Clean Logix BLX-900S-GEN2 User manual

USER

MANUAL

English (Original Instrucons)

Updated: 10/19/21

MODEL:

BLX-900S-GEN2

Compact Walkthrough Boot Scrubber

BLX-900-GEN2 User Manual Page 2 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

!WARNING:

1. All personnel using this unit must be familiar with

the informaon contained in this manual. Follow all

installaon and maintenance instrucons.

2. Always wear appropriate footwear. Secure or remove

loose items on footwear.

3. Ensure solid foong and use both hands when operang

the unit.

4. Avoid contact of chemicals with skin and eyes. If contact

occurs, see MSDS sheet for further rst aid measures.

5. Follow safety instrucons of chemical manufacturer

(MSDS).

6. Always follow plant and OSHA guidelines about the use

of equipment.

7. Disconnect power before servicing equipment.

8. Always follow safety precauons and obey warning

labels. Failure to do so could result in injury or death.

Table of Contents

System Requirements

Installaon

Physical Set-Up

Plumbing Connecons

Motor Speed Adjustment

Operaon

Start Up

Use

Shut Down

Cleaning

Opening Grate

Removing Brushes

03

05

05

06

07

07

07

08

08

Removing Steps

Removing Spring Balancer

Advanced Conguraon

Brush RPM Adjustment

Drive Parameters

Timing Relay

Maintenance

Troubleshoong

Appendices

Parts Callouts

Electrical Schemacs

Non-Diluon Specic

09

09

10

11

11

12

13

14

22

26

BLX-900-GEN2 User Manual Page 3 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Water Supply

• Flow: 1.5 GPM (3.8 L/m) minimum*

• Pressure: 30-60 psi (207-414 kPa)**

• Temperature: 40-100⁰F (4-38⁰C)

Minimum 3/8" supply piping size recommended

*Minimum pressure must be maintained during

specied water ow!

**For consistent operaon of Venturi Injector and

spray nozzles, a water pressure regulator and lter is

recommended.

Electrical

• 115VAC, single phase, 60Hz, 19.1A

(BLX-900S-GEN2-115V)

• 230VAC, single phase, 60Hz, 13.7A

(BLX-900S-GEN2-230V)

• 480VAC, triple phase, 60Hz, 3.9A

(BLX-900S-GEN2-480V)

The BLX-900S-GEN2 is a compact walkthrough, sole-

only, footwear scrubbing unit built to accommodate

1 user at a me with the ability to put through 15-25

users per minute.

The included user manual contain installaon,

operaon, and maintenance instrucons for all BLX-

900S-GEN2 (115V, 230V, or 480V) Boot Scrubbers.

The reference images and diagrams contained within

will vary by model, but are subject to the same

procedures as outlined.

For further support or informaon please contact

your sanitaon representave or Clean Logix technical

support.

Overview

NOTE: A back ow preventer must be installed

in the water line to this unit. Check local

codes to ensure proper installaon.

System Requirements

!

WARNING:

DO NOT EXCEED maximum water

temperature! Damage to brushes can result.

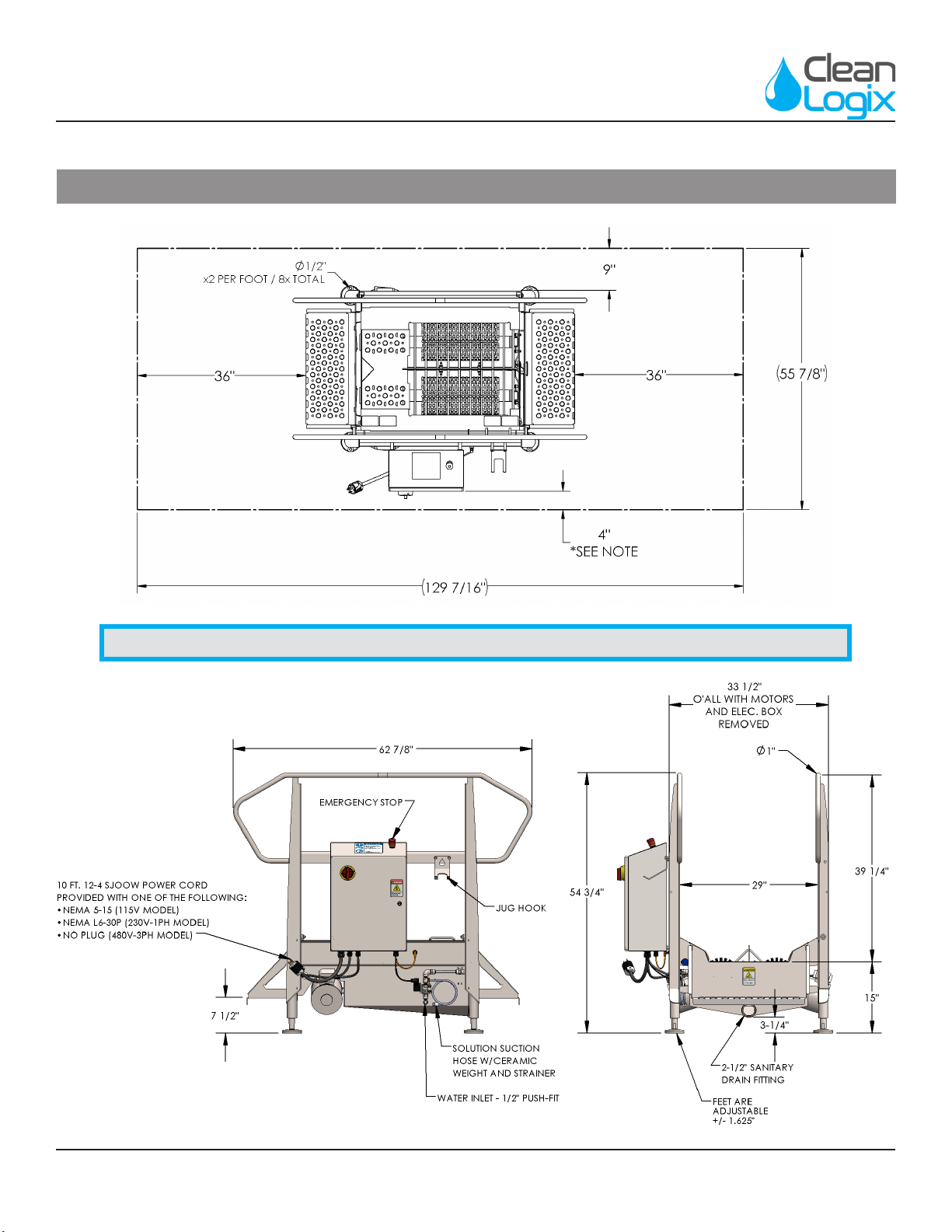

• Construcon: 304L stainless steel, UHMW,

Polypropylene

• Weight: 425 lb (192.78 kg)

• Dimensions: 62 7/8” x 45 3/8” x 54 3/4”

(1,597 x 1,152.5 x 1,390.65 mm)

• Max grate load: 350 lbs. (158.7 kg.)

• Water Consumpon: 0.75-1.5 GPM

(2.8 - 3.8 L/m)

• Minimum Chemical Diluon Rao: 1:230*

Specicaons

*NOTE: Unit tested at 70°F using water with

30-50 psi injector inlet pressure and capillary-

tube style injector metering p.

!

WARNING:

DO NOT use ammable liquids (i.e. alcohol

based soluons or similar) without diluon

unless equipped with a non-diluon ojet kit

(NDF model).

NOTE: Instrucons and specicaons are for

standard units only. See page 26 for units

equipped with Non-diluon kits (NDF).

BLX-900-GEN2 User Manual Page 4 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Installaon

NOTE: For xed installaons, area in front of electrical panel must have at least 36" of clearance.

