7

Contents

Contents

1. EnergyTech 203 CO and O2 Gas Analysing System.........................................................................9

1.1. Introducton..........................................................................................................................9

1.2. System Operation ............................................................................................................11

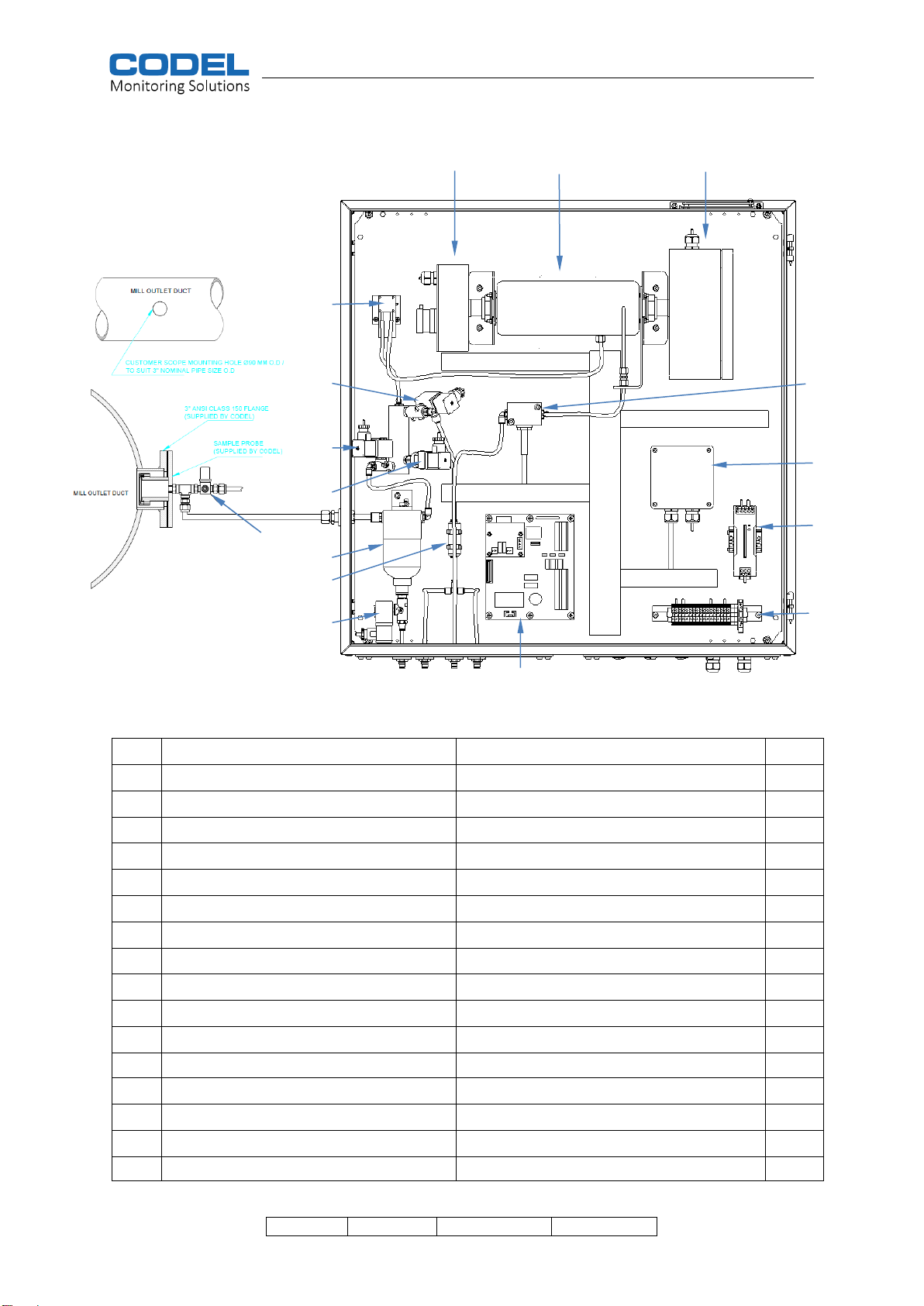

1.3. Measurement Cabinet.....................................................................................................12

2. Measurement Principle...........................................................................................................13

3. Summary Specification ..........................................................................................................15

4. Preparing for Installation .......................................................................................................16

4.1. Unpacking..............................................................................................................................16

4.2. Additional Materials.........................................................................................................17

5. Installation .................................................................................................................................18

5.1. General................................................................................................................................18

5.3. Measurement Cabinet.....................................................................................................19

5.3.1. Remote-Mounted Installation....................................................................................19

5.4. Terminal Connections.....................................................................................................20

5.5. Compressed Air Connections ......................................................................................20

6. Commissioning.........................................................................................................................21

6.1. Pre-Commissioning Checks..........................................................................................21

6.2. Normal Start-Up Sequence............................................................................................21

7. Normal Operation.....................................................................................................................22

7.1. Introduction.......................................................................................................................22

7.2. Normal Start-Up Procedure...........................................................................................22

7.3. Modes of Operation.........................................................................................................23

7.4. Key Operation...................................................................................................................24

7.5. Program Tree.....................................................................................................................25

7.6. Operating Mode................................................................................................................26

7.8. Parameter Mode ...............................................................................................................26

7.9. Chamber.............................................................................................................................28

7.9.1. Display Format............................................................................................................28

7.10. Diagnostic Mode...........................................................................................................29

7.10.1. Detector Outputs (CO sensor)...........................................................................30

7.9.2. Thermistor (CO sensor)..................................................................................................30