441-622-119 Type 2000 Page 10

5. SPARE PARTS

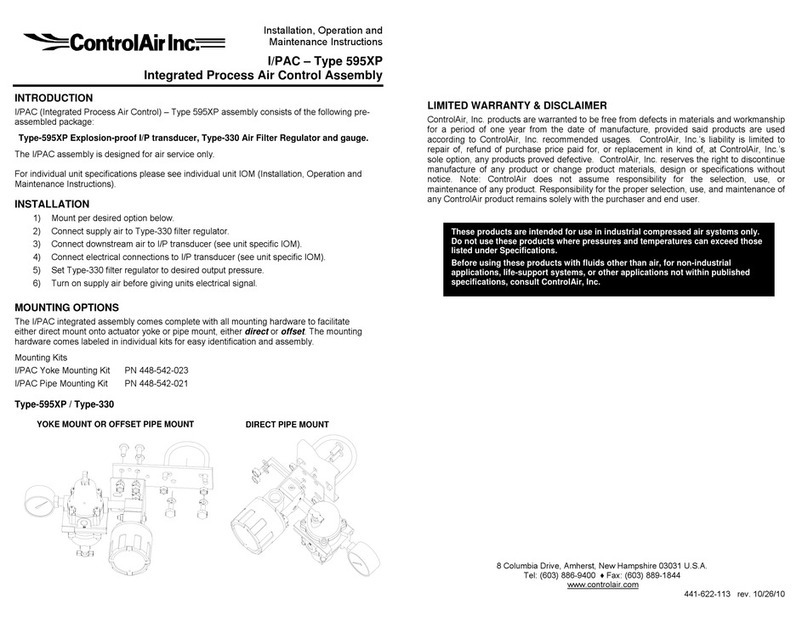

5.1 PARTS LIST

6. WARRANTY & DISCLAIMER

ControlAir, Inc. products are warranted to e free from defects in materials and workmanship for a period of eighteen months from the

date of sale, provided said products are used according to ControlAir, Inc. recommended usages. ControlAir, Inc.’s lia ility is limited to the

repair, purchase price refund, or replacement in kind, at ControlAir, Inc.’s sole option, of any products proved defective. ControlAir, Inc.

reserves the right to discontinue manufacture of any products or change products materials, designs or specifications without notice.

These products are intended for use in industrial compressed-air systems only.

Do not use these products where pressures and temperatures can exceed those

listed under Specifications.

Before using these products with fluids other than air, for non-industrial application, life-support systems, or other applications not

within pu lished specifications, consult ControlAir, Inc.

WARNING

Item Description . . . . . . . . . . . . . . .Qty

1 iaphragm Cover (includes) . . . .1

-Screw . . . . . . . . . . . . . . . . . . . .4

-O-ring . . . . . . . . . . . . . . . . . . .1

2 Cover Plate . . . . . . . . . . . . . . . .1

-Screw . . . . . . . . . . . . . . . . . . .2

3 I/P Transducer Plate . . . . . . . . .1

-590-AC Transducer . . . . . . . . . .1

-Screw . . . . . . . . . . . . . . . . . . . .2

4 XP I/P Transducer Plate . . . . . .1

-595-AC Transducer . . . . . . . . . .1

-Screw . . . . . . . . . . . . . . . . . . .2

5 Screw, iaphragm . . . . . . . . . .1

6 Washer, iaphragm . . . . . . . . . .1

Item Description . . . . . . . . . . . . . . .Qty

7 iaphragm . . . . . . . . . . . . . . . . .1

8 Piston, iaphragm . . . . . . . . . . .1

9 O-ring Seal . . . . . . . . . . . . . . . .1

10 Filter Cap . . . . . . . . . . . . . . . . . .2

-Rubber Channel . . . . . . . . . . .1

-Filter . . . . . . . . . . . . . . . . . . . . . .1

11 Housing . . . . . . . . . . . . . . . . . . . .1

12 rive Shaft . . . . . . . . . . . . . . . . .1

-O-ring . . . . . . . . . . . . . . . . . . .1

-O-ring . . . . . . . . . . . . . . . . . . .1

13 Screw, Back Plate . . . . . . . . . .4

14 Back Plate . . . . . . . . . . . . . . . . .1

Item Description . . . . . . . . . . . . . . .Qty

15 Nitrile Gasket . . . . . . . . . . . . . .1

16 Spring, Safety Valve . . . . . . . . . .1

17 Safety Valve . . . . . . . . . . . . . . . .1

18 Pipe Plug ¼ NPT . . . . . . . . . . .1

19 O-ring Seal . . . . . . . . . . . . . . . . .1

20 Pilot Valve . . . . . . . . . . . . . . . . . .1

-Screw . . . . . . . . . . . . . . . . . . .1

- Gasket . . . . . . . . . . . . . . . . . . .1

21 Pipe Plug, 1/8 NPT . . . . . . . . . . .4

22 Exhaust Filter . . . . . . . . . . . . . . .1

23 Zero Plug . . . . . . . . . . . . . . . . .1

24 Balance Arm . . . . . . . . . . . . . . . .1

25 Spring, Guide Arm . . . . . . . . . . .1

26 Guide Pin . . . . . . . . . . . . . . . . . .1

27 Guide Arm . . . . . . . . . . . . . . . .1

-Roller Bearing . . . . . . . . . . . . . .1

-Zero Screw . . . . . . . . . . . . . . . .1

-Screw . . . . . . . . . . . . . . . . . . .1

-Bearing . . . . . . . . . . . . . . . . . .1

28 Holding Washer . . . . . . . . . . . . .1

-Screw . . . . . . . . . . . . . . . . . . .1

29 Feedback Spring Assembly . . . .1

30 E-clip . . . . . . . . . . . . . . . . . . . . . .1

31 Cam (C1 Shown) . . . . . . . . . . . .1

32 Cam Nut . . . . . . . . . . . . . . . . . . .1

-Screw . . . . . . . . . . . . . . . . . . .1

33 Indicator with Label . . . . . . . . .1

-Screw . . . . . . . . . . . . . . . . . . .1

34 Front Cover Seal . . . . . . . . . . . . .1

35 Front Cover . . . . . . . . . . . . . . . .1

- Label . . . . . . . . . . . . . . . . . . . . .1

-Screw . . . . . . . . . . . . . . . . . . .4

36 Screw, Pin Retain . . . . . . . . . . .2

37 Screw, Balance Arm . . . . . . . . .2

38 Screw, Terminal Block . . . . . . . .1

39 Screw, Ground . . . . . . . . . . . . .2

40 Lock Washer, Ground . . . . . . . .2

1

2

3

4

5

6

7

8

10

9

11

12

13

141516 17

18

19

20

21

23

24

25

26

27

28

29 30

31

32

33

34

35

36

37

38

39

39

40

22