3

6X-1048B

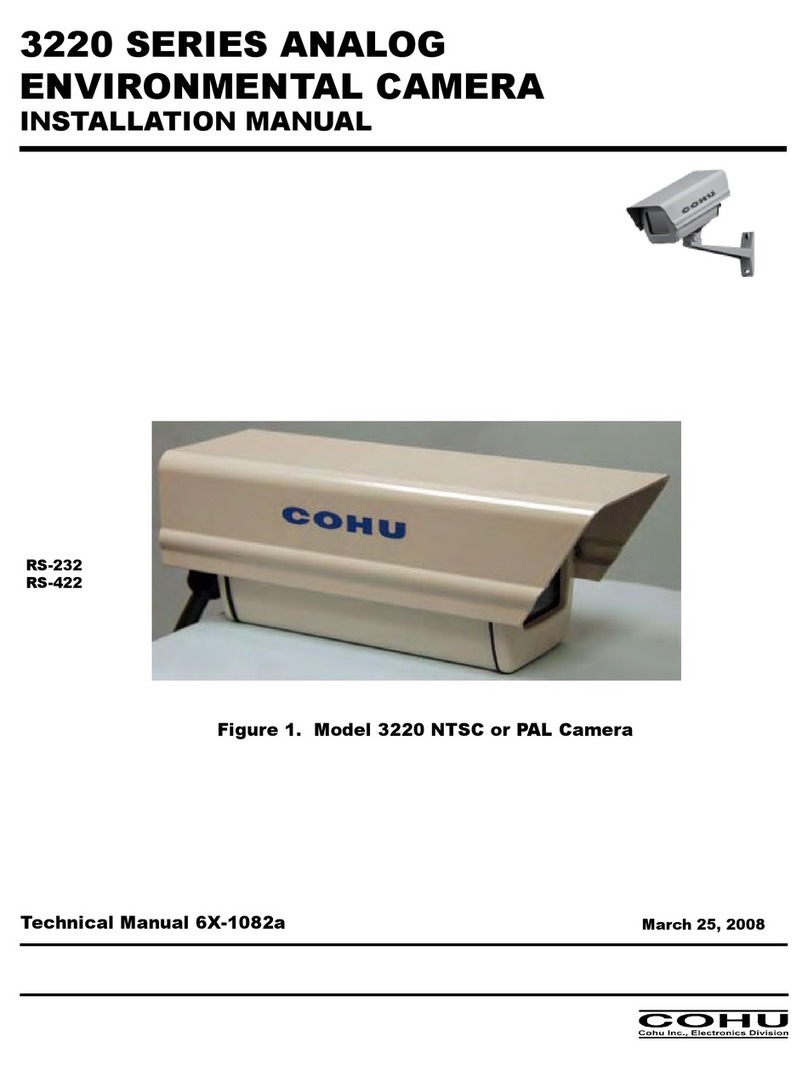

2740 CAMERA

INSTALLATION AND OPERATION

1.0 GENERAL DESCRIPTION

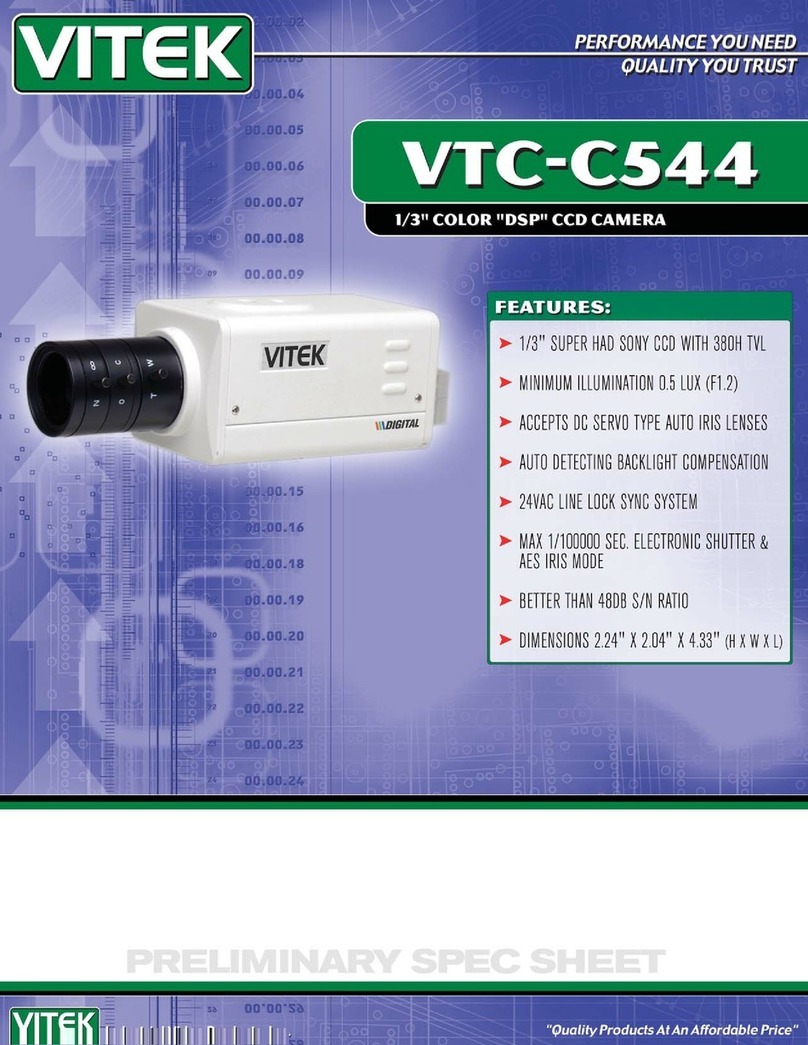

This introduction briefly describes overall

characteristics of the Model 2740 monochrome

Camera (figure 1) related to its installation and

operation.

