STANDARD RECOMMENDED PROCEDURE 003-722 | ISSUE 4 | OCTOBER 2015 | PAGE 9 OF 10

Step 2: Slide drawer back to original position.

Step 3: If previously removed, slide the cover back in the retaining anges on top of the

housing. Push the plunger fasteners to secure.

Step 4: Close the front and rear doors.

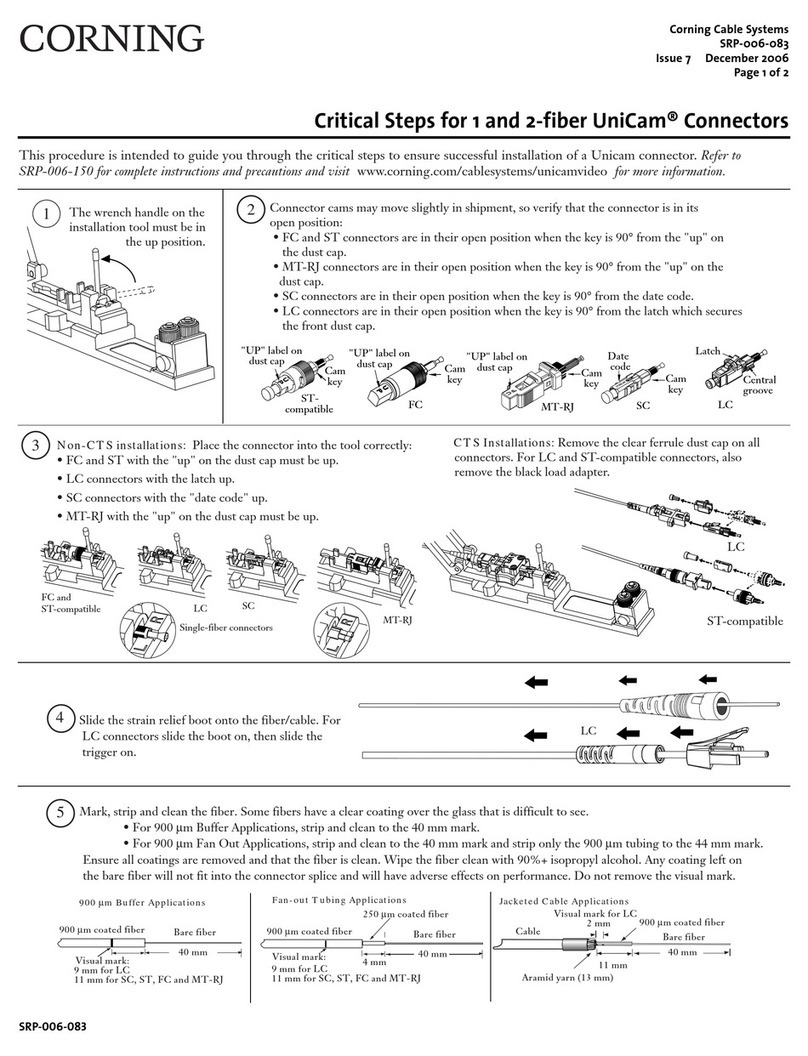

4.8 Install Jumpers

Step 1: Remove dust caps from the

connectors and adapters into

which they will be mated. Refer to

Section 5 for cleaning instructions.

Clean connector end-faces and

adapters per standard company

practices and insert connectors

into adapters.