BLX-900-GEN2 User Manual Page 5 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Physical Set Up:

1. Set unit in desired locaon.

2. Aspects to consider when deciding on placement:

• Clearance for entering and exing

• Locaon of drain

• Emergency exit paths or egress in case of

emergency

• Head room for personnel while using the unit

• Access to control box

• Connecons for water and electricity

3. Use a level to make sure the unit is stable and

leveled at each end of the tub [Figure 5.1].

4. Connect unit to electrical supply.

Plumbing Connecons:

1. Connect water source to solenoid valve quick

ng inlet using 1/2" Polyethylene tubing or

similar [Figure 5.2].

2. If necessary, adjust the diluon rao by selecng

an appropriate metering p (included) and test.

• The smallest metering p is a yellow p with a

small tube aached [Figure 5.3].

• This tube can be trimmed to alter the diluon

rao.

• Full length capillary tube results in a diluon

rao of approximately 1:670 at 30-50 psi

water inlet pressure.

3. With the metering p installed, connect soluon

source to orange hose barb of the Venturi Injector

(located above water inlet) using 1/4" clear PVC

tubing (included) [Figure 5.2].

Installaon

NOTE: To move the unit use a pallet jack or

a hi-lo to li from the boom or using the

handrails. Pad the forks to protect the nish.

Fig. 5.2: Water and Venturi Injector (soluon) inlets

Capillary

Tube

Addional

Metering Tips

Fig. 5.3: Metering Tips and Capillary Tube

Fig. 5.1: Level and stabilize unit using level against end cap of tub

BLX-900-GEN2 User Manual Page 6 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Motor Speed Adjustment

The speed of the motor(s) is controlled by the Variable

Frequency Drive (VFD). To adjust the speed, turn the knob

on the front of the VFD while the unit is under power and

motor is running.

Default: 1750 RPM at 45 Hz

• Recommended speed: 45 Hz

• Minimum speed: 15 Hz

• Maxiumum Speed: 60 Hz

To adjust the speed:

1. Open the control box.

2. Acvate the sensor to turn on the motor.

3. As the motor is spinning, the unit will display the

operang speed in Hz.

4. Turn the knob counter clockwise to decrease the

speed, or clockwise to increase speed. [Figure 6.1]

Installaon (connued)

!

DANGER:

Do not open control box during wash down

or cleaning. Only authorized personnel should

open the control box.

Fig. 6.1: Delta MS300 (AD GS20) Variable Frequency Drive

Speed

Adjustment

BLX-900-GEN2 User Manual Page 7 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Operaon

Fig. 7.2: Grate triggering Prox Switch (some components

hidden for clarity)

Start Up

1. Verify installaon has been completed:

• Brushes are secure

• Walkway grate is lowered

• Unit is plugged in and receiving power

• Water and soluon have been plumbed and

lines are open

2. Pull the E-STOP switches up and engage power,

the E-STOP will illuminate red when the unit is

receiving power [Figure 7.1].

Use

1. Step onto the walkway grate.

2. The walkway grate will depress, acvang a

proximity sensor which starts the brush rotaon

and soluon spray [Figure 7.2].

3. Walk through the unit, allowing the rotang

brushes to clean by moving the boot to make

contact with hard to reach areas.

4. One second aer the user steps o of the

walkway grate the brushes and sanizer will stop.

Shut Down

• Press the red E-STOP buon on the control box.

• Disconnect power and follow lockout-tagout

procedures as necessary.

!

CAUTION:

When operang: always ensure solid foong

and use both handrails for stability.

NOTE: Prior to placing footwear into the unit,

test that it is working properly by acvang

the sensor (put weight on the grate).

Fig. 7.1: E-STOP indicator light on control box

BLX-900-GEN2 User Manual Page 8 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Cleaning Procedures

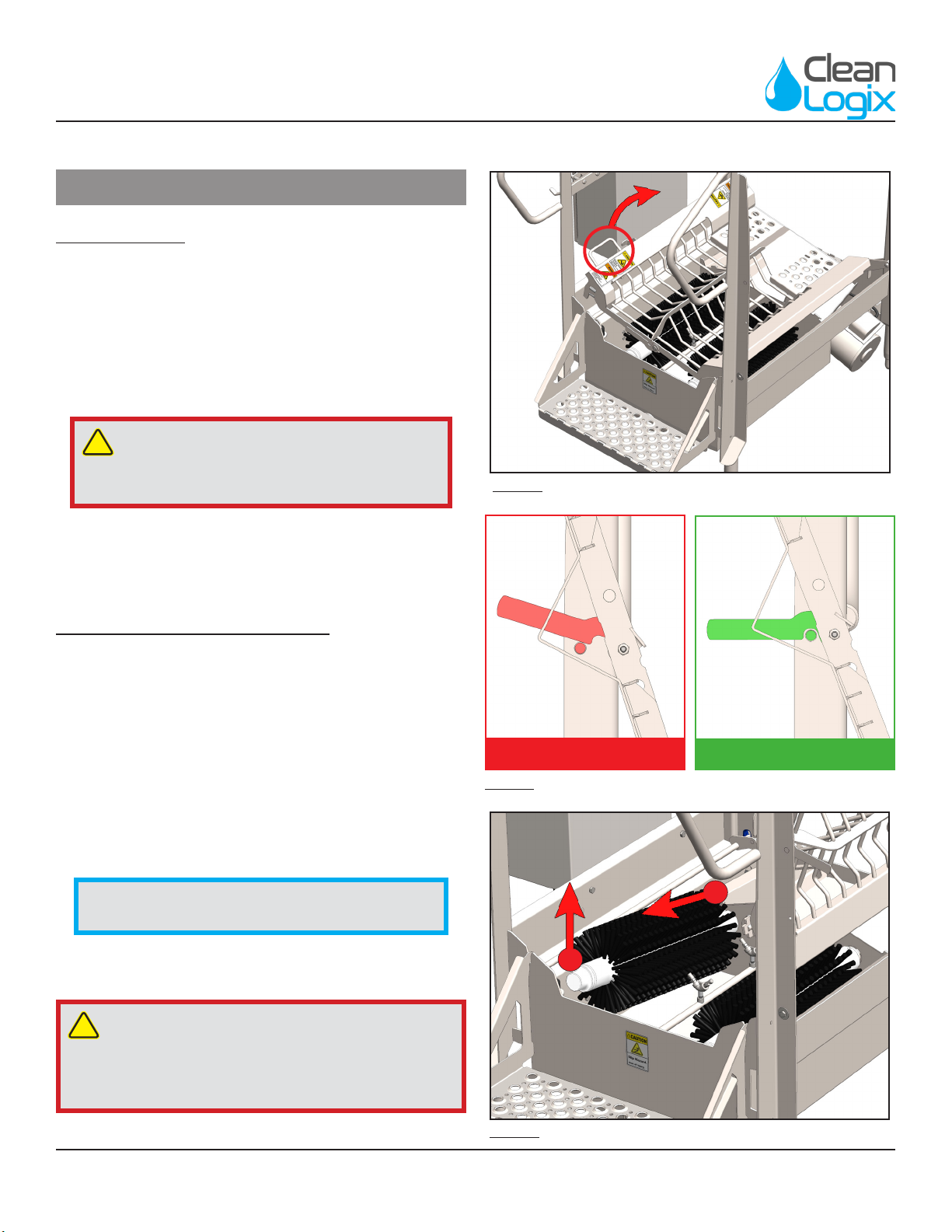

Opening Grate

1. Shut down the unit (see pg. 5) and li the grate up

by its handle [Figure 8.1].

2. Swing the grate open completely

3. Latch into place against the pin aached to the

corner rail [Figure 8.2].

Fig. 8.1: Grate Liing, shown on BLX-1000S

!

CAUTION:

Failure to latch the grate properly could result

in grate falling closed unexpectedly.

INCOMPLETE COMPLETE

Fig. 8.2: Grate Latch Orientaon

!

CAUTION:

Use of high pressure (above 400 PSI) is not

recommended on sensive areas such as electrical

components, motors, or gearboxes.

