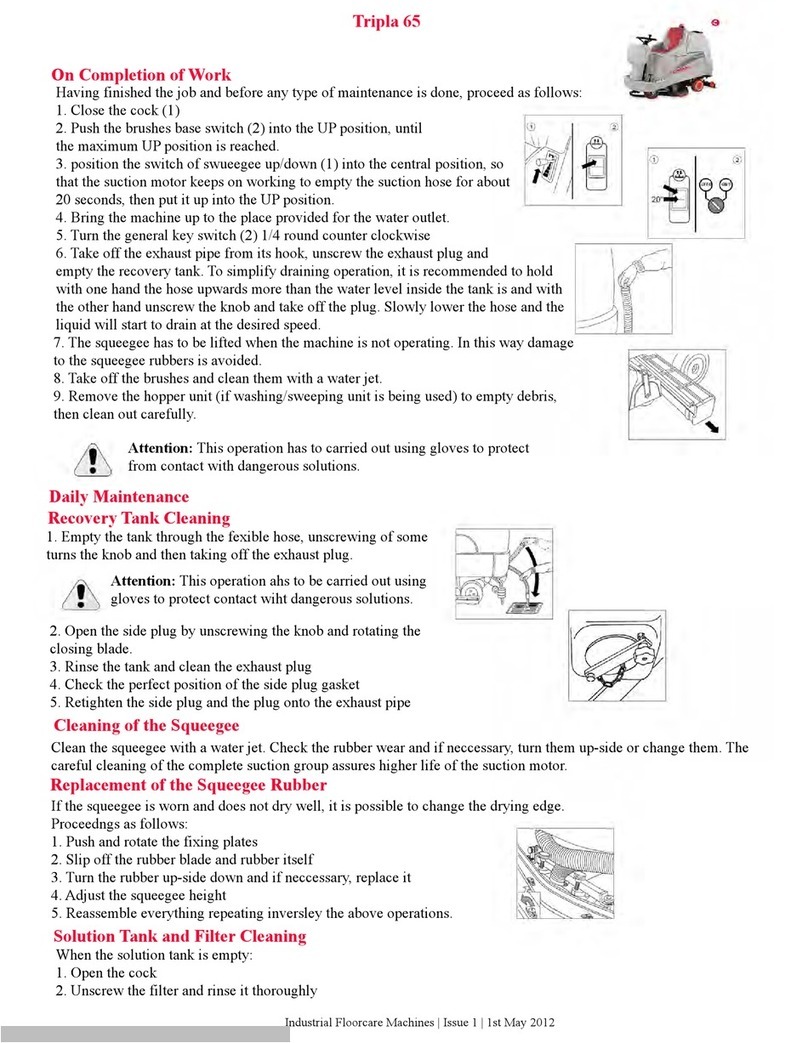

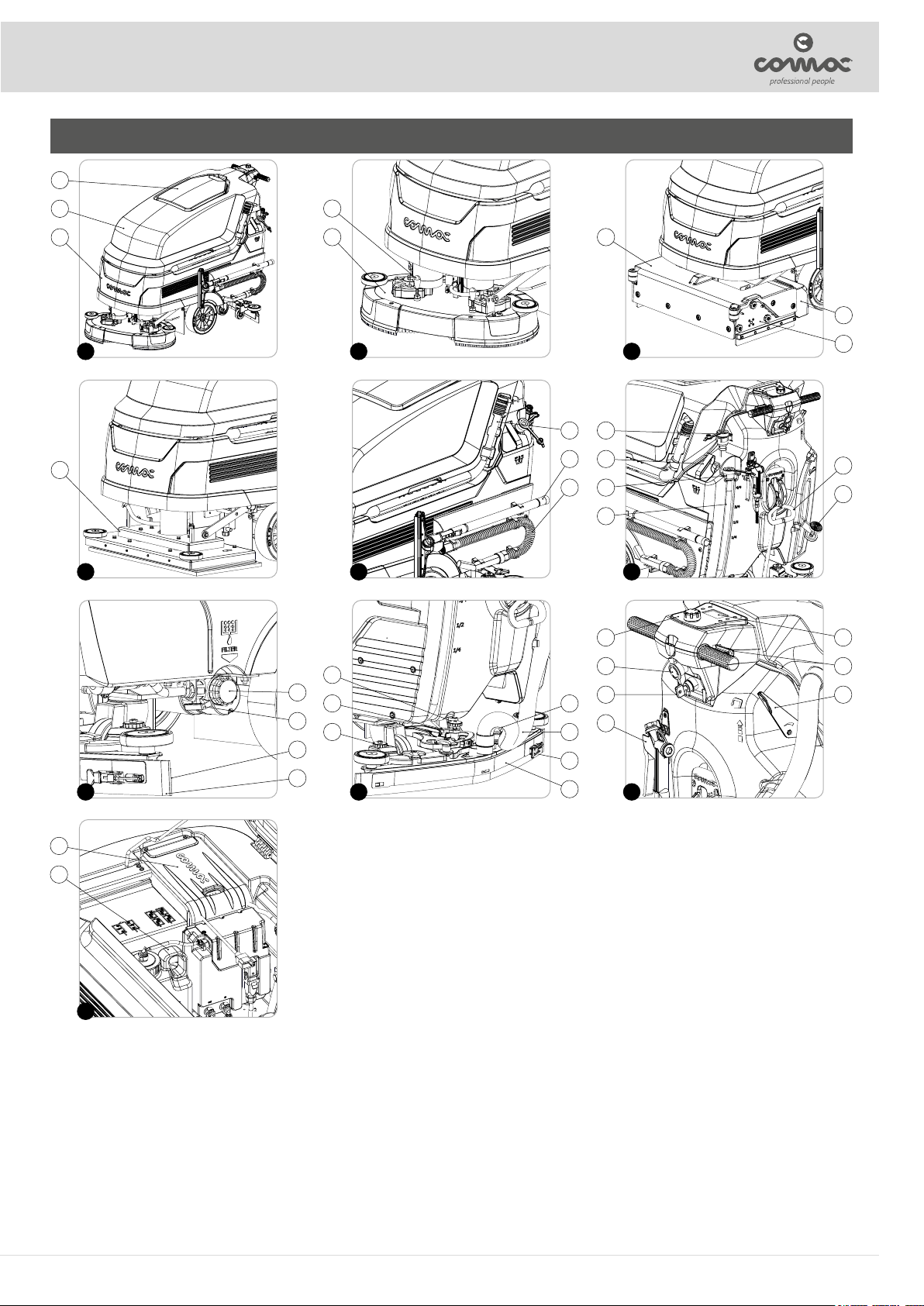

LABELS USED ON THE MACHINE

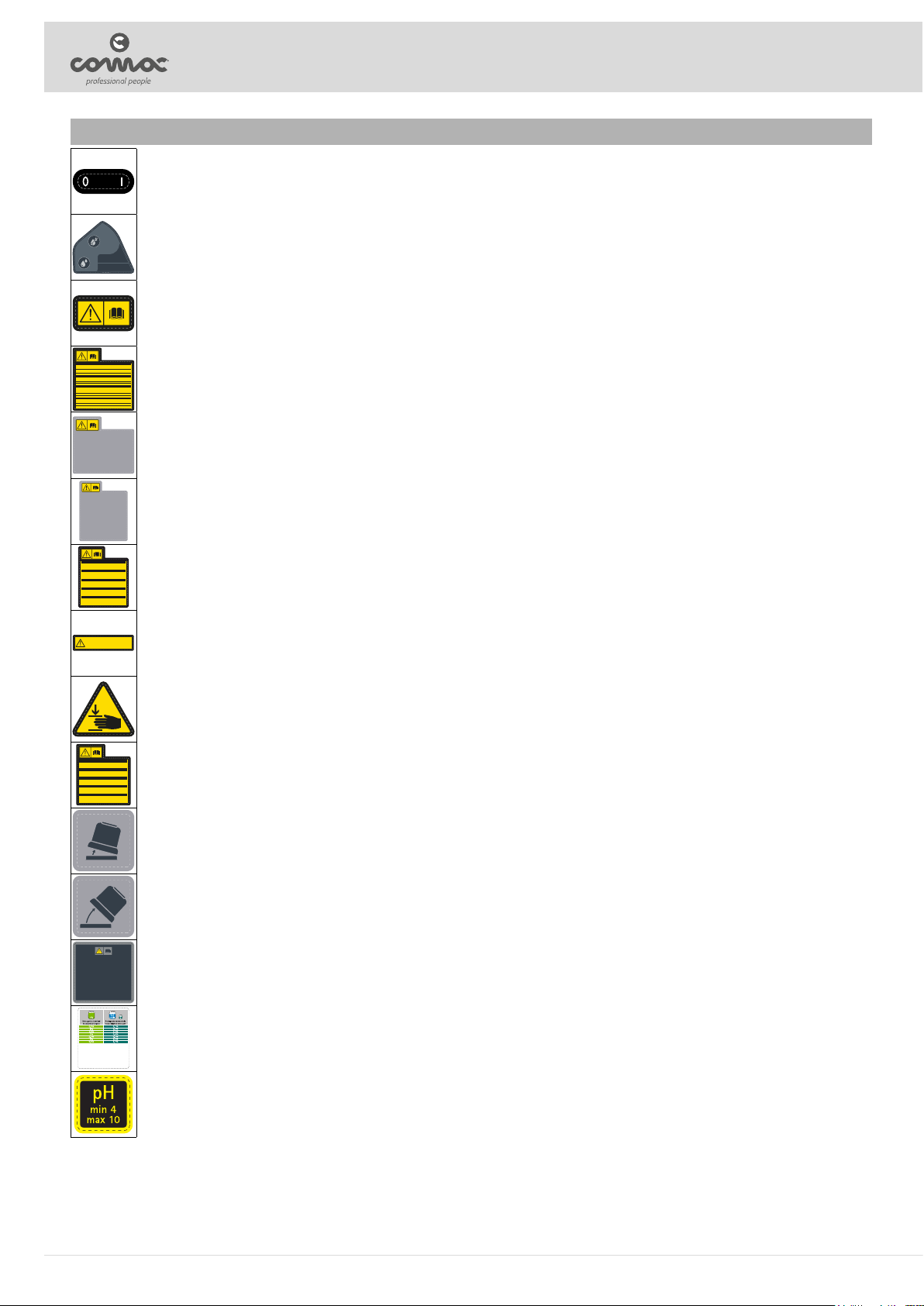

Main switch symbol:

Used by the control handlebars to indicate the main switch on the machine.

-Chiudere il rubinetto a fine lavoro

-Turn off the cock when operations are finished

-Cierrese el grifo al finalizar el trabajo

-Fermer le robinet a la fin du travail

-Den Hahn bei Arbeitsschluss schliessen

-Pulire giornalmente il tergipavimento e i filtri

-Clean the squeegee and the filters

-Limpiar a diario la boquilla de secado y los filtros

-Nettoyer le suceur et les filtres tous les jours

-Taegliche Reinigung des Saugfusses und der Filter

