Clean Logix ALX-PRO User manual

USER

MANUAL

English (Original Instrucons)

Updated: 02/22/2022

MODEL:

ALX-PRO

Chemical Allocaon Controller

Page 2 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Table of Contents

General

Overview

Specicaons

Terminology

Installaon

Installaon Requirements

Mounng Controller

Connecng Devices

Conguraon

General Sengs

Users

Pumps

Manifolds

Pump Priming

03

03

03

04

05

05

07

08

09

11

12

Safety Warning

• All personnel servicing this unit must be familiar with

the informaon contained in this manual. Follow all

installaon and maintenance instrucons.

• Follow safety instrucons of chemical manufacturer (SDS).

• Wear proper PPE when working with chemicals (gloves,

safety glasses, face shield, etc.)

• Always follow plant and OSHA guidelines.

• Avoid contact of chemicals with skin and eyes. If contact

occurs, see SDS sheet for further rst aid measures.

• Follow all local codes for backow prevenon when

connecng to a potable water supply.

• Disconnect power before servicing equipment.

• WARNING: Severe damage to your facility, or

contaminaon of your water supply, can occur without

proper backow prevenon.

Calibraon

Scale Set-Up

Weight Based Calibraon

Time Based Calibraons

Operaon

Dispensing an Applicaon

Water Flush

Reporng

Syncing to Clean Intel

Historical Logs

Troubleshoong

Appendices

Parts Callout

Electrical Schemac

Air-Water Kit Set Up

Network Conguraon

Monitor Calibraon

13

14

15

17

18

19

20

21

26

30

31

32

33

Page 3 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

GeneralInstallaonConguraonAppendices Operaon

Troubleshoong General

The ALX-PRO oers the highest level control system

available to accurately measure, dispense, and record

chemical consumpon. PRO units allow authorized

Users to log in with a 4-digit code or RFID card to

reliably dispense chemicals via me or weight-based

methods. The 10” touchscreen and stainless steel

keypad provide an easy interacve plaorm, making

the dispensing process as smooth as possible.

All PRO systems integrate with the Clean Intel web-

site, an online reporng and conguraon dashboard.

Its secure connecon ensures privacy of all data and

allows managers to create new users, monitor dis-

pense permissions, construct chemical applicaon

recipes, and more both in the eld or on the go.

Overview

• Dimensions: 16” x 14” x 8”

Soware [V5]

• Maximum number of Users: 500

• Maximum number of Manifolds: 10

• Max number of pumps/chemicals: 32

• Maximum number of Applicaons: 500

• Maximum Dispense Steps per Applicaon: 6

• Dispense Step me range: 00.1s - 99m:99.9s

• Permissions me range: 1-24 hours

• Max Permissions count: 99

• Maximum number of Devices: 16

Acceptable Chemical Products

• Acids • Sanizer

• Causcs • Chlorine

Specicaons

Terminology

• Users - The people who will be using the system

to dispense Applicaons. Up to 999 users can be

stored.

• Permissions - Control the number of mes

each User can access each Applicaon. Can be

disabled.

• Devices - The physical outputs and/or inputs that

connect to the controller to perform a funcon.

The ALX-PRO is compable CAN-SO-1 and CAN-

SO-4 solenoid valve output devices as well as

CAN-SC devices for weight-based applicaons.

• Applicaons - Recipes which determine the

type and sequence of Dispense Steps. Up to 999

recipes can be stored.

• Dispense Steps - Segments of an Applicaon that

determine which output Device will be energized

and for how long. Each Applicaon can contain

up to 6 Steps.

• Fixed Time Step - Will energize an output Device

for a specied amount of me. Reported Step

volume must be manually entered.

• Calibrated Step - Uses Device Calibraon to

determine how long an output Device should be

energized, based on a specied target volume.

• Weight-Based Step - Uses Scale Calibraons to

determine how long an output Device should be

energized, based on weight. Requires CAN-SC

device for integraon with ALX-PRO.

NOTE: A single CAN-SO-4 counts as 4 Devices.

PROTECT THE ENVIRONMENT

Please dispose of packaging materials, old machine

components, and hazardous uids in an environmentally safe

way according to local waste disposal regulaons.