1.1 Electrical Characteristics

The 2740 camera provides a highly sensitive

interline transfer CCD Camera in a pressurized

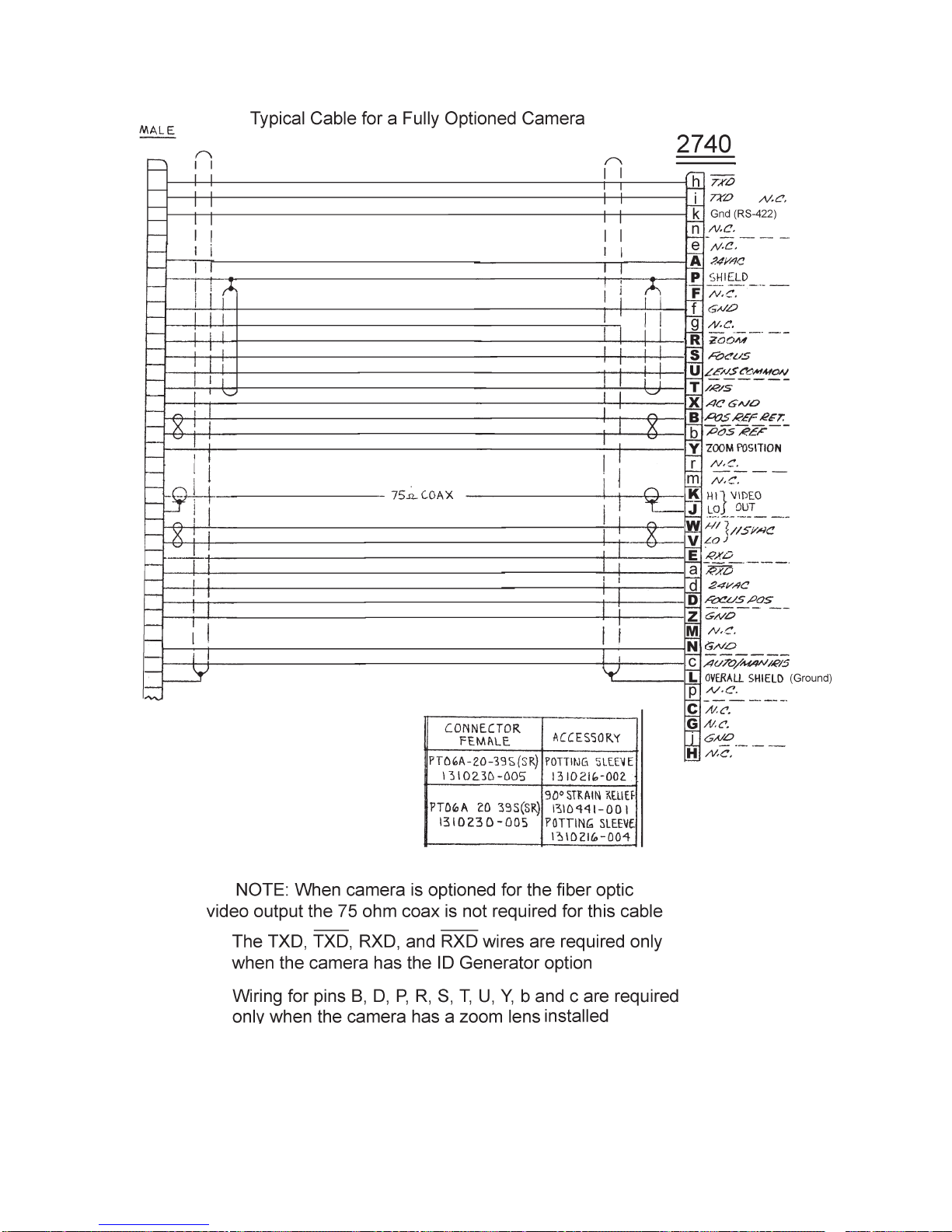

environmental housing. All electrical connections

are via a single 39 pin rear panel connector. Table

1 lists electrical, mechanical, and environmental

specifications for the 2740 Camera.

Video output may be provided by an optional

fiber optic connector added on the rear panel.

When this option is selected, the 75 ohm output

on the 39 pin connector should not be terminated.

Any temporary connections to this 75 ohm output

for maintenance purposes should be done with a

short 75 ohm coax cable to avoid any “stub” effect

that may cause ghosting in the video.

The Camera operates with either NTSC or

PAL format, depending on the model. Both of

these formats are available in a high-sensitivity

version.

This Camera operates at an internal clock rate

of 28.6363 MHz (NTSC) or 28.375 MHz (PAL).

If the phase adjust line lock option is installed,

the vertical interval of the camera is referenced to

the 60 Hz power input for NTSC (or the 50 Hz

power input for PAL). A six position switch on

the rear panel then makes it possible to shift

this reference in 60 degree increments so that

the camera can be phased with other cam-

eras in the system that may not have the

same power line phase reference. This phase

difference can occur either because the other

cameras are on a different phase of the power

source or perhaps because they are con-

nected to a power source operating from a

different transformer.

The Camera is available with either 115 V

ac or 24 V ac input power — depending on the

model. An internal 20 watt heater cycles on an

off at low environmental temperatures to maintain

temperature inside the housing at operating

levels.

When an optional zoom lens is installed,

dedicated pins on the connector provide for

control of zoom, focus, and iris. Pins are also

assigned for location of the lens zoom position.

When an optional ID generator is mounted

inside the camera housing, it can be programmed

to provide messages in the video. It also provides

barrel pressure and temperature when these

displays are turned on.

Programming and control of the ID generator

is via RS-422 on the rear panel multipin connec-

tor. Cohu’s Win MPC graphical user interface

(GUI) software can be used to program these

messages. (WinMPC is available at no cost from

the cohu-cameras web site or by mail on CD.) —

or the system control software can be used if it

has been implemented with the proper protocol

messages.

If either shuttering or a manual gain setting is

desired, these setting must be performed before

the camera housing is sealed and pressurized.

