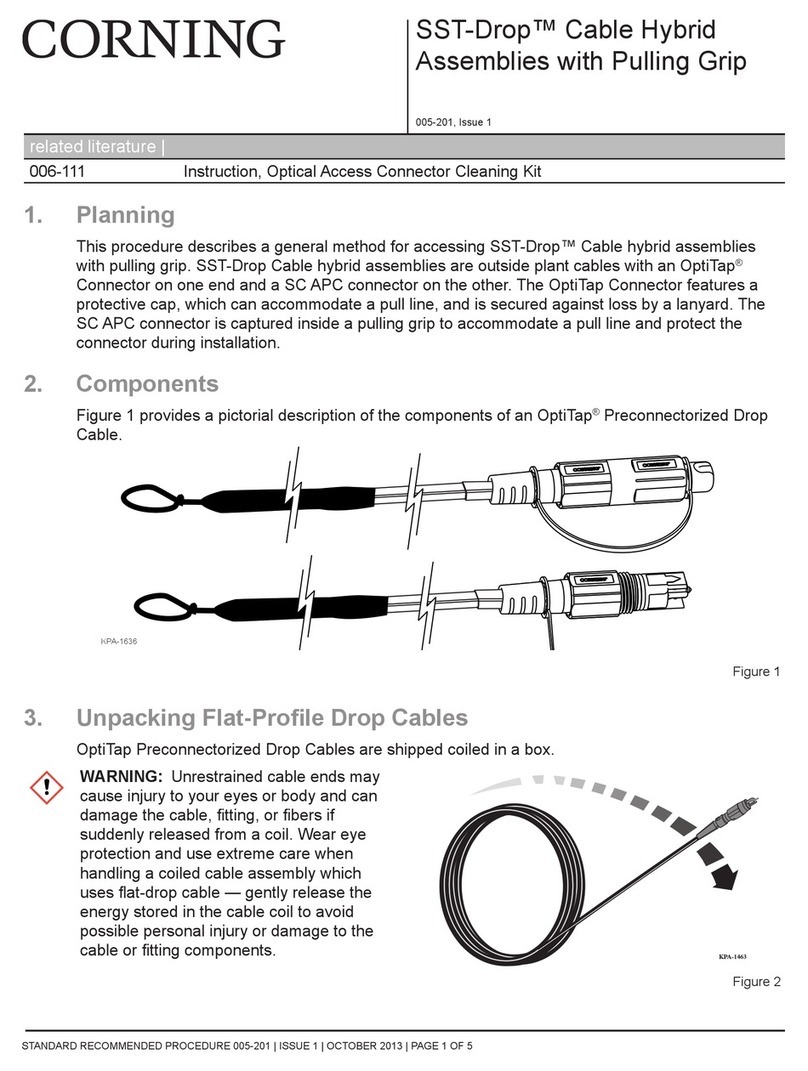

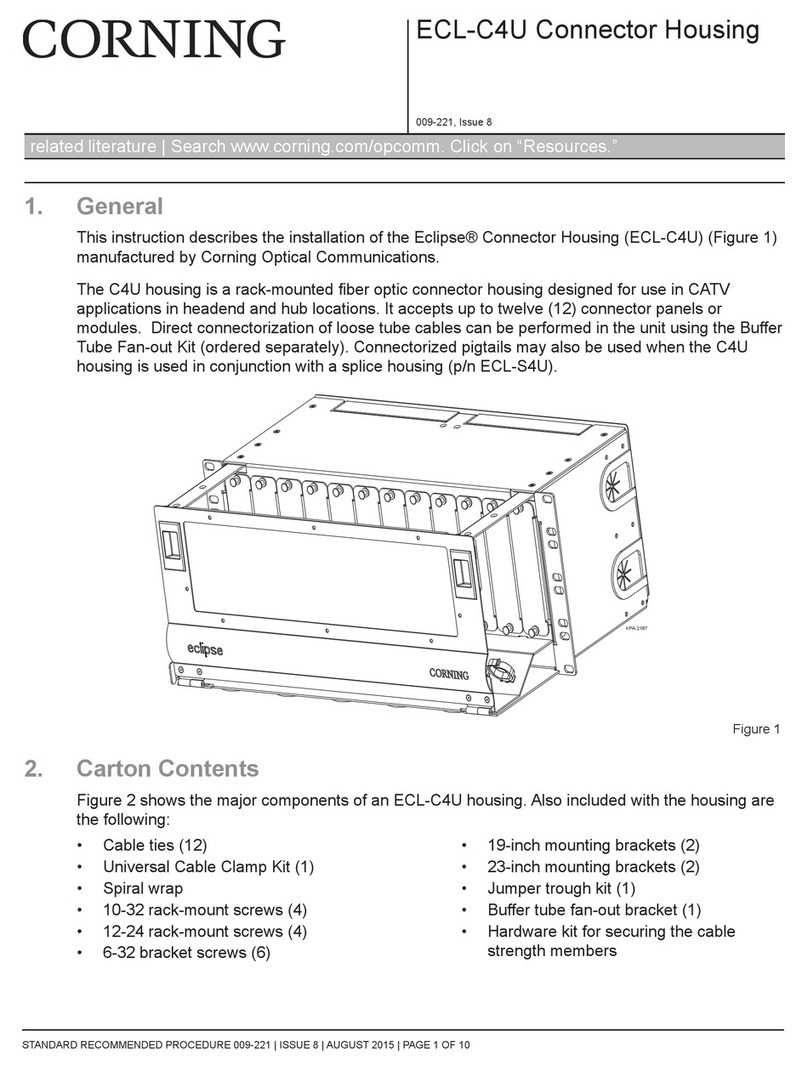

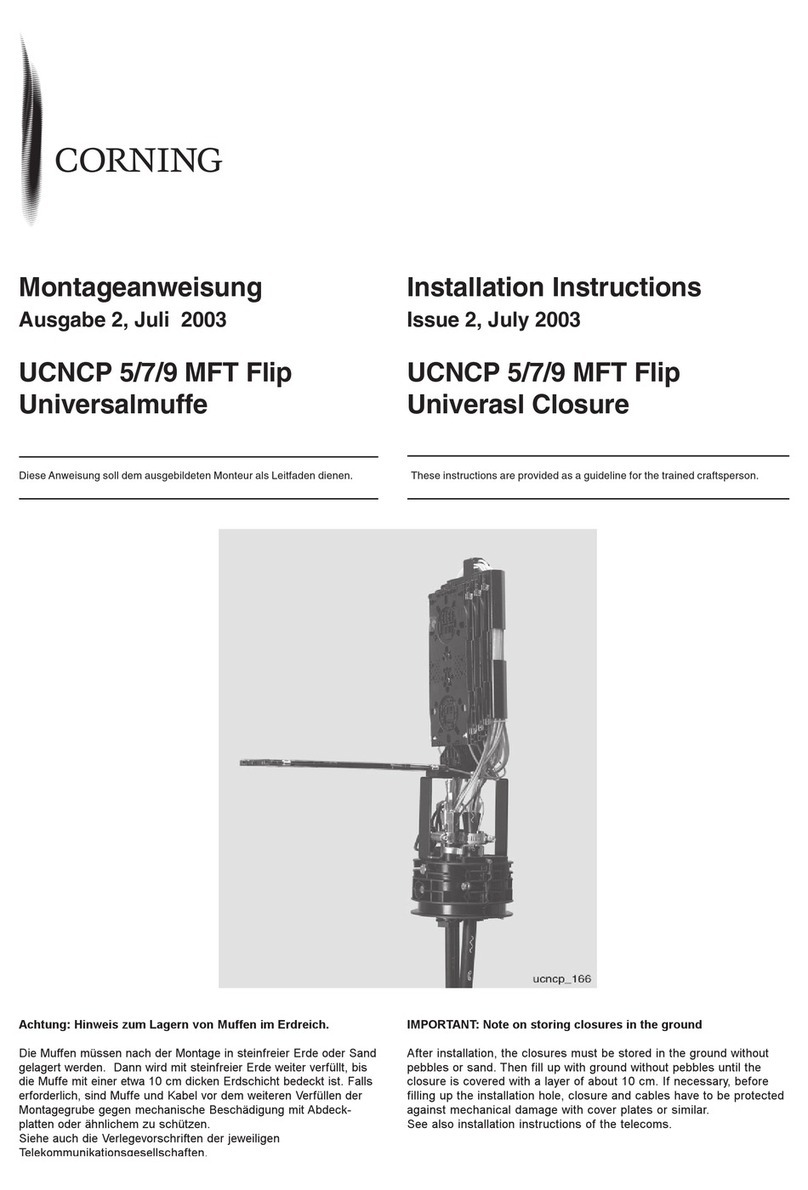

Figure 1

1. General

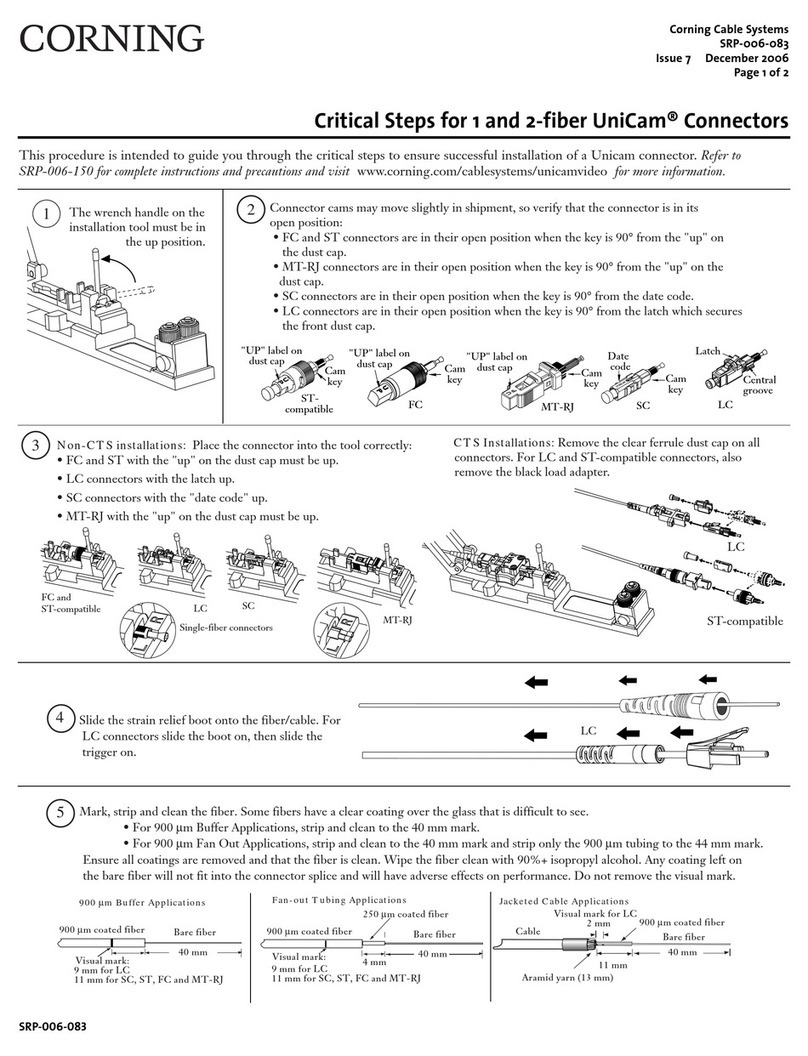

1.1 This procedure provides instructions for installing a

wire mesh pulling grip on Corning Cable Systems SST,

SST-Ribbon™, SST- ltraRibbon™, SST-Ribbon™ Dry-

Lock, ALTOS, and ALTOS Riser fiber optic cables

(Figure 1).

1.2 This procedure describes how to use a pulling grip to

couple the pulling load to a single-tube cable’s jacket.

Please read and understand this procedure completely before

starting the installation of a wire pulling grip.

1.3 This includes ALTOS And ALTOS Riser cables.

2. Precautions

2.1 General Precautions

2.2 Cable Handling Precautions

3. Tools and Materials

3.1 The following tools and materials are required to

