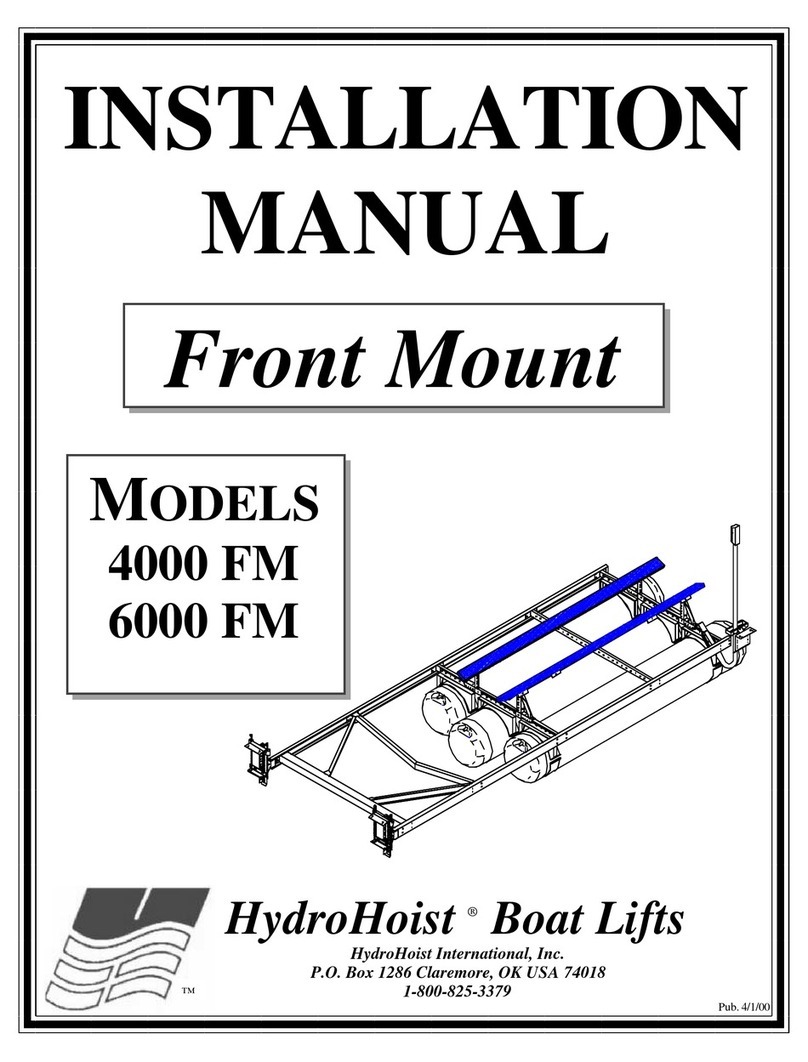

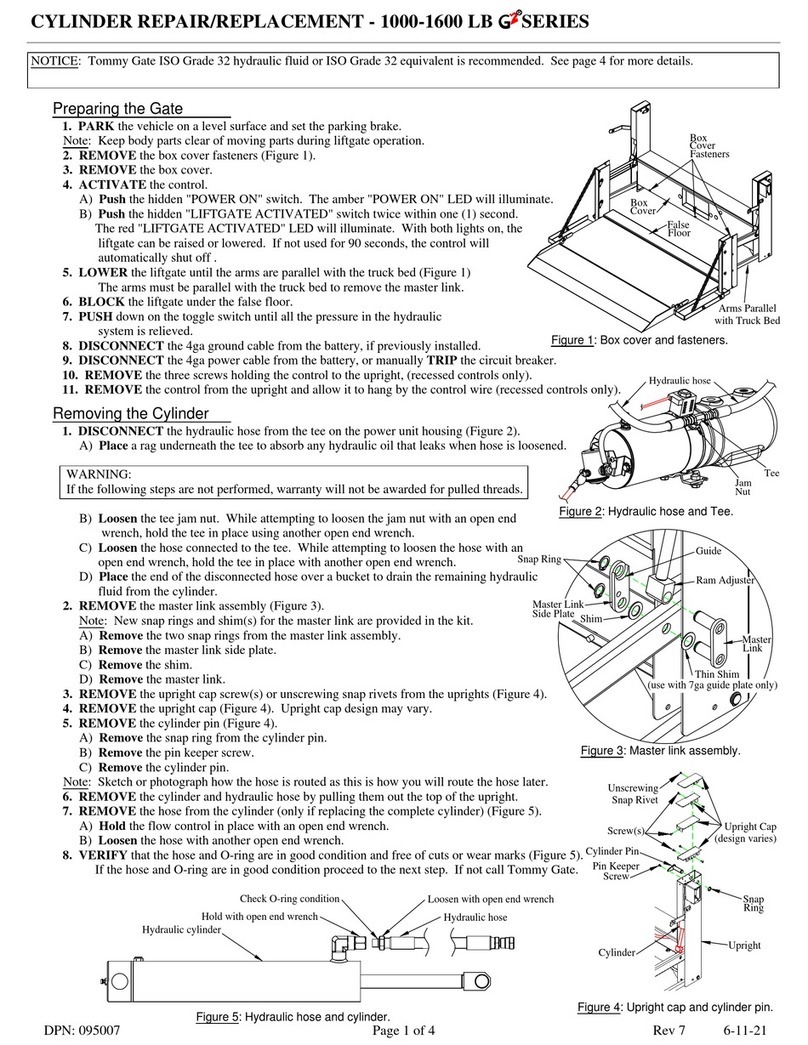

CLASSIC LIFT CL4500 Manual

TWO-POST LIFT

Model:CL4500

CONTENTS

Product Features and Specifications ..............................................1

Installation Requirement .............................................................5

Steps of Installation ...................................................................7

Exploded View ...........................................................................22

Test Run ...................................................................................33

Operation Instruction .................................................................35

Maintenance .............................................................................36

Trouble Shooting .......................................................................37