Removing & Replacing BrusheS

1. Shut down the unit and open the grate.

2. Li each brush out of the tub by grabbing the

open end and liing up [Figure 8.3 - Arrow 1].

3. With the open end lied, the brush can be

detached from its anchor [Figure 8.3 - Arrow 2].

4. Repeat this process to remove the other brush.

5. Brushes can be washed individually in a COP tank

or wash machine.

6. The tub can be washed by convenonal means.

NOTE: It is NOT recommended to use hot water

(over 120°F) to clean brushes.

Fig. 8.3: Brush removal process

2

1

BLX-900-GEN2 User Manual Page 9 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Cleaning Procedures (connued)

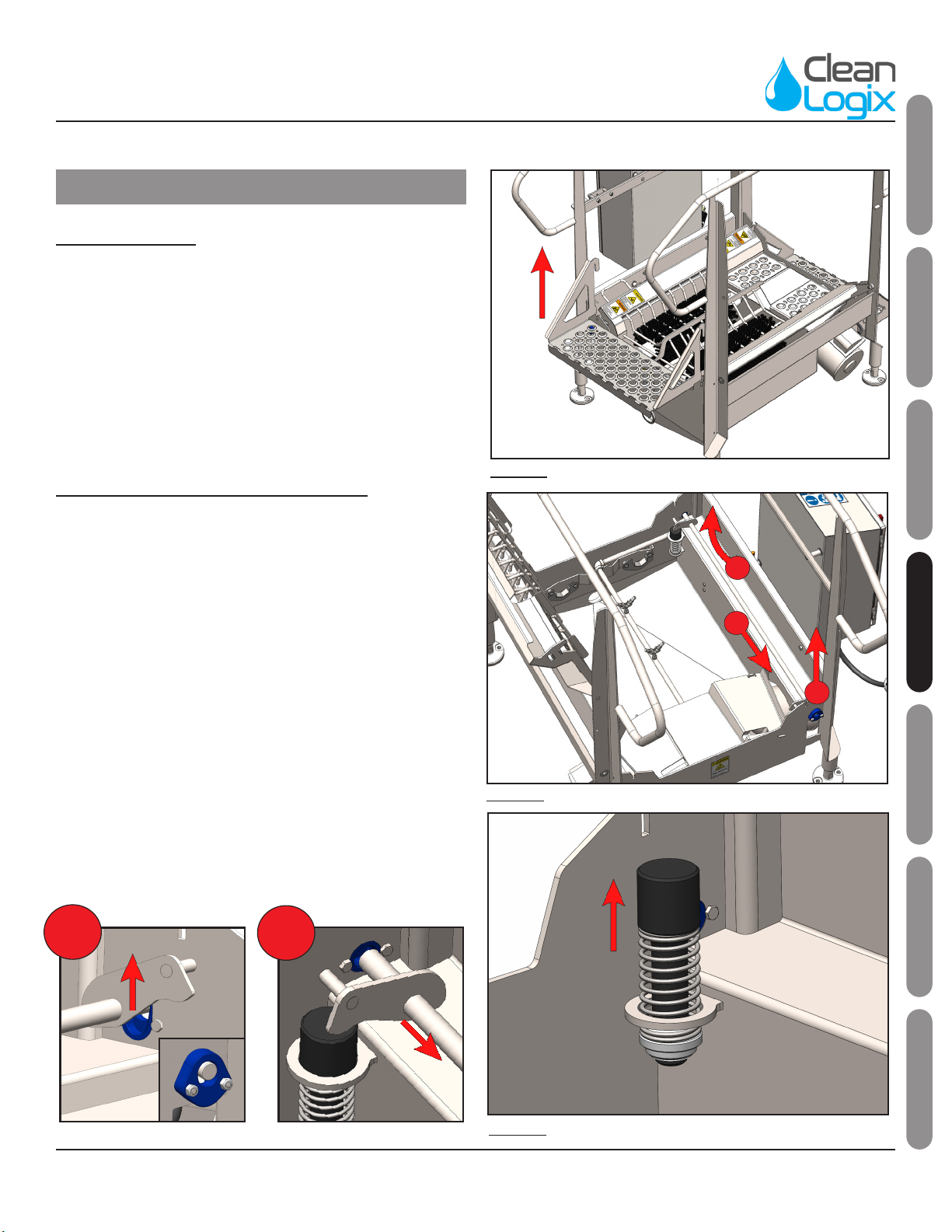

Removing Steps

1. Shut down the unit.

2. Grab either side of the step by the handles.

3. Li up to remove from tub [Figure 10.1].

4. Steps can be washed individually in a COP tank or

wash machine.

5. Replace steps before enabling power and/or use.

Removing Grate Springs & Balancer

1. Open the Grate.

2. Li the end of the Spring Balancer into the upper

secon of its keyhole. [Figure 10.2 - Arrow 1]

3. Slide the Spring Balancer through the upper

secon of the keyhole to release its other end.

[Figure 10.2 - Arrow 2]

4. Li the free end up while sliding the Spring

Balancer out the keyhole to remove from the tub.

[Figure 10.2 - Arrow 3]

5. Slide each spring up to remove them from the tub

[Figure 10.3].

6. Springs and Balancer Weldment can be washed

individually in a COP tank or wash machine.

7. Once clean, re-install in reverse order.

Fig. 10.1: Step removal

Fig. 10.3: Spring removal procedure

Fig. 10.2: Balancer Weldment removal procedure

3

2

2

1

1

BLX-900-GEN2 User Manual Page 10 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Advanced Conguraon Opons

!

DANGER:

Do not open control box during wash down

or cleaning. Only authorized personnel should

open the control box.

Brush RPM Formula:

The formula for calculang Speed in RPM from Drive

Frequency in Hertz is:

[Motor Nameplate RPM] x [Drive Frequency (Hz)]

÷ [Motor Nameplate Frequency (Hz)] ÷ [Gear

Reducon]

Example:

• Motor Nameplate RPM = 1750

• Motor Nameplate Frequency (Hz) = 60

• Gear Reducon = 20

• Drive Frequency (Hz) = 48

1750 x 48 ÷ 60 ÷ 20 = 70 RPM

The formula for calculang Drive Frequency in Hertz

from Desired Speed in RPM is:

[Desired Speed RPM] x [Gear Reducon] x[Motor

Nameplate Frequency (Hz)] ÷ [Motor Nameplate

RPM]

Example:

