4

AC power. The battery is checked for presence once an

hour for 10 seconds. If this test fails, the battery has

failed or is significantly depleted. A major fault (see “a”

and “b” examples) is declared and must be immediately

rectified. The battery is also load tested for five minutes.

The five minute load test is performed once per week to

ensure that the power remaining in the batteries is

sufficient to handle an emergency condition. The test will

occur within 12 hours of a power outage or an aborted

test due to user input.

The severity of the battery test failures are defined as a

minor fault and a major fault and are described as

follows:

a. Minor Fault. This fault mode occurs when the system

determines that the batteries fail to maintain the

minimum voltage between 10 seconds and 5 minutes

of load testing. The alarm within operator will begin

notification immediately at 3 seconds per minute. The

batteries will be retested every week. The controller

will attempt to close the door after 45 days of

notification and test failures.

b. Major Fault. This fault mode occurs when the system

determines the batteries fail to maintain the minimum

voltage for less than 10 seconds of load testing. The

batteries are either not connected or are significantly

depleted. The system will attempt to close the door

after the DIP switch selected alarm delay. (See DIP

Switch section of this manual.) Notification will occur

as a 1 second on 1 second off pulse train until Battery

Test passes.

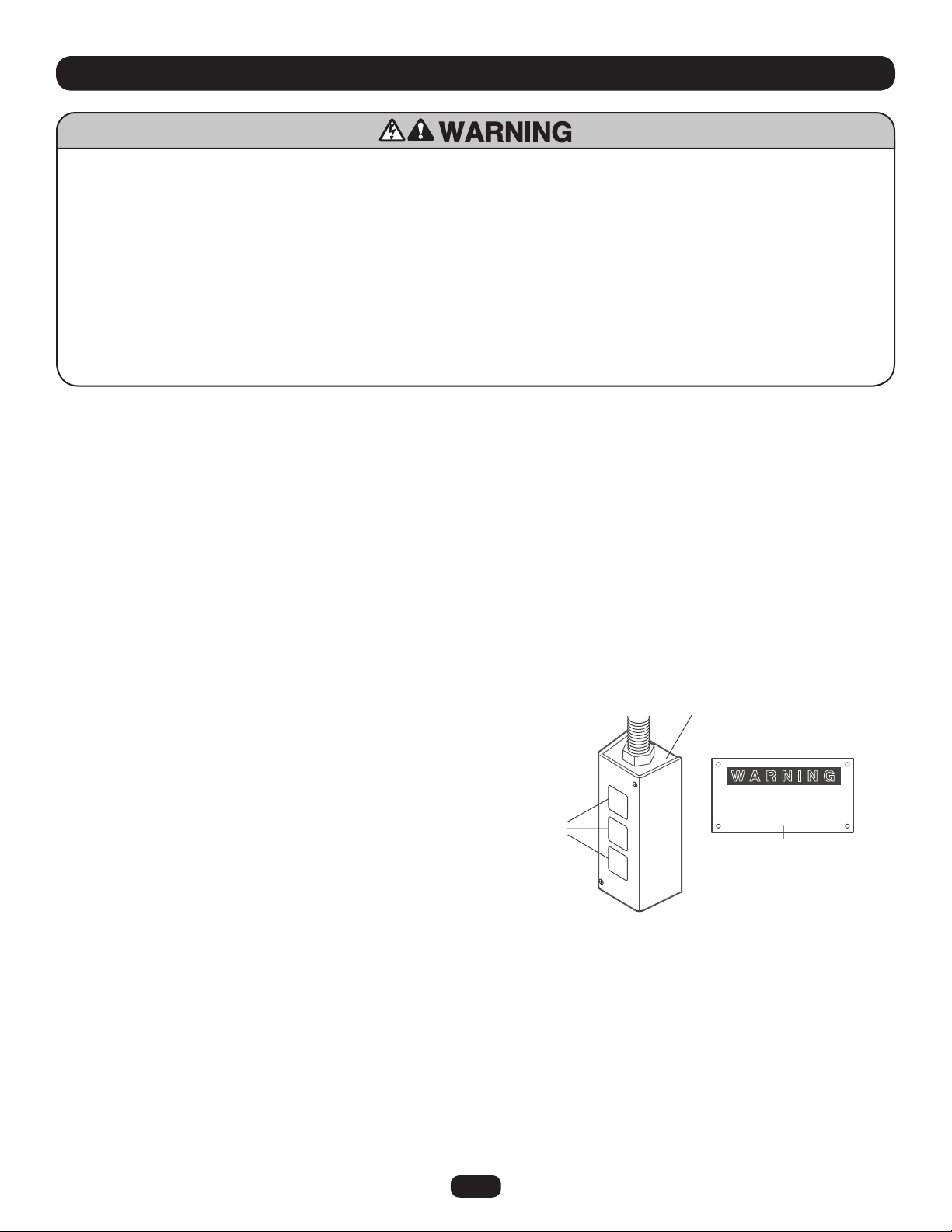

Whenever a battery failure occurs, the batteries must be

connected or replaced immediately in order to ensure

normal system operation. If for any reason the battery

voltage drops below the minimum voltage, the unit will

activate the optional warning system and automatically

close the door via a controlled descent.