LIFT DISPOSAL ...............................................................................37

1

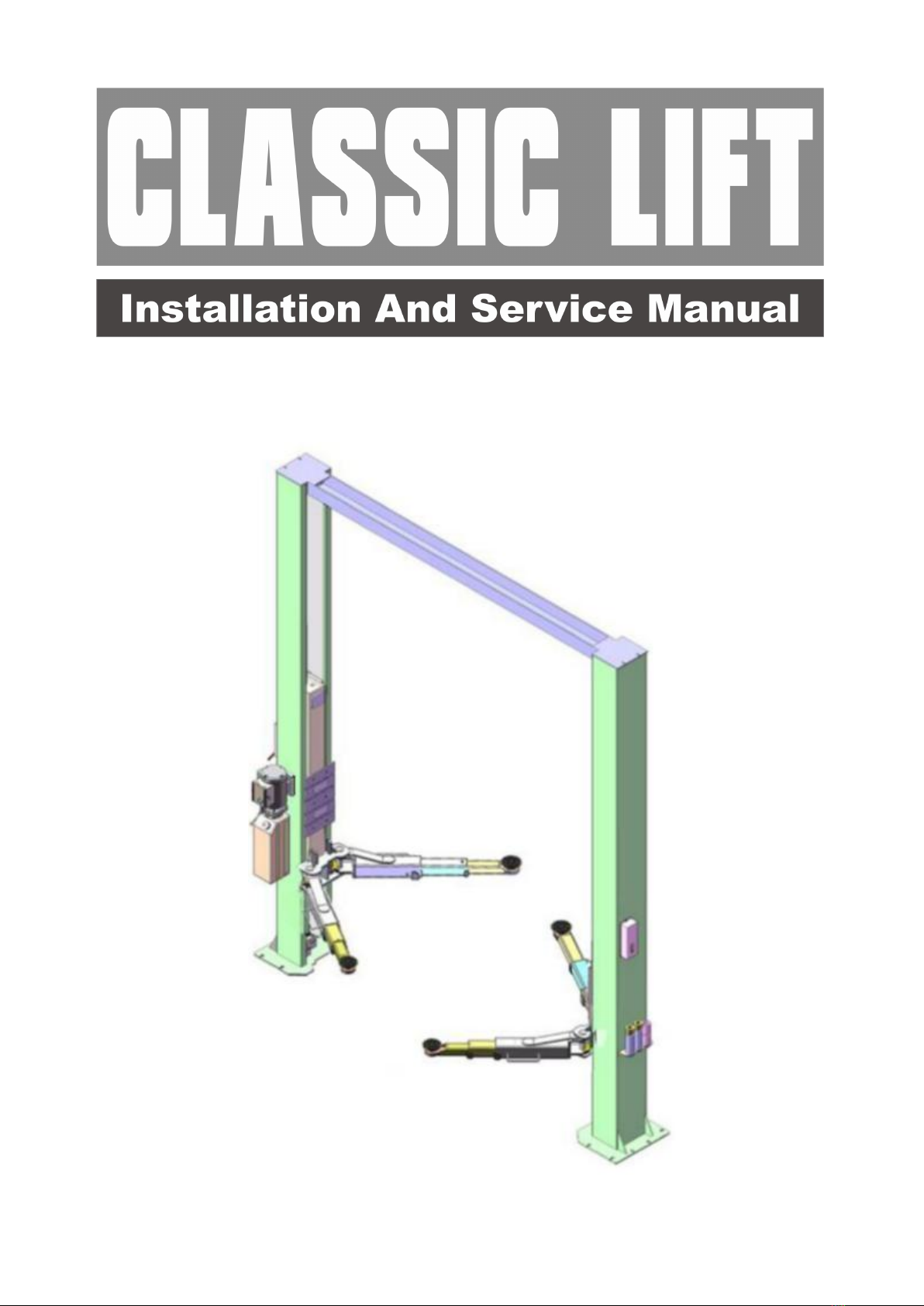

I. PRODUCT FEATURES AND SPECIFICATIONS

CLEARFLOOR DIRECT-DRIVED MODEL FEATURES

MODEL CL4500(See Fig.1)

· Direct-driving design, minimize the lift wear parts and breakdown ratio.

· Dual hydraulic cylinders, designed and made on high standard, high quality seals.

· Self-lubricating UHMW Polyethylene sliders and bronze bush.

· Single-point safety release, and dual safety design.

· Clear-floor design, provide unobstructed floor space.

· Overhead safety shut-off device.

· With 4 three stages arms, make lifts easily find the lift point of the car.

· Stackable adapters 1.5”, 2.5”, 5” as standard.