Label for detergent solution tap command:

Used on the rear right-hand side of the machine to identify the detergent solution tap control lever.

Label indicating the need to read the Use and Maintenance Manual:

Used above the recovery tank, near the control handlebar, to indicate to the operator that he/she must read the use and

maintenance manual before using the machine.

ATTENZIONE

Le batterie emettono gas di idrogeno infiammabile. Ne può risultare un incendio o un

esplosione. Tenere scintille e fiamme libere lontane quando la macchina è in carica.

Disconnettere il cavo delle batterie e del carica batterie prima di eseguire la

manutenzione

Non caricare le batterie con il cavo danneggiato

ATTENTION!

Batteriesemit flammacle hydrogen gas. Explosion or fire can result. Keep sparks and

open flame away when charging

Disconnect battery cables and charger plug before servicing machine

Do not charge batteries with damaged cord

¡ATENCIÓN!

Les batteries émettent gaz inflammables. Cela peut provoquer un incendie ou une

explosion.Gardez des étincelles et des flammes à distance lorsque la machine est en

charge.

Débranchez le câble de la batterie et du chargeur avant d'effectuer la manutention.

Ne charger pas les batteries dans le cas où les câbles soient endommagés.

ACHTUNG!

Batterienentwickeln entzündbare Gase. Es kann zu einem Brand oder einer Explosion

führen. Halten Sie Funken und offene Flammen, während der Batterieladung.