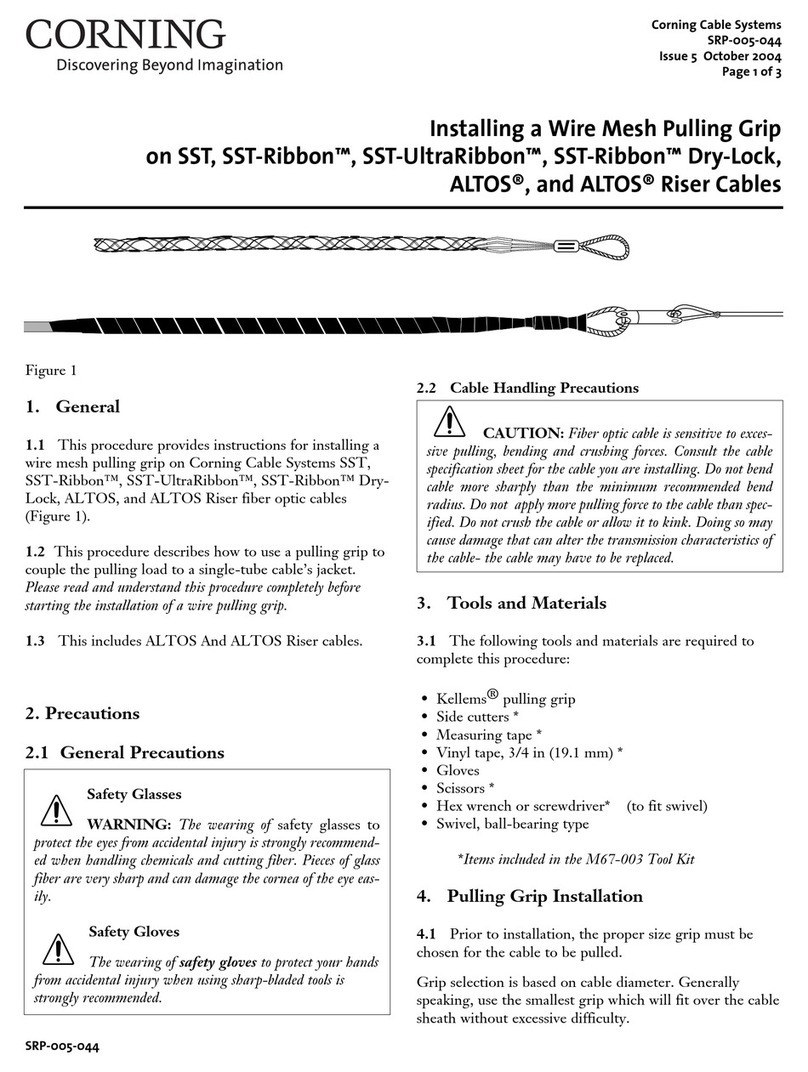

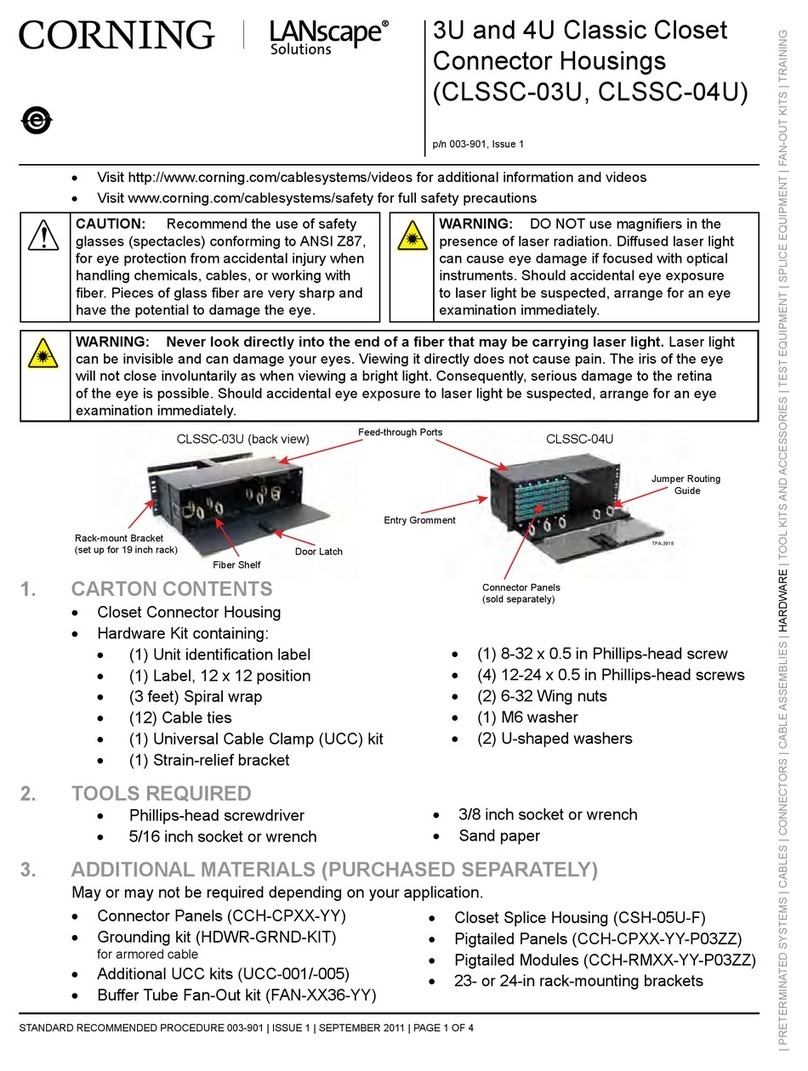

Figure 12

Step 2: Install jumpers as specied on planning diagrams. Route jumpers through the routing

clips on either side at the front of the housing (Figure 12).

Step 3: Provide enough jumper slack to allow the connector panel tray to slide to the back

and forward positions without violating the minimum bend radius of the jumper.

Step 4: Record jumper routing information on the provided identication label. Accurate

recordkeeping is imperative for an organized installation.

5. Connector Care and Cleaning

WARNING: Isopropyl alcohol is ammable with a ashpoint at 54ºF. It can cause irritation to

eyes on contact. In case of contact, ush eyes with water for at least 15 minutes. Inhalation

of vapors irritates the respiratory tract. Exposure to high concentrations has a narcotic effect,

producing symptoms of dizziness, drowsiness, headache, staggering, unconsciousness and

possibly death.

• Always keep dust caps on connectors and adapters when not in use.

• Ensure dust caps are clean before reuse.

• Use optical cleaning materials as standardized by your company.

• Clean the connector before every mating, especially for test equipment patch cords

(jumpers).

• A minimum level of cleaning is listed below. Local procedures may require more rigorous

cleaning methods.

Step 1: Remove plugs from the connector adapter.

Step 2: Wipe the connector ferrule twice with a lint-free wiping material moistened with

isopropyl alcohol. Then wipe across the end of the ferrule.

Step 3: Repeat previous step with a dry wipe.

6. Testing

6.1 Provisioning Tests

Equipment should be tested from the source (or central ofce) to receiver at the time of

provisioning to verify signal continuity and acceptable loss limits. Use an optical power meter to

verify signal continuity and determine loss measurements are within specied local standards.

KPA-0156

Clips

Jumpers