If the system passes the Battery Test, then all alarms are

cleared.

Battery Disposal

Replaced batteries must be treated as a hazardous waste

and disposed on in accordance with State, Local and

Federal Regulations. See the battery manufacturer’s

Material Safety Data Sheets (01-30839 "MSDS Sheets,

Battery, Standard").

Battery Replacement

To order a replacement battery kit, see contact

information on page 18.

Battery Maintenance / Testing

The batteries are maintenance free. However, to insure

proper and safe operation, it is recommended that the

batteries be replaced every two years. Battery testing is

conducted automatically. See the Battery Test Description.

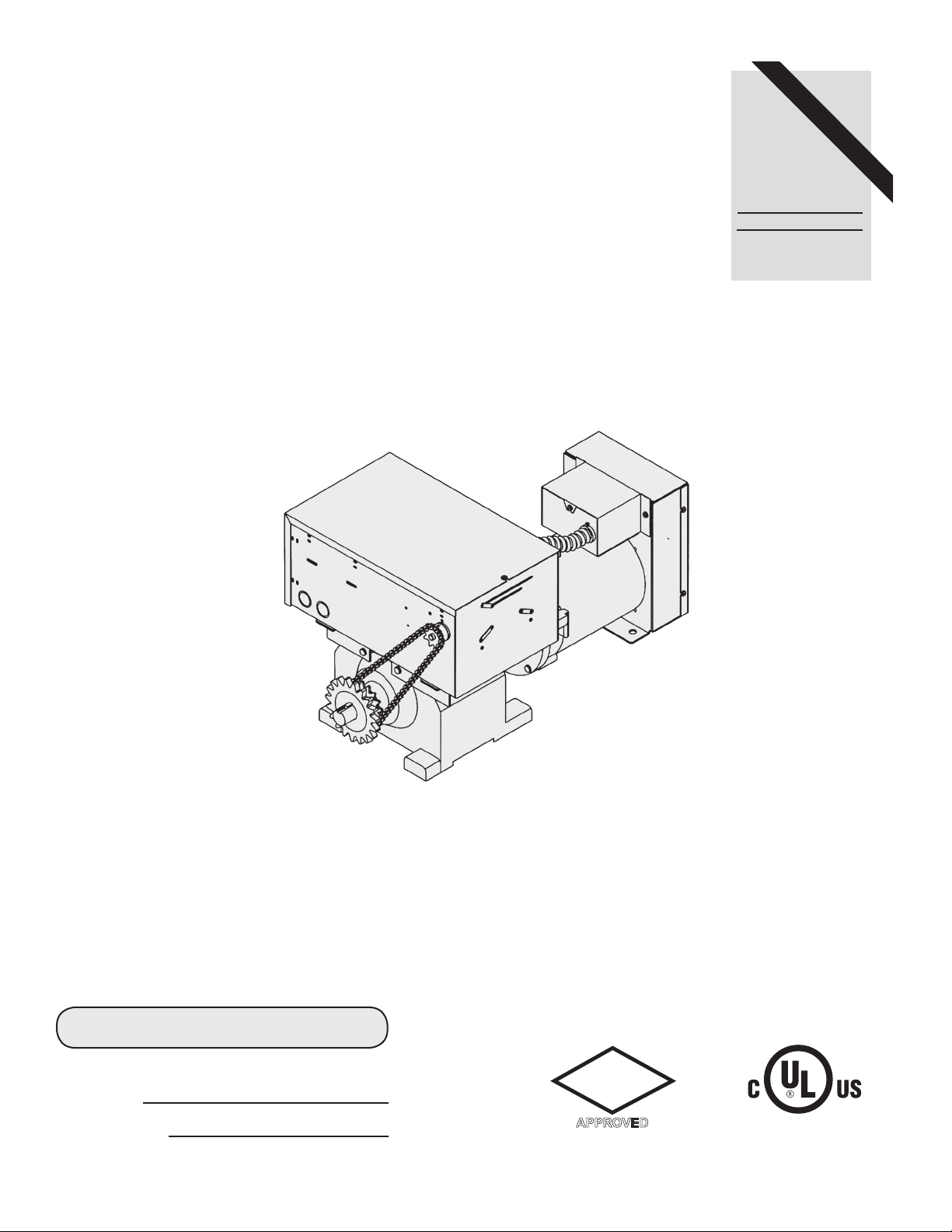

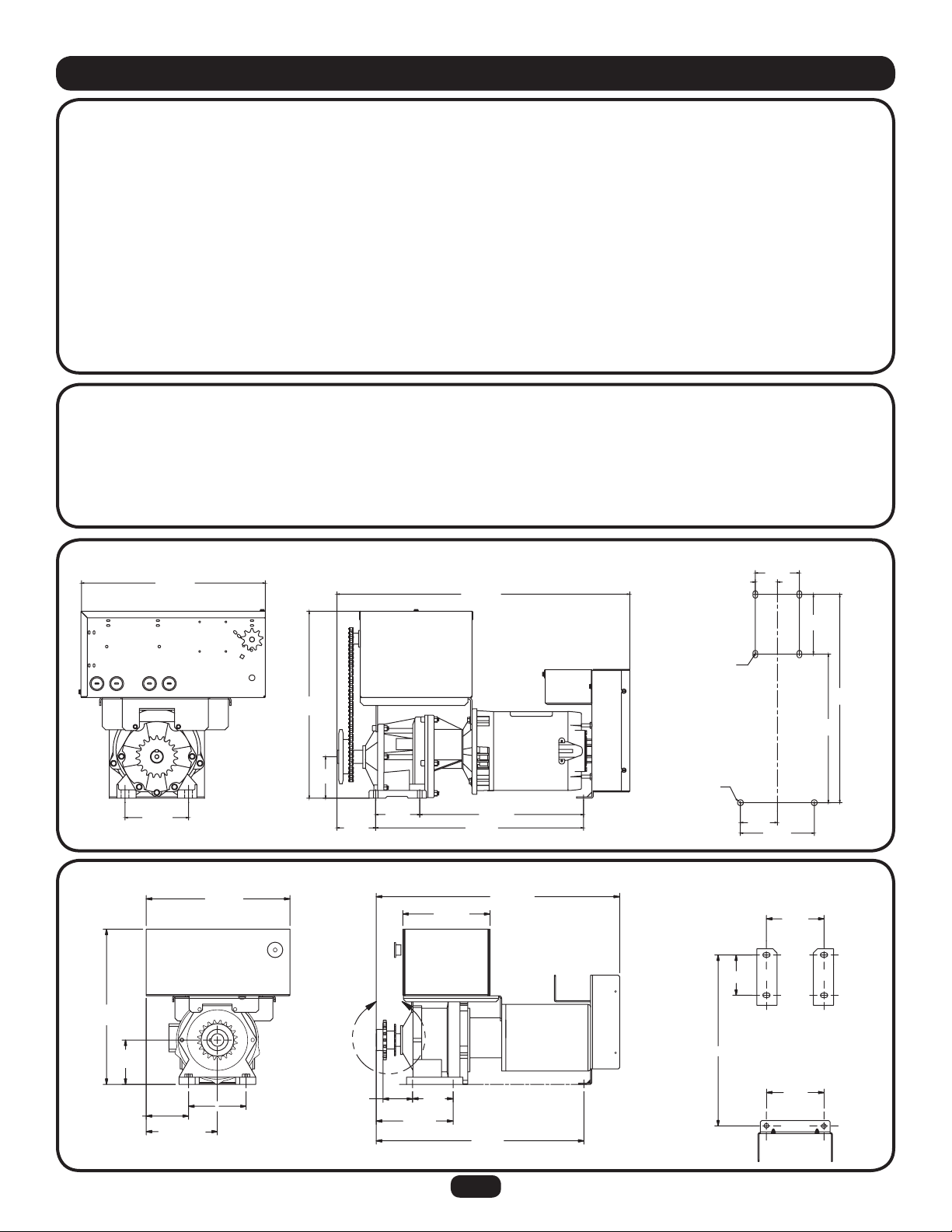

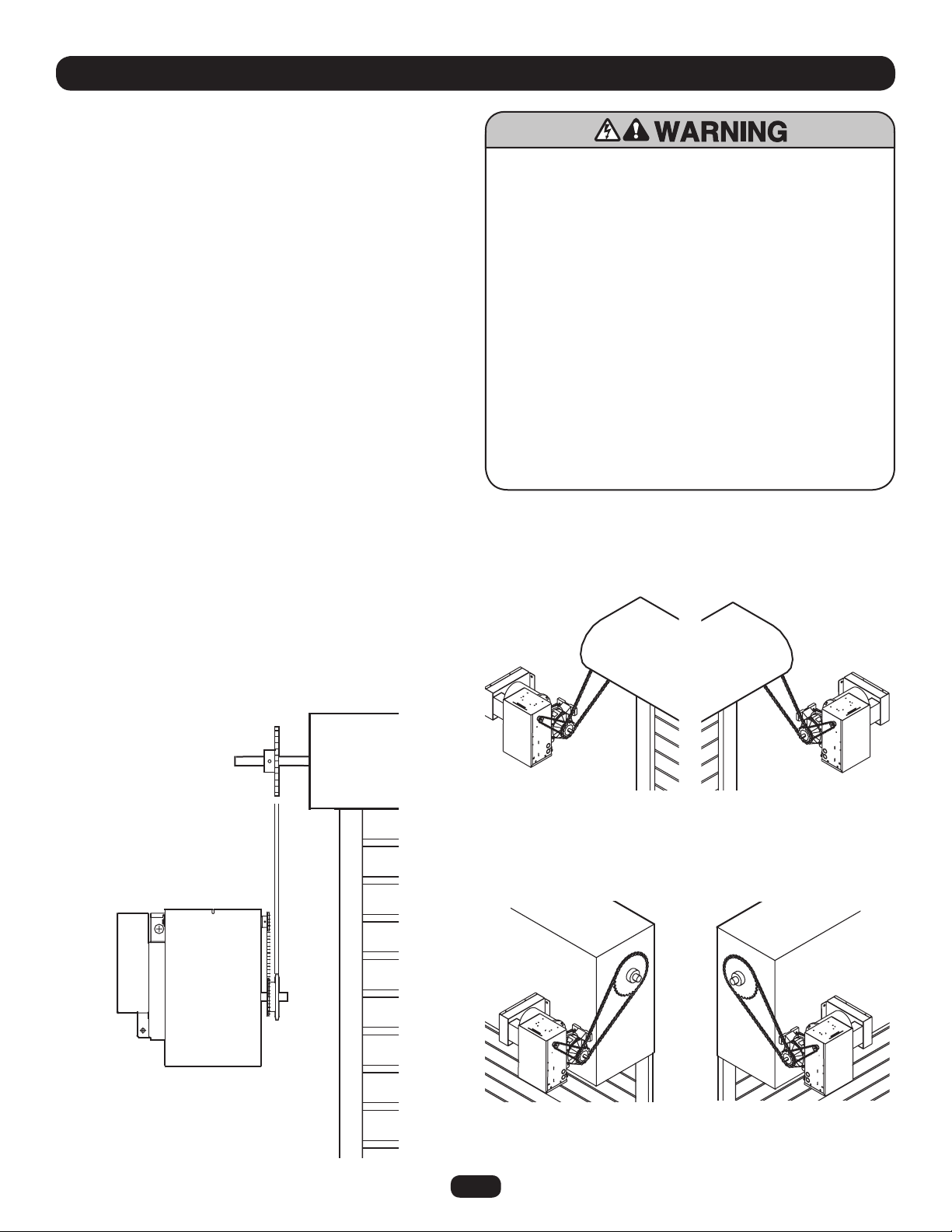