Please remember to recycle.

Page 4 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Compressed Air (typical installaon)

• Clean, dry air

• 10 CFM (283 L/min) @ 80 psi (5.5 bar) minimum

• 100 psi (6.9 bar) maximum supply pressure

• Recommended regulator seng: 80 PSI (5.5 bar).

Water Supply (typical installaon)

• Cold Portable Water

• 7 GPM (26.5 Lpm) @ 35 psi (2.5 bar) minimum

• 100 psi (6.9 bar) maximum supply pressure

• Recommended regulator seng: 50 PSI (3.4 bar)

Electrical

• 110 VAC, 5A, Single Phase, 50-60 Hz

• NEMA 5-15 GFCI Protected Outlet

• Surge suppression recommended

Network

• Cat 5e or higher Ethernet cable connecon (eld-

wired sealed plug included with unit)

• CELL-POE cellular box (sold separately)

Installaon Requirements

NOTE: A back ow preventer must be installed in the water supply to this unit, per local codes.

Page 5 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

GeneralInstallaonConguraonAppendices Operaon

Troubleshoong General

1. Determine mounng locaon, with consideraon

of the following:

• User accessibility

• Distance to electrical outlet

• Distance to Devices/pumps

• Accessibility to Ethernet

2. Aach the included mounng feet to the

controller.

3. Securely mount unit to wall using appropriate

hardware (not included).

4. Plug power cord into a 115 VAC, GFCI protected

receptacle.

5. Using the included sealed ethernet plug, connect

Ethernet (either from the facility or CELL-POE) via

Cat 5e cable (or similar).

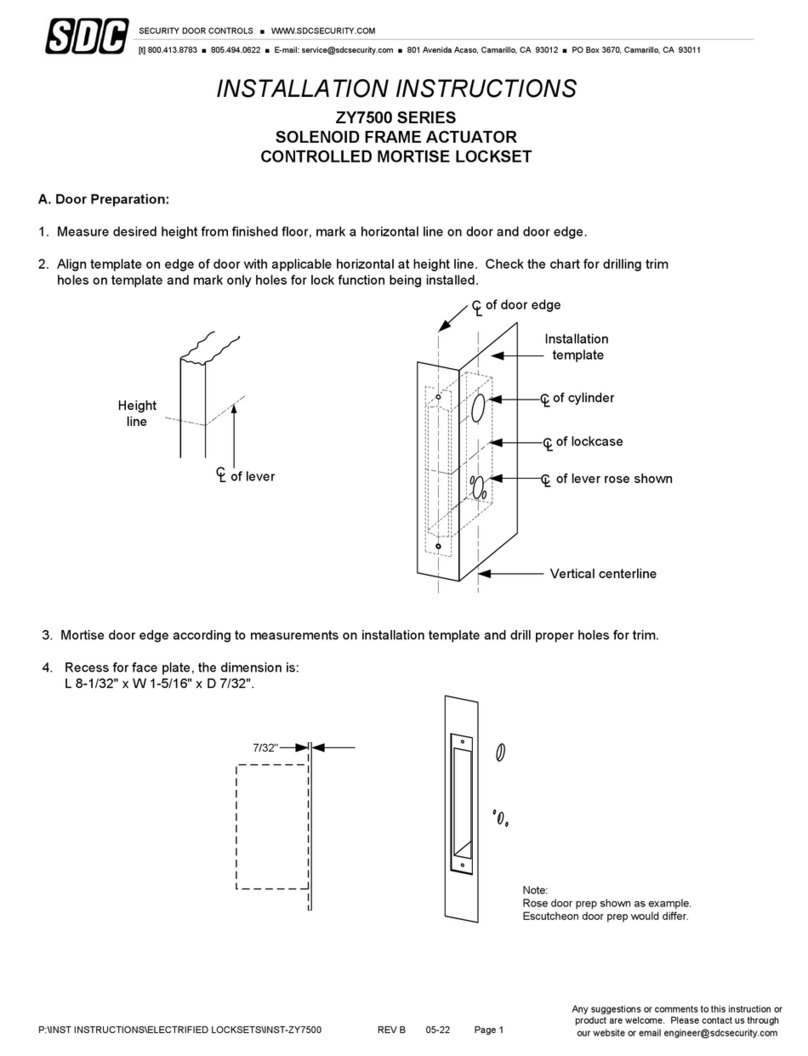

AIR OUTPUTS

(3/8" PUSH-FIT)