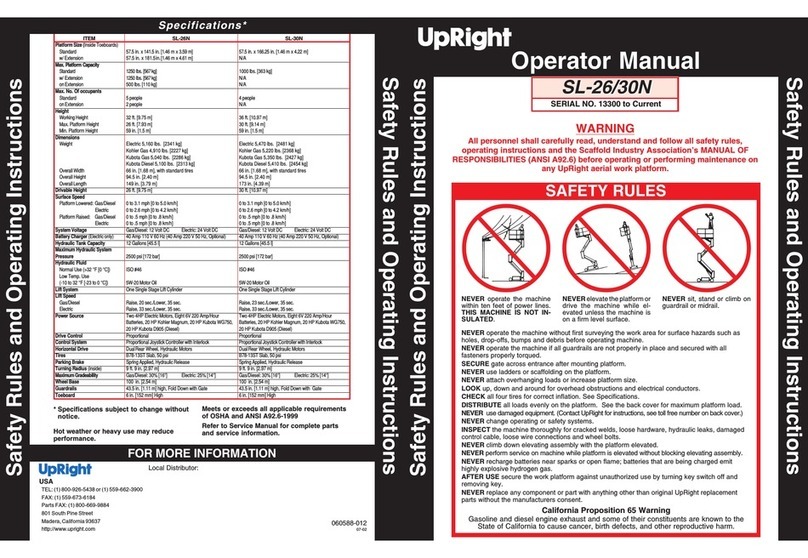

MODEL CL4500SPECIFICATIONS

Model

Style

Lifting

Capacity

Lifting

Time

Lifting Height

Overall

Height

Overall

Width

Minimum

Pad Height

Motor

CL4500

Clear-floor

Direct-drive

4500KG

60s

1940-2169mm

3854mm

3516mm

90-319mm

3.0HP

Fig. 1

2

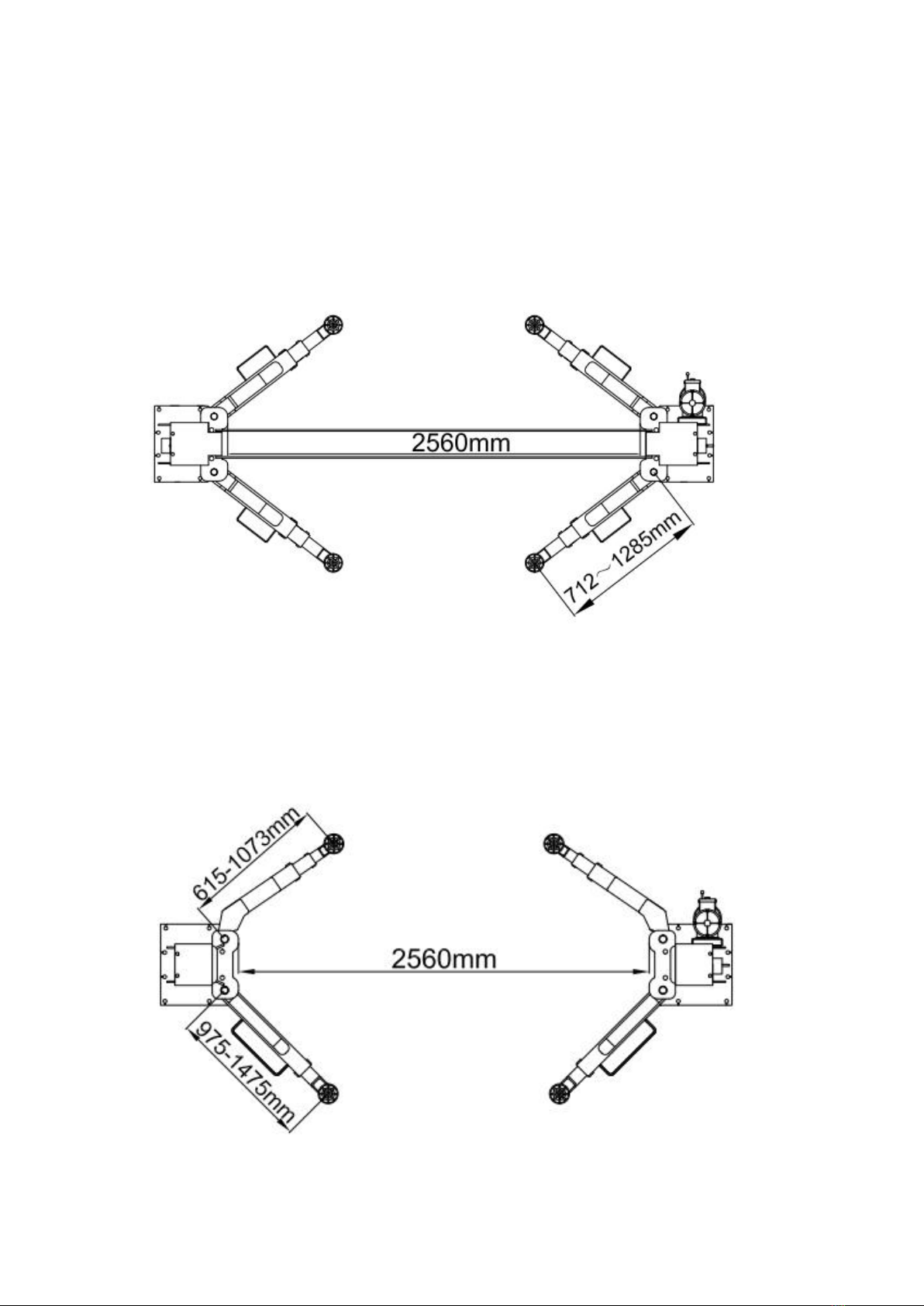

Arm Swings View

Fig. 3

For Model 210C

Fig. 4

For Model 210SAC

3

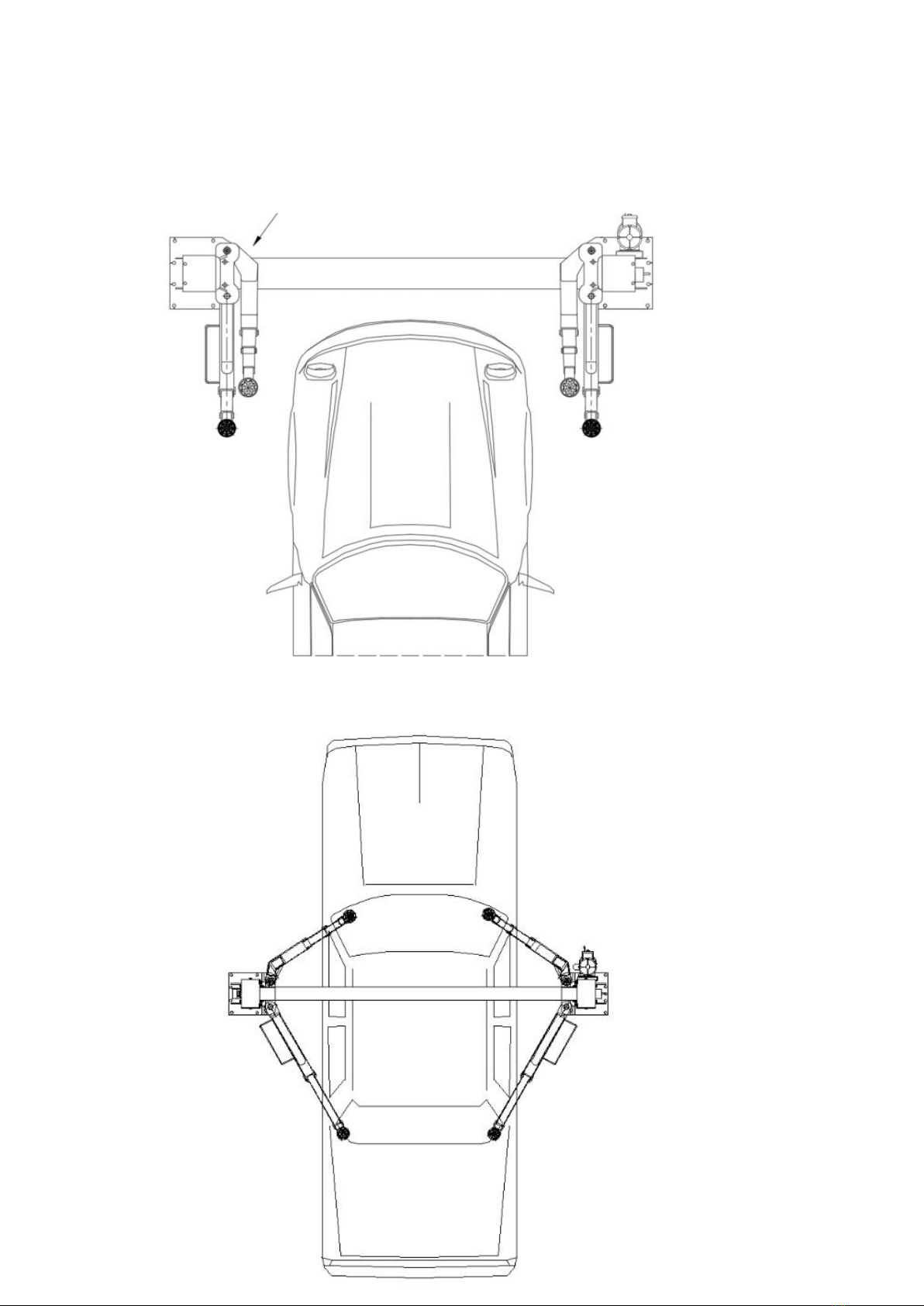

Swing and extending the arms to the lifting point of vehicle

Attention! Please make sure to place the arms in correct

position before car drive in!

Fig. 5

4

II. INSTALLATION REQUIREMENT

A. TOOLS REQUIRED

Rotary Hammer Drill (Φ19)

Hammer

Level Bar

English Spanner (12")

Ratchet Spanner With Socket (28#)

Wrench set

(10#, 13#, 14#, 15#, 17#, 19#, 24#,27#)

Carpenter’s Chalk

Screw Sets

Tape Measure (7.5m)

Pliers

Socket Head Wrench (3#, 6#)

Lock Wrench

Fig. 7

Fig. 6

5

B. Equipment storage and installation requirements.

The equipment should be stored or installed in a shady, normal temperature,

ventilated and dry place.