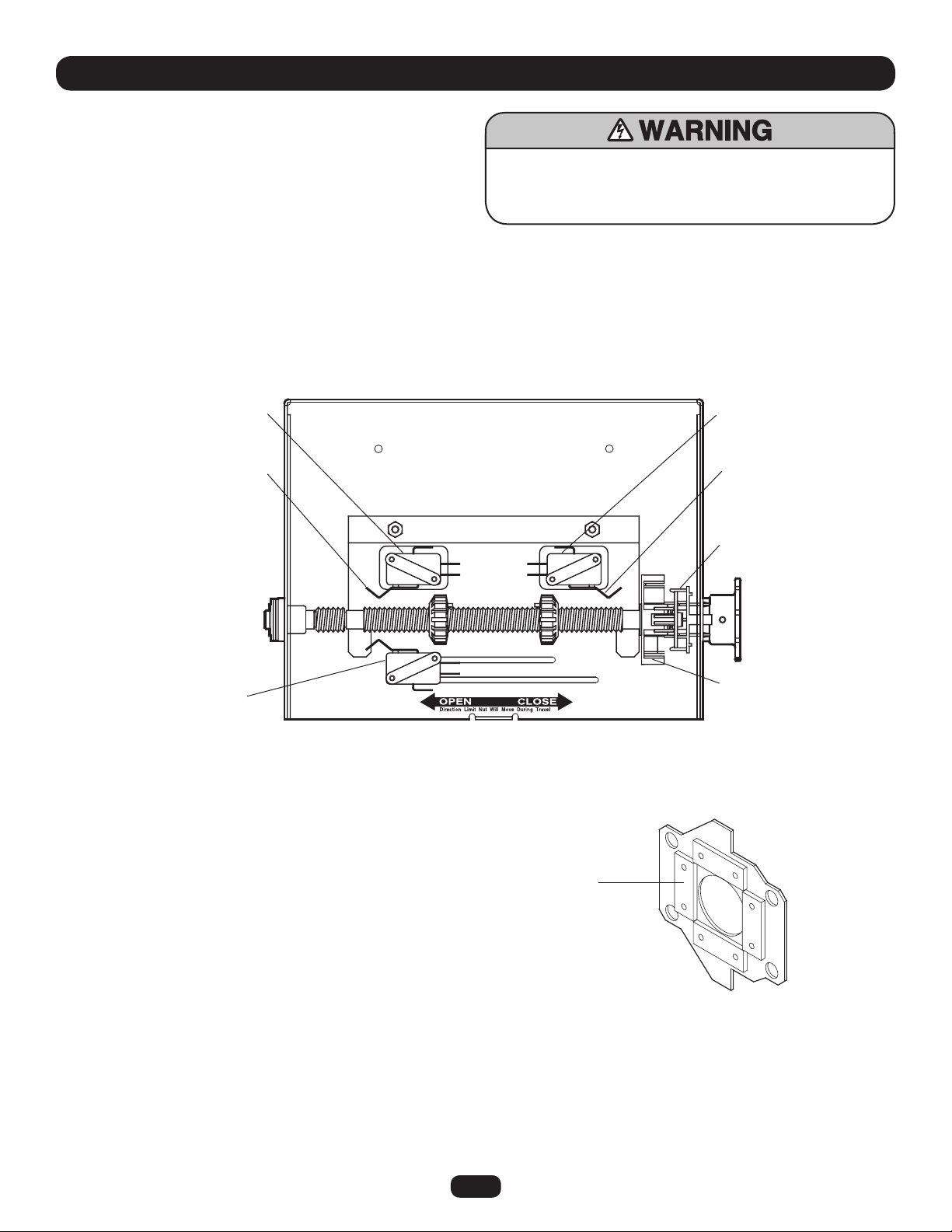

GENERAL DESCRIPTION:

The Fire Door Operator, FDO-A or FDO-B, is an integrated fire

door control system. It is designed to interface with a normally

close (NC) or normally open (NO) dry contact alarm system to

control the operation of a fire door. The control station is the

standard B2/C2 wiring. There are two (2) models for the FDO:

• A model: A (AC only) model has no battery backup nor

electronic speed control for door’s descent. The

brake is disengaged when there is no AC power.

• B model: B (Battery backup) model provides battery backup

operations and electronic speed control for door’s

descent when there is no AC power. The brake is

engaged when there is no power.

NOTE: This operator is not a fire alarm system. It can not detect a

