Repair or Warranty Contact Clayton Associates, Inc. • 1650 Oak Street • Lakewood, New Jersey 08701 • P.+1-732-363-2100 F.+1-732-364-6084

Page 3

READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE

When using an electrical appliance, basic precautions should always be followed, including the following:

WARNING

• Do not leave appliance when plugged in. Unplug from outlet when not in use and before servicing.

• This unit is to be used only indoors and in a dry location.

• Use only as described in this manual. Use only manufacturer’s recommended attachments.

• Do not use with damaged cord or plug. If appliance is not working as it should, has been dropped, damaged, left outdoors,

or dropped into water, return it to a service center.

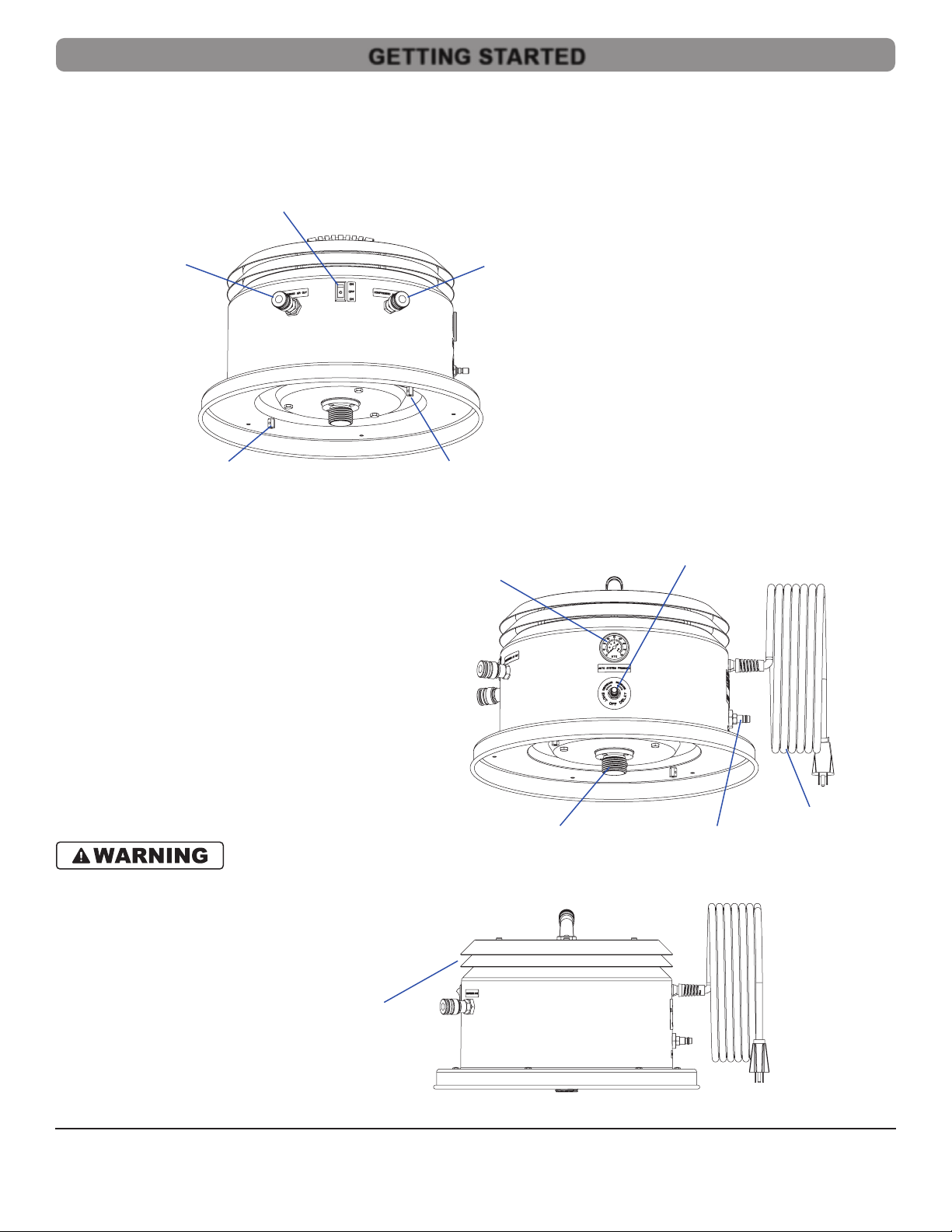

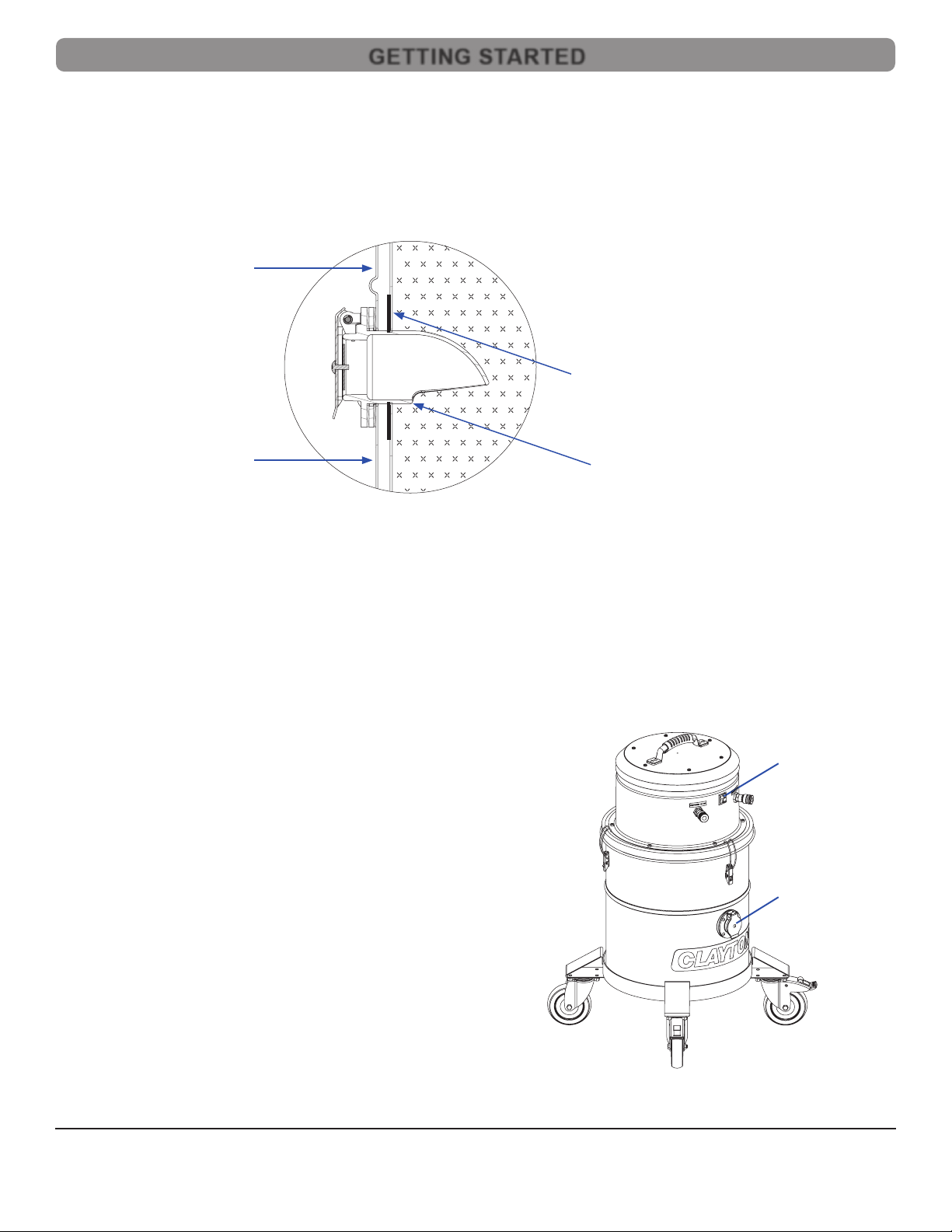

• Handle provided on power head is used only for removal of power head during maintenance.

• Before separation of power head from tank, users must disengage draw latches on tank.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around sharp edges or corners.

• Do not run appliance over cord. Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that may

•

•

• Do not

• Connect to a properly grounded outlet only. Refer to “EARTHING/GROUNDING INSTRUCTIONS” on page 3.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

• Do not

• Do not allow to be used as a toy. Close attention necessary when used by or near children.

EARTHING/GROUNDING INSTRUCTIONS

This appliance must be earthed/grounded. If it should malfunction or breakdown, earthing/grounding provides a path of least resistance

conductor and earthing/grounding plug. The plug must be inserted into an appropriate outlet that is properly installed and earthed/grounded in

accordance with all local codes and ordinances.

WARNING

electrician or service person if you are in doubt as to whether the outlet is properly earthed/grounded. Do not modify the plug provided with the

Refer to Name Plate for electrical requirements.

• USA 120 V

This appliance has a earthing/grounding attachment plug that looks like the

plug illustrated in Figure 1. Make sure that the appliance is connected to an

with this appliance.

• International 120 V

This appliance has an IEC 60309 120 V earthing/grounding attachment plug.

Make sure that the appliance is connected to an outlet having the same

• International 220 V – 240 V

This appliance has an IEC 60309 250 V earthing/grounding attachment plug.

Make sure that the appliance is connected to an outlet having the same

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Figure 1: Earthed/Grounded Outlet and Plug

GL_002

Grounded

Outlet Box

Grounded Outlet

Grounding Pin