C.The equipment should be unload and transfer by forklift.

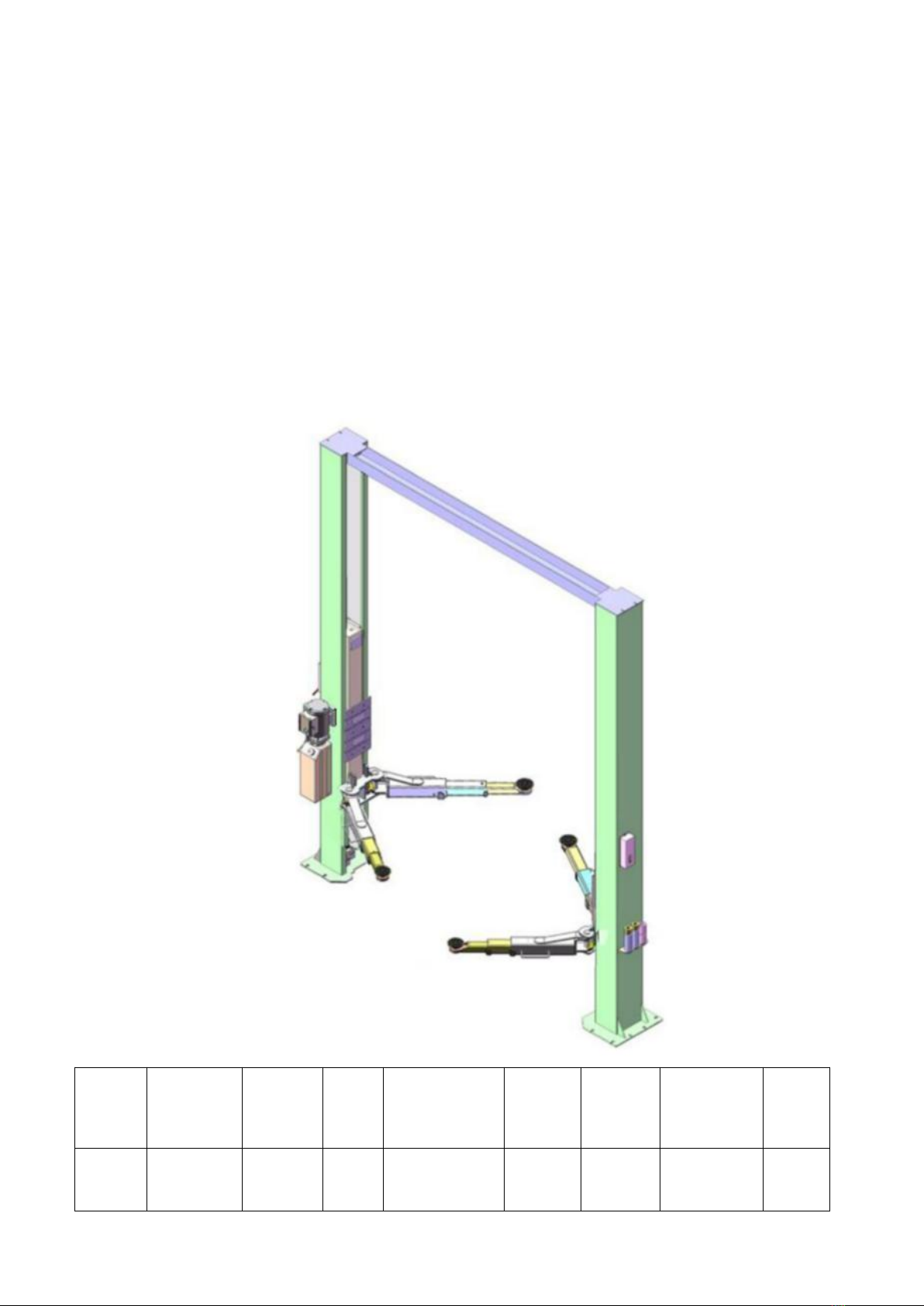

D. SPECIFICATIONS OF CONCRETE (See Fig. 9)

Specifications of concrete must be adhered to the specification as following.

Failure to do so may result in lift and/or vehicle falling.

1. Concrete must be thickness 100mm minimum and without reinforcing steel bars,

and must be dried completely before the installation.

2. Concrete must be in good condition and must be of test strength 3,000psi

(210kg/cm²) minimum.

3. Floors must be level without cracks.

E. POWER SUPPLY

The electrical source must be 2.2KW minimum. The source cable size must be

2.5mm² and in good condition of contacting with floor.

Fig. 9

Concrete intensive must be

3,000psi(210kg/cm²) minimum

67

Fig.8

100

6

III. STEPS OF INSTALLATION

A. Location of Installation

Check and insure the installation location (concrete, layout, space size etc.) is

suitable for lift installation.

B. Use a carpenter’s chalk line to establish installation layout of base plate (See Fig.

10).