• Desired Speed in RPM = 70

• Gear Reducon = 20

• Motor Nameplate Frequency (Hz) = 60

• Motor Nameplate RPM = 1750

70 x 20 x 60 ÷ 1750 = 48 Hz

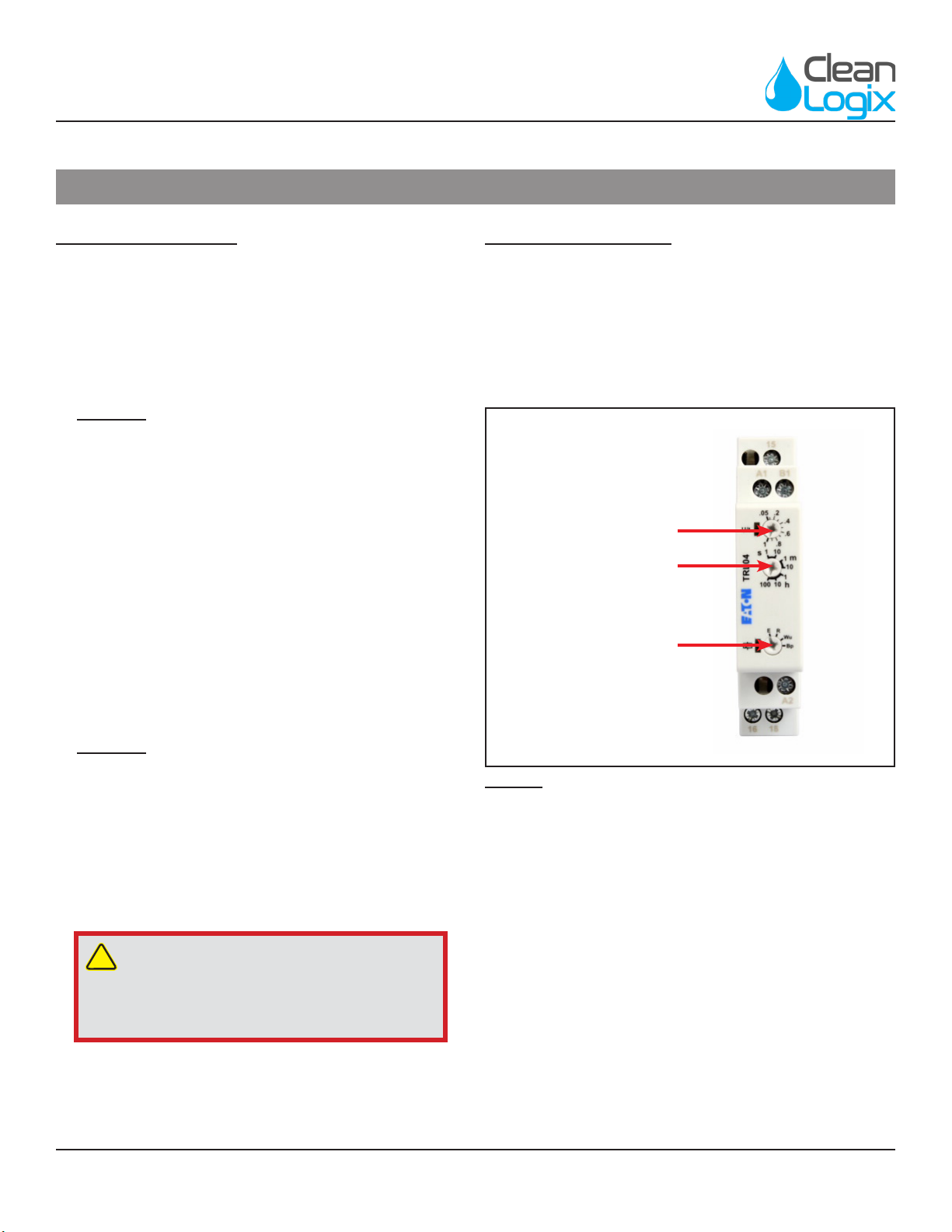

Timing Relay Sengs

Eaton TRL04

• Funcon: R (O Delay)

• Time Range: 1-10 seconds

• Seng: 1 second

FUNCTION

TIME RANGE

ADJUSTMENT RANGE

Fig. 12.2: Eaton TRL04 Seng Idencaon

BLX-900-GEN2 User Manual Page 11 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Advanced Conguraon Opons (connued)

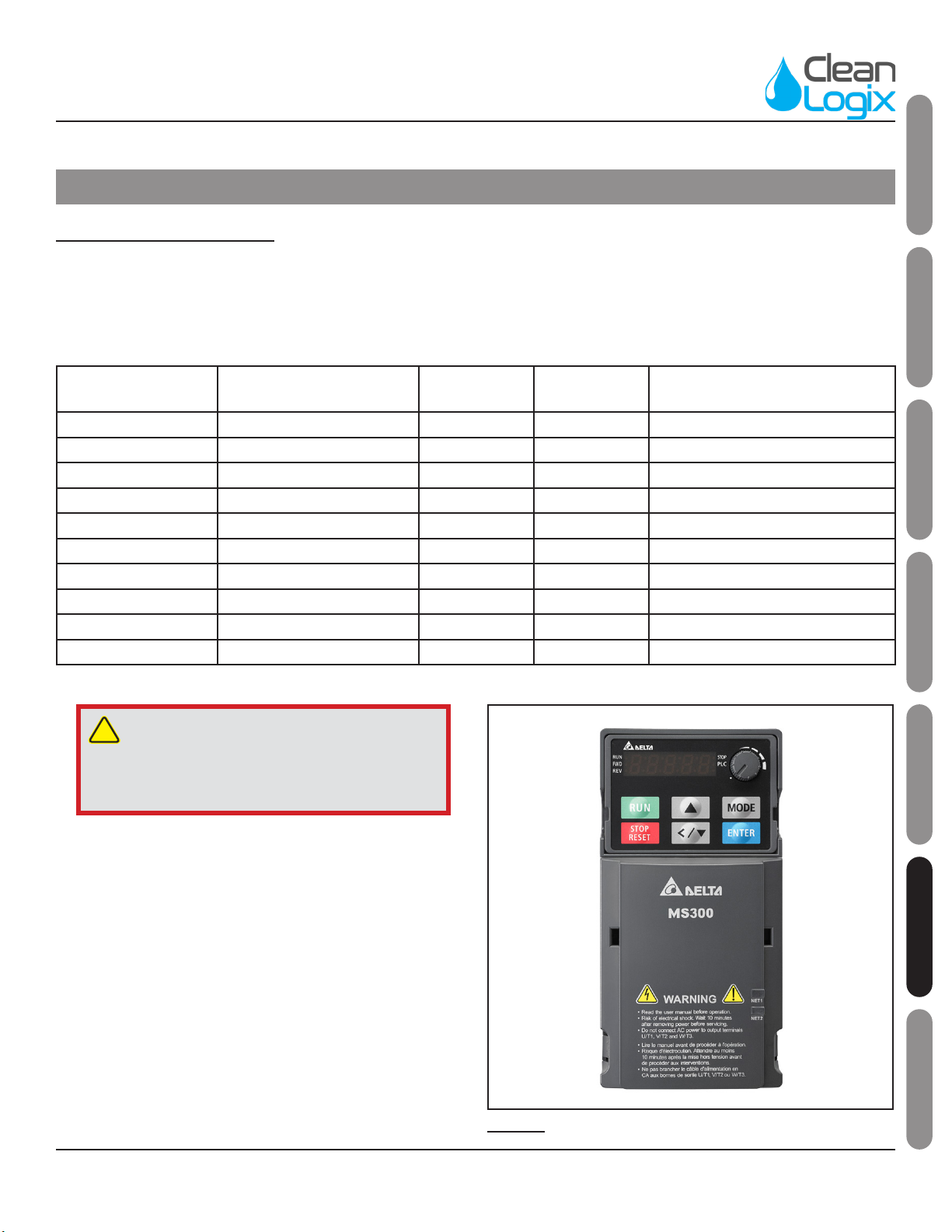

Drive Parameter Sengs

Delta MS300 (AD GS20) Variable Frequency Drive

Review drive specicaons for your system's specic

power requirements (115V, 230V, or 480V).

PARAMETER

NUMBER DESCRIPTION 115V - 230V 480V UNITS/DESC

P00.20 Source of Frequency 7 7 Digital Keypad Dial

P00.21 Source of Oper 1 1 External Terminals

P01.12 1st ACC Time 1 1 Seconds

P01.13 1st DEC Time 2 2 Seconds

P02.13 Mul Funct Relay 22 7 Overcurrent Stall Protecon

P06.03 OCA Level 90 47 Percent

P06.04 OCN Level 90 47 Percent

P06.06 Over TQC1 Method 4 4 Stop Aer Overtorque

P06.07 Over TQC1 Level 90 47 Percent

P06.08 Over TQC1 Time 0.3 0.3 Seconds

!

DANGER:

Do not open control box during wash down

or cleaning. Only authorized personnel should

open the control box.

Fig. 12.1: Delta MS300 (AD GS20) Variable Frequency Drive

BLX-900-GEN2 User Manual Page 12 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

The following maintenance procedures are

recommended for normal use. Units which see a

high amount of daily use should be inspected more

frequently as necessary.

Weekly:

• Check unit for proper sensor funcon and brush

rotaon.

