Cozzia 16019 Manual

1

中国·厦门蒙发利科技有限公司

Xiamen Comfort Science & Technology Co.,Ltd

Maintenance Service Manual

MODEL:16019

VOLTAGE SPESIFICATION: 120 V

By Customer Service Dept

2

16019 Malfunction catalog

一. Malfunction List

Common Trouble and processing Methods are listed as follow:

Error

NO Phenomenon Description Processing Methods

01 No Function

When Starting.

The Controller`s LCD Nodisplay:

① Fuse melts (in the Power Source Box or on the

main PCB).

② Power supply circuit poorly connected.

③ EMC Board fails.

④ Main PCB fails.

①Replace Fuse

②Replace Power Box.

③Replace EMC Board.

④Replace main PCB.

02 No Function

When Starting.

The Controller`s LCD Display:

① Mechanical switch fails or it’s wire is opened.

② Up or Down Stroke Photo-electricity fails.

③ Main PCB fails.

④Kneading is on without pressing any key when

starting and no response by pressing other keys.

①Replace mechanical switch or

it's wire.

②Replace Stroke Photo-

electricity.

③Replace the main PCB.

④Width Inspection Board of PCB

fails, replace it.

03 No Width

switchover.

①The terminals of Width Inspection on main PCB

and wires are poorly connected.

②The terminals of Width Inspection on massage

mechanical and wires are poorly connected.

③Width Inspection fails.

④Main PCB fails.

①&②Plug the terminal securely

or replace the wires.

③Replace Width Inspection.

④Replace the main PCB.

3

04 No Partial

Function.

①Height Inspection Terminal or

Wire Poorly Contacts.

②Height Counting Subassembly fails.

③Photo-electricity Subassembly fails.

①Plug the terminal securely

or replace the wires.

②Replace Height Counting

Subassembly.

③Replace Photo-electricity

Subassembly.

05 No Rolling. ①Terminal or Wire Poorly Contacts.

②Down-stroke Photo-electricity Subassembly Fails.

③Up-stroke Photo-electricity Subassembly Fails.

④Rolling Motor Fails.

⑤Main PCB Fails.

①Plug the terminal securely

or replace the wires.

②Replace Down-Stroke

Subassembly.

③Replace Up-Stroke

Subassembly.

④Replace Rolling Motor.

⑤Replace main PCB.

06

No kneading ①The terminals on main PCB and

wires are poorly connected.

②Kneading motor fails.

③Main PCB fails.

①Plug the terminal securely or

replace the wires.

②Replace the kneading motor.

③Replace main PCB.

07 No tapping ①The terminals on main PCB

and wires are poorly connected.

②Tapping motor fails.

③Main PCB fails.

①Plug the terminal securely or

replace the wires.

②Replace the kneading motor.

③Replace the main PCB.

08 No response when

pressing the keys on

the remote controller

①The terminals and wires are poorly connected.

②The PCB of remote controller fails.

①Plug the terminal securely or

replace the wires.

②replace the remote controller.

09 The Backrest cannot

recline or set up.

①the terminal of reclining actuator and wires are

poorly connected.

②the reclining actuator fails.

③main PCB fails.

①Plug the terminal securely.

②replace the reclining actuator.

③replace the main PCB.

4

10 The Footrest cannot

lift or recline.

①the terminal of foot rest actuator and wires are

poorly connected..

②the foot rest actuator fails.

③main PCB fails.

①Plug the terminal securely.

②replace the foot rest actuator.

③replace the main PCB.

11 No vibration by the

motors in the seat

pad.

①The vibrational motor fail

②The terminals and wires are poorly connected

or the wires fail.

③Main PCB fails.

①Replace the vibrational motor.

②Plug the terminal securely or

replace the wires.

③Replace the main PCB.

12 No kneading of the

Footrest

①The terminals are not touch well with PCB

or the wires are not connected.

②Main PCB fails。

①Plug the terminal securely or

replace the wires.

②Replace the main PCB。

14 No gas charging in

the seat-pad.

①The terminal of the snuffle valves

and wires are poorly connected.

②The snuffle valves fail.

③The inflator pump fails.

④Main PCB fails.

①Plug the terminal securely.

