3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SAFETY INSTRUCTIONS

The operator should read all warning signs and instructions here and on the

pallet truck before use.

1. Examine the condition of the pallet truck before use, with particular

attention to the wheels, handle, forks and lift/lower controls. DO NOT use

the pallet truck if any defects are found.

2. DO NOT operate a hand pallet truck unless you are familiar with it and

have been trained or authorized to do so.

3. DO NOT make any changes or modifications to the pallet truck.

4. DO NOT use if the wheels or rollers are damaged. Have them replaced

immediately.

5. Keep the work area tidy and well lit.

6. Keep children and bystanders away from the work area.

7. DO NOT exceed the capacity of the pallet truck. Refer to the labelling on

the pallet truck and the Product Specification section in this manual,

8. DO NOT use on rough terrain. The pallet truck is designed for use on smooth

flooring only.

9. DO NOT use the pallet truck on a gradient if the load is too heavy to be

easily handled by the operator. The pallet truck must not be used by

anyone not capable of handling the full weight of the truck when loaded.

10. Watch for differences in the floor levels when moving the truck. The load

may overbalance or the truck could become uncontrollable.

11. DO NOT let the pallet truck come into direct contact with food.

12. DO NOT use the truck in explosive atmospheres.

13. The operator must wear safety shoes and gloves.

14. DO NOT allow personnel other than the operator to stand in front of or

behind the truck when it is moving or lifting/lowering.

15. DO NOT put your foot in front of rolling wheels. Injury could result.

16. DO NOT use the pallet truck as a jack.

17. Ensure nothing is beneath the pallet truck forks prior to lowering, especially

anyone’s feet.

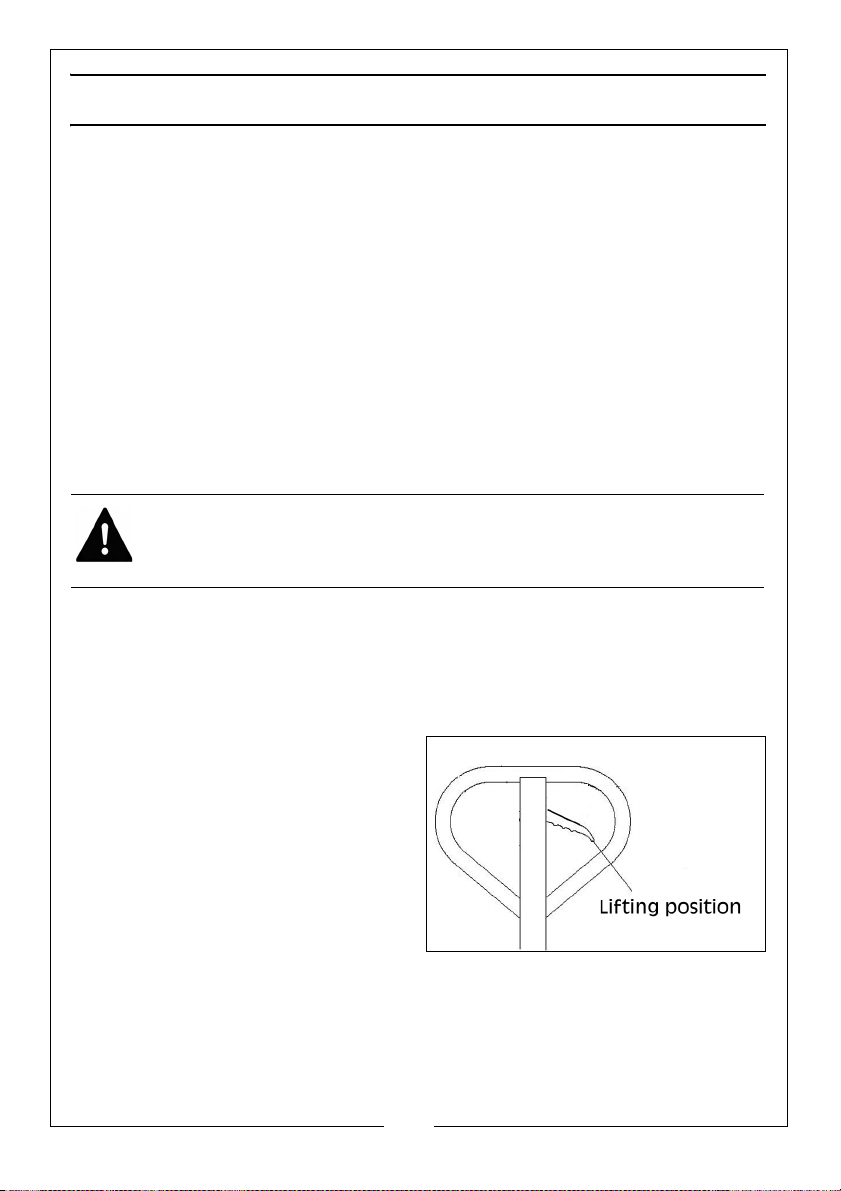

WARNING: THE TRUCK HAS TO BE USED ON SUBSTANTIALLY FIRM,

SMOOTH, LEVEL AND PREPARED SURFACES. THE LOAD MUST BE PLACED

CENTRALLY ON THE FORKS.