QUICK-START

G

UIDE

This Quick-Start Guide covers basic

operation. For detailed operating

instructions, please see the User’s

Manual supplied with the printer.

ThermalLabel&BarcodePrinter

CLP-8301

For the safe operation of your printer, please read the following important operation and safety instructions

carefully. Failuretoobservetheseprecautionscanresultinpersonalinjuryor property damage or, in extreme

situation,serious injury or death.

1. Readall of these instructions and save them for later reference.

2. Follow all warnings and instructions marked on the product.

3. Unplugthis product from thewall outlet before cleaning. Donotuse liquid or aerosolcleaners, thinner,

trichloroethylene,benzine, ketone or similar chemicals. Instead use a dampclothfor cleaning, when

theprinter is disconnected from the mains supply.

4. Donot use this product near water orwhere a chemical reaction can occur suchasin a laboratory or

wherethereisalotofoil,dust,saltorironparticles.

5. Donot place this product on an unstable cart, stand or table. The product may fall, causing serious

damageto the product and people around it.

6. Slots and openings on the cabinet and the back or bottom are provided for ventilation.

7. Toensure reliable operation of the product and to protect it from overheating,donotblock or cover

theseopenings. The openings should never beblockedby placing the product onabed, sofa, rug or

othersimilar surface. This product shouldneverbe placed near or overa radiator or heat source. This

productshouldnot be placed in a built-in installation unless proper ventilation is provided.

8. Thisproduct should be operatedfrom the type of powersourceindicated on the marking label. Ifyou

are not sure of the type of power available, consult your dealer or local power company.

9. Thisproduct is equippedwitha three-pronged plug,aplug having a thirdgrounding pin. This plug will

onlyfit into agrounding-typepower outlet. This is asafetyfeature. If you are unabletoinsert the plug

into the outlet, contact your electrician to replace your obsolete outlet. Do not defeat the safety

purposeof the grounding-type plug.

10. Donotallowanythingtorestonthepower cord. Do not locate this product where the cord will be

walked on. Do not pull on the power cord or data cables or keep them under tension.

11. If an extension cord is used with this product, make sure that the total of the ampere ratings on the

productsplugged into the extensioncorddo not exceed theextension cord ampere rating. Also, make

surethat the total of all products plugged intothewall outlet does not exceed 7.5 amperes for 220/

240V outlet and 15 amperes for a 120Voutlet.

12. Neverpush objects of any kindinto this product through cabinet slotsas they may touch dangerous

voltagepoints or short out parts that could result inarisk of fire or electric shock. Never spill liquid

of any kind on the product.

13. Except as explained elsewhere in this manual, don’t attempt to service or disassemble this product

yourself. Openingand removing those covers that are marked“DoNot Remove” may expose you to

dangerousvoltage points orother risks. Refer allservicing on thosecompartmentsto service personnel.

14. The mains plug on this equipment must be used to disconnect mains power. Please ensure that the

socketoutlet is installed near the equipmentandshall be easily accessible.

15. Unplugthis product from the wall outlet and refer servicingtoqualified service personnel under the

followingconditions:

a. When the power cord or plug is damaged or frayed.

b. Ifliquid, aerosol chemicals or other chemicals have been spilled intothe product.

c. If the product has been exposed to rain or water or excessive humidity.

d. If the product does not operate normally when the operating instructions are followed. Adjust only

those controls that are covered by the operating instructions since improper adjustment of other

controlsmay result indamageand will often requireextensive work by aqualified technician to restore

the product to normal operation.

e. If the product has been dropped or knocked or the cabinet has been damaged.

f. If the product exhibits a distinct change in performance, indicating a need for service.

16. Discardor safely store theplastic packing bag. This bag shouldbe kept away fromchildren. Ifthe bag

ispulled over child’s head, it may cause suffocation.

17. Make sure if you open the top cover, it is opened all the way. If only partially open, the cover could

slamshut, possibly causinginjury.

18. When the cover is open, be careful of the corners of cover. They could cause injury.

19. Do not open the printer during printing.

20. Operate the control panel properly. A careless, rough handling may cause problems or malfunction.

Donot use such sharp-edged tool as a ballpoint for operation.

21. Ifa problem occurs during printing,stop the printer immediately andunplug the power cord fromthe

outlet.

22. Thecontentsof this manual may be changed without prior notice.

23. Reproduction,transfer, or transmission of thecontents of this manual without priorconsent is strictly

prohibited.