②Replace the snuffle valves.

③Replace the inflator pump.

④Replace main PCB.

15 No gas charging in

the Footrest

①The terminal of the snuffle valves and wires are

poorly connected.

②The snuffle valves fail.

③The inflator pump fails.

④Main PCB fails.

①Plug the terminal securely.

②Replace the snuffle valves.

③Replace the inflator pump.

④Replace main PCB.

二. Troubleshooting Process

Attention for repairing chair or replacing parts:

①Make sure the power is OFF before tearing down the wires, moving terminals or replacing parts.

②Semiconductors (such as IC and others) are very easy to be damaged by static, so when you touch

the PCB, please make sure your body is grounding (by wearing a girding static ring), or your hands

are touching with earthing grip (household electrical appliances putting to earth, such as fridges,

washers and …) to release all static of the body.

5

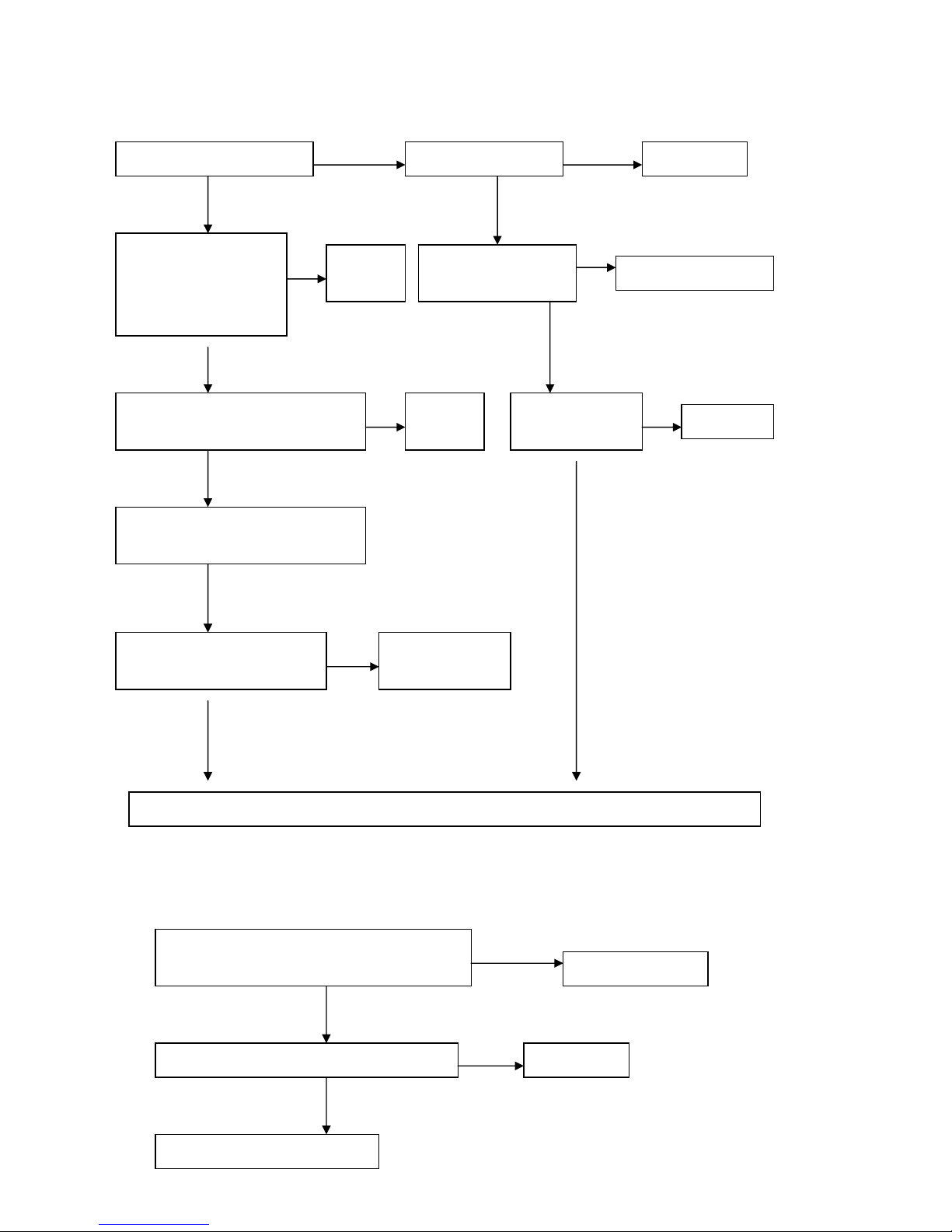

1. No function of starting.

2. No width switchover

Is the LCD illuminating? Is the fuse melted? Replace fuse.

