STANDARD RECOMMENDED PROCEDURE 009-221 | ISSUE 8 | AUGUST 2015 | PAGE 8 OF 10

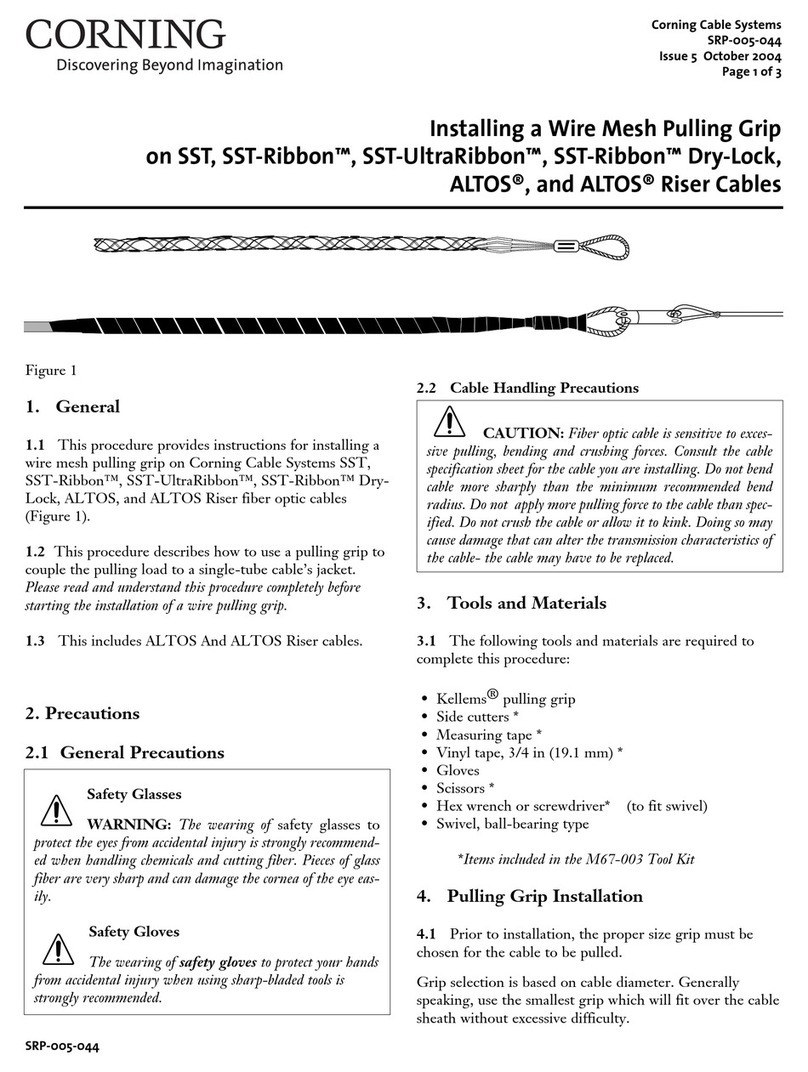

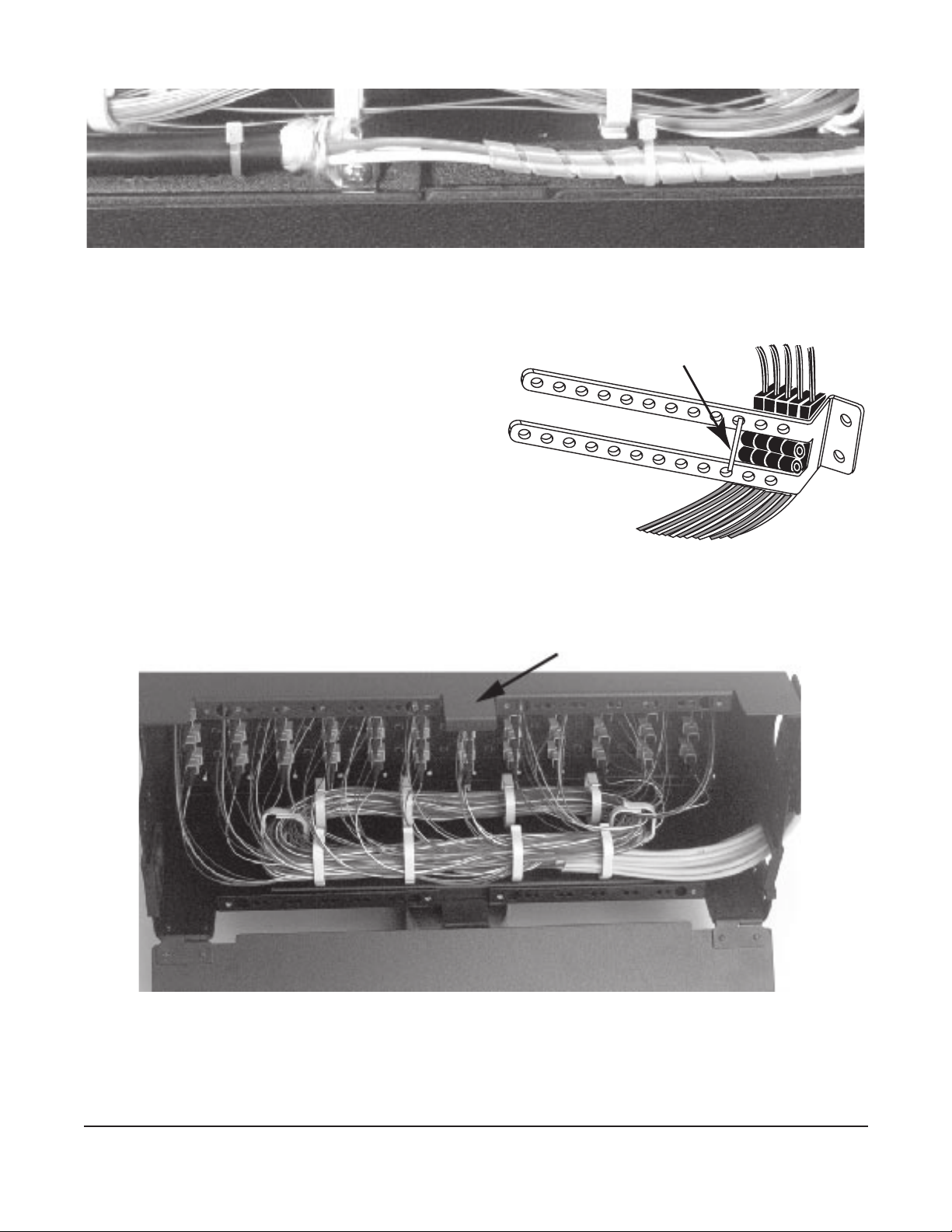

7.3.1 Routing Cable

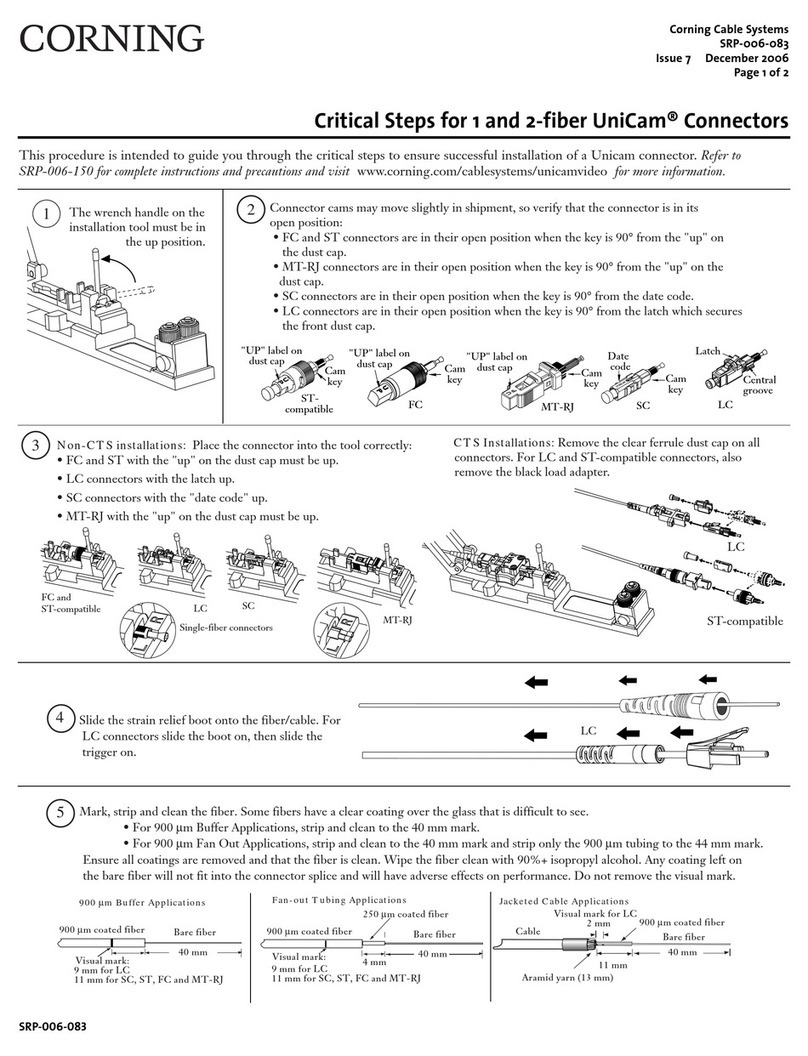

Step 1: Install connectors on the bers per instructions provided with the connectors.

Step 2: Route the ber slack inside the housing in the pattern shown in Figure 13.

Step 3: Clean the adapters and connector end-faces per standard company practices or as

described in Section 9; then plug the connectors into the adapters at the rear of the

connector panels.

Step 4: If routing pigtails to the housing, attach an identication tag to the end of each

bundle, indicating the number of the panel to which it is attached. Pigtail bers can

be routed through the pass-through ports in the top and bottom of the housing to

splice hardware in splice shelves.

Step 5: Attach a numerical identication tag to each tight-buffered ber, indicating the

connector location on the panel.

NOTE: If it is necessary to remove any excess length of spiral-wrapped ber, make sure to place new

identication tags on the new working length prior to removing the excess.

