1

S420-S430-S520-S530 1-2003

1 FOREWORD 1

1.1 - PUBLICATION IDENTIFICATION

The “OPERATION AND MAINTENANCE INSTRUCTIONS” manual is an integrative part of the dusters.

It is identified by a Publication No. located on the frontispiece, and through which the document can

be identified, traced and/or subsequently referred to.

The information elements contained herein are updated as at the date of publication. C.I.M.A. S.p.A.

reserves the right to modify its machines without notice, with the purpose of applying technical

enhancements, and it declines all responsibility for possible omissions from the publication.

All rights are reserved. No parts of this book may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying, recording, or by any information storage and retrieval

system, without permission in writing by C.I.M.A. S.p.A.

1.2 - ATTACHED PUBLICATIONS

— Spare parts catalogue;

1.3 - PURPOSE OF PUBLICATION

All indications contained in this manual are aimed at the user of the duster.

The duration of the machine and its operation, the operator’s safety and the respect for the environment

are dependent upon scrupulous observance of the stated norms.

Before making use of the duster, the user must read, understand and abide by all regulations listed

in this manual.

1.4 - REFERENCE TO REGULATIONS

This manual was set out conforming to the regulations contained in following documents:

— Attachment “I” to Directive 89/392/C and subsequent modifications (letters “b”, “c” of point 1.1.2

and point 1.7.4);

— UNI EN 907 - 1997 and to all the documents in it quoted.

1.5 - USING THE MANUAL

Read every part of this manual, paying attention to the WARNING and DANGER indications both on

the text and on the machine or on components.

All operations suggested by the manual will have to be followed with the utmost care and only after

having understood the negative consequences of improper usage.

The following “symbols “ are used within the text in order to highlight and visually identify the

importance of the various types of information:

Indicates important additional information

Non observance can result in permanent damage to the duster.

Highlights possibly dangerous situations to people.

24

S420-S430-S520-S530 1-2003

13 TROUBLE SHOOTING 13

A. PROBLEM: Oil leakage from the cover of the multiplier box

1. CAUSE: The cover seal is defective.

REMEDY: Refer to CIMA after sale service.

2. CAUSE: The sealing ring on the cover is defective.

REMEDY: Refer to CIMA after-sale service.

B. PROBLEM: Vibration of the ventilator group

1. CAUSE: The fan is dirty or out of balance.

REMEDY: Refer to CIMA after-sale service.

2. CAUSE: The PdPs are not aligned or are not parallel.

REMEDY: Position the PdPs in the correct way.

C. PROBLEM: Abnormal and constant noise with vibrations

1. CAUSE: Breakage of the multiplier bearings.

REMEDY: Refer to CIMA after sale service.

D. PROBLEM: Non-delivery of powders

1. CAUSE: The feeding holes on the tank bottom are clogged.

REMEDY: Clean them.

2. CAUSE: Caking of the tank’s contents.

REMEDY: Breake up the powder.

