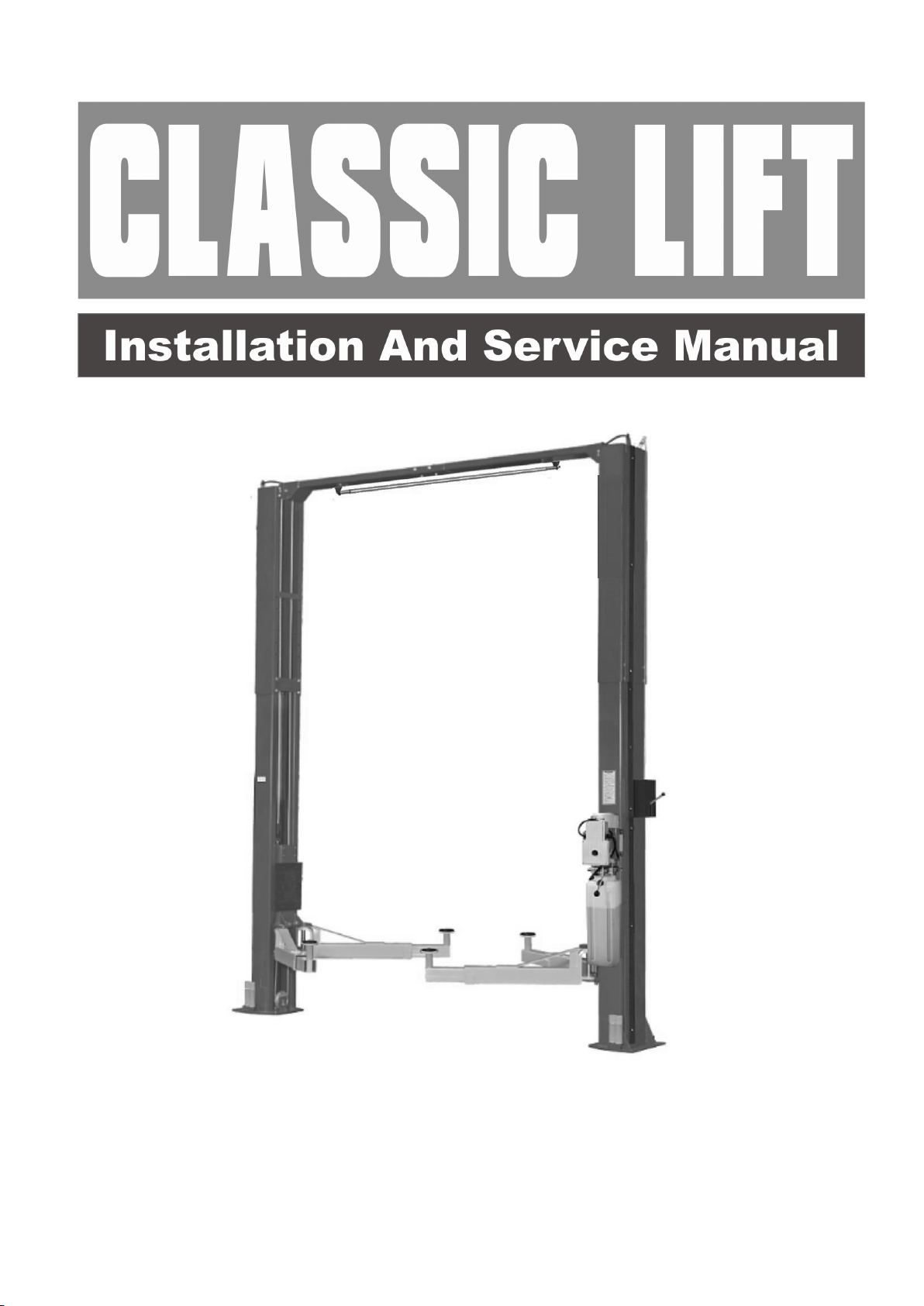

CLASSIC LIFT CL6800C Manual

Table of contents

Other CLASSIC LIFT Lifting System manuals

Popular Lifting System manuals by other brands

TLS

TLS TLS430FDCEx1 Series Installation, operation & service parts manual

Fantek

Fantek T-103 operating instructions

REID LIFTING

REID LIFTING T-DAVIT Series Assembly & operation

Tecnimoem

Tecnimoem Powerlift Up 2 user manual

Challenger Lifts

Challenger Lifts SA10 Installation, operation & maintenance manual

