StableTemp 1100°C Box Furnace

Start Up

Cole

-

Parmer

6

6 Start Up

CAUTION!

Observe the following precautions

when operating the furnace:

Never stand in front of an open furnace.

Wear protective eyeware.

Wear protective gloves.

Use tongs to insert and remove furnace load.

Do not allow the load to touch the furnace walls.

Always use a hearth plate on the furnace bottom.

WARNING! Before operating this equipment, read

the applicable MSDS (Material Safety Data Sheets) at

the back of this manual.

WARNING! When Installing, maintaining, or

removing the refractory insulation, the following

precautions will minimize airborne dust and ceramic

fiber:

Keep personnel not involved in the Installation out of

the area.

Use a good vacuum to clean area and equipment.

Do

not

use compressed air.

Use NIOSH high efficiency respirator (3M #8710 or

equivalent).

Wear long sleeve clothing, gloves, hat, and eye

protection to minimize skin and eye contact.

Do not

wear contact lenses.

Thoroughly wash self after work is complete.

Launder work clothing separate from other clothes

and thoroughly clean laundering equipment after

use. If clothing contains a large amount

of dust

and/or ceramic fiber, dispose of rather than clean.

Promptly place used ceramic fiber parts and dust in

plastic bags and dispose of properly.

6.1 Door Seal Check

It is very important to check the door seal before using this

furnace. Door seal integrity is essential to maintain

temperature uniformity and prevent fumes being released into

the area surrounding the furnace.

To check the door seal:

1.

With the furnace power off and chamber cold, open the door.

2.

Insert a strip of paper (a couple of inches wide) between the

door insulation and the chamber opening. Do not position the

paper in the corner of the chamber.

Close the door.

3.

Slowly pull the paper strip from the outside. You should feel

some resistance. If

the paper does not pull out, this area of the

door seal may be causing a gap in another area of the door

seal.

4.

Repeat this test at 2

-

inch intervals around the door. If the

door does not seal properly, a door adjustment must be done .

To start up the furnace, complete the following steps:

1. Turn furnace ON.

2.

Adjust the setpoint to 200°C, following the controller

instruction manual (provided separately).

3. Run the furnace for two hours at 200°C.

4.

Check for heat loss through the door. In the event of heat

loss, recheck the door seal (refer to Section 5.1).

5. Adjust the setpoint to 550°C.

6. Run the furnace for two hours at 550°C.

7. Adjust the setpoint to 1,000°C.

8. Run the furnace for two hours at 1,000°C.

9. Adjust setpoint to room temperature.

7 Control Operation

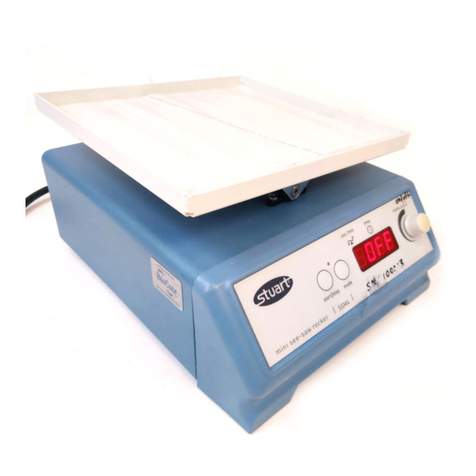

7.1 Main Temperature Control

The programmable process temperature controller is located on

the left side of the control panel.

516 models have single setpoint temperature controls; 517

models have single setpoint with dual display; 518 models have

16

-

segment programmable controls.

All controllers have a maximum process temperature setpoint of

1100°C.

For instructions on control operation, refer to the separate

manual provided.

7.2 Overtemperature Control

("L"

Models Only)

In addition to the main temperature controller, "L" models also

have an overtemperature controller which you can use to set an

alarm setpoint and monitor alarm conditions.

The overtemperature control is located in the middle of the

control panel, to the right of the main controller.

The display shows the current process value.

To view the alarm

setpoint, press and hold star *. The display will toggle between

units (°C) and alarm setpoint.

When the cabinet temperature

exceeds the alarm setpoint, a light flashes on the controller and

power of the heating elements is shut off.

The factory

-

set value of the alarm setpoint is 1100 °C. You may

not set this value higher, but you may change it to a value lower

than 1100

°C.

If the factory

-

set alarm setpoint of 1100 °C is appropriate to your

application, then you do not need to do anything to adjust or

activate the alarm. The overtemperature alarm is automatically

activated when the furnace is powered up.

To change the se

tpoint, press and hold star * and use up button

to increase and down button

to decrease the reading.

6.2 Furnace Start Up

The furnace has a power interrupt switch. Opening the furnace

door shuts off power to the heating unit. The door must be

completely closed before the furnace will operate.

7.3

Communications Option

For enabling communications, order kit part number 7232. Kit

includes Communications PC Board Module (with instructions) to

install into main controller and two RS485 DB9 (one Male and

one Female) wire harnesses to connect from controller to the

two rectangular slots located in the back of the furnace. This

kit MUST BE INSTALLED BY QUALIFIED TECHNICIAN.

For adaptive connections, order accessory kit number 7233.

Kit includes a 300” long RS485 DB9 Male to Female

conversion connection plus a RS232 to RS485 converter

connector.