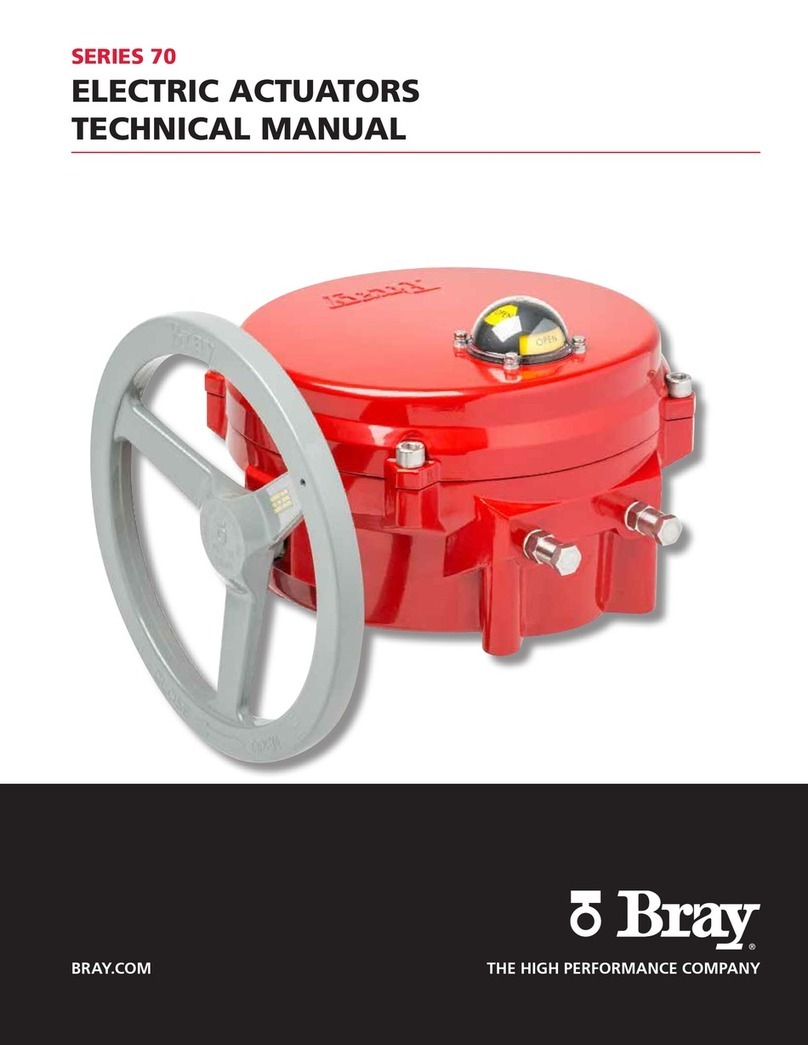

SERIES 70 ELECTRIC ACTUATOR

Installation, Operation, and Maintenance Manual

2 of 48

© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM

The Information contained herein shall not be copied, transferred, conveyed, or displayed in any manner

that would violate its proprietary nature without the express written permission of Bray International, Inc.

TABLE OF CONTENTS

Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Series – Size E E E – Electric Actuator Exploded View . . .

Series – Size E E E – Electric Actuator Exploded View . . .

Series – Size – Electric Actuator Exploded View . . . . . .

Series – Size – Electric Actuator Exploded View . . . . . .

Series – Size – Gear Box Exploded View . . . . . . . .

Hazard-Free Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S OnO Actuator with Interposing Relay Board (IRB). . . . . . .

Servo NXT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting the Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring the Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Travel Limit Switches . . . . . . . . . . . . . . . . . . . . . . . .

Setting Mechanical Travel Stops . . . . . . . . . . . . . . . . . . . . . .

Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field or Factory Installable Options . . . . . . . . . . . . . . . . . . . . . . . .

Auxiliary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Backup Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indication of Remote Control . . . . . . . . . . . . . . . . . . . . . . . .

Spinner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receptacles (Quick Connectors) . . . . . . . . . . . . . . . . . . . . . .

External Signal Feedback Potentiometer . . . . . . . . . . . . . . . . .

Appendix A - Basic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B - Actuator Troubleshooting Chart . . . . . . . . . . . . . . . . . .