Thank you for purchasing this CLARKE Battery Tester, which is designed to test the state

and condition of 6 and 12 volt batteries.

Before using this product, read this leaflet thoroughly, and follow the instructions carefully,

with particular emphasis on the safety precautions. This will ensure your own safety and

that of others around you.

Although this product is of rugged construction, it should nevertheless be used with care

and consideration, you can then look forward to it giving long and reliable service.

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of 12 months

from the date of purchase. Your receipt is required as proof of purchase.

This guarantee is invalid if the product is found to have been abused in any way, or not

used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be returned

to us without prior permission.

This guarantee in no way effects your statutory rights under common law.

OPERATION

With the meter disconnected from the battery, ensure the gauge needle is set to zero,

using the screw on the front of the gauge as necessary.

1. BATTERY TEST.

A. Connect the RED clamp to the POSITIVE terminal, and the BLACK clamp to the

NEGATIVE terminal, ensuring the contacts are clean and firm, and that on small

batteries, there is absolutely no possibility of the clamps touching each other.

B. Operate the spring loaded LOAD Switch, and hold for at least 10 seconds to allow

the load to take effect. With the load switch held, read the condition of the battery

on the scale provided, referring to the Battery Analysis chart, opposite.

2. CHARGING SYSTEM TEST

Connect the leads to the battery, as above, and run the engine at a fast idle speed.

Read the gauge (charging system). Do not operate the Load Switch.

SAFETY PRECAUTIONS

1. Always avoid creating sparks in a battery charging environment, as this could cause

fire, or even an explosion.

Similarly, it is vital to avoid creating sparks when testing a battery in a motor vehicle in

situ,asspikesinthesystemcouldcauseseriousdamagetothevehicleelectroniccircuitry.

Ensure that the RED or POSITIVE clamp does not touch any other part of the vehicle,

and be particularly careful where you place the tester within the engine

compartment. The main body of the tester is metal, and if placed carelessly, it could

cause a short circuit and hence damage to the electrical system.

2. Avoiddroppingthe tester, asthis could cause damage,which may notperhaps prevent the

device from working, but could nevertheless cause the readings to be inaccurate.

MAINTENANCE

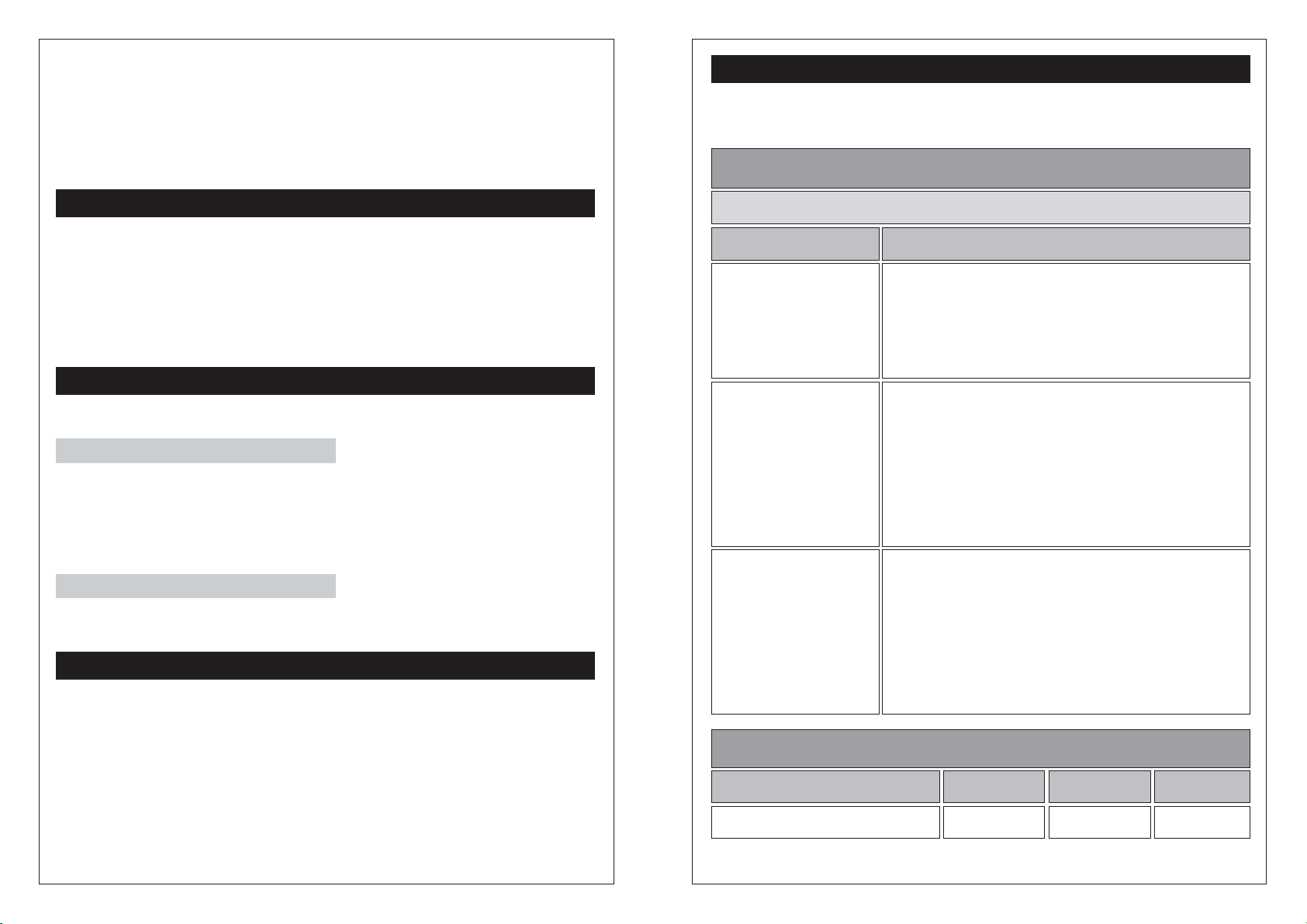

BATTERY ANALYSIS

Meter reading after 10 seconds of load

LOAD TEST BATTERY CONDITION

OK (Green Band) Battery capacity is GOOD. May or may not be fully

charged.

Check the state of charge by checking Specific

Gravity with a hydrometer. If SG is less than Full

charge,check for possible charging system trouble.

Re-chargebattery to full charge

WEAK or BAD Battery capacity is unsatisfactory. Battery may be:

but needle is steady. a) defective or b) partly discharged.

To determine which, check Specific Gravity.

If SG is over 1.225, the battery is considered defective.

If SG is below 1.225, re-charge battery and re-test.

If difference in cell to cell SG is greater than 0.025

(25 points), cell trouble may exist.

If charging does not bring SG to full charge level, then

battery is either sulphated, or has lost its active material.

WEAK or BAD Battery may be defective (e.g. A bad cell).

and needle is falling For a quick check, release load switch, and note

voltmeter reaction.

If voltage recovers to its full potential after only a

few seconds, the battery is probably defective.

If the voltage recovers slowly, the battery may only

be very run down.

For more accurate results, check Specific Gravity

and follow above procedure.

TEMPERATURE COMPENSATION

Battery temperature 0OC -10OC -20OC

Decrease battery rating by: 1 STEP 2 STEP 3 STEP

1 STEP = 50 CRANKING AMPS

As the metal clamps are liable to come into contact with battery electrolyte, it is advisable

to wipe them clean and dry after use, and apply a thin film of silicon grease to prevent the

possibility of corrosion.