24. Weare not liable foranydamage resulting from theuse of the informationcontainedherein, regardless

oferrors, omissions, or misprints.

25. Weare not liableforany problems resultingfromthe use ofoptionalproducts and consumablesupplies

other than the designated products contained herein.

26. We are not liable for any damage caused by user’s erroneous use of the printer and inadequate

environment.

27. Data residing in the printer is temporary. Therefore, all data will be lost if power is lost. We are not

liablefor any damage or loss of profitscaused by data loss due to failures,repairs,inspections, etc.

28. Pleasecontact us if there are any mistakes orambiguitieswithin this manual.

29. Ifthere are missing or incorrectly collated pages in this manual, contact us to obtain a new manual.

30. Trademarks or registered trademarks of other companies and products are included in this manual.

Citizenacknowledges all trademarks.

COMPLIANCE STATEMENT

FOR EUROPEAN USERS

CE marking shows conformity to the following criteria and provisions:

LowVoltage Directive (73/23/EEC)/EN60950

EMCDirective (89/336/EEC)/EN55022, EN55024, EN61000-3-2 & EN61000-3-3

SAFETY INSTRUCTIONS

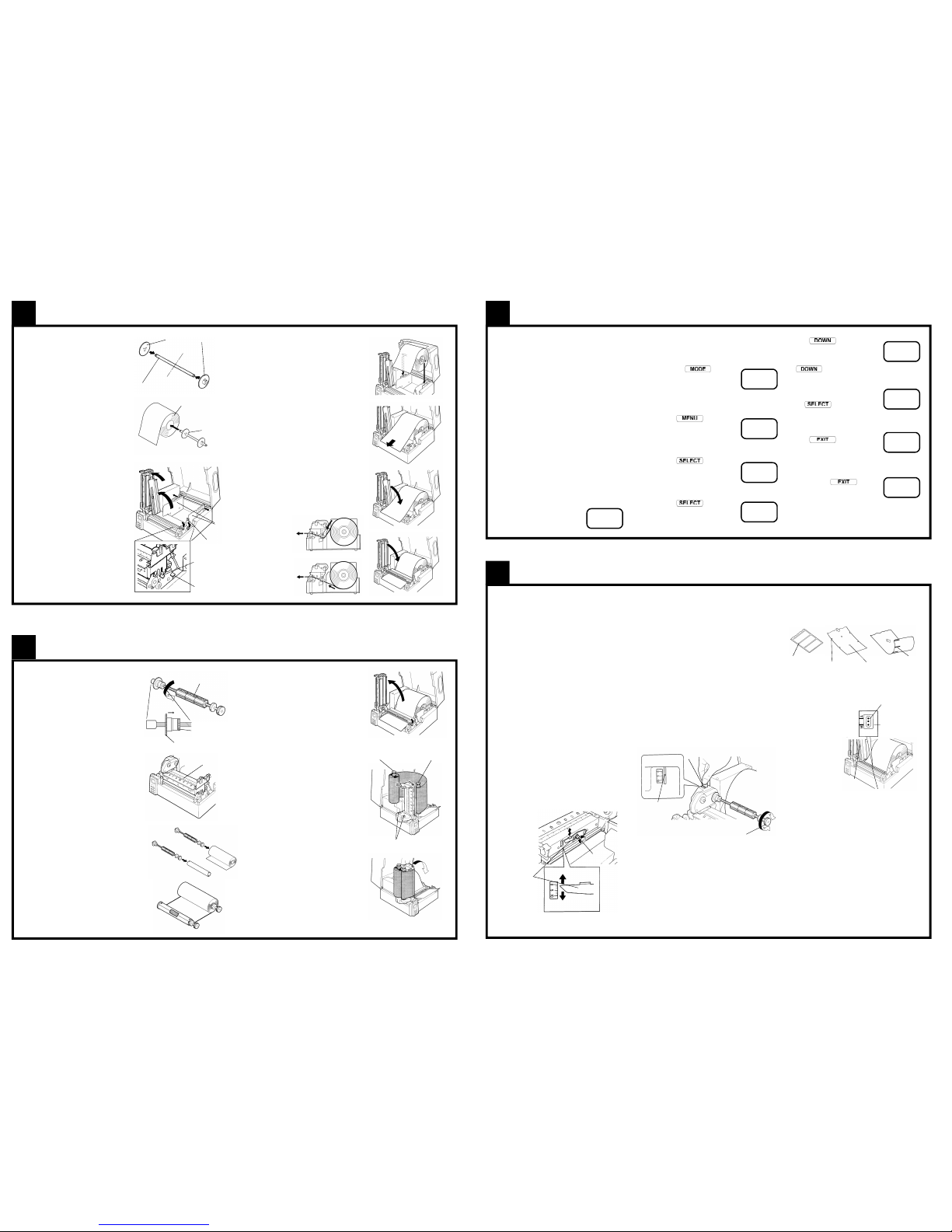

Removing Adhesive Tapes

a. The printer is shipped with adhesive tape in place to hold

the top cover closed. Simply remove the two pieces of

tape on either side of the top cover. Then open the top

cover by lifting up and tipping it backwards.

b. Thereare twopieces oftape onthe rightside ofthe printer

preventing the head release levers from being pressed.

Carefully remove these pieces of tape.

c. Lastly, there is another strip of adhesive tape holding the

