STANDARD RECOMMENDED PROCEDURE 000-274 | ISSUE 4 | AUGUST 2016 | PAGE 2 OF 7

NOTE: This procedure assumes that the EDGE™ solution housing is on a work surface or has been

installed into the frame.

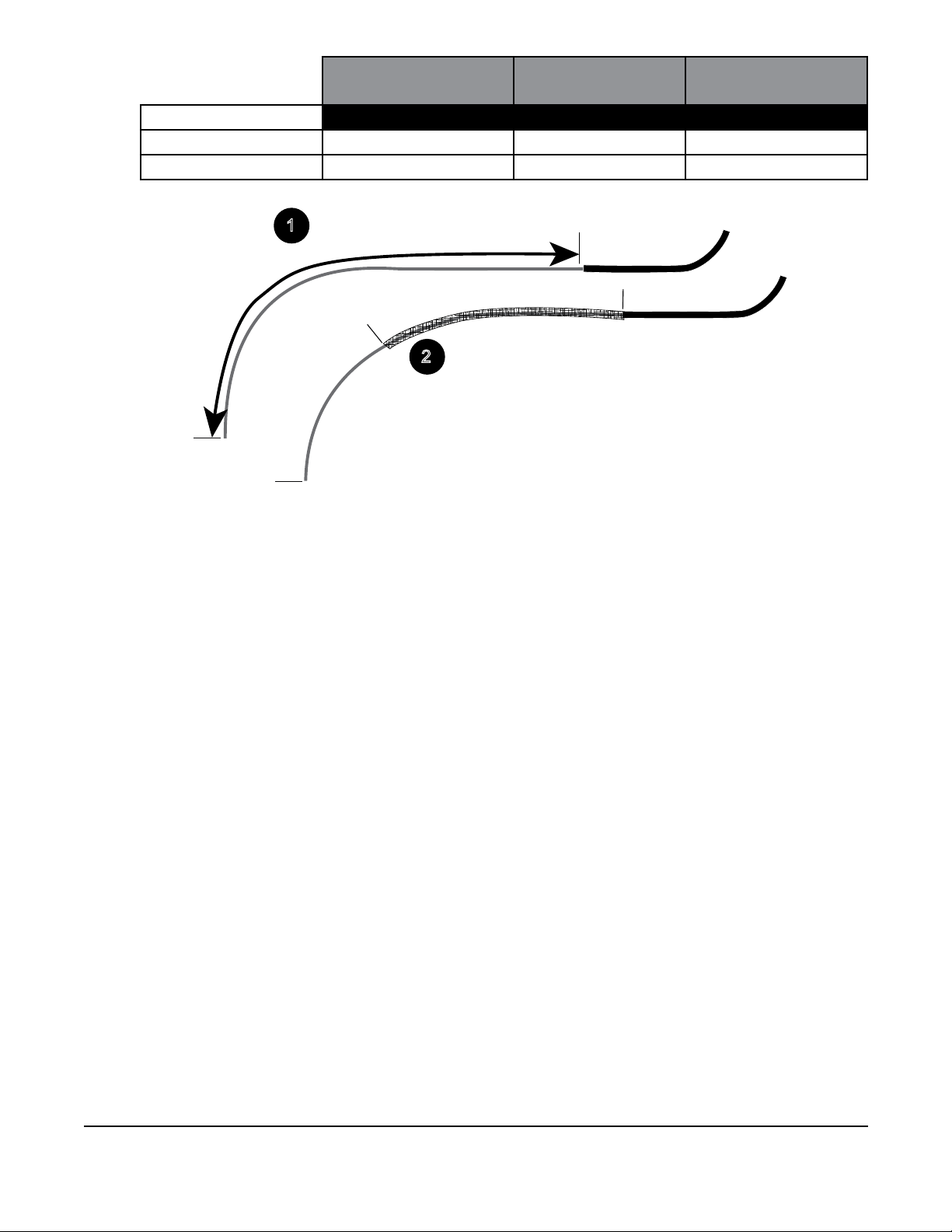

Fiber Inside Cassette Jacketed Subunit Total Outer Jacket

Strip Length

For Splicing 33 in 33 in 66 in

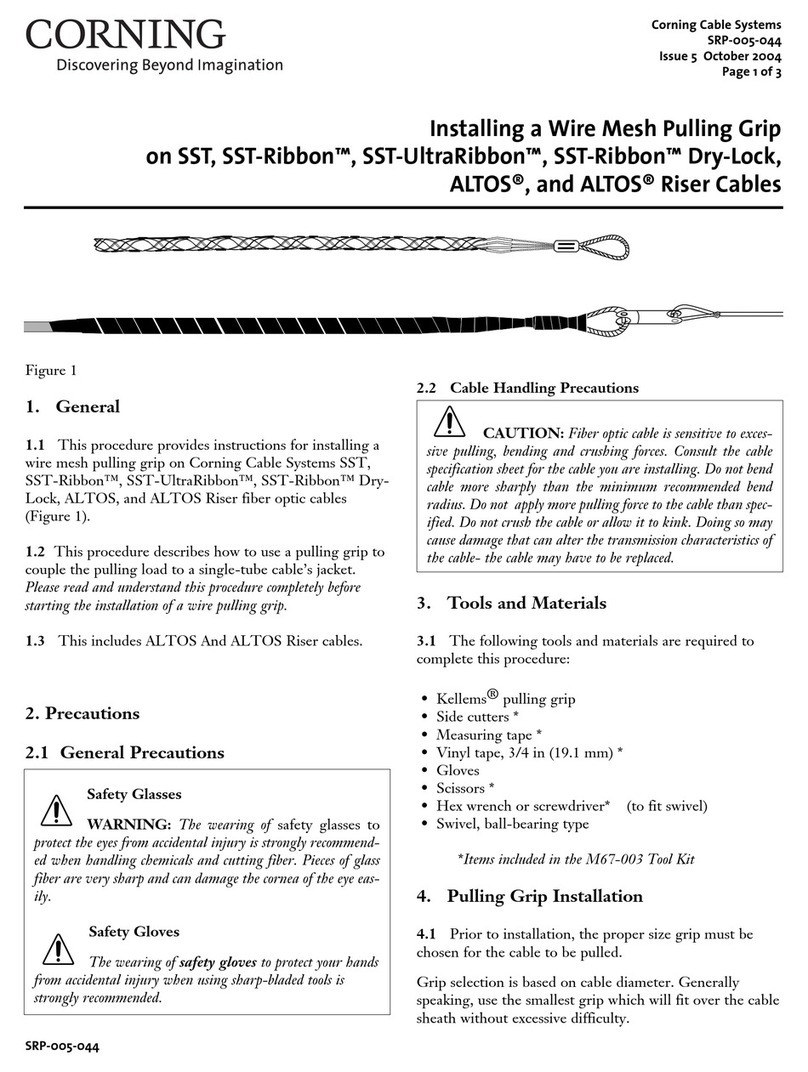

