1

1.

ADJUSTEMENT OF THE BAR PARAMETERS.........................................................3

1.1

Programming of the BAR menu...............................................................................................3

1.2

Adjustement of the coffee temperature....................................................................................3

1.3

Menu "Infos display".................................................................................................................3

1.4

Menu "Product parameter adjustment"....................................................................................3

2

PROGRAMMING INSTRUCTIONS................................................................................4

2.1

Enter the programming mode ..................................................................................................4

2.2

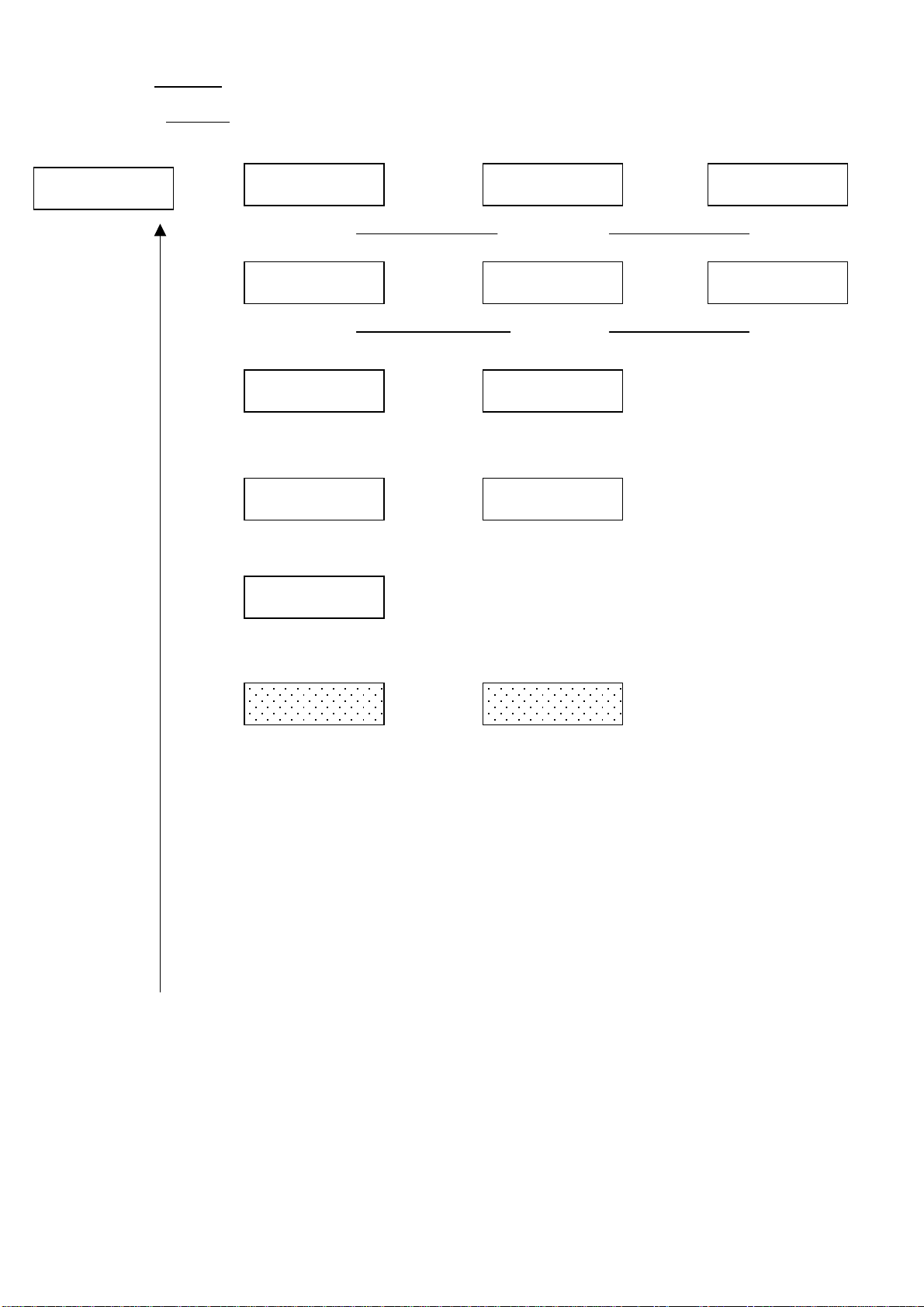

General view of programming steps........................................................................................5

2.3

Access to level 1 (Technical / Factory)....................................................................................7

2.4

SET UP.....................................................................................................................................8

2.4.1

Browsing.......................................................................................................................................8

2.4.2

Language....................................................................................................................................10

2.4.3

Machine type...............................................................................................................................10

2.4.4

Manual /automatic switch on.......................................................................................................10

2.4.5

T°Measure .................................................................................................................................10

2.4.6

Adjusting of the T°coffee boiler..................................................................................................10

2.4.7

Display coffee boiler T°...............................................................................................................11

2.4.8

PID parameters...........................................................................................................................11

2.4.9

PID regulation field .....................................................................................................................12

2.4.10

Number of coffee grounds in the drawer ....................................................................................12

2.4.11

Water softener............................................................................................................................12

2.4.12

Service group..............................................................................................................................13

2.4.13

Electrical Heating management..................................................................................................13

2.4.14

Double click activation................................................................................................................13

2.4.15

Boiler filling .................................................................................................................................13

2.4.16

Drying time of the coffee grounds...............................................................................................13

2.5

Infos display........................................................................................................................... 14

2.5.1

Mode of navigation in the menu..................................................................................................14

2.5.2

Date and Hour.............................................................................................................................14

2.5.3

Restaurant Name........................................................................................................................14

2.5.4

Service name..............................................................................................................................15

2.5.5

Service phone.............................................................................................................................15

2.5.6

Informations showed on the display: ..........................................................................................16

2.6

MENU: Programming Measures........................................................................................... 17

2.6.1

Product definition........................................................................................................................17

2.6.2

Menu: Coffee Products...............................................................................................................18

2.6.3

Menu: Decaf...............................................................................................................................19

2.6.4

Menu: Tea...................................................................................................................................20

2.6.5

Menu: Steam...............................................................................................................................20

2.6.6

Menu: Milk products....................................................................................................................21

2.6.7

Menu: Coffee & Milk products.....................................................................................................22

2.6.8

Menu: Grinding test.....................................................................................................................23

2.7

MENU: Cleaning / Rinsing ................................................................................................... 24

2.7.1

Group cleaning alarm..................................................................................................................24

2.7.2

Compulsory cleaning ..................................................................................................................24

2.7.3

Switch OFF cleaning...................................................................................................................25

2.7.4

Auto rinsing group.......................................................................................................................25

2.7.5

Rinsing cycle...............................................................................................................................25