Are the terminals of Up

and Down Stroke

Subassembly connected

securely?

Is the power cord

open-circuit? Replace power cord.

Connect

securely.

The switches of Up and Down

Stroke Subassembly fail or not?

The EMC Board

fails or not Replace it.

Replace

them

Is kneading on without pressing any

key when starting?

Width Inspection Board fails

or not?

Replace Width

Inspection Board.

Replace main PCB

Y

N Y

N

N

Y

Y N

Y

Y

N

N

N

Are the terminals of Width Inspection Board

and main PCB connected securely? Connect securely.

Width Inspection Board fails or not? Replace it.

Replace main PCB.

N

Y

Y

N

6

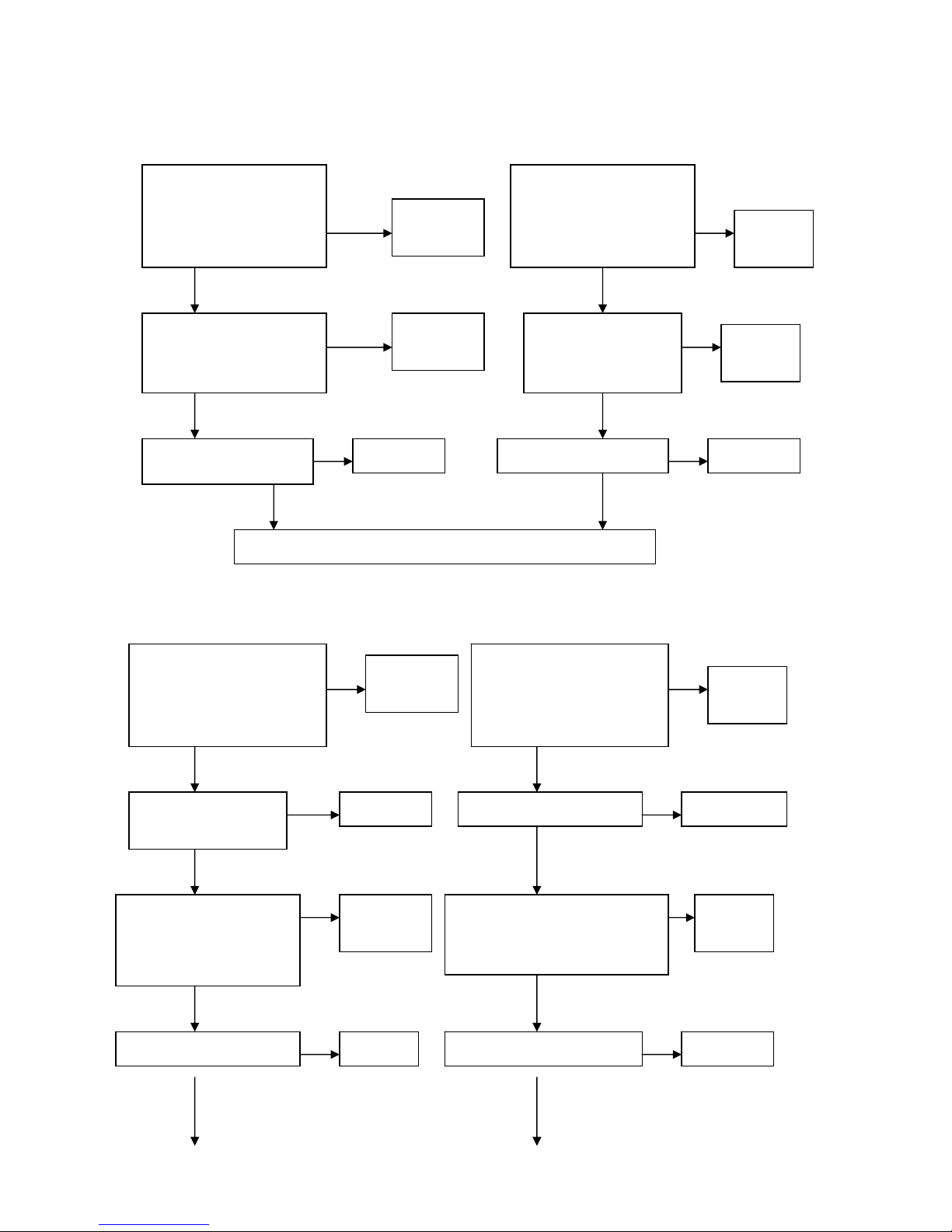

3. No function(fixed-spot or partial)

否

是

4. No rolling

5. No kneading.

Are the terminals of Height Inspection

Board and main PCB connected securely?

Connect securely.

Height Inspection Subassembly fails or not? Replace it.

Replace Main PCB.

Y

N

Y

N

Are the terminals of rolling motor wire and

main PCB connected securely? Connect securely

Rolling motor fails or not Replace the motor

Up stroke Photo-electricity subassembly fails or not Replace it

Down stroke Photo-electricity subassembly fails or not Replace it

Replace main PCB

N

Y

Y

Y

Y

N

N

N

Are the terminals of kneading motor wire

and main PCB connected securely? Connect securely.

Kneading motor fails or not?

Width Inspection Board fails or not?

Replace the motor.

Replace it.

N

Y

Y

N

N

7

6. No tapping.

7、The key of the remote comtroller was not function

8. Actuator doesn’t work.

Replace main PCB.

Are the terminals of tapping motor wire and

main PCB connected securely? Connect securely.

Tapping motor fails or not? Replace the motor.

Replace main PCB.

N

Y

N

Y

Are the terminals of remote controller

wire and main PCB connected securely? Connect securely.