Trennen Sie die Kabel der Batterie und Ladegerät Bevor jede Wartung.

Die Batterien nicht laden mit beschädigten Batteriekabeln.

Battery recharge warning label:

This is located inside the machine above the recovery tank, near the batteries, to indicate to the operator that he/she must pay

attention when performing the battery recharge cycle.

RICARICA DELLE BATTERIE

Disinserire il connettore di alimentazione della macchina e collegare il

caricabatterie.

BATTERYCHARGING

Remove the power supply connector of the machine and connect the

battery charger.

CARGA DE LA BATERIA

Quitar el conector de alimentación de la máquina y conectar el

cargador de baterias.

RECHARGE DES BATTERIES

Detacher le connecteur d’alimentation de la machine et brancher le

chargeur des batteries.

WIEDERAUFLADEN DER BATTERIEN

Den Ladestecker der Maschine abschalten und mit dem Ladegeraet

verbinden.

Battery charging sequence label (versions without Battery Charger):

This is located inside the machine above the recovery tank, near the batteries, to indicate to the operator the sequence to be

followed in order to charge the batteries correctly.

ATTENZIONE: caricare la batteria solamente quando il display o le

spie sul cruscotto indicano il livello zero. Il tempo di ricarica della

batteria deve essere di minimo 12 ore. Attendere sempre

l’accensionedel led verde prima di considerare terminata la ricarica.

WARNING:charge the battery only when the display or the lights of

the instrument board indicate level zero. Charge time of the battery

must be at least 12 hours. Always wait for the switching on of the

greenled, only then the recharge has been completed.

ATENCIÓN:cargar la batería solamente cuando el señal baterías y

lasluces pilotos sobre el tablero de instrumentos indican el nivel cero.

El tiempo de carga de la batería será de 12 horas como mínimo.

Esperar siempre el encendido de la led vierde antes que considerar

larecarga terminada.

ATTENTION: charger la batterie seulement quand le témoin de

batterieou la lampe témoin sur le tableau de bord indiquent le niveau

zéro.Le temps de recharge de la batterie doit être au minimum de 12

heures.Attendre toujours l’allumage du led vert avant de considérer

larecharge terminée.

ACTHTUNG:die Batterie darf nur geladen werden, wenn die Batterie

Standsanzeigeoder die Batteriekontrollleuchte den

Batteriestand von Null signalisiert. Die Ladezeit der Batterie muß

mindestens 12 Stunden betragen. WartenSie immer bis die Anzeige

grünaufleuchtet, erst dann ist die Ladung vollständing durchgeführt.

Battery charging sequence label (versions with battery charger):

This is located inside the machine above the recovery tank, near the batteries, to indicate to the operator the sequence to be

followed in order to charge the batteries correctly.

ATTENZIONE!

È fattoassoluto divieto di aspirare/raccogliere con questo

apparecchiopolveri e/o liquidi infiammabili e/o esplosivi

o particelle incandescenti.

ATTENTION!

It is absolutely forbidden to suck/pick up inflammable

and/orexplosive liquid and/or solid substances or aflame

particles with this machine.

¡ATENCIÓN!

Queda terminantemente prohibido aspirar/recoger con

esta maquina polvo y/o líquidos inflamables y/o

explosivos o partículas incandescentes.

ATTENTION!

Il est strictement interdit d'aspirer/ramasser avec cette

machine, poussières et/ou de liquides inflammables

et/ou particules explosives ou incandescentes.

ACHTUNG!

Es ist streng verboten, um Staub und/oder brennbare

Flüssigkeiten,und/oder explosive oder glühendePartikel,

mit dieser Maschine zu saugen/sammeln

Machine use warning label:

Used on the rear of the machine, near the main switch, to indicate to the operator that vacuuming/collecting ammable and/or

explosive powders and/or liquids or incandescent particles is strictly prohibited.

- Pulire sempre il filtro del serbatoio soluzione dopo ogni uso.

- Clean the solution tank filter after every use.

- Limpiar el filtro del tanque solución después de cada uso.

- Nettoyer toujours le filtre du réservoir solution après chaque usage.

- Reinigungslösungstank immer nach jeder Benutzung säubern.

