6X-1026

6

INSTALLATION AND OPERATION 3920iDOME

2.1UNPACKING AND RECEIVING INSPECTION

This iDome was thoroughly tested and carefully

packed in the factory. Upon acceptance by the

carrier, they assume responsibility for its safe arrival.

Should you receive this item in a damaged condition,

apparent or concealed, a claim for damage must be

made to the carrier. To return an iDome or related

product to the factory for service, please contact the

Customer Service Department for a Return Authori-

zation Number.“ If a visual inspection shows dam-

age upon receipt of this shipment, it must be noted

on the freight bill or express receipt and the notation

signed by the carrier's agent. Failure to do this can

result in the carrier refusing to honor the claim.“

When the damage is not apparent until the unit is

unpacked, a claim for concealed damage must be

made. Make a mail or phone request to the carrier

for inspection immediately upon discovery of the

concealed damage. Keep all cartons and packing

materials. Since shipping damage is the carrier's

responsibility, the carrier will furnish you with an

inspection report and the necessary forms for filing

the concealed-damage claim

2.2STATIC DISCHARGE PROTECTION

Procedures in this manual do not require entry into

the housing of the iDome. However in the event that

an open unit were available, the following precau-

tions should be followed:

CAUTION

This iDome contains sensitive devices that can

be damaged by static discharge. Use appropri-

ate static control methods when working inside

the iDome.

Components used in modern electronic equipment,

especially solid state devices, are susceptible to

damage from static discharge. The relative suscep-

tibility to damage for semiconductors varies from

low with TTL to high with CMOS. Most other semi-

conductors fall between TTL and CMOS in suscepti-

bility to static discharge. As a minimum, therefore,

observe the following practices when working inside

this or any other electronic equipment:

1. Use conductive sheet stock on the work bench sur-

face.

2. Connect the sheet stock to ground through an 1

megohm or greater value resistor.

3. Use a wrist strap connected to ground through an 1

megohm or greater value resistor when working at

the bench.

4. Maintain relative humidity of the room above 30 per-

cent. This may require a room humidifier. Working

on circuits with relative humidity below 30 percent

requires extraordinary procedures not listed here.

5. Use antistatic bags to store and transport an ex-

poses chassis, circuit boards, and components.

Usenewantistatic bags.Old,used bagsloosetheir

static protection properties.

