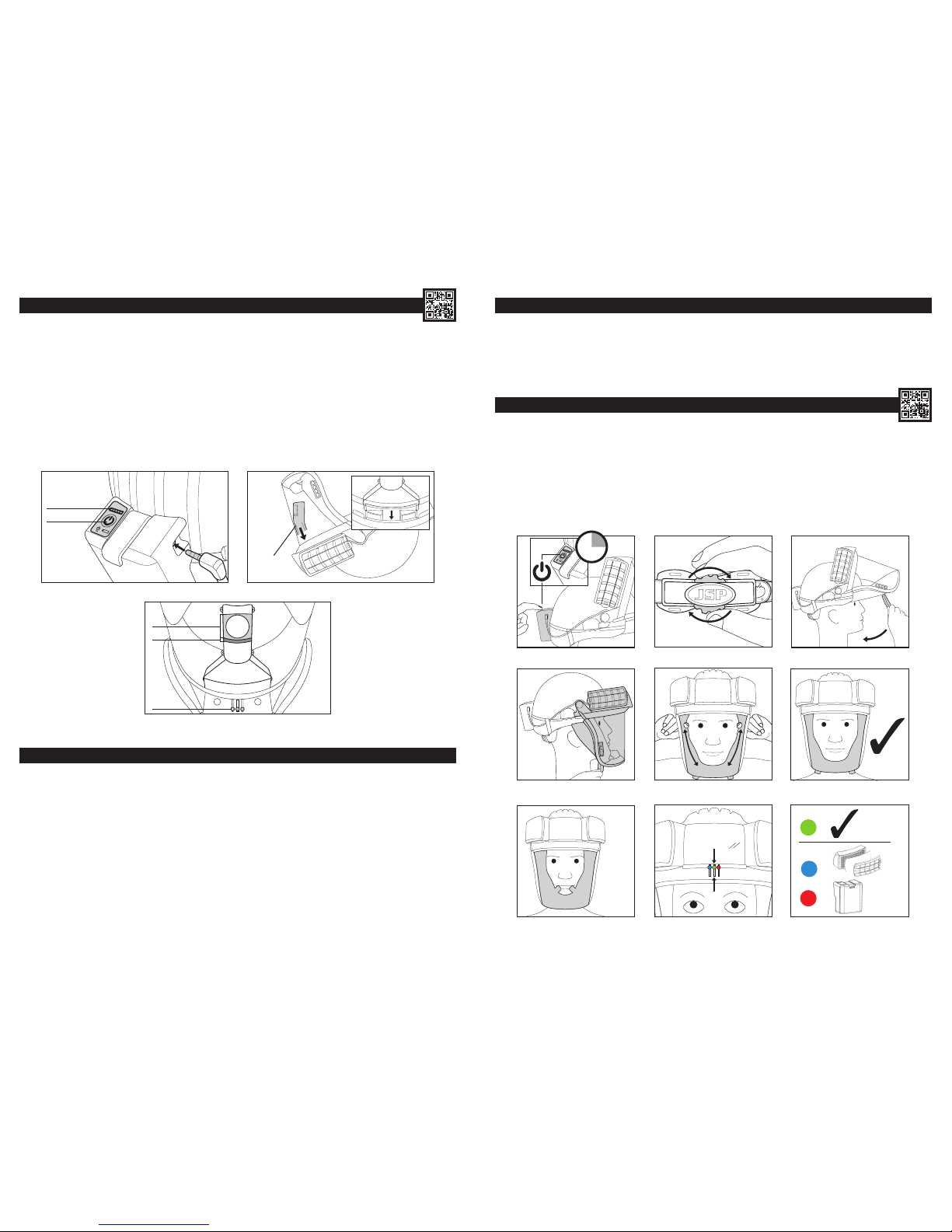

PowerCap® Innity® should be used in situations where the requirements for EN 12941:TH3, EN166:2002 and/or EN 397:2012 protection applies.

• This apparatus must not be worn in the hazard zone with the drive unit switched off. • When switched off a build up of carbon dioxide and depletion of

oxygen may occur. • When switched off no respiratory protection is provided; this is considered to be an abnormal running condition.