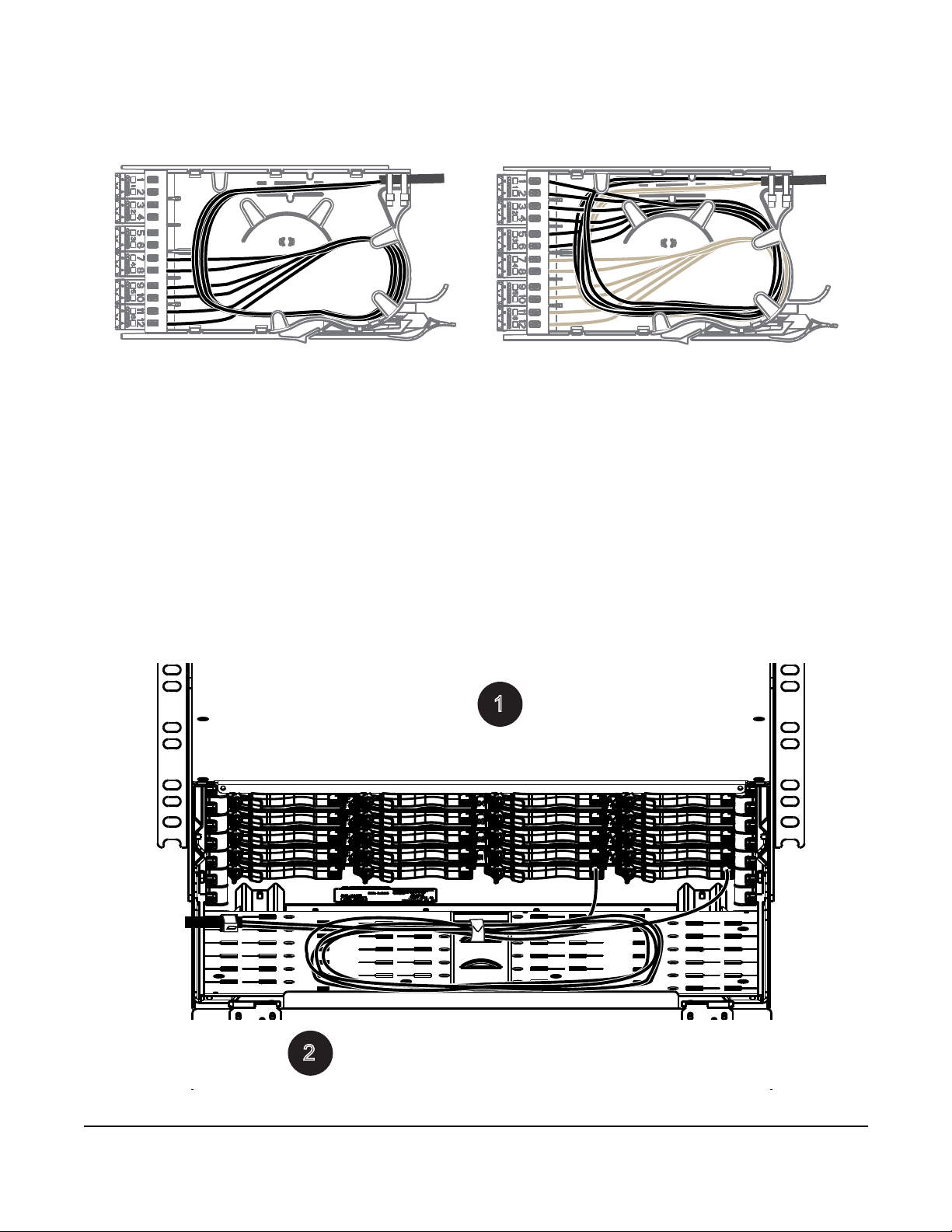

Figure 1

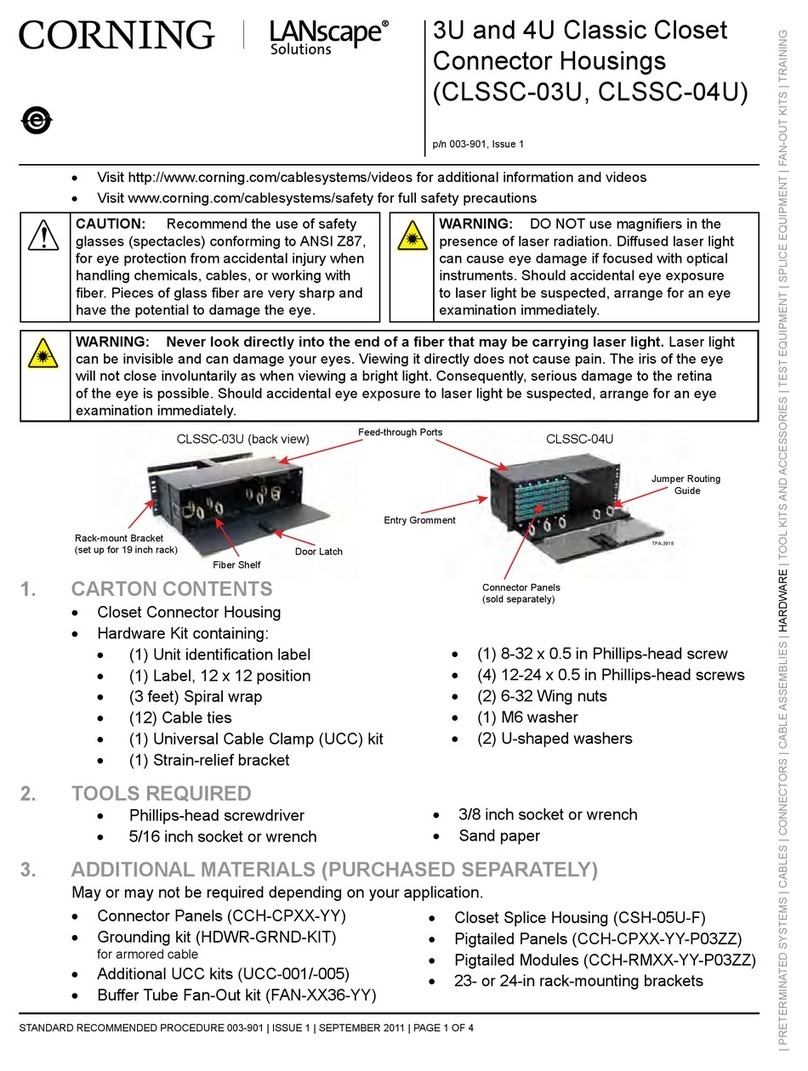

Step 1: Determine from which side the cable will enter the housing (Figure 1). Measure

and mark the length specied in the table above from cable end and strip cable per

instructions provided with the cable or per standard company practices. Then mark

the subunit at the required length from the end of the cable. This mark denotes the

point at which the bers will enter the cassette.

Step 2: Strip the subunits from the mark to the end of the subunit.

NOTE: If additional protection for the ribbon or 900 µm subunits is desired, install 33 in (0.84 m) of

braided tubing over the ribbons or 900 µm bers beginning at the point where the jacket is

strain-relieved in the cradle.