complete this procedure:

• Kellems®pulling grip

• Side cutters *

• Measuring tape *

• Vinyl tape, 3/4 in (19.1 mm) *

• Gloves

• Scissors *

• Hex wrench or screwdriver* (to fit swivel)

• Swivel, ball-bearing type

*Items included in the M67-003 Tool it

4. Pulling Grip Installation

4.1 Prior to installation, the proper size grip must be

chosen for the cable to be pulled.

Grip selection is based on cable diameter. Generally

speaking, use the smallest grip which will fit over the cable

sheath without excessive difficulty.

Corning Cable Systems

SRP-005-044

Issue 5 October 2004

Page 1 of 3

Installing a Wire esh Pulling Grip

on SST, SST-Ribbon™, SST-UltraRibbon™, SST-Ribbon™ Dry-Lock,

ALTOS®, and ALTOS® Riser Cables

SRP-005-044

Safety Glasses

WARNING: The wearing of safety glasses to

protect the eyes from accidental injury is strongly recommend-

ed when handling chemicals and cutting fiber. Pieces of glass

fiber are very sharp and can damage the cornea of the eye eas-

ily.

Safety Gloves

The wearing of safety gloves to protect your hands

from accidental injury when using sharp-bladed tools is

strongly recommended.

CAUTION: Fiber optic cable is sensitive to exces-

sive pulling, bending and crushing forces. Consult the cable

specification sheet for the cable you are installing. Do not bend

cable more sharply than the minimum recommended bend

radius. Do not apply more pulling force to the cable than spec-

ified. Do not crush the cable or allow it to kink. Doing so may

cause damage that can alter the transmission characteristics of

the cable- the cable may have to be replaced.