• The apparatus should not be used in explosive atmospheres unless it is marked with the mark. • The apparatus should not be used in oxygen

decient atmospheres. • The apparatus should not be used in an atmosphere immediately hazardous to life or health. • At high work rates the pressure

in the device may become negative at peak inhalation ow. • Using the apparatus in high wind velocities may affect ltering efciency.

• Only use genuine Powercap® Innity® lters supplied in pairs from JSP Ltd or its distributors. • Do not lift the visor whilst in the hazard zone

• Do not expose Powercap® Innity® to ames or sparks. • Do not use Powercap® Innity® in conned spaces or areas of poor ventilation. • Do not

alter or modify the product in any way. • Do not touch any moving part. • Do not allow water or other liquids to enter the inside of the motor housing or

battery compartment. • Care should be taken to avoid the possibility of the power cable from the battery pack to drive unit becoming caught up in use.

As required by European Health and Safety requirements, the user is advised that when in contact with the wearer’s skin, the unit may cause allergic

reactions to susceptible individuals. If this is the case the wearer should leave the hazard area, remove the unit and seek doctor’s advice.

4 65

1 2 3

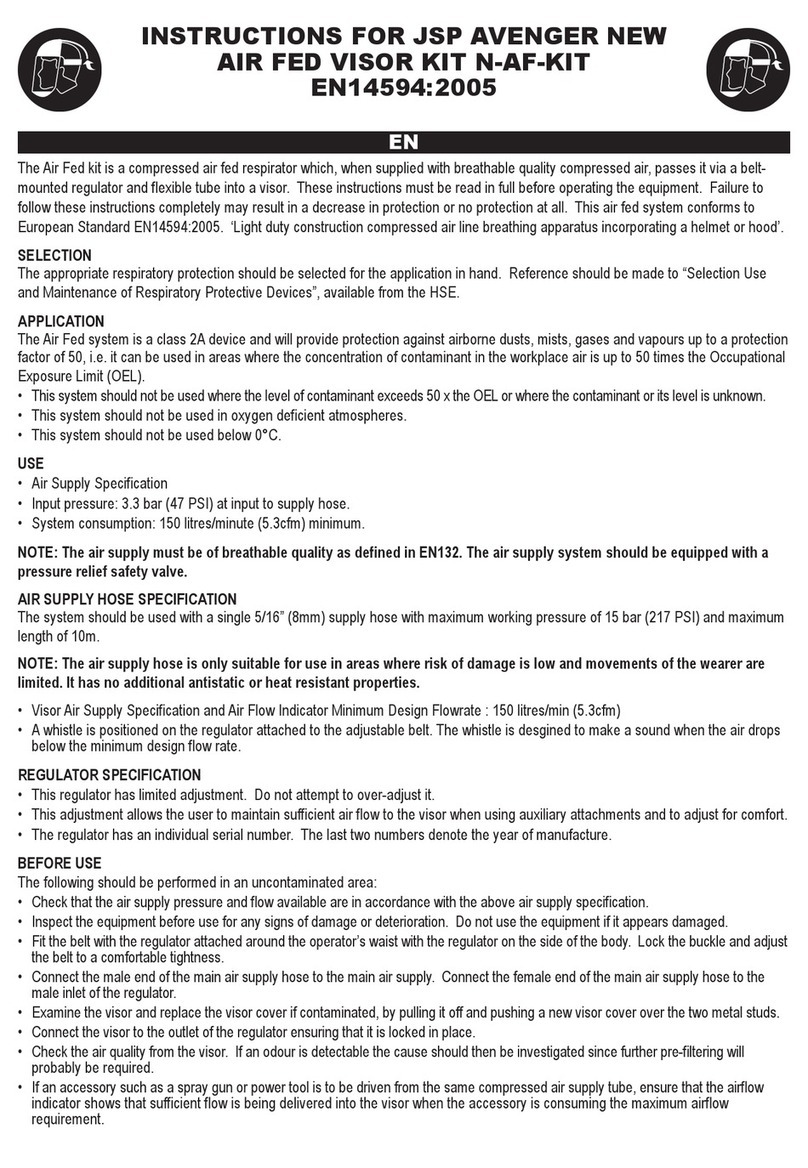

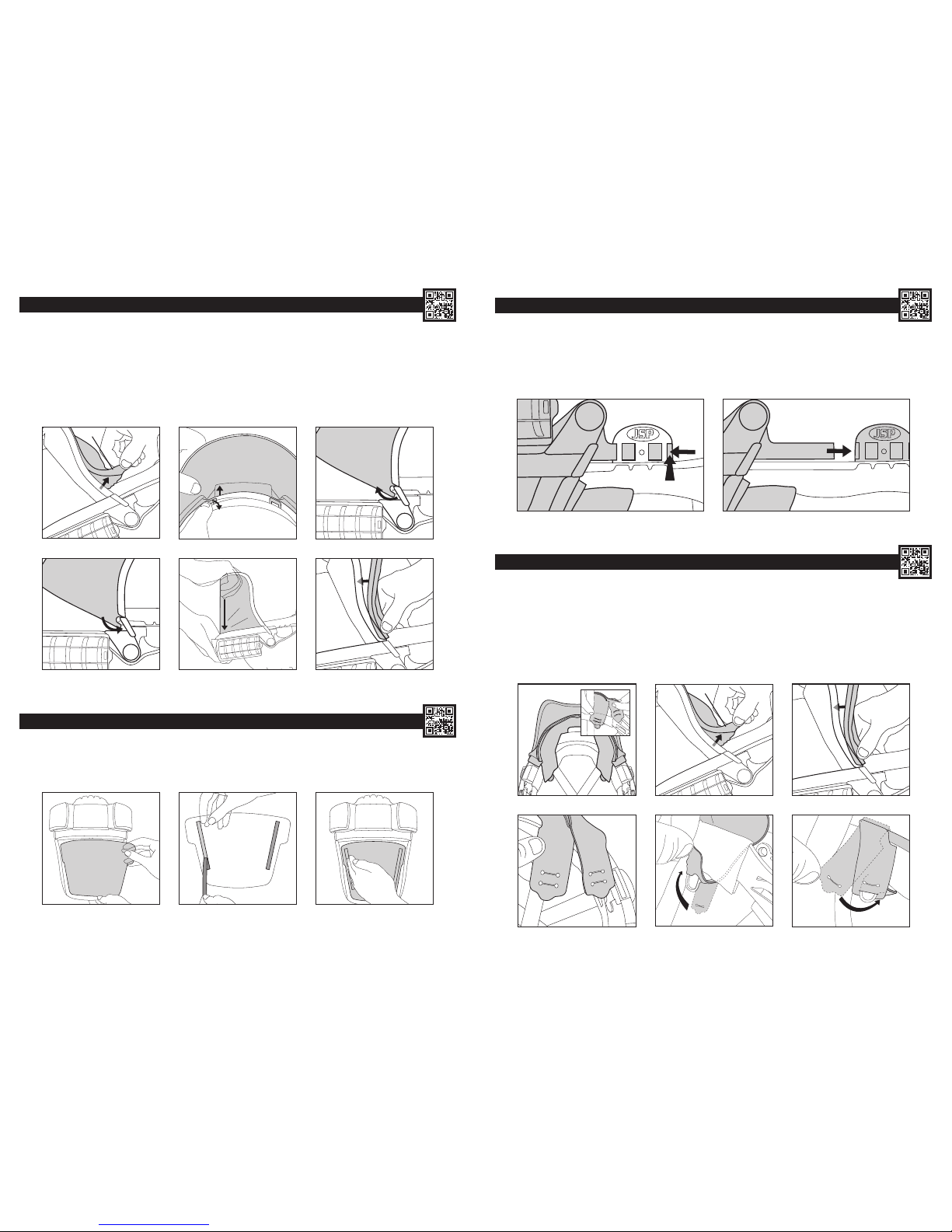

REMOVING & REPLACING THE HARNESS STRAP:

1. Unhook the four inner and outer face-seal skirt loops from the harness mounting points inside the helmet.

2. Remove the harness strap by un-popping the arm from the receiver (hold the helmet and receiver rmly whilst doing so).

3. Repeat this process for all 4 arms then take the harness strap out from the helmet. Dispose of used strap in accordance with local legislation.