AIR INLET 2

(3/8" PUSH-FIT)

AIR INLET 1

(3/8" PUSH-FIT)

CONNECT TO

OTHER CAN

DEVICE

CAN-SO-4

AIR OUTPUT

(3/8" PUSH-FIT)

CONNECT TO

OTHER CAN DEVICE

CONNECT TO ALX

CONTROLLER OR

OTHER CAN DEVICE

AIR INLET (3/8"

PUSH-FIT)

CAN-SO-1

Mounng Controller

The following types of Devices are compable with

the ALX-PRO:

• CAN-SO-4: A four output, 3-way solenoid valve

pack for controlling 1/2" or smaller AODD pumps

and/or air operated valves

• CAN-SO-1: A single output, 2-way solenoid

valve for controlling up to a 1" Air Operated

Double Diaphragm (AODD) pumps

Connecng Devices

Page 6 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

1. Mount and connect Devices in a daisy-chain fashion using the orange M12 cables. They can be installed in

any order. (NOTE: If purchased as a -KIT, the Devices will be supplied pre-mounted and connected)

2. Hand ghten M12 cable connecons, then ghten two more clicks using wrenches.

3. Plumb compressed air lines and uid lines for pumps and valves as necessary [see below]

*See Appendix for IVX Sensor Integraon

Connecng Devices (connued)

Installaon Example:

*

Page 7 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

GeneralInstallaonConguraonAppendices Operaon

Troubleshoong Installaon

General Sengs

1. Login as admin using the keypad or RFID

1. Press CONFIG on the side menu

2. Under the General tab, the soware version and

unit ID can be viewed.

3. The following Conguraon opons are

available:

• Dispense Permissions: limit the number of

dispenses each user can access per/day or

not. Toggle on (to the right/blue) to enable.

• Max Dispense Time: If enabled, will limit the

maximum amount of me (seconds) that

an applicaon recipe can be dispensed for.

Use the + and - buons or press the entry

window to type in a value.

• Time Zone: Idenes Time Zone for

operaon area. Used in reports and logs.

• Water Flush: If enabled, will allow water

ushes for an alloed amount of me.

Use the + and - buons or press the entry

window to type in a value.

• Water Flush Required: If enabled, requires

a water ush between dispense applicaons

to ush manifold and dispense lines.

• Clear All Learned Calibraons: Clears all

previously logged dispense calibraons for

pump overshoot.

Conguraon

NOTE: Contact Clean Logix for admin setup.

Fig. 7.1: Home screen, Conguraon selecon

Fig. 7.2: Admin screen, General selecon

Fig. 7.3: General sengs screen

NOTE: To avoid ending dispenses early, set

the Max Dispense Time so that it will not

compromise larger dispense Applicaons.

Please contact Clean Logix at:

iMore Informaon

Page 8 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Add New User

1. From the conguraon screen, select Users.

2. Click the blue Add New User buon to add a

new user

• Name: User name, used in reporng

• Key Code: 4-digit passcode for login.

• RFID: Oponal RFID access. Scan RFID code

at unit to enter.

• RFID cards must be assigned to each

user. RFID codes cannot be used

between mulple users.

• iClass or MIFARE cards will not register

3. Select the green check mark to save user.

4. Sync with Clean Intel - Unit must be synced

before user is added to list and able to login.

Conguraon (cont.)

NOTE: To edit or delete an exisng user log

onto Clean Intel.

Fig. 8.1: Admin screen, General selecon

Fig. 8.2: Users screen

NOTE: HID Prox cards are fully supported. RFID

cards are availabe for purchase from Clean

Logix. Contact us for more details.

