66X-1082a

3220 CAMERA INSTALLATION MANUAL

2.3.1 Mounting Hardware Not Supplied

No hardware is supplied for securing a wall,

ceiling, or pedestal mount to their mounting surface.

However, the pole mount does not require any

additional hardware to mount it to a pole. It can be

clamped to a pole with two threaded rods that are

supplied in its hardware kit.

2.4 Equipment Required but Not Supplied

As a minimum the 3220 requires a source of

operating power, a monitor on which to view the

scene, an interconnection cable, and a computer

running Graphical User Interface (GUI) software for

control of the 3220 if this is desired.

During maintenance and setup operations us-

ing either a laptop or desktop PC it is likely that a

USB to RS-232 converter will be required.

Typically PC’s have had only an RS-232 port

— and rarely an RS-422 port.

However, newer PC’s and laptops no longer

have an RS-232 port and instead rely on USB and

other newer type ports.

With these computers, a USB to RS-232 con-

verter will be required. Be aware that some of these

converters do not provide reliable RS-232 com-

munications If problems are experienced determine

whether it is the converter.

If it is desired to use the RS-422 feature of the

camera it will then be necessary to add an RS-232

to RS-422 converter.

Or a USB to RS-422 converter could be used

directly but these are not common devices.

2.5 Cabling Requirements

Two versions of the camera have slightly dif-

ferent cabling requirements. With one version the

system interconnection cable plugs into a camera

connector. With the second version the system in-

terconnection cable must be directly wired to inter-

nal terminals inside the camera.

2.5.1 Model 3221 and 3223 Cameras

For the model 3221 and model 3223 versions

of the camera, system interconnections are made

to the connector on a permanently attached 9-inch

“pigtail” cable. A connector (gure 29) is provided to

mate with this pigtail connector.

Figure 6 through gure 15 show typical cables

available for use with the pigtail connector.

2.5.2 Model 3222 and 3224 Cameras

For the model 3222 and model 3224 versions

of the camera, system interconnections are made

directly to terminals inside the camera (gure 16

and gure 17).

2.5.3 Customer Supplied Cable

A high quality multiconductor shielded cable

must be used with this camera both to minimize EMI

radiation and to reduce susceptibility to interference.

The cable must have an overall shield with at

least 95 percent coverage.

Data wiring must be twisted pairs similar to that

used in CAT-5e cable. A data ground wire must be

used.

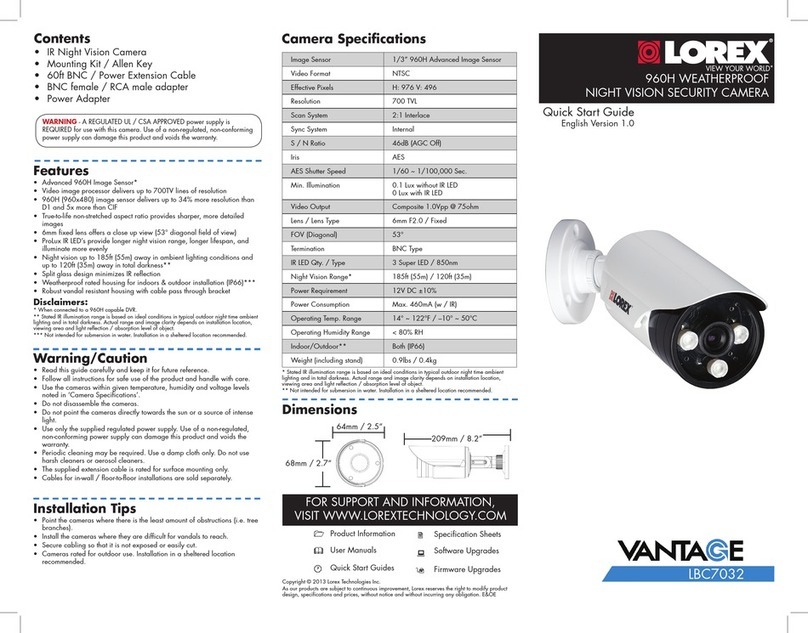

Table 2. Mounting Hardware Kit 8498-8

ITEM DESCRIPTION QTY PART NUMBER WHERE USED

11/4-20 x 1/2 Hex Head Screw 2 2010730-006 Pedestal Mount

2 1/4-20 x 5/8 Hex Head Screw 2 2010730-005 Ceiling Mount

3 1/4 Spring Lock Washer 2 2010732-002 Pedestal Mount; Ceiling Mount

4 1/4 Flat Washer 2 2010731-002 Pedestal Mount; Ceiling Mount

5 1/4-20 x 1/2 Flat Head Screw 2 0310010-091 Heavy Duty Wall Mount

Notes: All dimensions in inches. This kit provides the hardware necessary to attach a 3220 series camera to a

Heavy Duty Wall Mount, a Ceiling Mount, or a Pedestal Mount. This hardware must be used in place of the metric

hardware included with these mounts. (The two athead screws in item 5 are required for the Pole mount option,

too, since it uses the Heavy Duty Wall Mount as part of its assembly.)