• Ensure spring loaded grate (if applicable) is

funconing properly.

• Inspect brushes for damage or wear. Check for

missing or deformed bristles.

• Inspect electrical cords and plumbing for

damage.

• Inspect and test funcon of emergency stop

switches.

Monthly:

• Check all fasteners to ensure they are ght.

• Ensure warning labels and decals are present

and in good condion.

• Inspect motors, gearboxes, and reducers for

signs of oil leakage.

• Inspect electrical enclosure for signs of water

intrusion.

• Inspect sensors for damage.

• Inspect moving parts for damage or wear.

Quarterly:

• Inspect structure for cracked welds or bent

components.

Gear Reducer:

• The gear reducer is supplied lled to capacity

with Mobil Cibus SHC 634 NSF H1 Food Grade

or equal synthec oil.

• The synthec lubricaon provided is

good for ambient temperatures -10°F -

105°F and is compable with standard

compounded oil.

• Oil should be changed every 2 years (or 6,000

operang hrs.)

• Designed with a bladder type vent system:

• Consists of an internal bladder that

seals the oil chamber from the outside

environment at all mes - as pressure

builds, the bladder contracts keeping the

internal pressure to a minimum.

• Advantage: The internal oil chamber is

completely sealed, ensuring oil is not

released causing contaminaon in the

applicaon.

Motor:

• Inspect at regular intervals.

• Keep clean and venlang openings (on TEFC

motors) clear of any obstrucons.

• Verify the mounng bolts and couplings

to ensure that they are ght and properly

adjusted.

• Motor bearings are sealed and not

re-greasable.

• Bearings should be replaced approximately

every 5 years for 8 hr./day service.

Preventave Maintenance

NOTE: Control box is equipped with a Lock-

Out/Tag-Out switch for restricted power

access when performing maintenance

procedures.

BLX-900-GEN2 User Manual Page 13 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Unit will not operate:

• Follow the startup procedure (pg. 5)

• Verify the control box is closed and the power-

disconnect switch is in the ON posion.

• Verify that there is power going to the unit.

• Verify the circuit breakers in the building

have not been tripped.

Unit will not spray:

• Verify water pressure at the inlet to the water/

soluon solenoid (35 psi min.)

• Inspect spray nozzles for clogging.

• Verify that the orange LED light on the solenoid

valve connector illuminates when the brushes

are rotang.

Green START buon is illuminated, but one

or more brushes will not rotate when unit is

acvated:

• Power cycle the unit by turning the disconnect

switch to OFF and then back to ON. Follow the

start up procedure on Page 6.

OT1 Fault Code "Over-Torque 1" on Variable

Frequency Drive:

The fault occurs when the torque load on any brush

exceeds the value set in parameter P06.03 [OCA

Level]. The soluon will stop spraying when a fault

occurs.

• Switch Disconnect to "OFF" or unplug the unit.

• Wait 20-30 seconds before re-applying power

to cycle power and clear the fault.

Troubleshoong

Unit is leaking onto oor:

• Check to make sure all joints are sealed.

• Verify water and soluon inlets are aached and

rmly in place.

Leaner Diluon Raos Required:

• Verify metering p is installed in the injector

chemical inlet hose barb

• Use the yellow “Capillary Tube” style metering p

(see pg. 4 for further informaon)

• If the desired diluon rao sll cannot be

achieved pre-diluon of the chemical may be

necessary.

Venturi will not draw Chemical Soluon:

• Verify water supply is sustaining 30 psi at the

injector inlet while unit is running

• Elevate the chemical jug above the injector (a jug

hook is provided for this purpose)

• Verify spray nozzles are not clogged. The nozzles

supplied with the equipment are rated at 0.2GPM

@ 10psi (0.28GPM @ 20 psi)

• Ensure the sucon lter is not clogged, kinked or

obstructed in any way that would restrict ow.

BLX-900-GEN2 User Manual Page 14 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

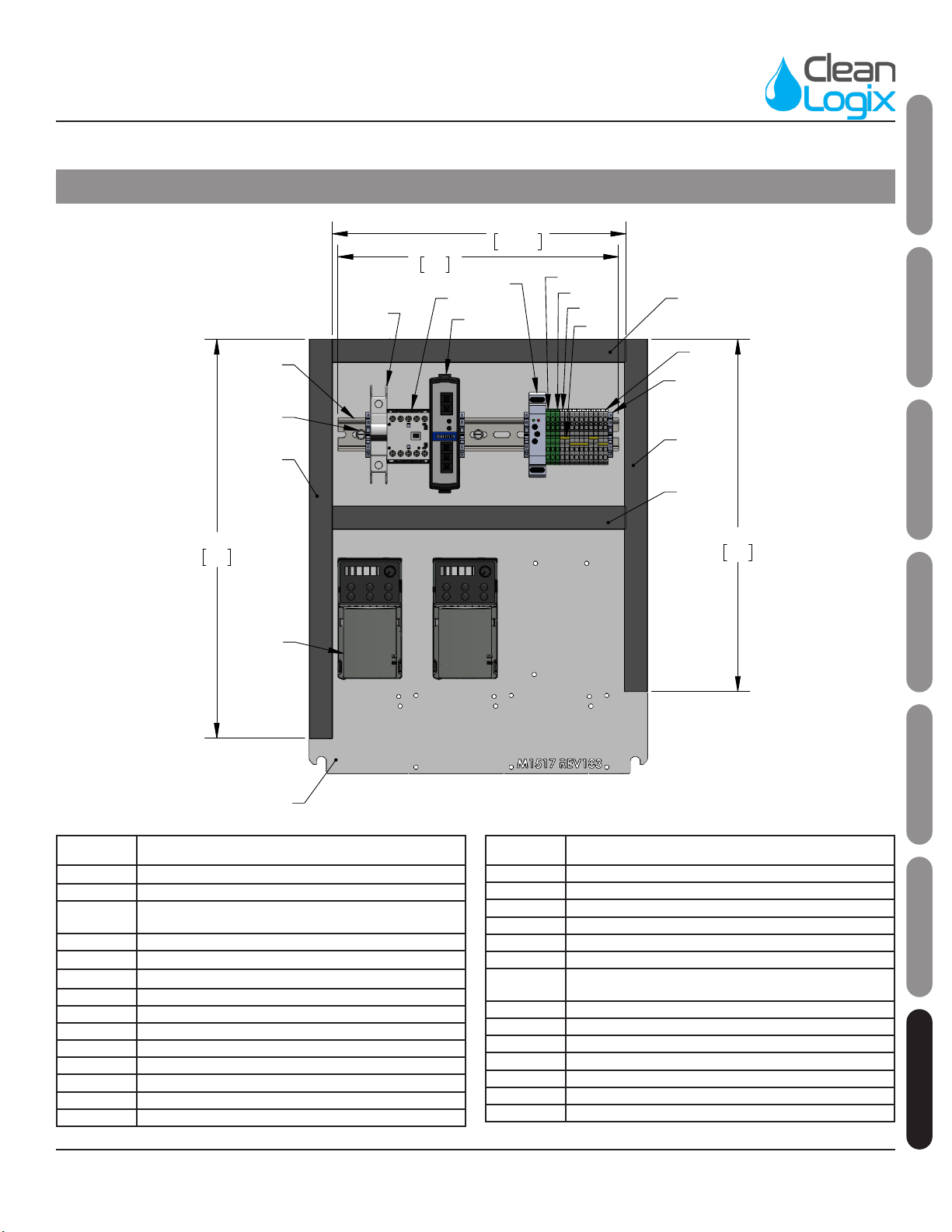

Appendix A - Parts Callout (BLX-900-GEN2)

M2193 (115V)

M2194 (230V)

M2195 (480V)

BLX-900-GEN2 User Manual Page 15 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Appendix A - Parts Callout (BLX-900-GEN2)