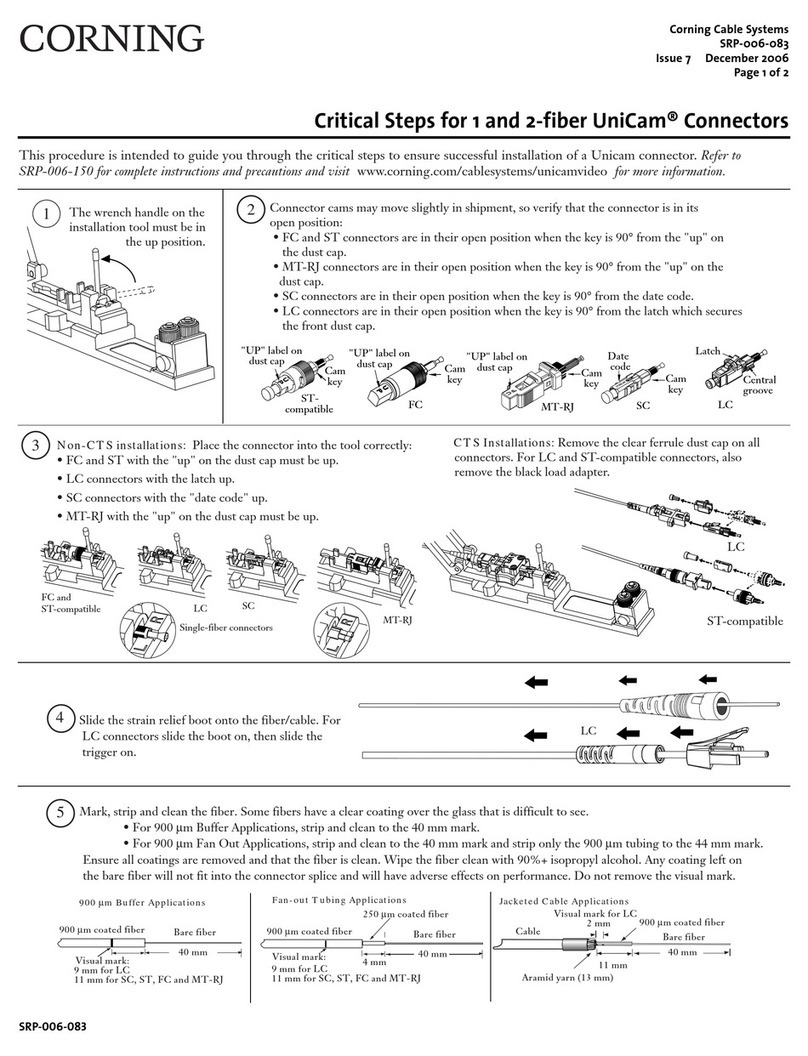

4. Splice Cassette Installation

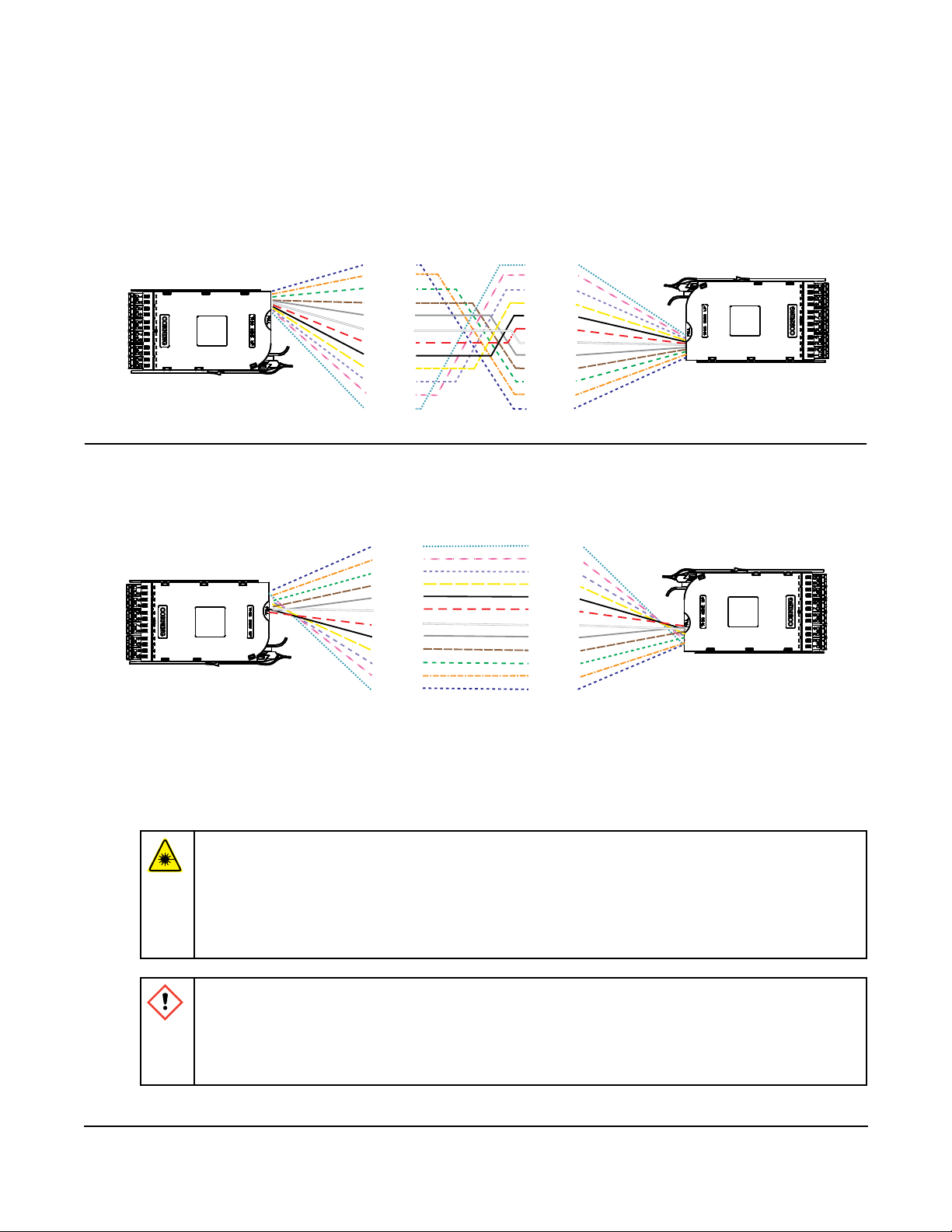

WARNING: Never look directly into the end of a ber that may be carrying laser

light. Laser light can be invisible and can damage your eyes. Viewing it directly

does not cause pain. The iris of the eye will not close involuntarily as when viewing a

bright light. Consequently, serious damage to the retina of the eye is possible. Should

accidental eye exposure to laser light be suspected, arrange for an eye examination

immediately.