Page 9 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

GeneralInstallaonConguraonAppendices Operaon

Troubleshoong Conguraon

Pumps

In order to dispense chemical with the ALX-PRO, the

following requirements are necessary:

• Each chemical being dispensed must be

assigned to a Pump (i.e. solenoid device).

• Water must be assigned to each manifold that

requires water or if the manifold ush funcon

will be used.

1. From the admin conguraon page select Pumps

2. The le sidebar will display a list of all the

available pump solenoid devices.

• Green: The device is connected

• Red: The device is disconnected or not

receiving power

• Orange: Current selected device.

3. Select a pump solenoid device from the list by

clicking on it. The following details and opons

will be available:

• ID: Solenoid device ID number. This number

will be labeled on a corresponding CAN-SO-4

or CAN-SO-1.

• Manifold: Manifold the pump is/will be

connected to physically for dispensing.

• Chemical: The chemical that will be pumped

for dispenses using this solenoid.

• Calibraon Type: Dispense calibraons for

precise measurements.

• Time Cal: always available

• Weight Cal: requires scale (see page 13 for

more informaon on calibraons).

Conguraon (cont.)

NOTE: Chemicals need to be set up on Clean

Intel for selecons to be available.

Fig. 9.1: Admin screen, Pumps selecon

Fig. 9.2: Pumps screen

Page 10 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Pumps (cont.)

• Prime: Acvely runs the pump for up to

30-seconds, without dispense applicaon

selecon. Used for inial set up and

troubleshoong.

• Idenfy: Causes light on solenoid device

to blink. Do not cause pump to run - visual

indicator only.

• Move To: Migrates the pump sengs to

another solenoid device. Pick a selecon from

the drop down menu, select Move To, and

conrm to save changes.

• Delete: to remove a pump and its sengs

select the blue delete buon.

!

CAUTION:

When deleng a pump, all calibraons for both

me and weight based dispensing will be removed.

If the pump device is later re-added it will need to

be recalibrated prior to dispensing.

NOTE: Deleng pumps should only happen when

a device breaks and is replaced. If the device is

deleted and reconnected, it will automacally

show up in the list of pumps again with no

chemical assignments.

Conguraon (cont.)

Fig. 10.1: Pumps screen, delete selecon.

Page 11 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

GeneralInstallaonConguraonAppendices Operaon

Troubleshoong Conguraon

Manifolds

1. From the conguraon page select Pumps

2. The le sidebar will display a list of all exisng

manifolds.

3. Select a manifold from the list to display its details

• Name: Text idener for manifold. Used in

various conguraon and operaon screens as

well as reports.

• Color Selecon: Visual reference for manifold,

used in conguraon and operaon screens.

Does not aect performance or funcons.

• Scale: For weight-based units only. Idenes

whether manifold will use a scale or not

for dispenses. Connected scales will appear

available for selecon.

• Water Conguraon: Idenes whether water

is currently connected and congured for a

pump on this manifold. Required for water

ushes.

• Delete: to remove a manifold enrely select

the blue delete buon at the boom right.

Adding Manifolds

1. Add a new manifold by clicking Add in the

Manifolds Sengs screen, at the boom of the

manifold list.

2. Give the Manifold a name.

3. Select the color to be displayed with this manifold.

4. If the manifold will use a scale for weight based

dispenses, select it from the list.

5. When nished, select the green checkmark to

save the Manifold and add it to the list.

NOTE: If the scale is not listed, it will need to

be added and congured (see page 13)

Conguraon (cont.)

Fig. 10.1: Admin screen, Manifolds selecon.

Fig. 10.2: Manifolds screen, acve manifold selecon.

Fig. 10.3: Manifolds screen, new manifold

Page 12 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Before the unit can dispense chemical, each pump

must be primed so the chemical lls up the hose to

the manifold for accurate dispense volumes.

Priming Pumps

1. Ensure tubing and hoses are all properly

connected between the chemical container,

pump, and manifold.

2. Arrange a suitable contain and ensure the

dispense line above or inside it to catch the liquid

to measure.

3. Navigate to the Pump conguraon screen.

4. Select the solenoid device for the pump you want

to prime.

5. Select the Prime buon at the boom right corner

of the screen.