This list serves as a reminder of the minimum

acceptable practices. Be sure that all static dis-

charge devices at the work bench are properly

installed and maintained.“ Standard grounding mats

and wrist straps purchased for use at work benches

are supplied with leads having current limiting

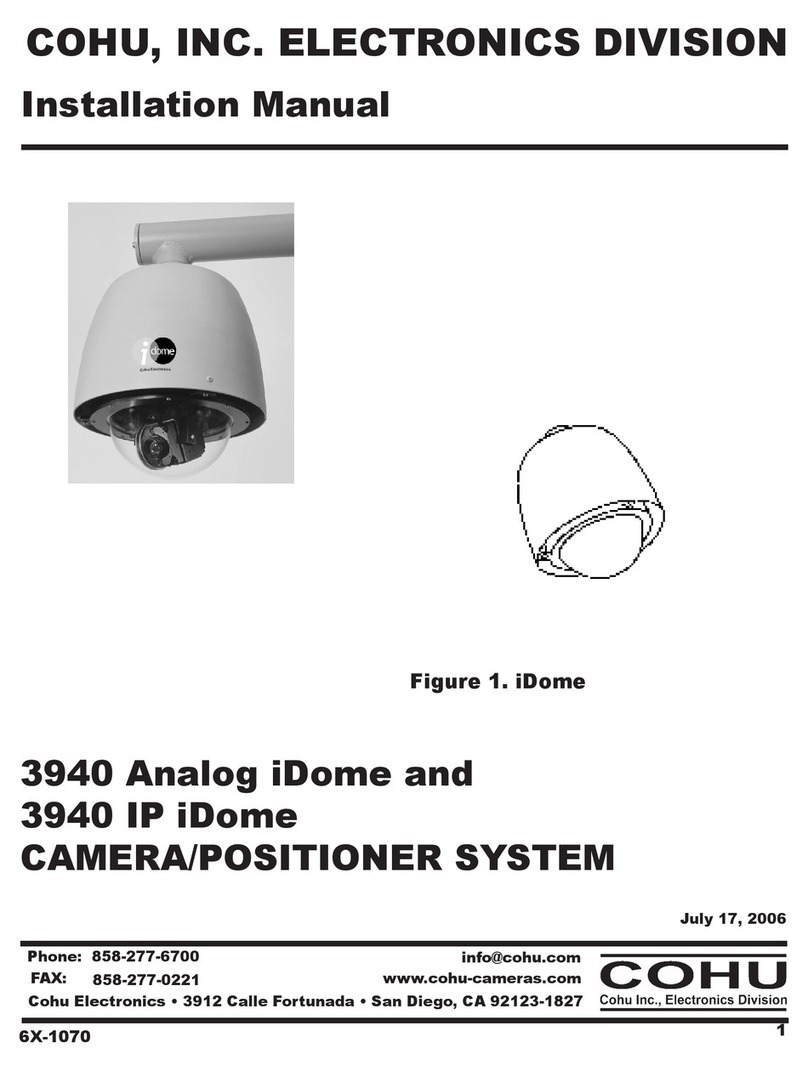

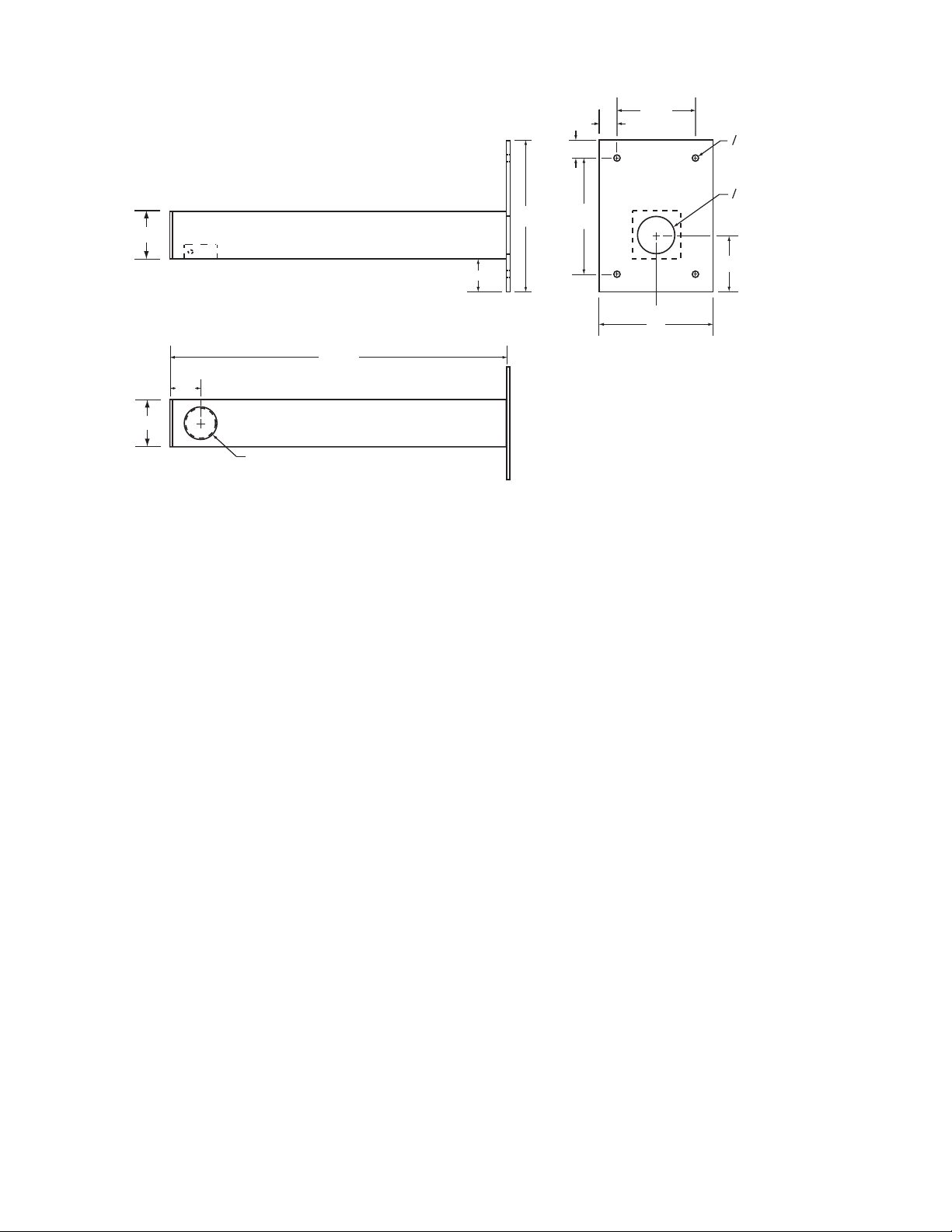

PENDANT MOUNT

WALL MOUNT

POLE MOUNT

Figure 3. Basic Mounting

Configurations