The conductive rubber fails or not? Replace it.

Replace the remote controller.

Y

N

N

Y

Are the terminals of

reclining actuator and

main PCB connected

securely?

Connect

securely.

Are the terminals of

foot rest actuator for

foot rest and main PCB

connected securely?

Connect

securely.

The reclining actuator

fails or not? The foot rest actuator

fails or not?

Replace it.

Replace main PCB.

Replace it.

Y

NN

Y

NN

Y

8

9. NO vibration

10. No gas charging

Y

Are the terminals of

print motors in the seat

pad and main PCB

connected securely?

Are the connectors in the

middle of the wire

connected securely?

Are the terminals of print

motors in the calves-rest

and main PCB connected

securely?

Are the connectors in

the middle of the wire

connected securely?

Replace main PCB.

Connect

securely. Connect

securely.

Print motor fails or not? Print motor fails or not?Replace it. Replace it

Connect

securely. Connect

securely.

N

Y

N

N

N

Y

Y

Y

Y

N

N

Are the terminals of snuffle

valve for bags in the seat

pad and main PCB

connected securely?

Snuffle valve fails or

not?

Are the terminals of snuffle

valve for bags in the Foot

Rest and main PCB

connected securely?

Snuffle valve fails or not?

Connect

securely. Connect

securely.

Are the terminals of

inflator pump and main

PCB connected securely?

Replace Replace it.

Replace it. Replace it.

Are the terminals of inflator

pump and main PCB connected

securely?

Connect

securely.

Connect

securely.

Inflator pump fails or not? Inflator pump fails or not?

Y

N

Y

Y

N

N

Y

N N

N

Y

Y

N

Y

N

Y

9

Common trouble about electric control and processing methods of this chair are mentioned above. It

is for indication only.

三. PF53197 Disassembly process

Please make sure the massage chair is POWER OFF before maintenance and repair.