Atlas Equipment

Atlas Equipment BP12000X Installation & operating manual

Dover

Dover BlitzRotary Chief MW80 operating instructions

AMGO Hydraulics

AMGO Hydraulics BP-12 Installation and service manual

WPG

WPG MRTA8 instructions

Sabaj

Sabaj MOBILIFT ECO 650 Assembly and operating manual

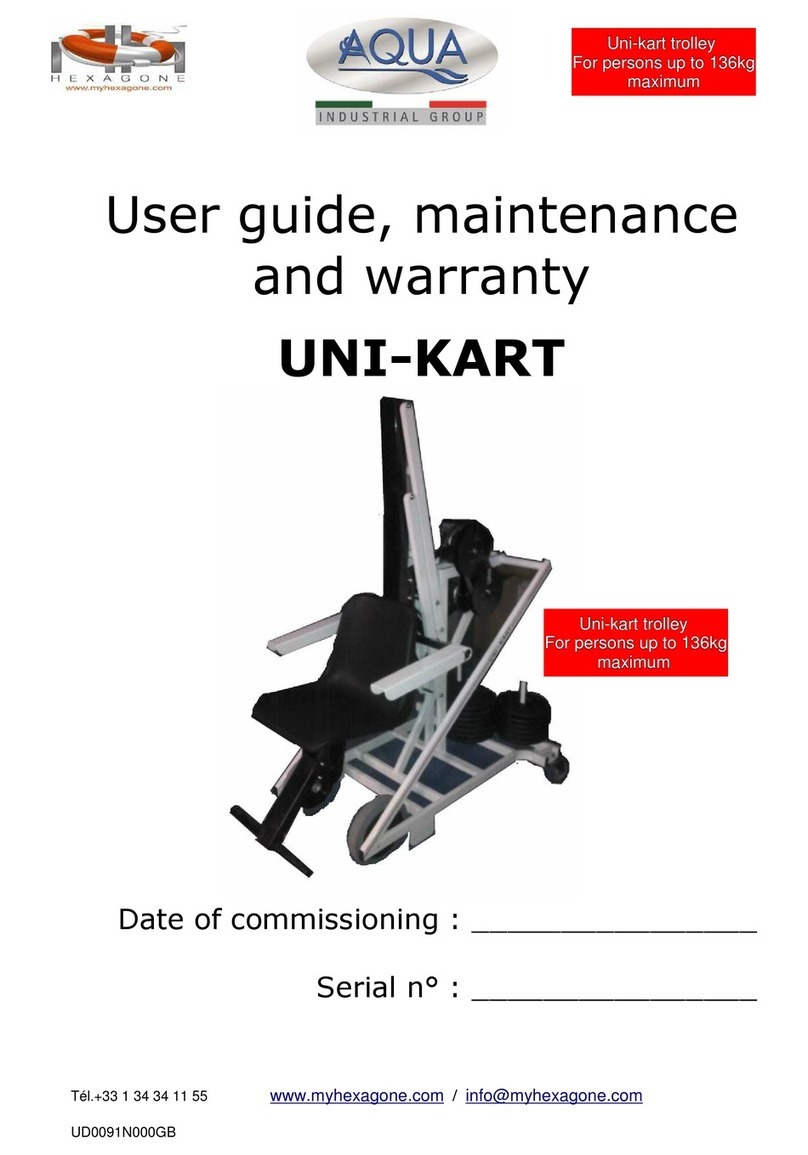

Aqua

Aqua Hexagone UNI-KART User guide, maintenance and warranty

North American Tool

North American Tool 7518 operating instructions