8Compact-S Model 350 - Parts Cleaning System

Owner’s Manual

Start Up Instructions

Please be sure to read and observe, the “SAFETY INSTRUCTIONS” at the

beginning of this manual. Detailed start-up instructions can also be found at

www.biocircle.com.

1. Remove the BIO-CIRCLE®Parts Cleaning System from its packaging

and check for any shipping damage. Should any be detected, DO NOT

connect the machine but report the damage to the transport carrier and

to Walter. Important: The original packaging must be retained.

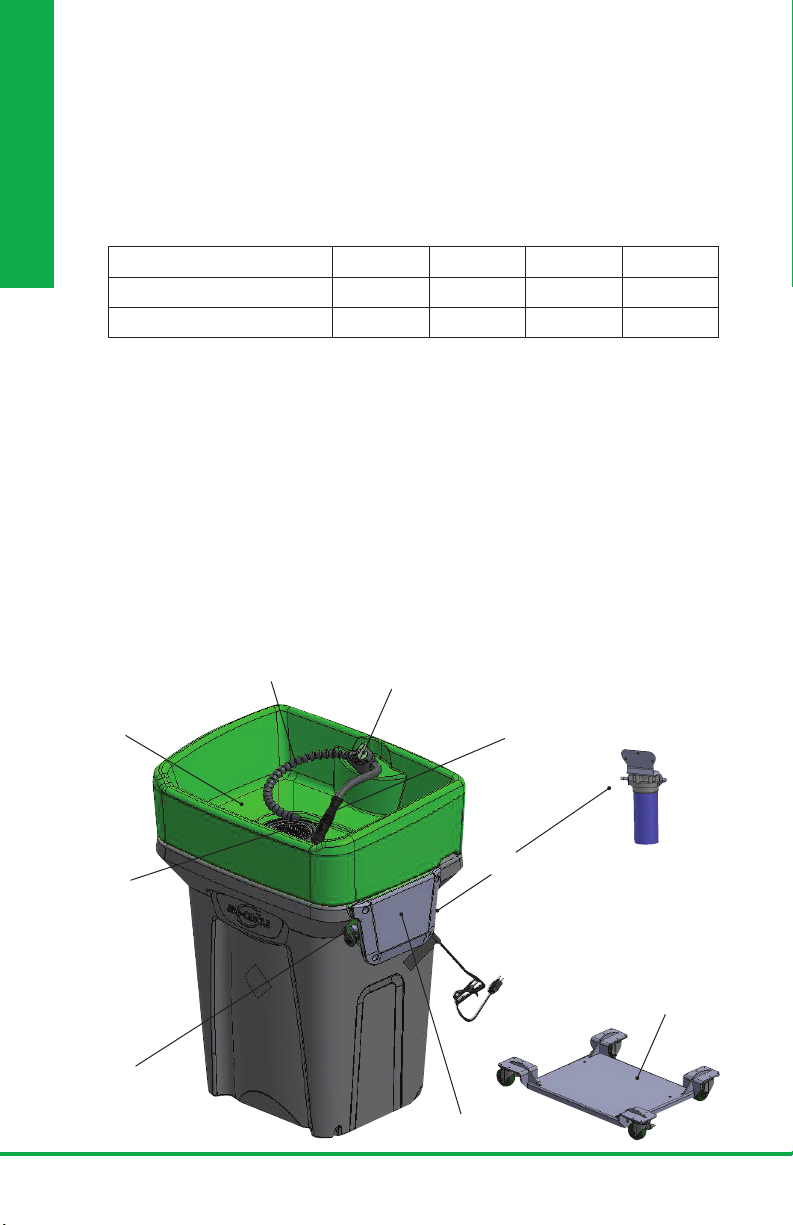

2. Open the sink (G), a sink holder bracket (N, page 12) is located

towards the rear left side to maintain the sink in the open position.

• Remove all packaging material around the unit and from inside the

tank. (Ex.: from underneath or behind pump/heater coil).

• Ensure filter bowl (D) is tightened if equipped. (Hand tighten only),

(sold separately as an accessory).

Place unit indoors, on a smooth level surface away from exposure to direct

sunlight. Use only genuine Bio-Circle Aero™ (55-A 207, 20 liters/5.3gal.

or 55-A 208, 208 liters/55 gal.) Bio-Circle L™ (55-A 007, 20 liters/5.3 gal.

or 55-A 008, 208 liters/55gal.) and Bio-Circle Ultra™ (55-A 107,

20 liters/5.3 gal. or 55-A 108, 208 liters/55gal.) cleaning solution.

When filling the unit from a drum, ensure the transfer pump being used is

clean and close the drum.

Fill the tank to normal operating capacity of up to 120 liters/31.7 gal. Refer

to level lines within the tank as shown on page 10.

Note: Open the container and pour slowly to prevent splashing and

excessive foaming of Bio-Circle Aero™, Bio-Circle L™ or Bio-Circle

Ultra™ liquid. If the container has a vent hole, open prior to pouring.

3. Plug power cord into properly grounded 3-prong, 120V, 60Hz, outlet

protected by a class A GFCI.

4. Allow the heater coil to warm Bio-Circle Aero™, Bio-Circle L™ or

Bio-Circle Ultra™ solution to working temperature to optimize cleaning

efficiency. This can take up to 2 or 3 hours.

Once the solution has reached its proper working temperature of

41ºC/106°F, the heater will turn off. Periodically, the heater will turn ON

automatically to maintain the proper working temperature.

Note: Do not plug in either the main power switch or the cleaning pump

switch (E) with no liquid inside the machine.

Never unplug the BIO-CIRCLE®unit except for servicing.