Part No. Descripon

F1000 STANDOFF 1/4-20 x 1/2 x 1/2 SS

F1040 BOLT HHC 5/16-18 x 1-1/4 SS

F1047 NUT NYLOCK 1/4-20 SS

F1052 NUT NYLOCK 5/16-18 SS

F1056 WASHER 1/4 SS TYPE A

F1066 NUT NYLOCK 10-32 SS

F1078 WASHER .5 X .88 X .06 UHMW

F1083 BOLT HHC 1/4-20 x 1-1/4 SS

F1085 WASHER FENDER 5/16-18 SS

F1088 BOLT HHC 1/4-20 X 1-3/4 SS

F1126 BOLT HHC 10-32 X 1 SS

F1130 BOLT HHC 5/16-18 X 5/8' SS

F1135 STANDOFF 1/4 X 1/2 X 3/16 SS

F1136 STANDOFF 1/4 X 1/2 X 1 SS

F1139 BOLT SHUTTER 1/4-20 X 1 SS

F1166 BOLT HHC 5/16-18 X 2-1/4' SS

M1134 SOLENOID BRACKET

M1183 DRIVE SHAFT MOTOR-BRUSH WELDMENT

M1237 GRATE LATCH

M1420 BRUSH SUPPORT WELDMENT

M1534 SPACER .313 X .5 X 1.5

M1720 BRUSH BLX HORIZONTAL SOLE

M1746 BLX GEN2 JUG HOOK

M1758 BLX GEN2 GRATE STEPPED HINGE PIN

M1795 BLX FORMED STEP 24 INCH

M1850 BLX-1000 GEN2 SPRAY NOZZLE RISER

WELDMENT

M1851 BLX-1000 GEN2 PIPE NIPPLE

M1852 BLX-1000 GEN2 MOTOR COVER

M1892 BLX-800 GEN2 SPRING BALANCER WELDMENT

V3

M1894 BLX C-CHANNEL GRATE LIFT PIN GLIDE

M1896 BLX GEN2 GRATE SPRING ASSEMBLY

M1904 BLX GEN2 SPRING BALANCER BEARING ROUND

M1905 BLX GEN2 SPRING BALANCER BEARING

SLOTTED

M1981 BLX-900 GEN2 TUB WELDMENT

M1982 BLX-900 GEN2 SPRAY MANIFOLD WELDMENT

Part No. Descripon

M1986 BLX-900 GEN2 GRATE V3 WLDMNT

P1005 STERLING SS MOTOR 1/2HP, 1800 RPM,

230/460/3/60, TENV, 56C FOOTLESS

P1006 STERLING GEAR REDUCER 20:1, 56C

P1046 VALVE, SOLENOID, 3/8" SS 24VDC DIN COIL, DEMA

463PS.4D

P1121 Induce Proxy 18mm PP 8mm RN 4-Wire DC

N.E./M.C. M12 IQ/D Shielded

P1147 CORD GRIP 1/2 NPT X .170-.450 BLK HEYCO M3231

P1148 CORD GRIP NUT 1/2' NPT BLACK - HEYCO 8463

P1187 SOLENOID CABLE 18MM DIN 24V LED 3M SC18-

LS24-3

P1242 TERMINAL, 1/4" RING, 14-16 AWG INS

P1252 PIPE PLUG 1/4" NPT SOCKET HD SS

P1331 1/2" OD POLYETHYLENE TUBING - NATURAL

P1400 CABLE, M12, 4 POLE, 5m (16.48 ), RT-ANG

FEMALE/AXIAL MALE

P1418 QUICK FIT ADAPTER 3/8 NPT X 1/2 TUBE PP

P1511 QUICK FIT STEM ELBOW 1/2' X 1/2'

P1599 METERING TIP, CAPILLARY TUBE

P1769 METERING TIPS, ULTRA LEAN 100-15KU

P1828 WIRE, VFD-MOTOR, 14 AWG, 4-CONDUCTOR,

SHIELDED, XLPE/PVC

P1830 PIPE ELBOW 3/8" x 90 304SS

P1903 VENTURI INJECTOR DEMA ROCKET, ORANGE,

.070", 1.3GPM@100PSI, SINGLE BARB

P1934 GREASE, ELECTRIC INSULATING .17OZ ONE TIME

USE PACK

P1944

NOZZLE, FAN SPRAY, 110 DEGREE, 1/8 MNPT,

304SS, FLOODJET TYPE K, 0.2 GPM @ 10 PSI

(1/8KSS-2)

P1945 VENTURI INJECTOR 1/4" SUCTION LINE AND

STRAINER

P1946 VENTURI INJECTOR SUCTION WEIGHT CERAMIC

FOR 1/4" TUBE

BLX-900-GEN2 User Manual Page 16 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

