6

Maintenance

Never perform service on the work platform

in the Elevating Assembly area while

platform is elevated without first blocking

the Elevating Assembly.

DO NOT stand in Elevating Assembly area

while installing or removing brace.

DO NOT support or raise the front of the

platform during any maintenance operation

as this may result in damage to the tension

members.

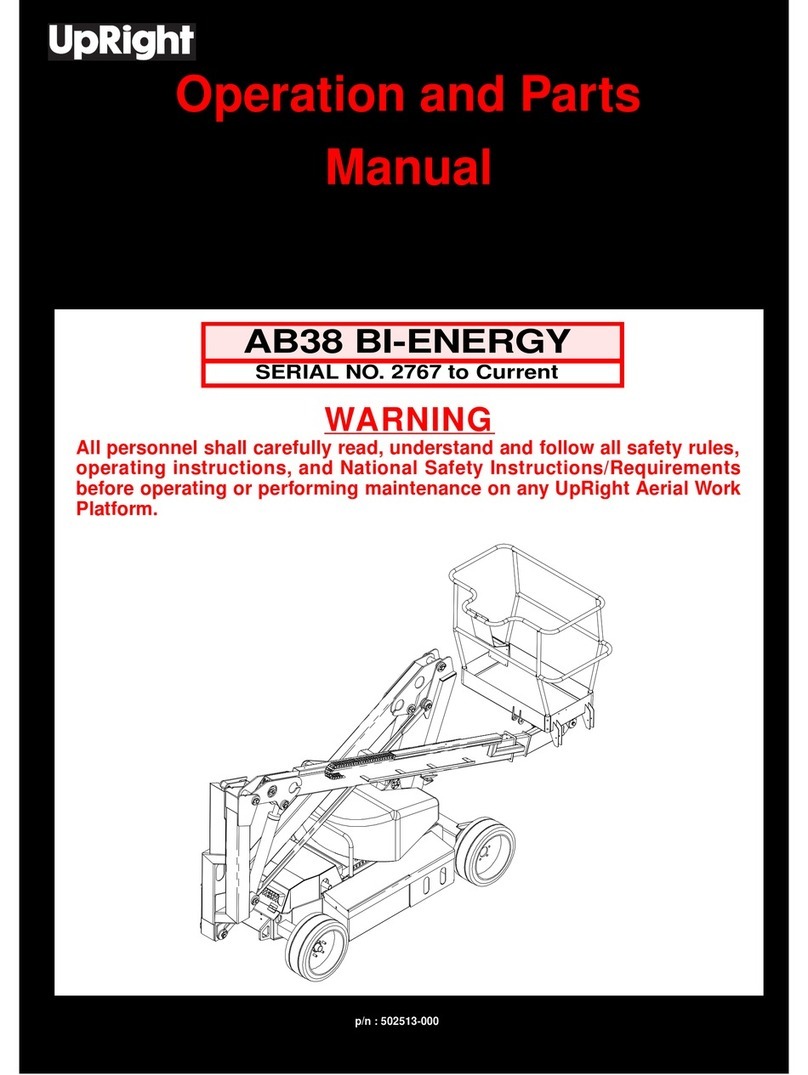

Blocking Elevating Assembly (Figure 6)

Installation

1. Park the work platform on firm level ground.

2. Remove Control Module covers.

3. Verify both Emergency Stop Switches are ON.

4. Turn Chassis Key Switch to CHASSIS.

5. Position Chassis Lift Switch to UP and elevate

platform approximately 12 inches 305 mm).

6. Place a jackstand with a minimum rating of

4,000 lbs. 1,814 Kg) between the Lower Arm

and Chassis just behind the front axle.

7. Push Chassis Lift Switch to OWN position

and gradually lower platform until jackstand is

secured tightly between Lower Arm and Chas-

sis.

Figure 6: Blocking Elevating Assembly

Lower Arm

Jackstand

O NOT lift or

support the

Platform from

the front

Removal

1. Push Chassis Lift Switch to UP position and

gradually raise platform until jackstand can be

removed.

2. Remove jackstand.

3. Push Chassis Lift Switch to OWN position

and completely lower platform.

7

Battery Maintenance

Hazard of explosive gas mixture. Keep

sparks, flame, and smoking material away

from battery ies).

Always wear safety glasses when working

with batteries.

Battery fluid is highly corrosive. Thoroughly

rinse away any spilled fluid with clean water.

Battery Inspection and Cleaning

Check battery fluid level daily, especially if work

platform is being used in a warm, dry climate. If

required, add distilled water ONLY. Use of tap

water with high mineral content will shorten battery

life.

If battery water level is not maintained,

batteries will not fully charge, creating a low

discharge rate which will damage motor/

pump unit and void warranty.

The batteries should be inspected regularly for

signs of cracks in the cases, electrolyte leakage

and corrosion of the terminals. Inspect cables for

worn spots or breaks in the insulation and for

broken cable terminals.

Clean the batteries when there are signs of corro-

sion at the terminals or when electrolyte has

overflowed during charging. Use a baking soda

solution to clean the battery, taking care not to get

the solution inside the cells. Rinse thoroughly with

clean water. Clean battery and cable contact

surfaces to a bright metal finish whenever a cable

is removed.

Battery Charging (Electric Model -Figure 7)

Charge the batteries at the end of each work shift

or sooner if the batteries have been discharged.

Charge the batteries only in a well venti-

lated area.

Do not charge the batteries when the work

platform is in an area containing sparks or

flames.

Permanent damage to the batteries will

result if the batteries are not immediately

recharged after discharging.

Never leave the charger unattended for

more than two days.

Never disconnect the cables from the

batteries when the charger is operating.

Keep the charger dry.

Charge batteries as follows:

1. Check the batteries fluid level. If the electrolyte

level is lower than 3/8 in. 10 mm) above the

plates, add clean, distilled water only.

2. Connect extension cord 12 gauge conductor

minimum and 50 ft. 15 m) in length maximum)

to the charger plug. Connect other end of

extension cord to properly grounded outlet of

proper voltage and frequency.

3. The charger turns on automatically after a

short delay.

4. The charger turns off automatically when the

batteries are fully charged.

Battery Cell Equalization

The specific gravity of the electrolyte in the battery

cells should be equalized monthly. To do this,

charge the battery as outlined in Battery Charging.

After this initial charge, check the electrolyte level

in all cells and add distilled water as necessary.

Then, charge the batteries for an additional 8

hours. During this time, the charging current will be

low 4 amps) as the cells are equalizing.

After equalization, the specific gravity of all cells

should be checked with a hydrometer. The tempera-

ture corrected specific gravity should be 1.260. If the

battery contains any cells with corrected readings

below 1.230, the battery should be replaced.

Do not check the specific gravity in a cell to which

water has just been added. If there is not enough

electrolyte in a fully charged cell to obtain a

sample for the hydrometer, add water and con-

tinue charging for 1 to 2 hours to adequately mix

the water and electrolyte.

Figure 7: Power Module, Chassis Right Side

Charger Plug

Ammeter