C. Check the parts before assembly

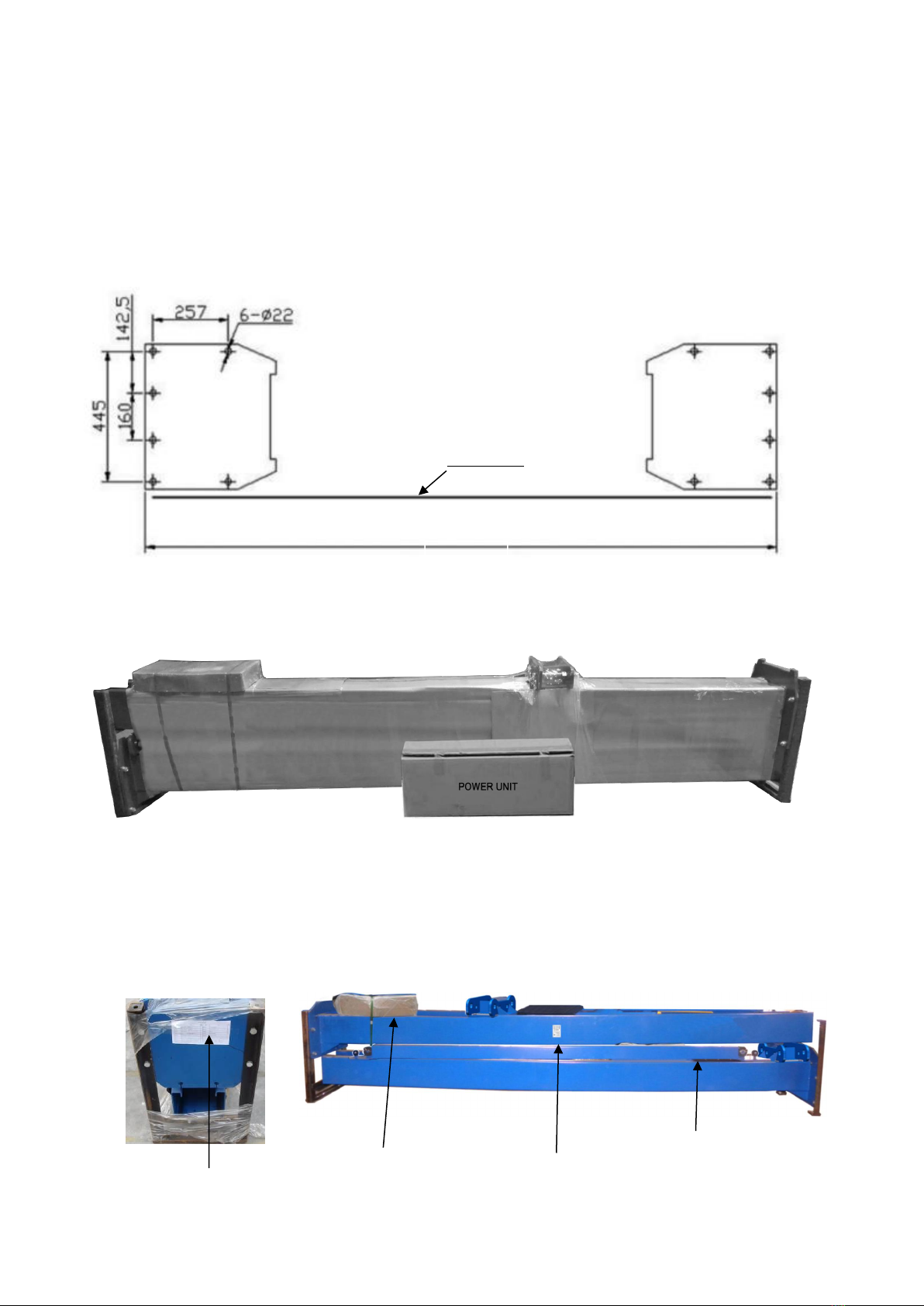

1.Packaged lift and hydraulic power unit (see Fig. 11)

2. Move the lift aside with a fork lift or hoist, and open the outer packing carefully ,

take off the parts from upper and inside the column, take out the parts box,check

the parts according to the shipment parts list (See Fig. 12).

Fig. 10

Fig. 11

Shipment Parts

list

Serial number

Top beam

Fig. 12

Chalk Line

Parts box.

3516mm

7

3. Loose the screws of the upper package stand, take off the upper column and remove

the package stand.

4. Move aside the parts and check the parts according to the shipment parts list

4.1 For Model 210C, (See Fig. 13, 14).

4.2 For Model 210SAC (See Fig. 15, 16).

37

Fig. 13

Parts in the shipment parts list

Fig. 14

Parts in the parts box (37)

37

Fig. 15

Parts in the shipment parts list

Fig. 16

Parts in the parts box (37)

8

5.Open the bag of parts and check the parts of the parts bag according to parts bag

list (See Fig. 17).

D. Position power side column

Lay down two columns on the installation site parallel, position the power side

column according to the actual installation site. Usually, it is suggested to install

power side column on the front-right side from which vehicles are driven to the lift

(See Fig. 18).

Fig. 17

Offside column

Power-side column

Car-in direction

Fig. 18

9

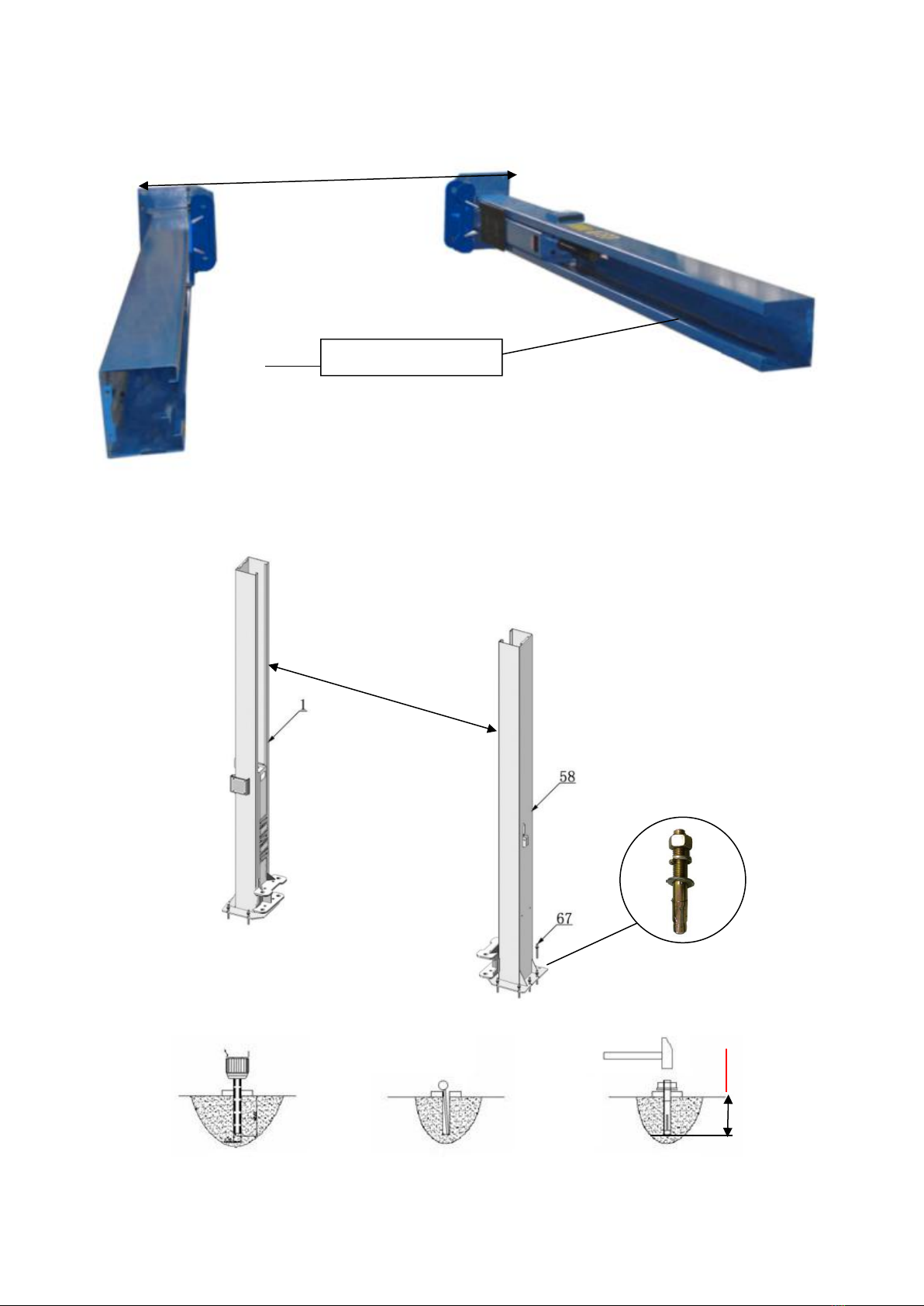

E. Lay down aside the columns with cables and oil hoses installed, face the

open way of each columns. (Fig.19)

F. Position columns

Place the columns on the installation layout of base plate. Install the anchor bolts.