mechanism closed for shipping. Remove the tape and

attached paper by carefully peeling from the case. A piece

of paper is also inside the mechanism to protect the

printhead.

Connection to Power

a. Ensure the power switch is turned OFF.

b. Connect the power cord supplied to the printer’s power cord inlet.

c. Insert the plug of the power cord in the AC outlet.

d. Turn the power switch on and the LCD panel on the front of the

printer will display “Power On” and, after a few seconds of testing,

it will display “Ready”.

Connection to a Computer

This product has two interfaces as standard that can be used to receive printing data: a serial

port(RS232C) and a parallelport. Anoptional internal Ethernet (LAN)port,an internal Wireless

LANport or enhanced “1284” parallel port can be added by yourdealer. Withthe exception of

awireless LAN connection, an interface cable is necessary to connect the printertoa computer.

a. With the power turned off, connect one end of the interface cable

to the interface connector on the back of the printer and secure it

with locks or locking screws, where available.

b. Connect the other end of the interface cable to the interface

connector on the computer and secure it with locks or locking

screws, where available.

Caution Usean AC outlet thatacceptsa three-pronged plug.

Otherwise, static electricity may be generated and

there will be danger of electric shock.

3Connection

2Remove Packing

Power Switch

Power Cord Inlet

PC card socket

(notusually

installed)

Mediaviewing

window

Embossedpattern

to make opening

easier

Front of printer

SerialPort

Parallel port (or

network card

option)