Changing either of these optional settings requires

complete disassembly of the camera housing. It

must then be re-sealed, purged with dry nitrogen,

and pressurized with the dry nitrogen before

returning to service. For more information about

the internal camera module refer to Cohu Techni-

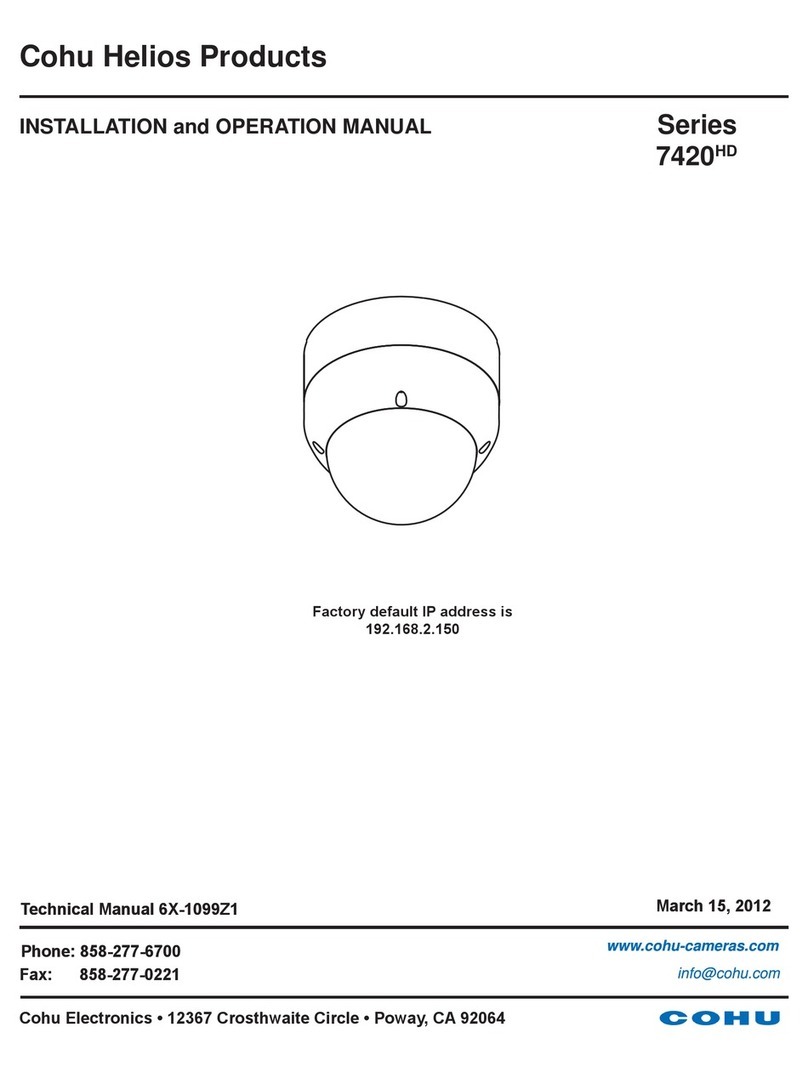

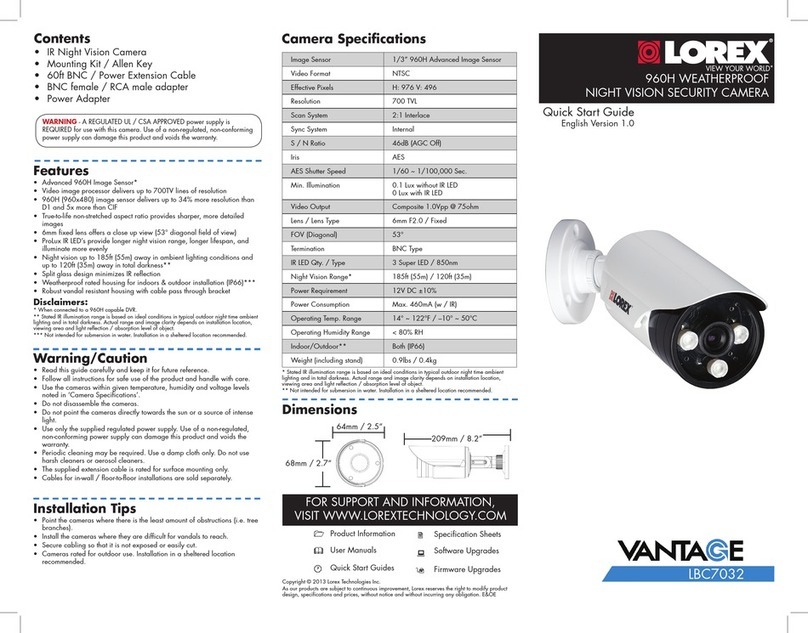