Do not tighten the anchor bolts (See Fig.20).

Fig. 19

Overall width:3516mm

Notch is relatively

Anchor Bolt

Width between

columns: 2850mm

Fig. 20

Cleaning

Bolting

Drilling

90mm

Note: Minimum embedment of

anchors is 90mm.

10

G. Mounting the top beam by lifting equipment,and attention should be paid

to distinguish the direction when installing the top beam. Fig.21

H. Check the vertical of the columns with level bar, and adjusting with the shims if the

columns are not vertical. Tighten the anchor bolts (See Fig.22).

Tighten anchor bolts

Adjusting with

the shims

Fig. 22

Note: Torque of Anchors

is 150N.m

Measure the

vertical of column

from front and

side by a lever bar

or not.

Fig. 21

34

Power-side

Column

11

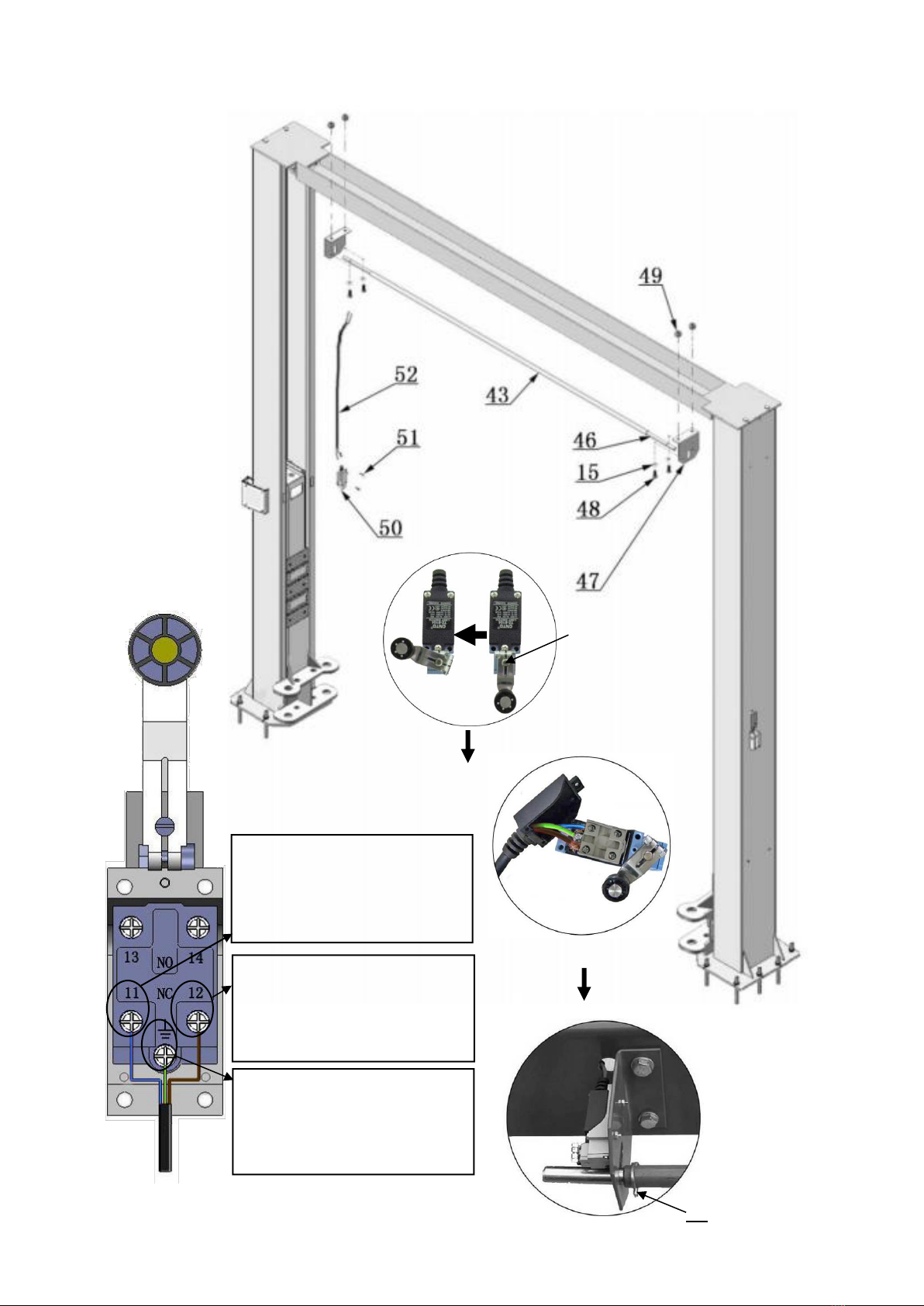

I. Install the limit switch control bar and limit switch (See Fig. 23).

NC: Normal contact

Fig. 23

Use 3# Socket

Head Wrench to

loosen the Screw

of drive rod for

adjustment

Limit switch is connected

with cable

Connect the blue wire to

terminal #11 on limit switch

and terminal A1 on AC

contactor of power unit.