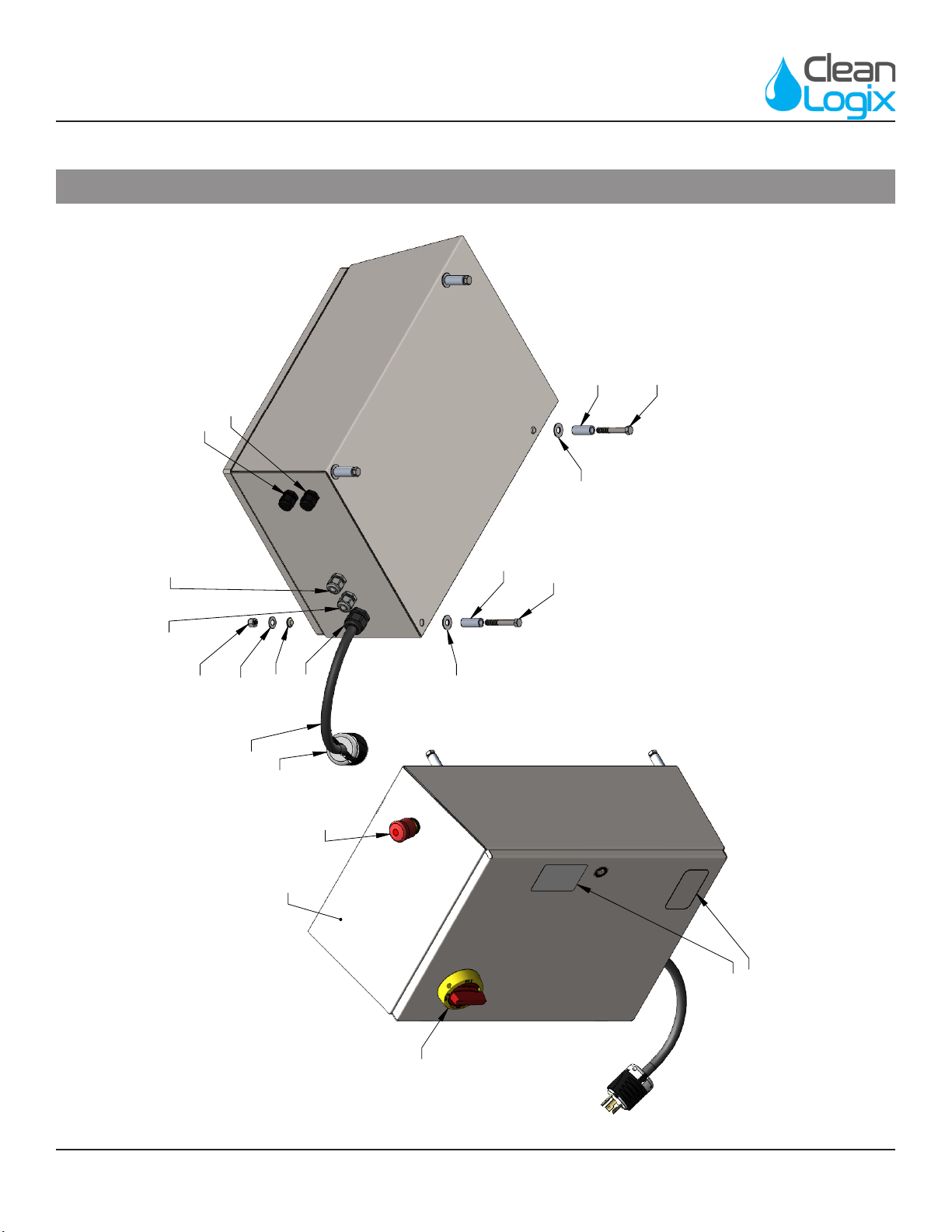

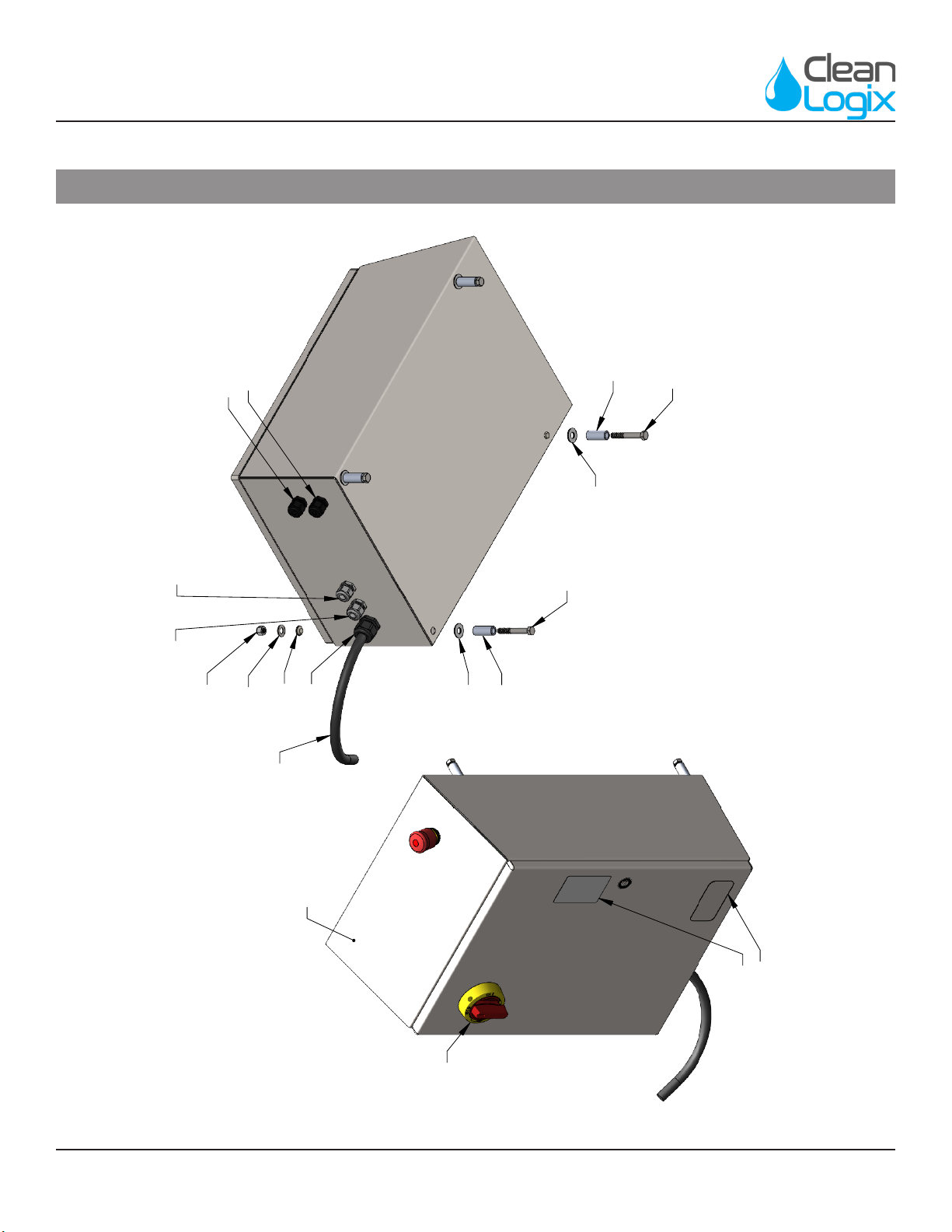

Appendix A - Parts Callout (M2193 : 115V, 1PH)

P1449

P1228

P1246

M1888

F1177

F1177

F1140

F1140

NONE

NONE

F1059

P1361

P1184

P1515

P1184

P1515

M1819

M1819

P1585

M2193 - 115V, 1PH

FOR ELECTRICAL SCHEMATIC, REFER TO

DRAWING NUMBER

ES1043

BLX-900-GEN2 User Manual Page 17 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Appendix A - Parts Callout (M2193 : 115V, 1PH)

14 3/4"

375

12 1/4"

312.50

16 3/4"

425

11 3/4"

299

P1172

P1172

P1172

P1172

P1169

P1122

P1939

P1111

F1172

P1874

P1874

P1873

P1880

P1881

M1517

P2429

P2444

P2052

FOR ELECTRICAL SCHEMATIC, REFER TO

DRAWING NUMBER

ES1043

M2193 - 115V, 1PH

Part No. Descripon

F1059 NUT NYLOCK 3/8-16 SS

F1140 WASHER SEALING 3/8 X 1 SS

F1172 SCREW THEAD FORMING 10-32 X 1/2 HEX WASHER

HEAD ZINC

F1177 BOLT HHC 3/8-16 X 2-1/2 SS

M1819 SPACER 3/8" X 1-1/2" SS

P1111 END STOP TERMINAL BLOCK

P1122 POWER SUPPLY 24VDC 60W

P1148 CORD GRIP NUT 1/2 NPS NYL

P1169 DIN RAIL 35mm X 300mm LONG

P1172 WIRE DUCT 25X60 X 312mm LONG

P1172 WIRE DUCT 25X60 X 375mm LONG

P1172 WIRE DUCT 25X60 X 425mm LONG

P1184 CORD GRIP 1/2 NPT X .095-.260 BLK

P1200 PLUG NEMA 5-15P

Part No. Descripon

P1228 ENCLOSURE HOFFMAN CONCEPT CSD20168SSST

P1246 LABEL DANGER ELECTRICAL

P1361 CORD GRIP 3/4 NPT X .435-.705 BLK

P1363 CORD GRIP NUT 3/4 NPT NYLON

P1449 E-STOP PUSH PULL ILLUMINATED 22mm 2NC

P1515 CORD GRIP PG16 X .260-.545 GREY W/NUT

P1585 WIRE SJOOW 12AWG 4 CONDUCTOR BLACK (0.650 OD)

600V 02726.41T.01

P1873 TERMINAL BLOCK SPRING CLAMP 5.1mm GRAY

P1874 TERMINAL BLOCK SPRING CLAMP 5.1mm GROUND

P1880 TERMINAL JUMPER 5.1mm

P1939 RELAY, TIMER, MULTIFUNCTION 24VDC

P2052 CIRCUIT BREAKER 20A, SINGLE POLE, D-CURVE

P2429 VARIABLE FREQUENCY DRIVE MS300 0.5HP 115-1PH

P2444 IEC CONTACTOR 3P 16A 24VDC 1 NO AUX CONTACTOR

BLX-900-GEN2 User Manual Page 18 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Appendix A - Parts Callout (M2194 : 230V, 1PH)

P1820

P1449

P1228

P1246

P1819

M1888

F1177

F1177

F1140

F1140

NONE

NONE

F1059

P1361

P1184

P1515

P1184

P1515

M1819

M1819

P1585

P1533

M2194 - 230V, 1PH

FOR ELECTRICAL SCHEMATIC, REFER TO

DRAWING NUMBER

ES1045

BLX-900-GEN2 User Manual Page 19 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