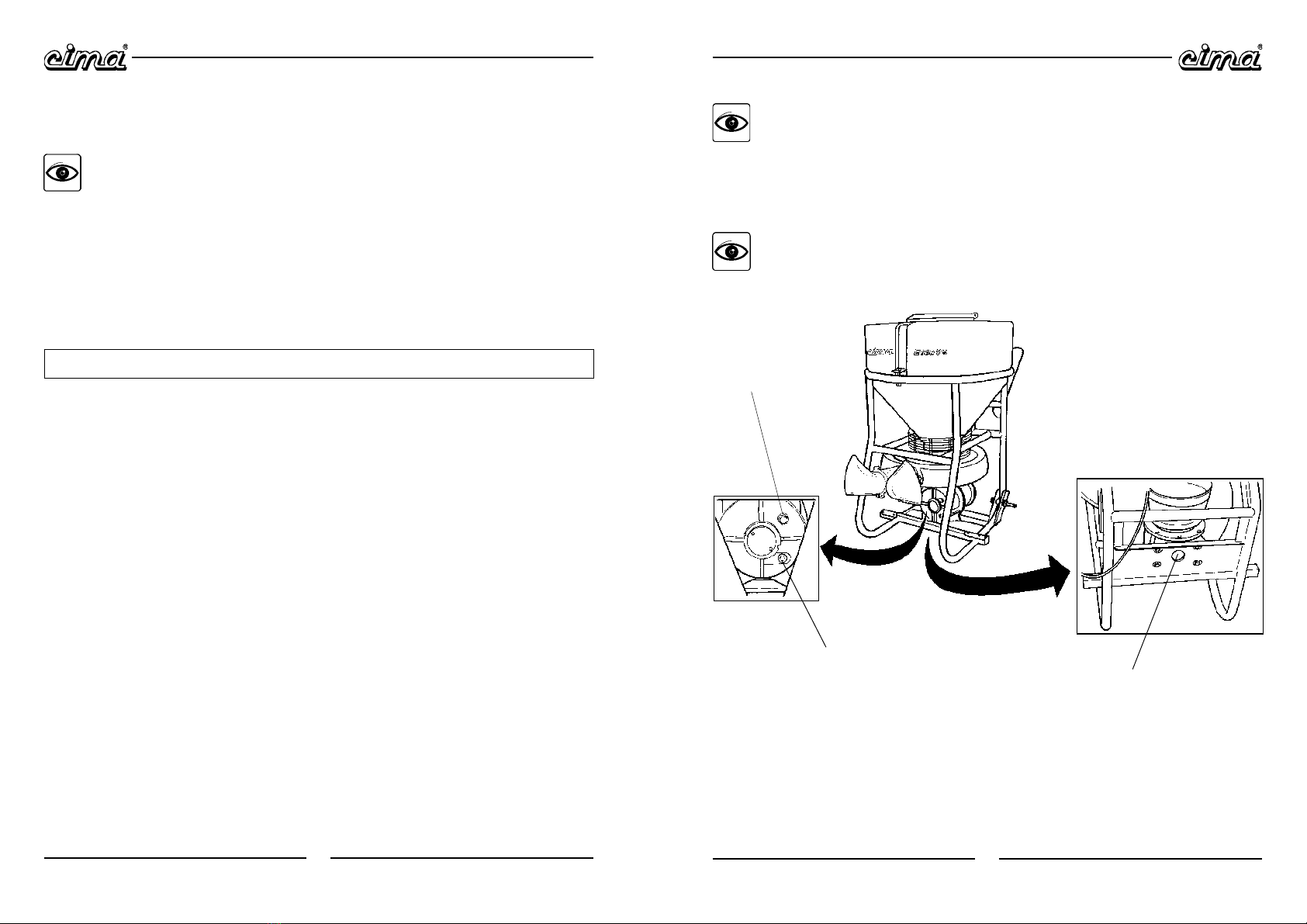

E. PROBLEM: Distribution on the two sides is not uniform

1. CAUSE: The compensation plate of the head has moved.

REMEDY: Adjust it in order to get a uniform distribution.

14 REPAIRS ALLOWED 14

THE OWNER AND/OR THE OPERATOR OF THE DUSTER ARE NOT PERMITTED TO MODIFY

THESTRUCTUREOR THESPECIFIC OPERATIONOFTHE DUSTERITSELF. ANYREPAIRING

INTERVENTION HAS TO BE CARRIED OUT EITHER AT THE DISTRIBUTORS’ OR AT THE

C.I.M.A. S.p.A. AUTHORIZED WORKSHOPS, OTHERWISE ANY KIND OF WARRANTY

IMMEDIATELY CEASES AND C.I.M.A. S.p.A. IS CLEARED OF ANY CONSEQUENT AND/OR

IMPLIED RESPONSIBILITY.