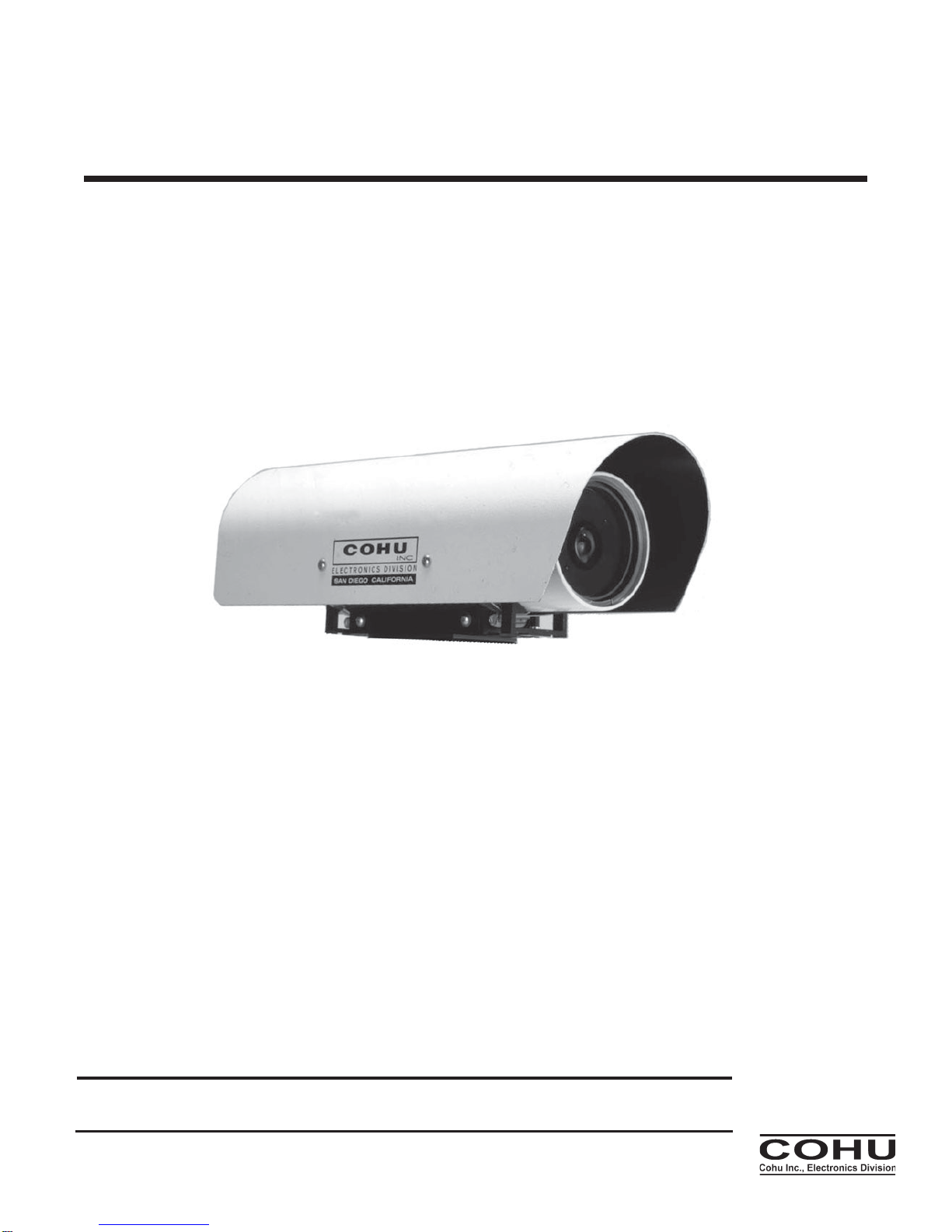

Figure 2. Sensor Wavelength

Response Characteristics

500

400 600 700 1000

900

800

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Wavelength (nm)

Relative Response

Standard Sensitivity

Enhanced Near IR

Sensitivity

Note: Both curves are normalized to 1.0 and thus the graph does not show comparative output levels