Compool Cp3000

4

6. For systems which incorporate a skimmer, it is possible to balance the amount of suction between the skimmer

and main drain for maintenance purposes. This is easily accomplished by installing a manual 3-port Freedom

Valve at the suction line. Plumb one port to the skimmer and the other to the main drain.

7. If a “booster pump” type pool cleaner is being used, plumb the pump so that its suction-side is connected to the

pool return, after the heater and as close to the ground as practical.

8. A motorized 3-port Freedom Valve can be installed to create a waterfall from the return line. This enables a

waterfall effect to occur whenever the filter pump is running, and eliminates the need for a separate pump.

9. For systems which utilize solar panels, plumb the solar feed and return lines between the filter and heater, and

install a motorized 3-port Compool Solar Valve at the solar feed line. Provide a vacuum relief valve at the

highest point of the solar panel array, and a ½ lb. spring check valve at the solar return line. Use Compool Solar

Valve (model SOL-2T), to allow the panels to automatically drain whenever the filter pump is not running.

10. For solar systems with very long plumbing runs, or where panels are installed at a very high elevation (higher

than reasonable head pressure of filter pump), a solar booster pump should be installed at the solar feed line. The

motorized Solar Valve should always be used in conjunction with this pump, except where the vertical elevation

of panels above pool water level exceeds 25 feet.

11. For solar systems with glazed panels, plumb a ½” motorized Solar Drain Valve (model HW-5B) from the solar

feed line, through a check valve, to a zero psi point (such as a jet air intake or pool fill line). Do not connect it to

pump suction. This will enable the panels to automatically drain whenever the solar turns off, even if the filter

pump is still running. This prevents possible scaling of panels and damage from overheating. The Solar Drain

Valve (model HW-5B) should also be used for solar systems which do not facilitate gravity drainage of panels

(i.e.: where solar plumbing crosses the ridge of the roof).

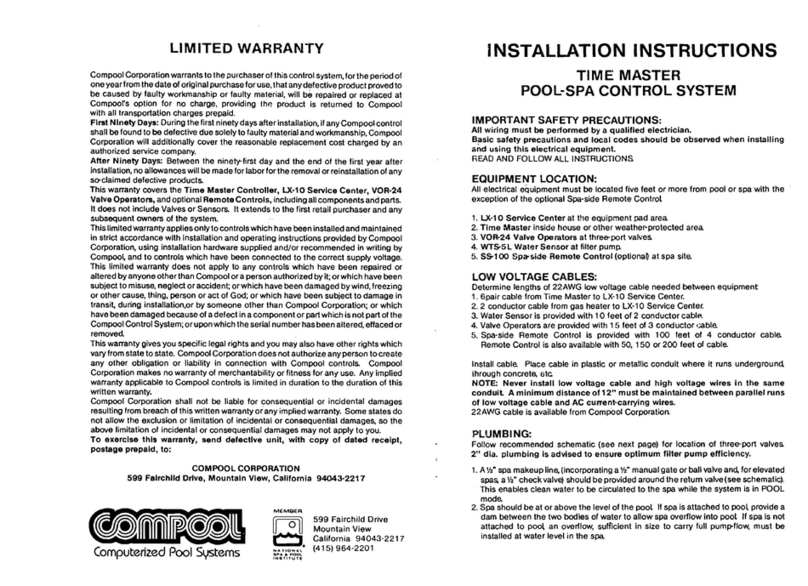

EQUIPMENT LOCATION

With the exception of the Spa-Side Remote (which is UL Listed for installation right at the tile-line of the spa), all

equipment must be located five feet or more from the water’s edge.

1. Lx3000 Power Center at the equipment site.

2. Cp3000 Controller inside the house or other weather-protected area.

3. CVA-24 Valve Actuator(s) at valve(s) to be motorized.

4. TS-5L Water Temperature Sensor at the filter pump.

5. TS-5L Solar Temperature Sensor at solar panels (where applicable).

6. Spa-Side Remote (optional) at spa wall or decking.

Installation