6 7

Setting the Volume

Afterfillingthepipet,theendshouldbedriedwithanabsorbentpaperthatwillnotleave

impurities,inordertoremoveanyexcesssolutionontheoutsidesurfaceofthepipet.

Tosettherequiredliquidvolumeprecisely,pressthedispensebuttongently(Figure3C),

dispense the excessive liquid from the pipet until the meniscus of the liquid aligns exactly

with the required volume mark on the pipet.

Emptying the Pipet

Holdingthevesselinanangledposition,placethepipetendincontactwiththevessel

wall and press the dispense button gently (Figure 3C). The dispensing intensity may be

adjusted depending on pressure applied to the dispense button. The greater the pressure

applied,thefastertheoutflowofliquidfromthepipet.

The pipet controller has two dispense modes. The dispense mode is selected with the

BLOW/GRAVswitch(Figure1D).

•Gravitymodemarkedwiththe icon on the display (Figure 2.4): Dispensing is effected

ingravitymode,whichmeansthattheliquidflowsoutofthepipetbyitsownweight.

•Blowoutmodemarkedwiththe icon on the display (Figure 2.5): Dispensing is effected

ingravitymode,however,whenthedispensebuttonispressedtothemiddleposition,

the pump is started and fast emptying of the pipet with a blow out is effected.

CAUTION: During gravimetric dispensing the pipet may not be completely emptied due

to the characteristics of pipets used with the pipet controller.

6. Troubleshooting

Ifduringyourworkthepipetcontrollerisnotfunctioningcorrectly,checkthecauseand

correct the fault.

Problem Possible cause Action

The pipet falls out (the

holding force of the pipet

istoosmall),ortiltstothe

side too much.

The pipet holder is dirty or wet

(Figure1G).

Takeoutthepipetholder,

andclean,wash,anddryit.

The pipet holder is damaged. Replace the pipet holder

with a new one.

Thepumpisworking,but

the pipet controller aid does

not draw liquid or draws

liquid very slowly.

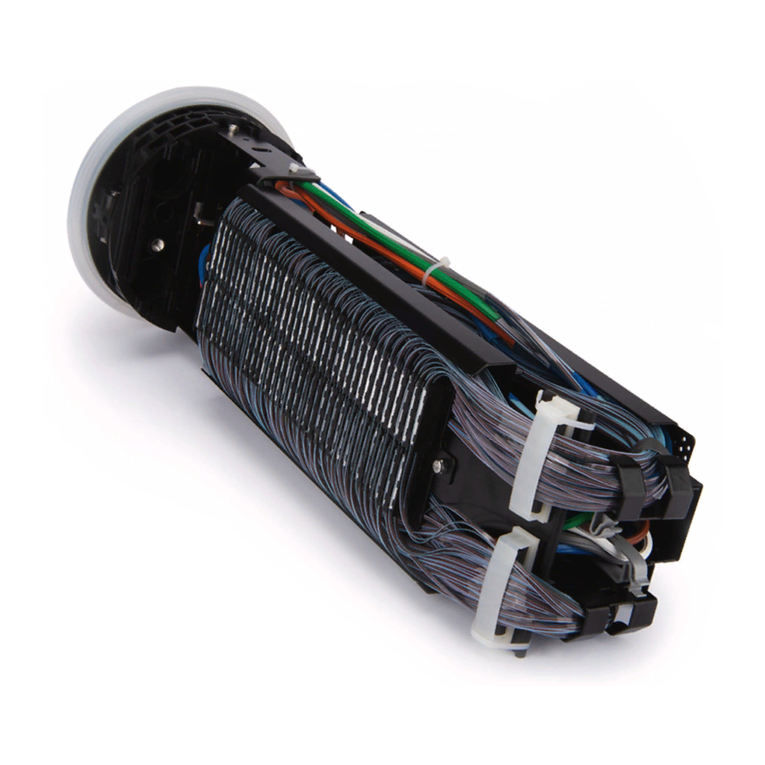

The filter is dirty (Figure 1H).

