Repair or Warranty Contact Clayton Associates, Inc. • 1650 Oak Street • Lakewood, New Jersey 08701 • P.+1-732-363-2100 F.+1-732-364-6084

Page 3

READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE

When using an electrical appliance, basic precautions should always be followed, including the following:

WARNING

• Do not leave appliance when plugged in. Unplug from outlet when not in use and before servicing.

• This unit is to be used only indoors and in a dry location.

• Use only as described in this manual. Use only manufacturer’s recommended attachments.

• Do not use with damaged cord or plug. If appliance is not working as it should, has been dropped, damaged, left outdoors,

or dropped into water, return it to a service center.

• Handle provided on power head is used only for removal of power head during maintenance.

• Before separation of power head from tank, users must disengage draw latches on tank.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around sharp edges or corners.

• Do not run appliance over cord. Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that may

reduce air ow.

• Keep hair, loose clothing, ngers, and all parts of body away from openings and moving parts.

• Turn o all controls before unplugging.

• Do not use to pick up ammable or combustible liquids, such as gasoline, or use in areas where they may be present.

• Connect to a properly grounded outlet only. Refer to “EARTHING/GROUNDING INSTRUCTIONS” on page 3.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

• Do not use without all lters in place.

• Do not allow to be used as a toy. Close attention necessary when used by or near children.

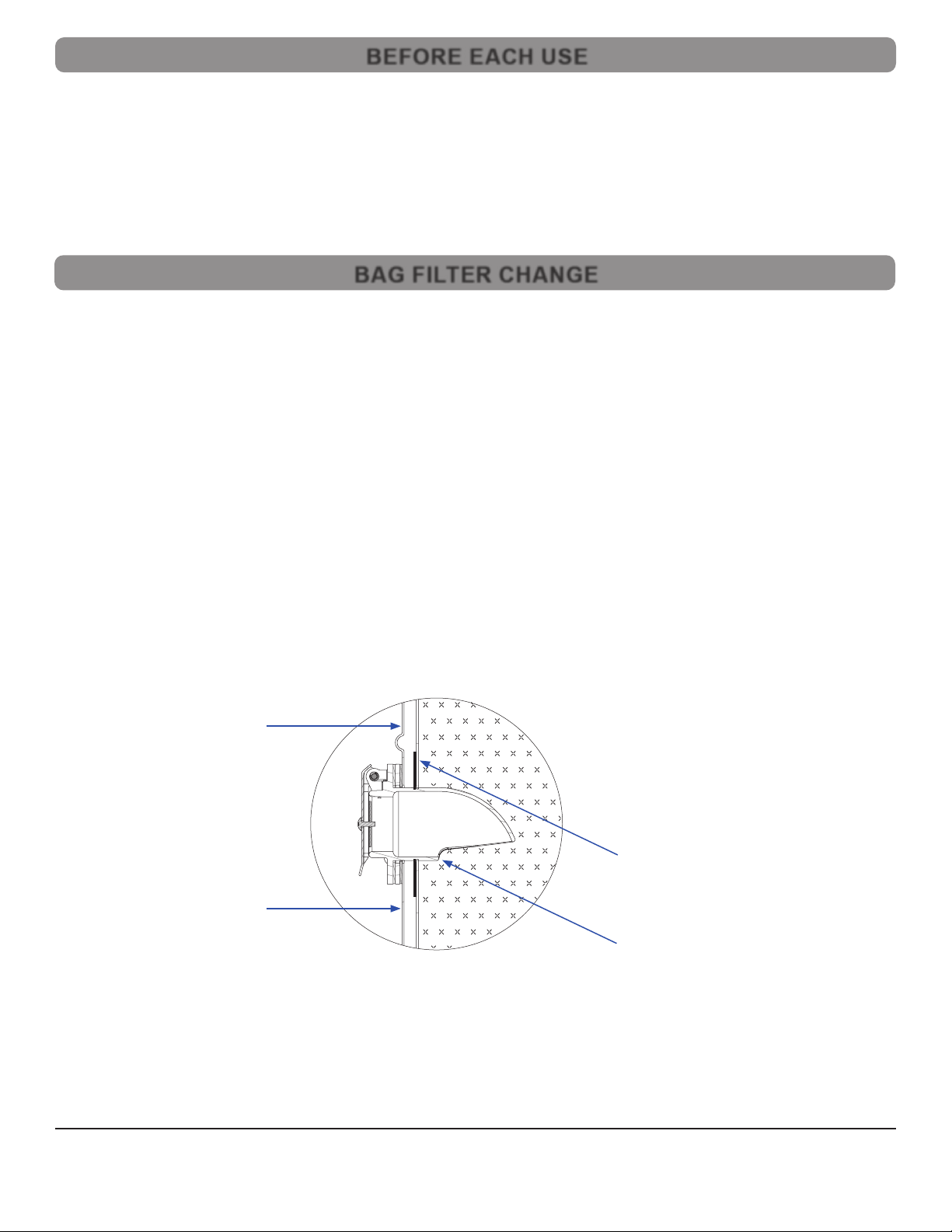

EARTHING/GROUNDING INSTRUCTIONS

This appliance must be earthed/grounded. If it should malfunction or breakdown, earthing/grounding provides a path of least resistance

for electric current to reduce the risk of electric shock. This appliance is equipped with a cord having an equipment-earthing/grounding

conductor and earthing/grounding plug. The plug must be inserted into an appropriate outlet that is properly installed and earthed/grounded in

accordance with all local codes and ordinances.

WARNING – Improper connection of the equipment-earthing/grounding conductor can result in a risk of electric shock. Check with a qualied

electrician or service person if you are in doubt as to whether the outlet is properly earthed/grounded. Do not modify the plug provided with the

appliance – if it will not t the outlet, have a proper outlet installed by a qualied electrician.

Refer to Name Plate for electrical requirements.

• USA 120 V

This appliance has a earthing/grounding attachment plug that looks like the

plug illustrated in Figure 1. Make sure that the appliance is connected to an

outlet having the same conguration as the plug. No adapter should be used

with this appliance.

• International 120 V

This appliance has an IEC 60309 120 V earthing/grounding attachment plug.

Make sure that the appliance is connected to an outlet having the same

conguration as the plug. No adapter should be used with this appliance.

• International 220–240 V

This appliance has an IEC 60309 250 V earthing/grounding attachment plug.

Make sure that the appliance is connected to an outlet having the same

conguration as the plug. No adapter should be used with this appliance.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Figure 1: Earthed/Grounded Outlet and Plug

GL_002

Grounded

Outlet Box

Grounded Outlet

Grounding Pin