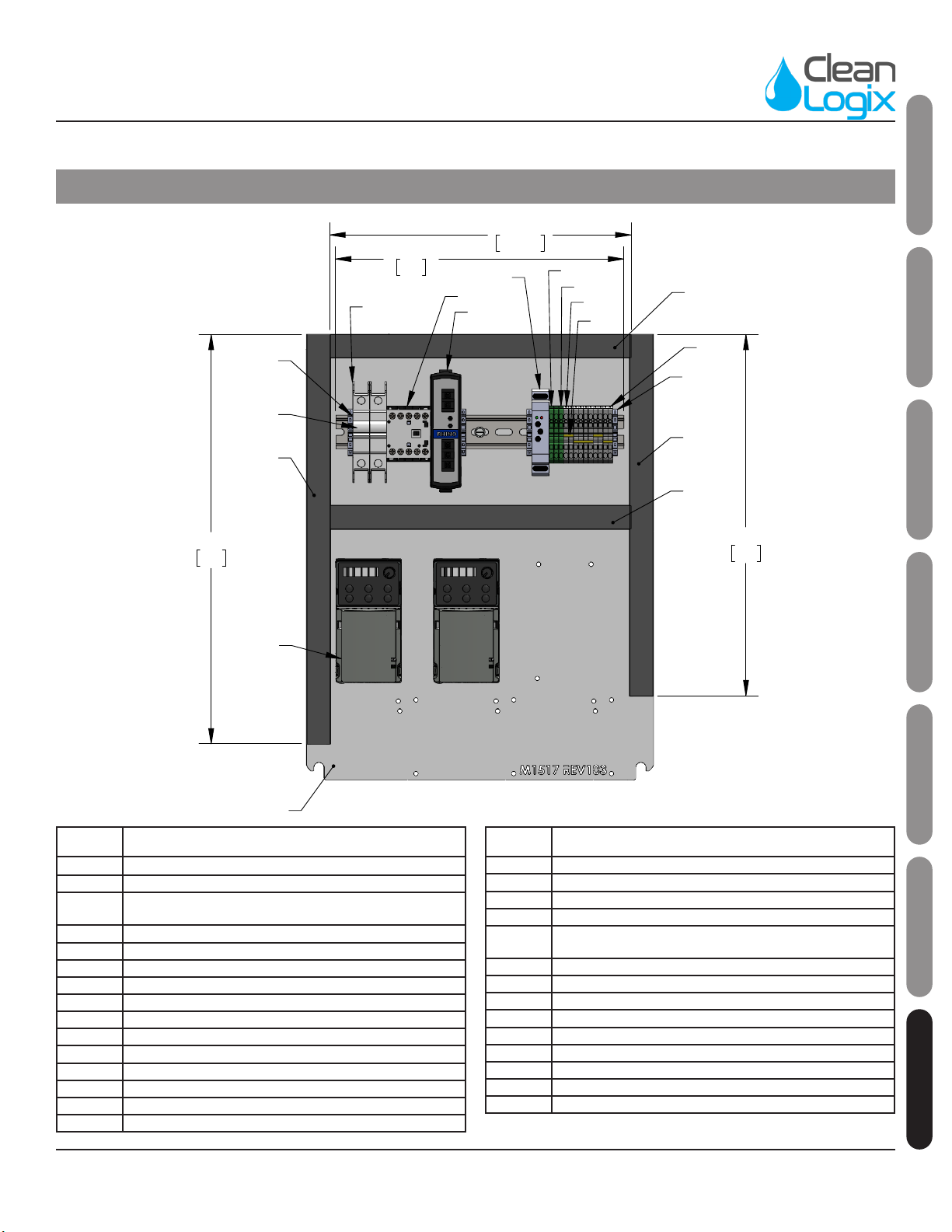

Appendix A - Parts Callout (M2194 : 230V, 1PH)

14 3/4"

375

12 1/4"

312.50

16 3/4"

425

11 3/4"

299

P1172

P1172

P1172

P1172

P1169

P1325 P1122

P1939

P1111

F1172

P1874

P1874

P1873

P1880

P1881

M1517

P2430

P2444

FOR ELECTRICAL SCHEMATIC, REFER TO

DRAWING NUMBER

ES1045

M2194 - 230V, 1PH

Part No. Descripon

F1059 NUT NYLOCK 3/8-16 SS

F1140 WASHER SEALING 3/8 X 1 SS

F1172 SCREW THEAD FORMING 10-32 X 1/2 HEX WASHER HEAD

ZINC

F1177 BOLT HHC 3/8-16 X 2-1/2 SS

M1819 SPACER 3/8" X 1-1/2" SS

P1111 END STOP TERMINAL BLOCK

P1122 POWER SUPPLY 24VDC 60W

P1148 CORD GRIP NUT 1/2 NPS NYL

P1169 DIN RAIL 35mm X 300mm LONG

P1172 WIRE DUCT 25X60

P1184 CORD GRIP 1/2 NPT X .095-.260 BLK

P1228 ENCLOSURE HOFFMAN CONCEPT CSD20168SSST

P1246 LABEL DANGER ELECTRICAL

P1325 CIRCUIT BREAKER 13A DOUBLE POLE

P1361 CORD GRIP 3/4 NPT X .435-.705 BLK

Part No. Descripon

P1363 CORD GRIP NUT 3/4 NPT NYLON

P1449 E-STOP PUSH PULL ILLUMINATED 22mm 2NC

P1515 CORD GRIP PG16 X .260-.545 GREY W/NUT

P1533 250V 30A L6-30 MALE PLUG

P1585 WIRE SJOOW 12AWG 4 CONDUCTOR BLACK (0.650 OD)

600V 02726.41T.01

P1758 LABEL - UL508 PANEL

P1819 DISCONNECT SWITCH 25A 3-POLE

P1820 DISCONNECT HANDLE KIT RED/YELLOW FOR P1819

P1873 TERMINAL BLOCK SPRING CLAMP 5.1mm GRAY

P1874 TERMINAL BLOCK SPRING CLAMP 5.1mm GROUND

P1880 TERMINAL JUMPER 5.1mm - 10 POSITION CUT TO 2

P1939 RELAY, TIMER, MULTIFUNCTION 24VDC (REPLACES P1115)

P2430 VARIABLE FREQUENCY DRIVE MS300 0.5HP 230-1PH

P2444 IEC CONTACTOR 3P 16A 24VDC 1 NO AUX CONTACTOR

BLX-900-GEN2 User Manual Page 20 of 29 Updated: 10/19/21

USER MANUAL: BLX-900S-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Appendix A - Parts Callout (M2195 : 480V, 3PH)

P1246

P1820

P1228

P1819

M1888

F1177

F1177

F1140

F1140

NONE

NONE

F1059

P1361

P1184

P1515

P1184

P1515

M1819

M1819

P1585

FOR ELECTRICAL SCHEMATIC, REFER TO

DRAWING NUMBER

ES1047

M12195 - 480V, 3PH

Table of contents

Other Clean Logix Cleaning Equipment manuals

Clean Logix

Clean Logix ALX-OMNI-LITE User manual

Clean Logix

Clean Logix BLX-1000-GEN2 User manual

Clean Logix

Clean Logix ALX-PRO User manual

Clean Logix

Clean Logix BLX-600-GEN2 User manual

Clean Logix

Clean Logix BLX-800-GEN2 User manual

Clean Logix

Clean Logix BLX-400 User manual

Clean Logix

Clean Logix BLX-700-GEN2 User manual

Clean Logix

Clean Logix EPX-TM User manual

Popular Cleaning Equipment manuals by other brands

Bissell

Bissell SPOTCLEAN AUTO 4720K user guide

Ultrawave

Ultrawave Q Series Operator's instruction manual

Nilfisk-Advance

Nilfisk-Advance Liberty SC50 Instructions for use

Kwunphi

Kwunphi Kwun-E22H manual

Alfalaval

Alfalaval Gunclean Toftejorg TZ-75 instruction manual

SkyVac

SkyVac Internal 37 Assembly & user's guide