Takeoutthepipetholder,takeout

thefilter,ifitisdirty,replaceit

with a new one.

Thepipetholderand/orthe

connector gasket is damaged

(Figure 1J).

Replace the mechanically

damaged elements with new

ones.

Liquid leaks from the pipet

(the aspiration and the

dispense buttons are not

pressed)

The pipet is damaged.

Check the pipet for damage

(cracks,dents)ifpresent,replace

the pipet with a new one.

The pipet is inserted

incorrectly.

Check whether the pipet has been

correctly inserted in the pipet

holder.

Thepipetholder,thefilter,or

the connector gasket is installed

incorrectly.

Check whether all parts are

present and correctly installed.

Thepipetholderand/orthe

connector gasket is damaged

(Figures1G,1J).

Replace the mechanically

damaged elements with new

ones.

Iftheaboveactionsdonotremedytheincorrectfunctioningofthepipetcontroller,the

deviceshouldbesenttothenearestauthorizedservicecenter.

•Thepipetcontrollershouldnotbeusedfordrawingsolutionswithatemperatureabove

50°C.

•Thepipetcontrollershouldbeoperatedinthetemperaturerangefrom+10°Cto+35°C.

•Thepipetcontrollerissuitableforgenerallaboratoryuseonly.Itmustbeusedonlyby

personnel who know the health risks associated with the substances that are normally

used with this instrument.

4. Turning On the Pipet Controller

The pipet controller is switched on by pressing the aspiration button (Figure 1A) or the

dispensebutton(Figure1B).Thedisplaywillshowtheselectedaspirationmode,dispense

mode,andthebatterylevelindicator(Figure2.3).Examplesofthedisplayindicationsare

shown in Figure 5. The battery is discharged and requires charging if the indicator displays

one“bar”(Figure5.3).Whenthebatteryisfullycharged,theindicatordisplaysthree“bars”

(Figure 5.1). The pipet controller will switch off automatically if not used for 5 minutes.

The pipet controller should be charged only with the original charger.

The main voltage should conform with the specification on the charger.

Charging should be done in accordance with section 8 of this instruction for use.

5. Aspirating and Dispensing Liquids

Attaching a pipet

CAUTION:Beforeattachingapipet,checkwhetherthepipetisnotdamaged,hasnodents

or sharp edges in the gripping section. Check to ensure the gripping section is dry.

The pipet controller should be gripped as close to the upper end as possible and carefully

inserted into the pipet controller holder until resistance is felt (Figure 3A). Do not apply

excessiveforce,topreventdamagetothinpipetscontrollerandtoavoidinjuryrisk.Apipet

that has been correctly attached and sealed in the holder should not tilt to the side.

Afterattachingapipet,holdthedeviceinsuchawayastokeepthepipetcontrollerin

averticalpositionwithanattachedpipet.Whennotinuse,itisnotrecommendedtoleave

thepipetattachedforlongperiods,forexampleovernightoroveraweekend.

Note: Do not rest the pipet controller on the bench if there is liquid in the pipet.

Filling the pipet

Beforeaspiratingisstarted,setthesuctionspeedswitchusingtheHIGH/LOWswitch

(Figure 1C):

•HIGHposition:fastaspirating(Figure2.1)

•LOWposition:slowaspirating(Figure2.2)

ItisrecommendedtochoosetheLOWpositionforpipetswithavolumeupto5mL,and

theHIGHpositionforpipetswithavolumegreaterthan5mL.Holdingthepipetcontroller

vertically,immersethepipetendintheliquidtobedrawnup(Figure3B),andpressthe

aspiration button gently. The pipet filling speed depends on the pressure applied to the

aspiratingbutton.Thegreaterthepressureapplied,thefastertheliquidisaspiratedinto

the pipet.

It is recommended to draw a slightly larger liquid volume than required (due to meniscus

abovetherequiredvolumemark),reducingtheaspirationspeed,particularlyinthefinal

fillingstage,soasnottooverfillthepipet.