4. Place the replacement strap inside the helmet shell, then pop the rst arm back into position and repeat the process for all 4 arms.

5. Feed the outer set of skirt loops behind the harness strap inside the helmet. Hook the loops over the harness mounting points inside the helmet.

6. Hook the inner set of skirt loops over the harness mounting point and outer loops. Repeat with the loops on the other end of the sealing skirt.

SKIRT LOOPS

ADDITIONAL INDUSTRIAL SAFETY HELMET INSTRUCTIONS:

Fitting and adjustment: Fit the helmet as described in the PowerCap® Innity®Donning section of this manual. For adequate protection PowerCap®

Innity® must t or be adjusted to the size of the user’s head.

Use: The helmet is made to absorb the energy of an impact by partial destruction or damage to the shell or harness and even though such damage

may not be readily apparent, any helmet subjected to severe impact should be replaced. This helmet has been designed to protect the wearer against

electrical shocks by preventing passage of dangerous current through the body via the head. The helmet must be used with other insulating protective

equipment when working on low voltage installations. The user should check that the electrical limits of the helmets correspond to the nominal voltage that

is likely to be encountered during use. Accessories and/or replacement components are available with tting instructions from JSP.

Inspection and care of the helmet: The helmet is a complete system consisting of shell and harness. The helmet’s useful life is affected by many

factors including the cold, heat, chemicals, sunlight and misuse. The helmet should be examined daily for obvious signs of cracking, brittleness or

damage to either helmet or harness. The user should be aware that there is potential risk of loss of protection due to ageing and/or inappropriate

cleaning. The effectiveness of the insulating properties of the helmet may be affected by the conditions of use. The date of manufacture is moulded into

the peak of the helmet. While the helmet is free from defects it is suitable for its intended purpose. If in any doubt destroy the helmet.

Useful life: Under normal circumstances the helmet has a maximum life of 5 years from date of manufacture. Under no circumstances must a

component other than a JSP component be used on a helmet.

MARKINGS:

ADDITIONAL INDUSTRIAL EYE PROTECTION INSTRUCTIONS:

Assembly: The PowerCap® Innity® visor should be tted to, and used with the PowerCap® Innity® visor carrier and helmet, see tting instructions in

the Removing & Replacing the Visor section of this manual.

Useful life: Under normal circumstances the visor should offer protection for up to 5 years. Scratched or damaged visors should be replaced.

Replacement visors are available.

MARK MEANING

EN12941:---- European standard for powered ltering respiratory

devices and its year of publication

A#:---- Amendment to EN12941 and its year of publication

TH3 Indicates a 99.8% efciency with an APF 40

R SL A reusable solid and liquid aerosol lter

EN397:---- The European standard number for industrial

safety helmets and its year of publication

EN50365:----

The European standard number for electrically

insulating helmets for use on low voltage

installations and its year of publication

The double triangle symbol means that this helmet

is electrically insulated for use working live or

close to live parts on installations not exceeding

1000Vac or 1500Vdc

53-63 cm The size range of the helmet, head circumference

-20°C / -30°C /

-40°C

The helmet will provide some protection when

worn in an environment at or above these

temperatures

MM The helmet will provide some protection against

molten metal splash

440 Vac

The helmet will protect the user against short term,

accidental contact with live electrical conductors

up to a voltage of 440 Vac

LD The helmet will provide some protection from

lateral compressive loads

MARK MEANING

EN166:2002 European standard for protective eyewear

2-1.2 Shade number

1Optical quality (high)

BProtection against medium energy impact against

high speed particles

8Protection against short circuit electric arc

9Protection against molten metals and hot solids

KResistance to surface damage by ne particles

See instructions for use. If the instructions for use

recommendations are not adhered to, the protection

afforded by the device may be severely impaired.

Storage temperature and humidity ranges

Indicates that product conforms to relevant EU

Directives and Regulations regarding health and

safety or environmental protection

Dispose of in accordance with local legislation

Some of the components of the device can be

recycled

Date of manufacture

Use by date