Blankingplate

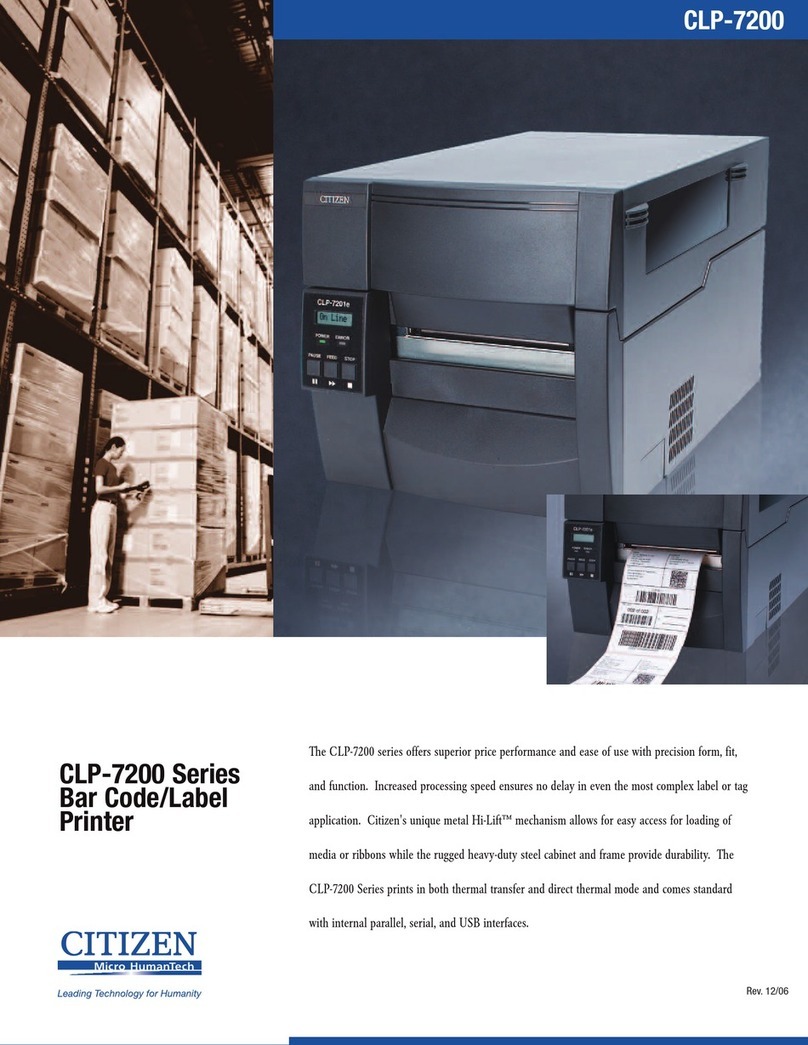

Congratulations....

On your choice of a Citizen CLP 8301 label printer.

Pleasetake a moment to read this Quick Start Guidewhichwill familiarise yourself with the

printerand its operation. Theprinter is a sophisticatedbut easy-to-use label printerfeaturing

simplemedia loading, quick connection anda powerful LCD configuration system.

We will guide you through unpacking of the printer from its carton, connection to your

computer system and installation of the media including a quick self-test of the printer to

ensure it is working.

Safety

Butfirst, please carefully readthe safety instructions includedinthis Quick Start Guideand in

moredetail in the user manual. Failureto observe the safety precautionscouldcause serious

injury or damage to both you and your property.

Unpacking Your Printer

Carefully openthe carton and lift out the upper foam damper containing the accessories.

Withtwo hands and, ifnecessary with someone else’sassistance, lift the printeroutof the box

holdingthe bottom of theprinterfirmly. Ensure there is spacetoset the printer down before

you lift it from the packing. Keep the carton, packing materials and printer mechanism

travellingtape for future shipment.

Insome cases, yoursupplier or Citizenmayhave added extraitems required for yourparticular

installation such as additional CD-ROM, cable or manuals. Instructions for each of these

itemswill be included within theindividualpackages.

Ifyou have any questions,orif you find anyof the items are missing,please initially refer back

toyour supplier. Otherwise, contact detailsfor our offices areshown on the backpage of this

QuickStart Guide.

1Read This First!

Carton Contents - Accessories

Windows®Driver Installation

Ifyou are using Windows®98, NT4, 2000,XPor 2003 or any newerversionsof Windows®, the

latestprinter drivers will usually besuppliedon CD in the boxby your dealer. If the drivers are

notincluded with the printer, youcandownload the latest version free-of-chargefrom our web

site,details of which are on the back of this Quick Start Guide.

Under the latest versions of Windows®, the computer will often automatically detect the

presence of the printer. Therefore it is advisable to download the drivers from our web site

beforeinstalling theprinterso the filesare ready forinstallation. Follow any on-screeninstruction

andalsoinstructionssuppliedwithanyadditionalCD-ROMorfloppydisk included with your

printer.

Your supplier will assist you with the correct drivers and software which are compatible with

your particular computer system if you are not using Windows®. Windows®is a trademark of

Microsoft®Corporation.

ForFurther Information ...

For further information and more detailed instructions on the use of

your new printer, please refer to the complete user manual accompanying

your printer.

Alternatively, please contact one of our local sales offices:

Citizen Systems Europe GmbH

Mettinger Strasse 11

D-73728 Esslingen

Germany

Tel: +49 (0) 711 3906 400

http://www.citizen-europe.com

Citizen Systems Europe UK

Park House, 643-651 Staines Road

Feltham, Middlesex, TW14 8PA

United Kingdom

Tel: +44 (0) 20 8893 1900

http://www.citizen-europe.com

Citizen America Corporation

2102 Alton Parkway, Unit A

Irvine, CA 92606. U.S.A.

Tel: (949) 428-3700

http://www.citizen-america.com

Ribbonbobbins

(2pieces)

Sampleribbon

Cardboardcore

Power cord

UserManual

Samplemedia

Head

cleaningpen

Mediaholder disks

(2pieces)

Mediaholder shaft

Upperfoam damper including

accessories,detailed above

Printer

Lower foam damper

(Thisdoes not need to be

removed from the carton)

Carton