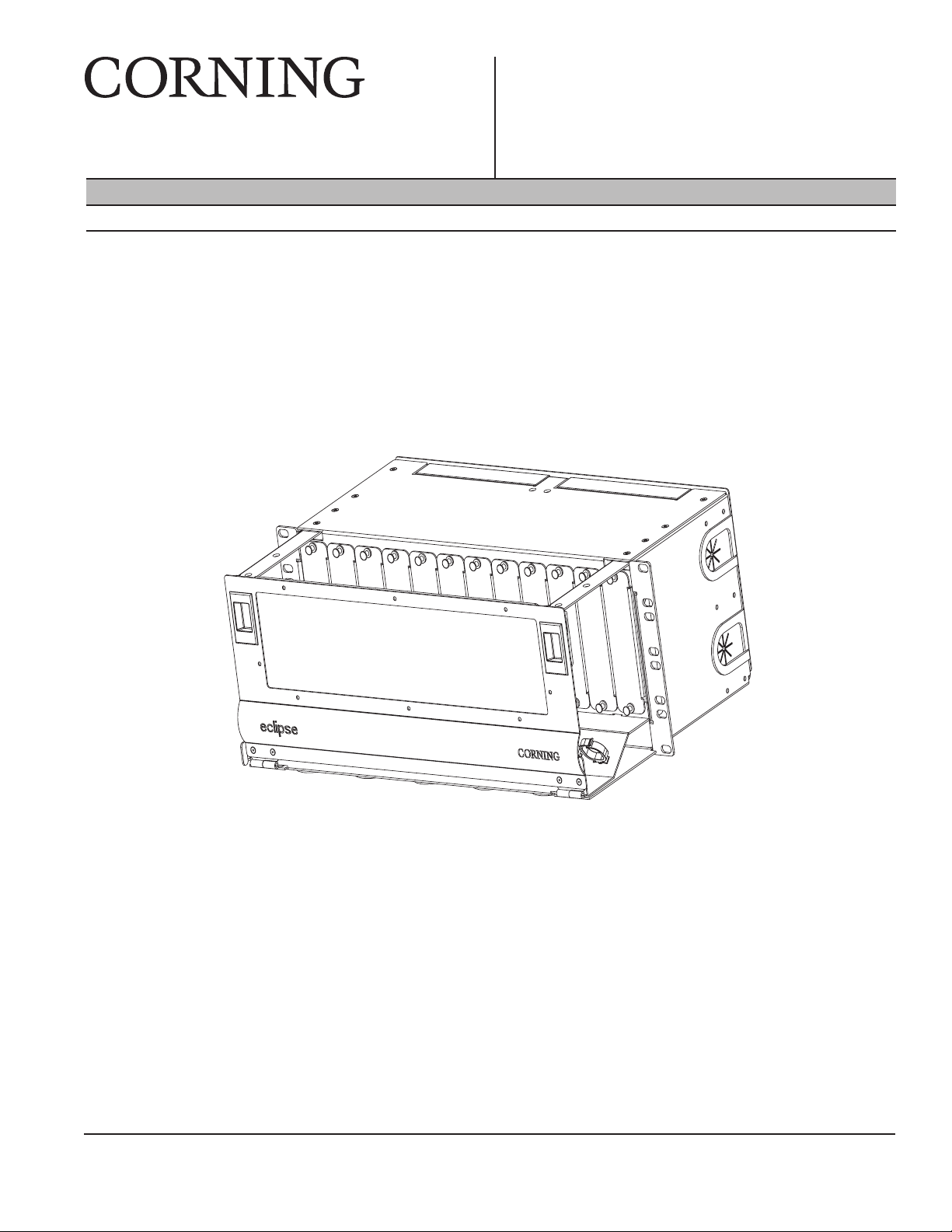

7.3.2 Install Jumpers

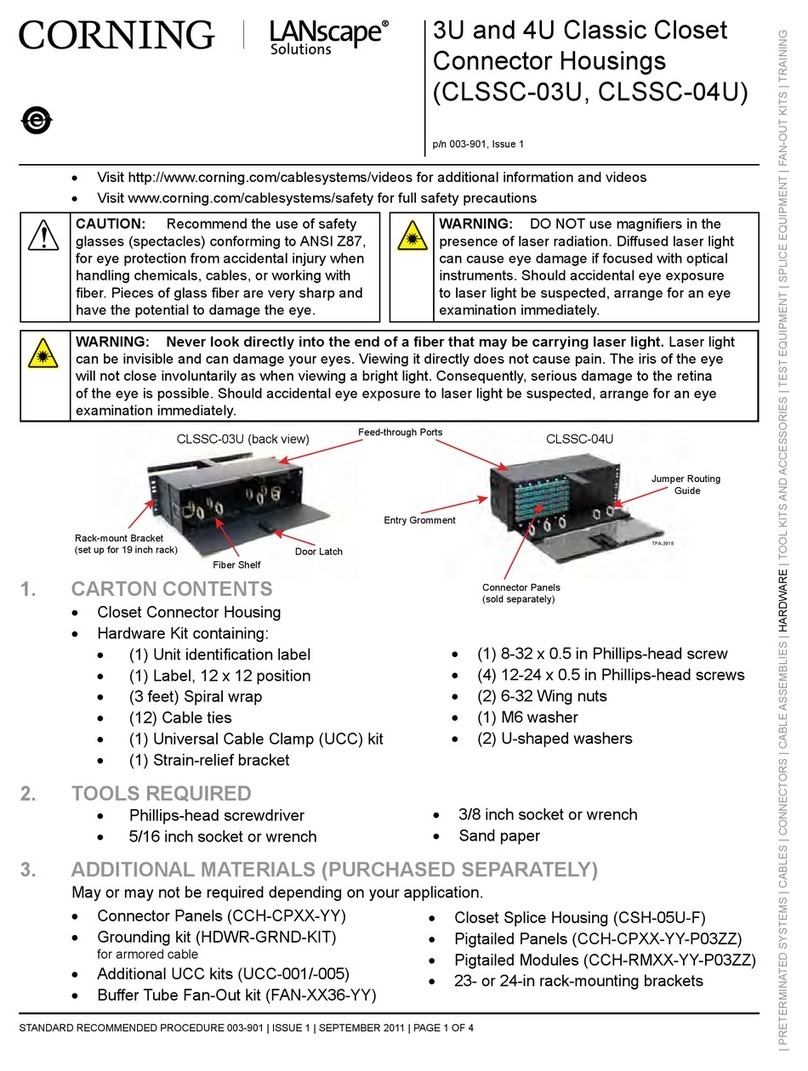

In the CATV environment where moves,

adds, and changes are frequent, good

jumper management and record keeping

are imperative. To help maintain a neat and

organized installation, Corning strongly

recommends the use of the Jumper

Management Panel and the Inter-Bay Storage

Unit (Figure 14) (contact your Corning

Optical Communications customer care

representative for assistance).