Connect the brown wire to

terminal #12 on limit switch

and terminal #4 on button of

power unit

Connect the yellow and green

wire to earth wire terminal on

limit switch and earth wire

terminal of power unit

44

12

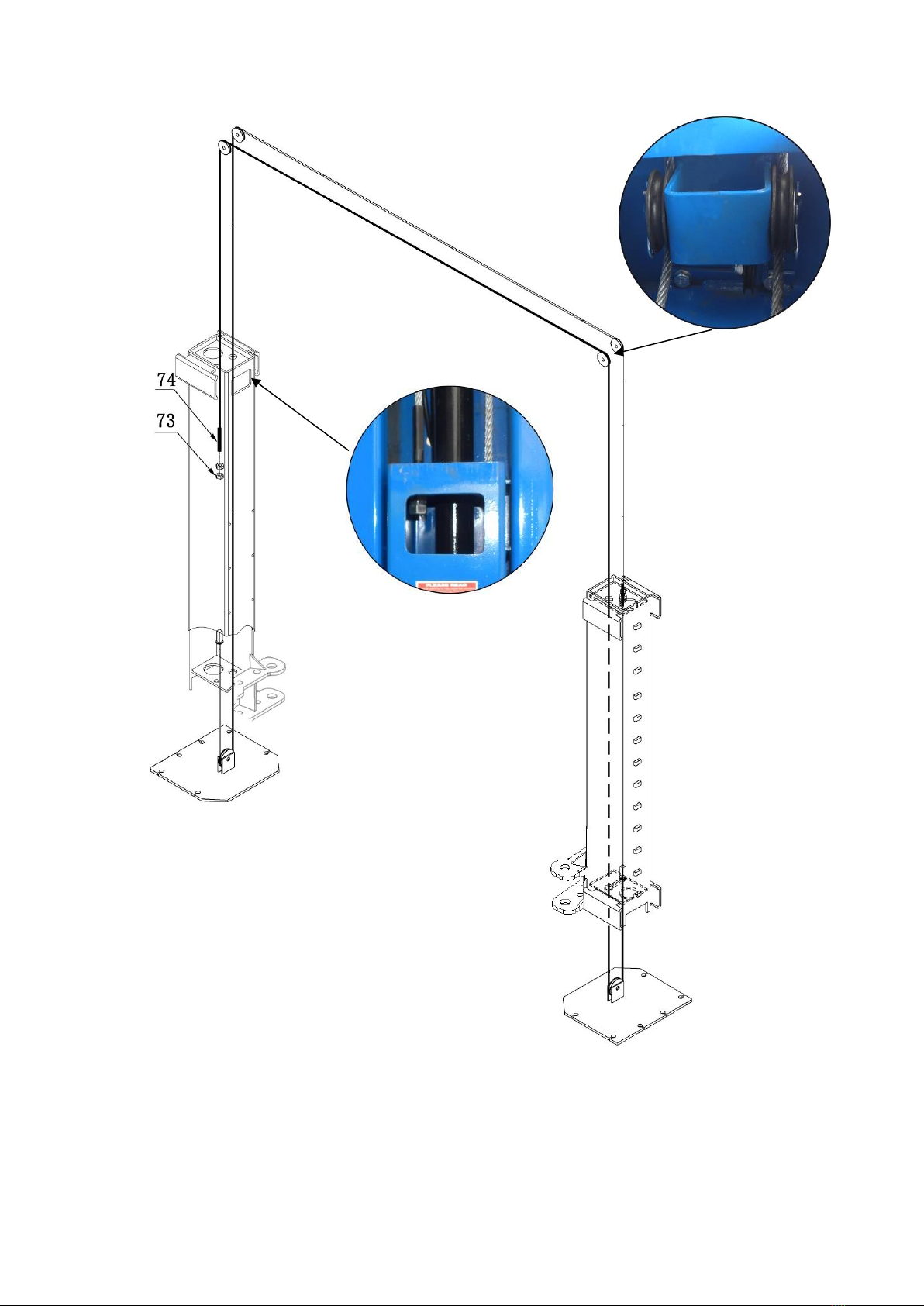

J. Install safety cable (See Fig. 24).

Cable through the bottom of the carriage

Cables pass through the

top plate of the carriages

Fig. 24

74

1. Pass one end of the

cable through the bottom

of the carriage and clamp

it on the slot

2. Pass the other end of

the cable up from the

bottom of the other lifting

carriage

20

74

After

installation

66

13

K. Install cables (See Fig. 25).

Fig. 25

14

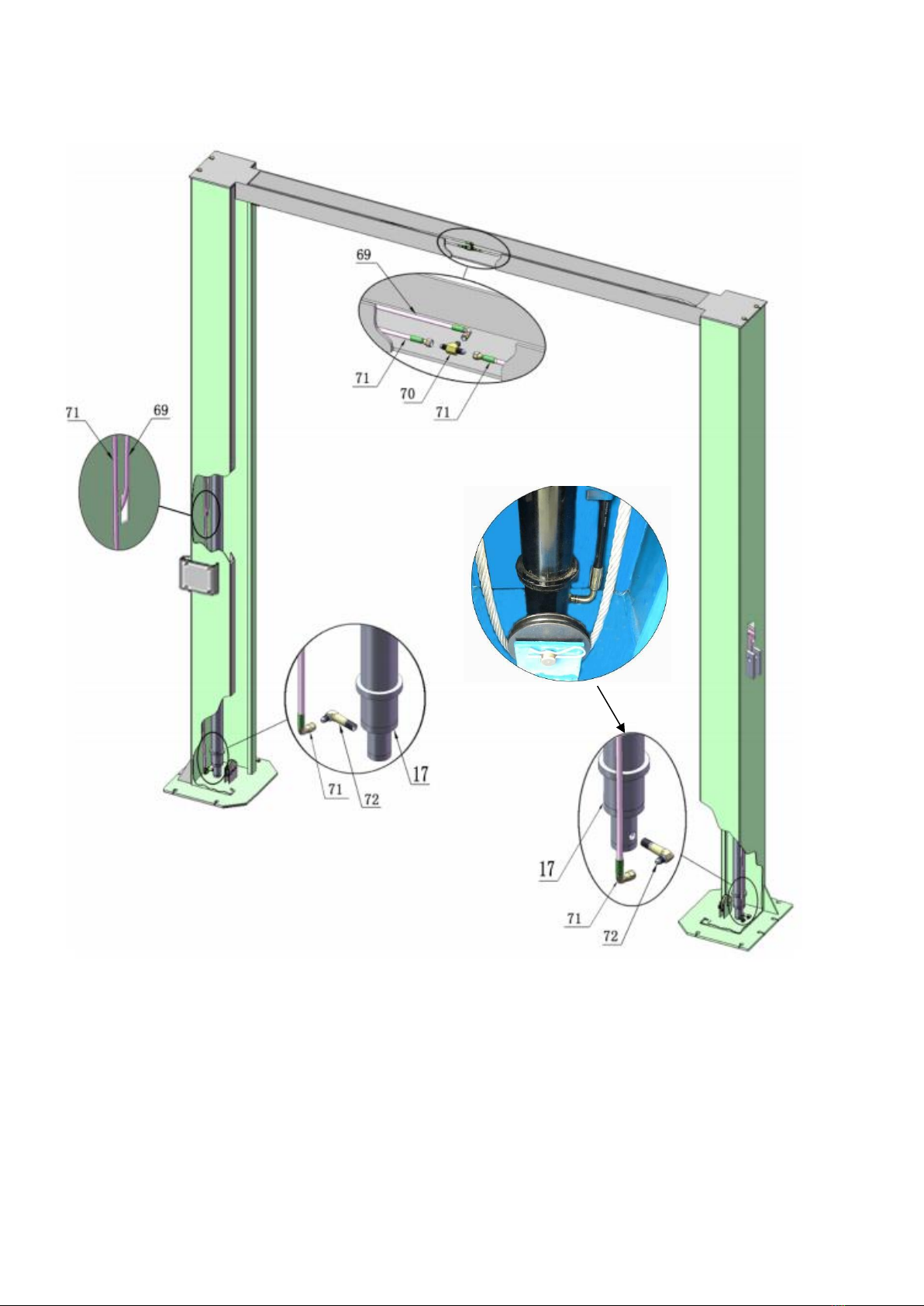

L. Assembly oil hose.

1. For model CL4500 (See Fig. 26).

Fig. 26

15

M. Install power unit and oil hoses (See Fig. 27)

Pay attention to lock the hose joint and power to prevent oil leakage

The hose goes

through the clamp

After installing the fitting of

the power unit, tighten the

nut with 19#Wrench

Fig. 27

16

N. Install safety cable (See Fig. 28).

Pass through safety cable

View A

View B

Fig. 28

17

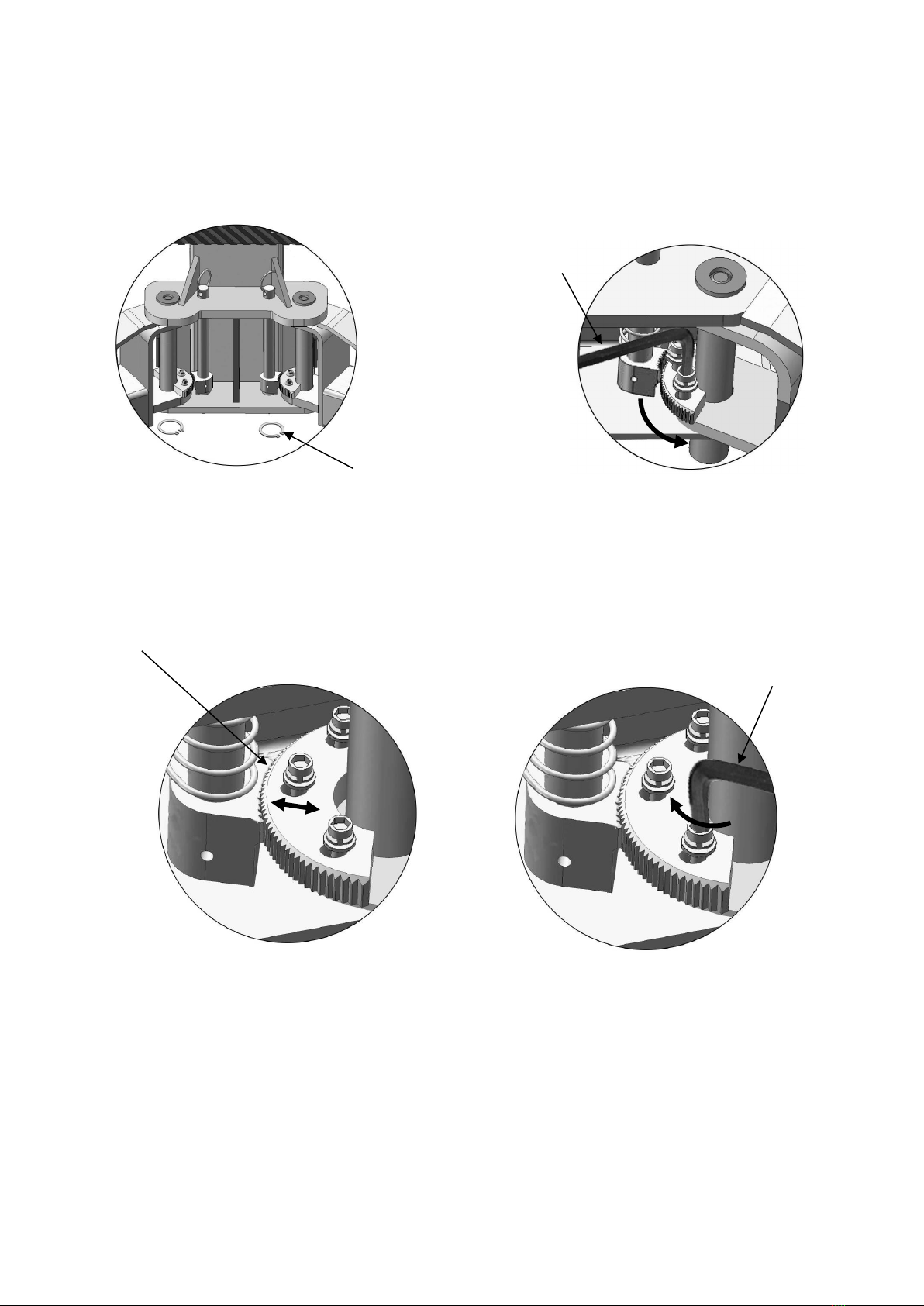

O. Install lifting arms and adjust the arm locks

1. Install the lifting arms (See Fig. 29).

2. Lowering the carriages to the lowest position, then use the 8#wrench to loosen the

nut of arm lock (See Fig. 30).

3. Adjust the arm lock as direction of arrow (See Fig. 31)

4. Adjust the moon gear and arm lock to make it to be meshed, then tighten the nut of

arm lock (See Fig. 32).

P. Tighten all the hydraulic fittings, and fill the reservoir with hydraulic oil.

Note: In consideration of Hydraulic Power Unit’s durability and keep the

equipment running in the perfect condition, please use Hydraulic Oil 46#.

Fig. 29

Fig. 30

Fig. 31

Fig. 32

Lock the nuts after the moon gear

and arm lock are engaged well

Lock the nut

Use the 8#wrench to

loosen the nut

Adjust the moon gear