6. When ready, press the Start buon to turn the

Device output on and begin pumping soluon.

7. When liquid begins dispensing out of the main

dispense line press Stop to cease pump acvity.

8. Perform a manual water ush to clean the

manifold and dispense line before priming or

dispensing another chemical.

Repeat this process for each pump.

Conguraon (cont.)

NOTE: Before the pumps start to prime, a solenoid

device must be assigned water to that manifold

to perform a manual water ush between priming

pumps.

!

WARNING:

Pressing the START key on this screen will cause

the output to turn on and the pump to run!

Wear PPE and be ready to contain the ow of

chemical in an appropriate vessel!

Fig. 12.1: Pumps screen, Prime selecon.

Fig. 12.2: Start buon

Fig. 12.3: Dispense container (shown on ALX Tower)

Page 13 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

GeneralInstallaonConguraonAppendices Operaon

Troubleshoong Conguraon

Weight-Based Scale Set-Up

Weight-based ALX-PRO models will require their

scales to be calibrated prior to use to ensure the best

accuracy when dispensing.

1. From the admin conguraon screen, select

Scales.

2. A list of connected scales will be listed

• Green: The device is connected, congured,

and ready to be used.

• Red: The scale is connected, but has not be

set up.

3. Select the scale to calibrate.

4. Make sure there is nothing on the scale, then click

Tare Scale. The scale will be zeroed out.

5. Place a weight, between 10-30 lbs., on the scale.

6. Using the keypad, enter the weight and click OK.

7. With the weight sll on the scale, press Measure

Now to display a live weight reading.

• The live reading should match your entered

value from the previous step.

• If it does not the scale must be recalibrated

- Remove all weight from the scale and click

Tare Scale to start over.

Clean Logix recommends recalibrang the scale every

2-3 months to ensure the best accuracy.

Calibraons

NOTE: The specic weight of this object must

be known and ideally calibrated for accuracy.

Fig. 13.2: Scales screen, no selecon, 1 un-congured scale

Fig. 13.1: Admin screen, Scales selecon

Fig. 13.3: Scales screen, scale calibraon in progress

25.00

NOTE: If installed in an ALX dispensing tower

kit with a scale, ensure the jug trays are empty,

properly installed, and nothing is underneath

or aecng their contact with the scale.

Page 14 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Weight-Based Overshoot Calibraons

When dispensing pump overshoot is always possible

which may alter your nal dispense volume. To help

ensure greater accuracy, Weight Calibraons can be

entered for each pump to help manage overshoot and

provide more accurate dispenses.

1. From the admin conguraon screen, select

Pumps.

2. Select a congured pump device to calibrate.

3. Ensure a manifold and chemical is idened for

the chosen pump solenoid devices and select

Weight Cal - The Weight Calibraon screen will

launch.

4. Idenfy sengs to calculate:

• Use Learning: OPTIONAL - if enabled, system

will auto-log dispense volumes and will

auto-calculate overshoot over me for more

accurate dispenses. (is not immediate)

• GPM: The esmated gallons per minute

measurement of the connected chemistry

or soluon. May vary depending on viscosity and

temperature. Contact your chemical manufacturer or

distributor for support.

• Pre Act: The overshot dispense amount (oz),

or the amount that connued to dispense

aer the pump turned o.

5. Once entered, select Calibrate Pre Act.

6. Arrange a suitable container, with accurate

volume markings, and ensure the dispense line is

above or inside it to catch the liquid to measure.

7. Enter the target volume for the dispense.

8. Press Start to begin dispensing - the scale will

measure the volume and will stop the pump once

the target volume is reached.

9. Wait for the dispense to nish.

10. Conrm the volume dispensed or alter as needed.

Repeat for all other pumps.

Calibraons (cont.)

Fig. 14.2: Pumps screen, pump selected with Cal opons

Fig. 14.1: Admin screen, Pumps selecon

Fig. 14.3: Scales screen, scale calibraon in progress

25.00

Page 15 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

GeneralInstallaonConguraonAppendices Operaon

Troubleshoong Conguraon

Time-Based Calibraons

Before pumps can perform Time-Based dispenses

they will each need to be calibrated for the chemical

they will be controlling. Time-based calibraon entry

requires pump to run and chemistry to be dispensed.