If using the jumper management panel, route

jumpers through the management panel and down into the C4U housing (Figure 14). Otherwise,

route jumpers into the housing from either side over the jumper trough (Figure 15), or in through

the ports in the oor of the housing (Figure 16).

NOTE: Allow the minimum bend radius when inserting the jumpers into the routing clip and routing the

jumpers out of the housing. Do not apply more pulling force to the cable than specied. Do not

use the clip when routing to a jumper management panel above the C4U housing.

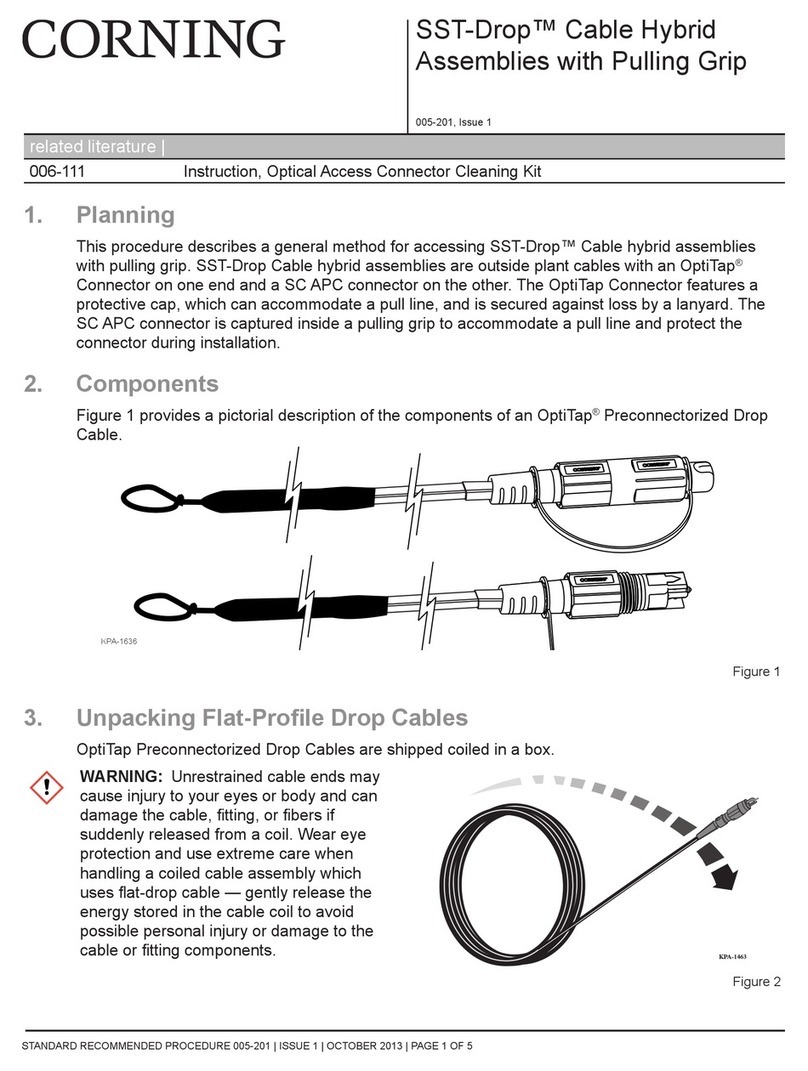

7.3.3 Jumper Management Using

Jumper Trough

Step 1: Install jumper trough in the front of the housing

using the two screws provided (Figure 15).

Step 2: Route jumpers through the routing clip

below the applicable adapter panel. Or route

jumpers through the jumper management

panel as shown in Figure 14.

Step 3: Clean the adapters and connector end-faces.

Mate the connectors in the adapters.

KPA-2204

Figure 14

KPA-2202

Figure 15