Water system lter maintenance label:

Use on the rear right-hand side of the machine to indicate to the operator that the water system lter must be cleaned after each

work cycle.

Label warning about the risk of crushed hands:

Used inside the machine above the solution tank, near the recovery tank lifting handle, to indicate to the operator that there is a risk

of injury to hands due to crushing between two surfaces.

ATTENZIONE!

Non usare l’apparecchio senza aver letto le istruzioni

per l’uso

ATTENTION!

Do not use the machine without having read the

instructions for the use

¡ATENCIÓN!

La maquina no debe ser utilizada sin haber leído las

instrucciones para el empleo

ATTENTION!

Ne pas utiliser la machine sans lire les instructions pour

l’emploi

ACHTUNG!

Die maschine nicht gebrauchen, ohne vorher die

anleitungen gelesen zu haben

Label indicating the need to read the Use and Maintenance Manual:

Used at the rear of the machine, near the squeegee control lever, to indicate to the operator that he/she must read the use and

maintenance manual before using the machine.

Battery charging position label:

Used inside the machine above the solution tank, near the recovery tank rotation stop lever, to indicate to the operator how the

recovery tank should be positioned when recharging the batteries.

Maintenance position label:

Used inside the machine above the solution tank, near the recovery tank rotation stop lever, to indicate to the operator how the

recovery tank should be positioned when carrying out maintenance on the components located inside the battery compartment.

ATTENZIONE: il sistema di dosaggio è particolarmente indicato per pulizia di

manutenzione frequente .

E’ possibile utilizzare detergenti di manutenzione acidi o alcalini con valori di pH

compresitra 4 e 10 e che non contengano: agenti ossidanti, cloro o bromo, formaldeide,

solventi minerali.

I detergenti utilizzati devono essere idonei per impiego con lavasciuga.

Se il sistema non viene utilizzato quotidianamente, a fine lavoro lavare il circuito con

acqua. Il sistema è escludibile. In caso di utilizzo saltuario di detergenti con pH

compreso tra 1-3 o 11-14 utilizzare la lavasciuga nella modalità tradizionale

aggiungendo il detergente nel serbatoio acqua pulita ed escludendo il circuito di

dosaggio.

WARNING: the dosing system has been specially designed for frequent maintenance

cleaning.

It is possible to use acid and alkaline maintenance detergents with pH values within 4

and 10 and that do not contain: oxidant agents, chlorine or bromine, formaldehyde,

mineral solvents.

Detergents used must be suitable for scrubbing machines.

If the system is not daily used, wash the circuit with water at the end of work. The

system can be cut out. In case of occasional use of detergents with pH within 1-3 or

11-14,use the scrubbing machine in the traditional way adding the detergent in the

clean water tank and cutting out the dosing circuit.

Detergent solution automatic dosing system warning label (versions with CDS):

Used inside the machine above the recovery tank, near the detergent tank, to indicate to the operator which type of pH detergent

can be used with the CDS system without damaging it.

+

MODALITÀ D’USO:

Inserirela tanica o versare direttamente

il detergente nella tanica da 3 litri in

dotazione.

Selezionare, tramite il selettore sul

cruscotto, la % diluizione detergente

desiderata tra i valori indicati nella

tabella.

INSTRUCTIONS:

Insert the can or pour directly the

detergentinto the 3 liter can.

Select with the knob on the instrument

panel the dilution % you need among

thevalues indicated in the table.

MODALITÀ D’USO:

Versare 0.6 litri di detergente

concentrato e riempire completamente

diacqua la tanica da 3 litri in dotazione.

Selezionare, tramite il selettore sul

cruscotto, la % diluizione detergente

desiderata tra i valori indicati nella

tabella.

INSTRUCTIONS:

Pour 0.6 liter concentrated detergent

and fill completely the equipped 3 liter

canwith water.

Select with the knob on the instrument

panel the dilution % you need among

thevalues indicated in the table.

Detergent dilution label (versions with CDS):

Used inside the machine above the recovery tank, near the detergent tank, to indicate to the operator the capacity of the detergent

tank and the dilution percentage for the CDS system.

Detergent solution automatic dosing system warning label (versions with CDS):

Used above the detergent tank to indicate to the operator which type of pH detergent can be used with the CDS system without

damaging it.

10