441-622-015 Type 500X Page 3

Port Sizes

1/4” NPT (Pneumatic)

1/2” NPT (Electric) 1/4” NPT (Pneumatic)

1/2” NPT (Electric)

Clean, dry, oil-free, instrument air, filtered to 40 micron

Electrical Connections

Conduit 1/2” NPT (standard); DIN 43650 (optional)

Pipe, panel, or bracket

2.1 lbs. (0.94 kg) 2.1 lbs. (0.94 kg)

2.1 Description

2.1.1 The ControlAir Type 500X converts a current or voltage input signal to a linearly proportional

pneumatic output

pressure. This versatile instrument is designed for control applications that

require a high degree of reliability and repeatability at an economical cost.

2.2 Principle of Operation

2.2.1 The Type 500X is a force balance device in which a coil is suspended in the field of a magnet by a

flexure. Current flowing through the coil generates axial movement of the coil and flexure. The

flexure moves towards the nozzle

and creates back pressure which acts as a pilot pressure to an

integral booster relay. Input signal increases (or

decreases for reverse acting) cause proportional

output pressure increases.

Zero and Span are calibrated by turning adjust screws on the front face of the unit. Adjustment of

the zero screw repositions the nozzle relative to the flexure. The span adjustment is a

potentiometer that controls the amount of

current through the coil.

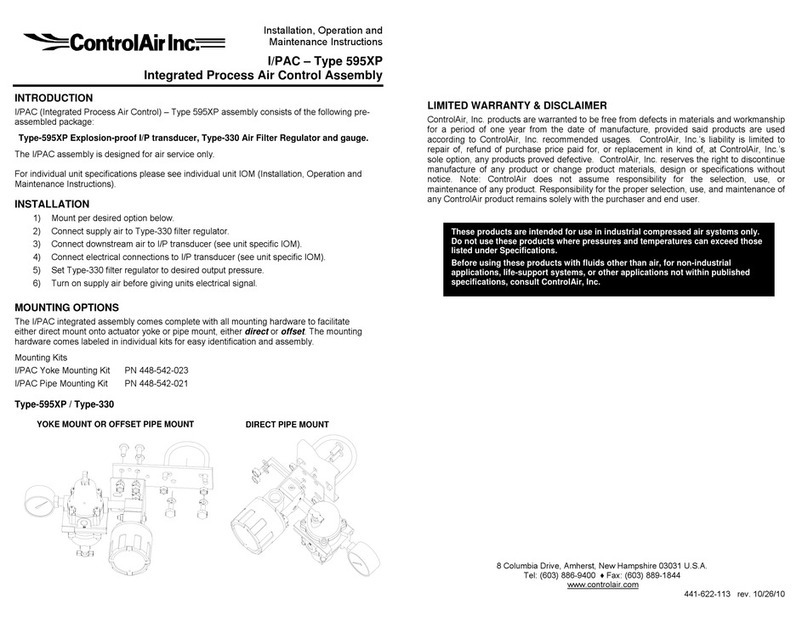

2.3 Mounting

2.3.1 Unit may be pipe, panel, or bracket mounted. Mounting may be at any angle, though may require field

adjustment. High external vibration may cause output fluctuations. Mounting in a vibration-free area is

recommended.

2.4 PneumaticConnections

2.4.1 The 1/4 NPT (1/4 BSP option) supply and output ports are marked “IN” and “OUT” respectively on

the base of the unit. Clean all

pipe lines to remove contamination before installation. Apply pipe

compound to male threads of the air line only. Avoid getting compound in the air lines.

Clean dry instrument quality air must be used. To ensure optimum performance supply pressure

should be regulated. To provide stable inlet pressure and prevent contamination of the internal

section of the transducer the use of an Instrument Air Filter Regulator is recommended.

The two unmarked ports on the base of the unit are gage ports but may be used as alternative

output ports. Any

unused ports must be plugged.

WARNING

The I/P transducer enclosure contains aluminum and is considered to constitute a potential risk of

ignition by impact or friction and must be considered during installation.

2.5 Electrical Connections

2.5.1 Electrical connections are made to the black and white leads extending out from the 1/2 NPT conduit

fitting. When the side of the input signal is connected to the black lead, the output pressure will

increase as the t signal increases.

Figure 1 DIN 43650 Connector (“D” option)

2. DESCRIPTION AND INSTALLATION