fire condition.

1. FDO-A MODEL:

IMPORTANT: Door Descent Speed Control is required for

FDO-A model.

1.1 UNIT HAS AC POWER & NO ALARM CONDITION:

• The B2/C2 control station is used to operate the door

electrically.

• Activation of the safety edge while door is closing will

cause it to reverse to full open limit.

• Activation of safety edge while door is opening will

cause it to stop.

• Activating the optional key-test switch for at least 6

seconds will put the operator in active alarm mode.

1.2 UNIT HAS AC POWER & ACTIVE ALARM CONDITION:

• The warning system (optional) will activate. The door

will automatically close after the preset time delay. The

time delay is set by means of DIP switches 1 and 2,

(See page 12).

• The door will reverse to full open limit if an obstruction

is encountered while closing. The door will automatically

close again after the preset time delay. If the obstruction

is not cleared, upon the 3rd attempt to close, the door

will stop on the obstruction and activate the warning

system (optional) then release the brake. Subsequent

obstruction will cause the door to stop for two (2)

seconds then release the brake.

1.3 UNIT HAS NO AC POWER:

• The unit is not functional and the brake is released.

2. FDO-B MODEL:

2.1 BATTERY MANAGEMENT SYSTEM:

• The battery is charged, tested and monitored

automatically by the microprocessor based system.

Battery Test

The FDO-B provides internal battery testing to ensure the

battery has not been disconnected and the system can

perform it’s intended functionality in the event of a loss of

THEORY OF OPERATION