1. From the conguraon screen, navigate to Pumps

2. Select a green, congured pump device to

calibrate

3. Ensure a manifold and chemical is idened for

the chosen pump solenoid devices and select

Time Cal

4. The Time Calibraon screen will appear with 2

calibraon point windows.

5. Ensure tubing and hoses are all properly

connected between the chemical container,

pump, and manifold.

6. Arrange a suitable container, with accurate

volume markings, and ensure the dispense line

above or inside it to catch the liquid to measure.

7. Press the Update for the rst calibraon point to

add or update the rst calibraon point. A new

window will appear with step-by-step instrucons.

8. Press Start to begin dispensing. The calibraon

mer will calculate how long the pump runs for.

TIP: For increased accuracy, dispense for the

shorest amount of me you intend to run this

pump for in regular applicaons.

Ex) if you ancipate the shortest dispense to

be 10 sec. long, run the pump for 6 sec.

!

WARNING:

Pressing START will cause the output to turn on

and the pump to run! Wear PPE and be ready

to contain the ow of chemical!!

Calibraons (cont.)

Fig. 15.1: Pumps screen, Time Calibraon selecon.

Fig. 15.2: Time Calibraon window, update selecon.

Fig. 15.3: Time Calibraon process window - new entry.

Page 16 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Time-Based Calibraons (cont.)

9. Press Stop to cease pump acvity.

10. Measure the volume dispensed in the container.

11. Enter the volume measurement to complete the

rst calibraon point.

12. Click Conrm to save the calibraon value. The

screen will return to the main Time Calibraon

window.

13. Select Update on the second calibraon to add a

second data point.

14. Press Start to begin dispensing and follow the

previous instrucons to enter the volume.

Repeat this process for ALL pumps (including water)

that will be dispensing via me based values.

Deleng Calibraons

1. Select the pump to remove calibraon point and

open the Time Cal screen.

2. Click Clear to remove values for each point.

NOTE: Only one calibraon point is required

to enable Timed Calibraons. Clean Logix

recommends having 2 calibraon points per

pump to ensure accuracy.

NOTE: Clearing calibraons should be a rare

occurrence, but may be required if changes in the

plant environment occur (e.g. change in air/water

pressure, hose length, pump type, etc). That may

aect the speed at which chemical is dispensed.

Calibraons (cont.)

TIP: For the second calibraon point, dispense

for the longest amount of me you intend to

run this pump for in regular applicaons.

Example) if you ancipate the longest dispense

to be 20 sec. long, run the pump for 25 sec.

Fig. 16.1: Time Calibraon screen with cleared values.

Page 17 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

GeneralInstallaonConguraonAppendices Operaon

Troubleshoong Operaon

Applicaon Dispensing

1. To begin dispensing, log in as a User by either

swiping a RFID card or typing their 4-digit

passcode to login.

2. On login, the Applicaon browser will load.

3. Select an applicaon to dispense by one of the

following methods:

• App Code: Begin typing in the app’s 4-digit

code. The browser will begin ltering down

the results.

• Filtering: Using the sidebar menu, select the

manifold, chemical, and/or locaon to lter

down the results.

• Browsing: Using the arrow keys at the top of

the screen, si through the applicaon recipes

page by page.

Operaon

NOTE: Applicaon cards will display the code, name, locaon, dispense type, # of chemicals/steps, and

which manifold it is connected to.

Fig. 17.1: App Selecon screen, no lters enabled.

App code Locaon

Name

Dispense type

(me or weight)

Applicaon

steps (max 6)

Chemical (displays color

set in Clean Intel)

Manifold

(displays color

set in cong)

4. Select the Applicaon to be used - the dispense

window will launch.

5. Arrange a suitable container and ensure the

dispense line above or inside it to catch the liquid

to measure.

Page 18 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Applicaon Dispensing (cont.)

6. Press Start to begin dispensing.

7. When the dispense has completed 3 opons will

be available:

• Go Back: Return to Applicaon Browser

• Flush: Perform a water ush (sengs

congured by admin, see page 7)

• Repeat: Dispense the same applicaon again,

immediately.

