2 3

Th s d vic s ar not d sign d to fit into rotors that only acc pt round bottom

29 mm x 105mm tub s, .g., Sorvall SS34 or B ckman JA 20.

Operation

1. S l ct th most appropriat m mbran cut-off for your sampl . For maximum

r cov ry s l ct a mol cular w ight cut off (MWCO) at l ast 50% small r than th

mol cular siz of th sp ci s of int r st.

2. Fill conc ntrator with up to maximum volum s shown in Tabl 1 (pag 4). Ensur

scr w closur is fully s at d.

3. Ins rt ass mbl d conc ntrator into c ntrifug (wh n fix d angl rotors ar us d,

angl conc ntrator so that th print d window fac s upwards/outwards).

4. C ntrifug at sp ds r comm nd d in Tabl 2 (pag 5), taking car not to xc d th

maximum g forc indicat d by m mbran typ and MWCO.

5. Onc th d sir d conc ntration is achi v d, (s Tabl s 3a and 3b, pag 5) for guid

to conc ntration tim s), r mov ass mbly and r cov r sampl from th bottom of

th conc ntrat pock t with a pip t.

Desalting/Buffer Exchange

1. Conc ntrat sampl to d sir d l v l.

2. Empty filtrat contain r.

3. R fill conc ntrator with an appropriat solv nt.

4. Conc ntrat th sampl again and r p at th proc ss

until th conc ntration of th contaminating micro-

solut is suffici ntly r duc d. Typically, 3 wash cycl s

will r mov 99% of initial salt cont nt.