Snap Ring

18

Q. Install electrical system

Connect the power source on the data plate of power unit.

Note: 1. For safety of operators, the power wiring must contact the floor well.

2. Pay attention to the direction of rotations when using three phase motors.

Single phase motor (See Fig. 33).

1. Connecting the two power supply lines (Active Land Neutral Wire N) to terminals of AC

contactor marked L1, L2 respectively.

2. Connecting the two motor wires to terminals of AC contactor marked T1, T2.

3. Connecting A2 to L2 of AC contactor.

4. Connecting the Limit Switch: Removing the wire of connecting terminal 4# on

control button and terminal A1 on AC contactor firstly (See Fig. 34), then

connecting wire 12# (brown color) of the limit switch with terminal 4# of the

control button and connecting wire 11# (blue color) with terminal A1 on AC

contactor respectively. Connecting the earth wire (green and yellow color) of the

limit switch with earth wire terminal on power unit. (See Fig. 35).

5. Connecting terminal 3# on control button with terminal L1 of AC contactor.

Switch Button

Limit Switch

AC contactor

Limit Switch

Switch Button

Power Supply

AC Contactor

Fig. 33

Table of contents

Other CLASSIC LIFT Lifting System manuals

Popular Lifting System manuals by other brands

ATD Tools

ATD Tools ATD2P11BS Installation & operation manual

ATH-Heinl

ATH-Heinl ATH Comfort Lift 2.35 user manual

Vestil

Vestil EHLTG owner's manual

HOMCOM

HOMCOM 713-087 Assembly & instruction manual

pewag

pewag levo hook LH Series Original operating manual

Southern States

Southern States EV installation instructions

Harmar Mobility

Harmar Mobility AL815CC Installation & owner's manual

Sinoboom

Sinoboom TB18E Plus Maintenance manual

R&M

R&M STAGEMAKER SM1 Technical guide

Schmalz

Schmalz VacuMaster Multi Series operating manual

Tommy Gate

Tommy Gate Railgate 1600 Series quick start guide

ato form

ato form VITA-LIFT user guide