CAUTION: Cleaved or broken glass bers are very sharp and can pierce the skin

easily. Do not let these pieces of ber stick to your clothing or drop in the work area

where they can cause injury later. Use tweezers to pick up cleaved or broken pieces

of glass bers and place them on a loop of tape kept for that purpose alone. Good

housekeeping is very important.

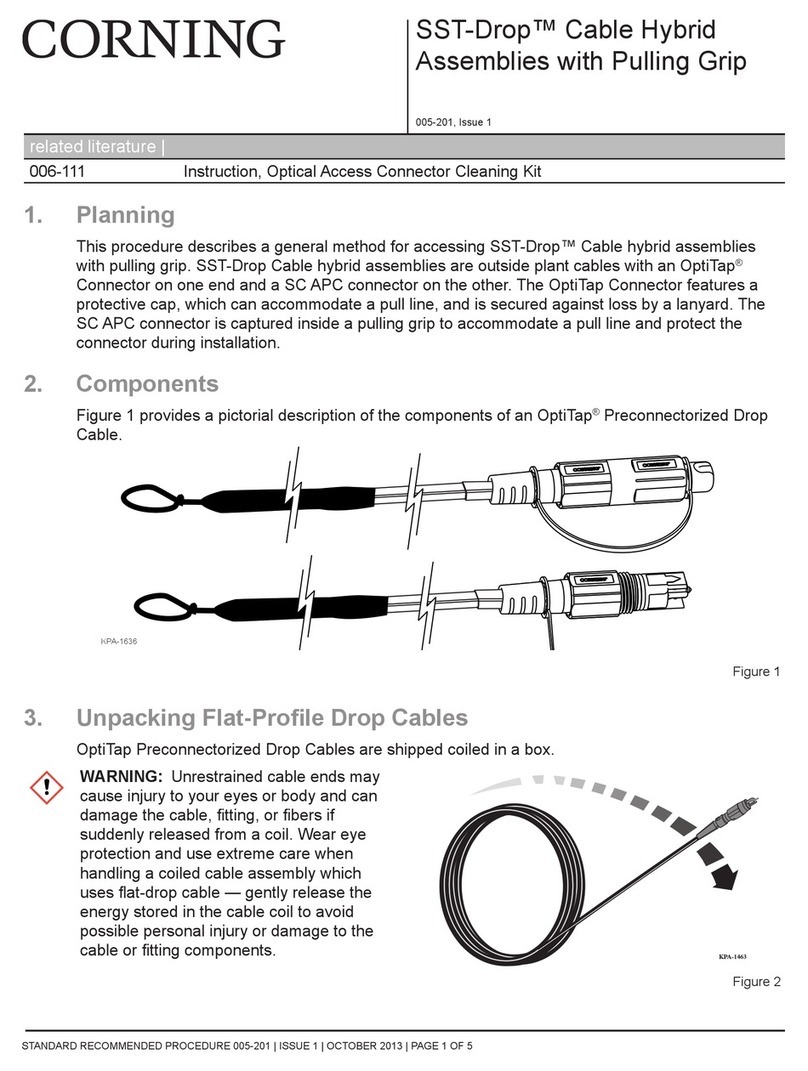

Step 1: Bring the subunits into the splice cassette. If using loose-tube cable, it is recomended

to use friction tape over the end of the buffer tube.

Step 2: Secure subunit with cable ties as it enters the cassette (Figure 2).

Strip jacket(s) per lengths specified in table above for your application.

(Optional) If cable is ribbon or single-fiber, install

33 inches (0.84 m) of braided or protective tubing,

leaving length required for splicing inside the

cassette or field-terminating the fiber.

1

2

3

3

i

n

c

h

e

s

3

3

i

n

c

h

e

s

b

r

a

i

d

e

d

t

u

b

i

n

g

TPA-4350A