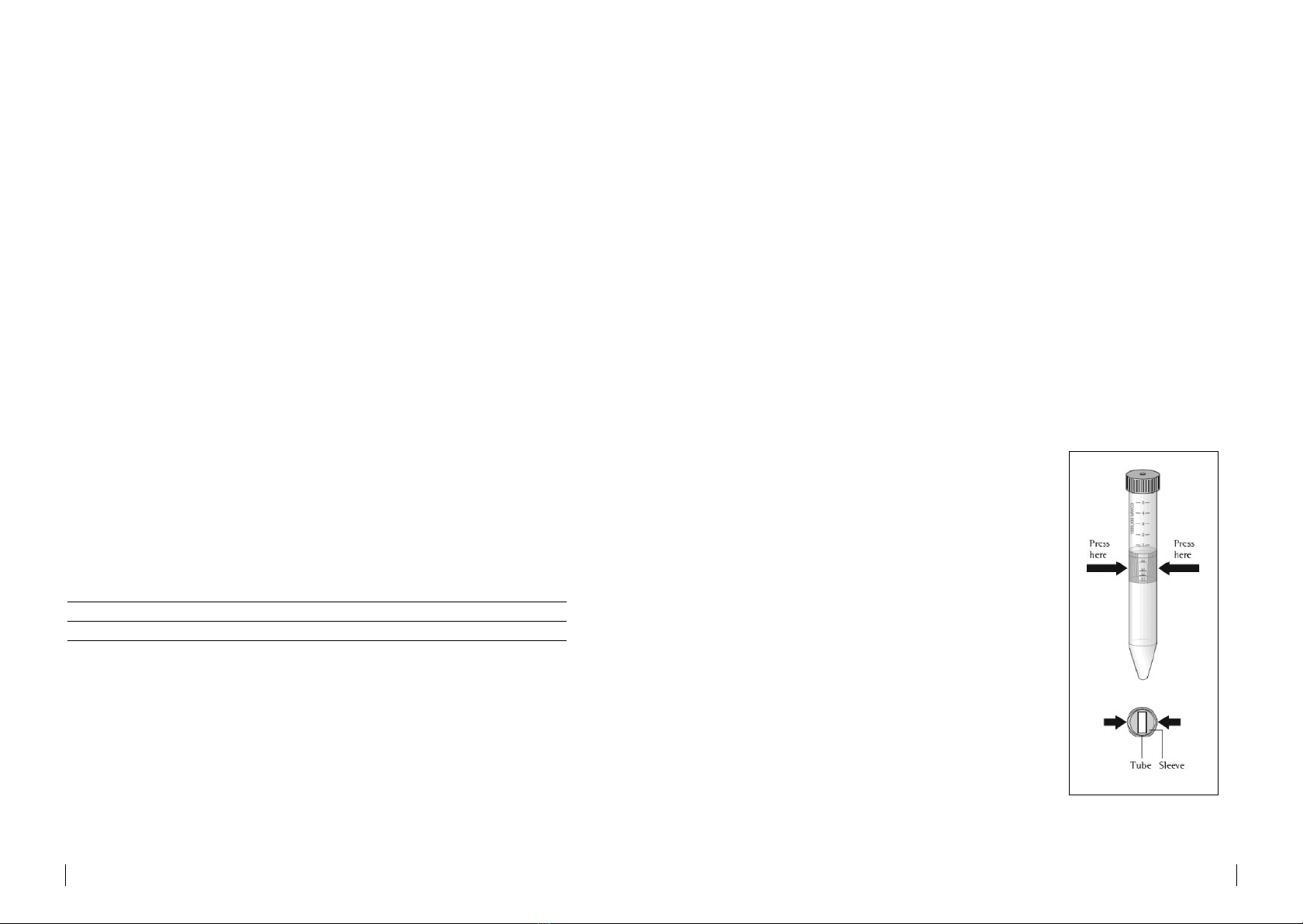

Removing the Spin-X® UF Body from the Filtrate Tube

Th sl v (s n from th nd) is oval in cross s ction

(Figur 1). Th tub is round in cross s ction to giv

a tight fit to th sl v . To r l as th tub from th

sl v , you must pinch th tub — to pr ss it into an

oval shap — b for r moving it with a twisting action.

Helpful Hints

1. Flow Rate

Filtration rat is aff ct d by s v ral param t rs, includ-

ing MWCO, porosity, sampl conc ntration, viscosity,

c ntrifugal forc and t mp ratur . Exp ct significantly

long r spin tim s for starting solutions with ov r 5%

solids. Wh n op rating at 4°C, flow rat s ar approxi-

mat ly 1.5 tim s slow r than at 25°C. Viscous solutions

such as 50% glyc rin will tak up to 5 tim s long r to con-

c ntrat than sampl s in a pr dominantly buff r solution.

Introduction

Corning®Spin-X®UF conc ntrators ar disposabl , singl us only ultrafiltration

d vic s with poly th rsulfon m mbran s (PES) for th conc ntration and/or

purification of biological sampl s. Spin-X UF 6 conc ntrators ar suitabl for sampl

volum s of 2 to 6 mL and th Spin-X UF 20 conc ntrators can handl sampl s up to

20 mL. Both products f atur twin v rtical m mbran s for unparall l d sp d.

Th innovativ d sign, as of us , sp d and xc ptional conc ntrat r cov ri s ar th

main f atur s of th conc ntrators.

Storage Conditions and Shelf Life

Spin-X UF conc ntrators should b stor d at room t mp ratur . Th d vic s should

b us d b for th xpiration dat print d on th box.

Chemical Compatibility

Spin-X UF conc ntrators ar d sign d for us with biological fluids and aqu ous

solutions. For ch mical compatibility d tails, r f r to Tabl 4 (pag 6).

Centrifugal Operation

Spin-X UF conc ntrators can b us d in swing buck t or fix d angl rotors acc pting

standard conical bottom tub s. In a singl spin, solutions can b conc ntrat d in

xc ss of 100-fold. Sampl s ar typically conc ntrat d in 10 to 30 minut s with

macromol cular r cov ri s in xc ss of 95%.

Th longitudinal m mbran ori ntation and thin chann l conc ntration chamb r provid

optimum cross flow conditions v n for particl lad n solutions; th c ntrifugal forc

pulling particl s and solids away from th m mbran to th bottom of th d vic .

Macromol cul s coll ct in an imp rm abl conc ntrat pock t int grally mold d

b low th m mbran surfac , th r by liminating th risk of filtration to dryn ss.

Required Equipment

1. C ntrifug with swing buck t or fix d angl rotor (minimum 25°).

Device Carrier Required

Spin-X UF 6 To fit 15 mL (17 mm diam t r) conical bottom tub s

Spin-X UF 20 To fit 50 mL (30 mm diam t r) conical bottom tub s

2. Past ur or standard pip ts for sampl addition. Pip ttors with g l loading tips ar

r comm nd d for sampl r moval from th conc ntrat pock t.

Rotor Compatibility

Please note: Spin-X UF 20 (30 mm x 116 mm) is d sign d to fit into rotors that can

accommodat Corning 50 mL conical bottom tub s, .g., B ckman All gra 25R with

TS-5.1-500 swing-out rotor with BUC 5 buck ts and 368327 adaptors; B ckman

TA-10.250 25° fix d angl rotor with 356966 adaptors; H ra us Multifug 3 S-R with

(H ra us/Sorvall) 75006445 swing out rotor with 75006441 buck ts and adaptors for

Corning 50 mL conical bottom tub s. Figure 1.