8. Alternavely, press Stop to log out.

Manual Water Flush

Manual water ushes can be performed at any me,

for any manifold with water connected.

1. Select Water Flush from the home screen - the

Manifold selecon screen will appear.

2. Select a Manifold to ush.

3. Press Start to open the solenoid valve and begin

dispensing water.

4. Press Stop to cease pump acvity and stop

ushing water.

5. Repeat with other manifolds as necessary or

return to the home screen.

NOTE: All manifolds will be listed, regardless

of water connecon. If a manifold does not

have water congured it will display an error

message on the top header and not funcon.

Operaon (cont.)

Fig. 18.1: Dispense screen - Ready

Fig. 18.2: Dispense screen - Complete

Fig. 18.3: Manual Flush Screen

Page 19 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

GeneralInstallaonConguraonAppendices Operaon

Troubleshoong Operaon

Syncing to Clean Intel

1. To sync informaon to and from CleanIntel.com,

press the Sync buon in the boom right corner

of the home screen.

2. A data transfer will automacally iniate from the

unit to the website and back again through the

cellular router.

3. The unit will sync up all the data logs of dispenses

including:

• Which users have logged in

• How much chemical has been dispensed

• Which applicaons have been used

• The me and duraon for all dispenses

4. If a manager has created a new user, updated the

list of chemicals or applicaons, or added new

user permissions on CleanIntel.com, the syncing

process will update the unit with this new data.

5. The unit is congured to sync to CleanIntel.com

hourly, so a user will rarely need to manually

sync.

6. If the syncing fails, ensure the unit has internet

connecon by checking the network connecon

method (ethernet, WiFi, or CELL-POE).

• If congured with a CELL-POE device, check

the router’s status lights:

• 4 Solid Bars = Strongest signal

• 1 Red Bar = Weakest signal

Reporng

NOTE: Consult the CELL User Manual for

addional informaon or troubleshoong.

Fig. 19.1: Home screen, Sync selecon

Fig. 19.2: Sync in progress

Fig. 19.3: Cradlepoint Cell Router connecon status lights

Page 20 of 33 ALX-PRO Manual V5 Updated: 02/22/2022

USER MANUAL: ALX-PRO

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

History Logs

The ALX-PRO will connually log data, which can be

viewed at any me via the Logs secon of the admin

conguraon menu.

1. From the conguraon screen, select Logs

2. Using the drop down menu, select which acvity

log to view

• Dispense History by App: Date, me, user, and

amount for each applicaon recipe. Organized

by Applicaon.

• Dispense History by User: Date, me, and

applicaon consumpon for each dispense.

Organized by User.

• Pump Calibraon History: Date, me, user,

and data entry for pump calibraons changes

(adding, eding, or deleng). Organized by

pump solenoid device.

• All Conguraon History: Complete history

log of all admin conguraon seng changes.

Organized by user.

• Manifold Conguraon History: Date, me,

user, and data entry for manifold conguraon

sengs (adding, eding, or deleng).

Organized by manifold.

• Pump Conguraon History: Date, me, user,

and data entry for pump conguraon sengs

(adding, eding, or deleng). Organized by

pump solenoid device.

• Scale Conguraon History: Date, me, user,

and data entry for weigh scale conguraon

sengs (adding, eding, or deleng).

Organized by scale.

Reporng (connued)

Fig. 20.1: Admin screen, Logs selecon

Fig. 20.1: Admin screen, Logs selecon

NOTE: Only weight based units equipped with

scales will display Scale Conguraon History.

Table of contents

Other Clean Logix Controllers manuals

Popular Controllers manuals by other brands

Addonics Technologies

Addonics Technologies AD2SAHMSA quick guide

ICM Controls

ICM Controls ICM492 manual

MESHLE

MESHLE flex 568M-1 operating instructions

SDC

SDC ZY7500 Series installation instructions

Peaktronics

Peaktronics DHC Series user guide

Hansen

Hansen HA4A series Specifications, Applications, Service Instructions & Parts