As the voltage specification is 220V AC, please make sure the plug is removed from

outlet for safety before processing operations as follow

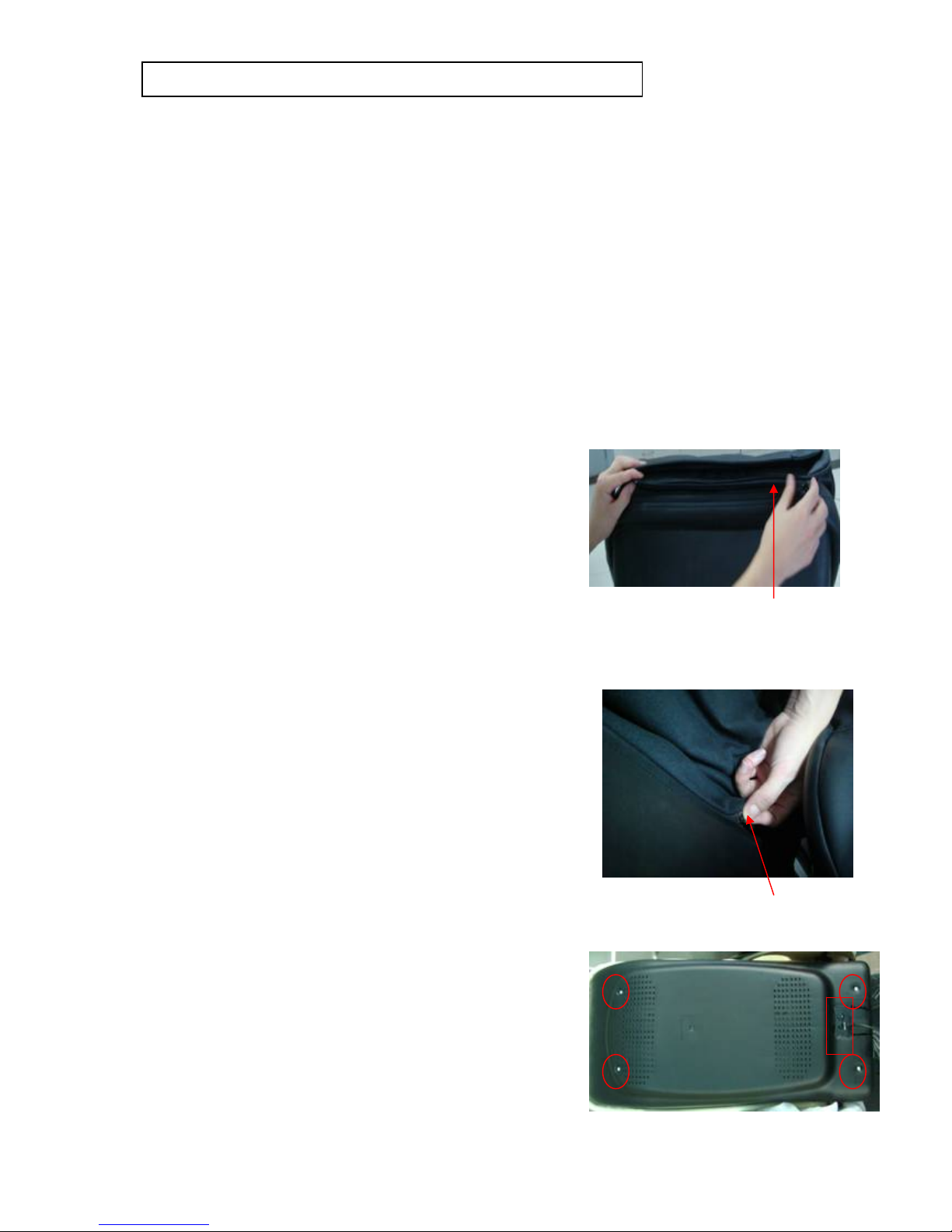

1:Disassembly of the back pad

①You can find a zip on the top of the back rest.

②Unzip, then the back pad can be removed.

③You should be replace if it was damaged

2:Replace the Sponge pad

A:You can see the Sponge pad after removed the back pad

B:the zip is on the left of below

C:Unzip of the sponge pad and replace it if you need

3. Replacement the rear cover of backrest

If disfiguring damage or crack happened, you can proceed as follow:

A:Find 4 pcs screws on the rear cover and 4 pcs screws on the

power switch, then Slacken and remove them (8PCS)

with a plus screwdriver.

Unzip of the sponge pad

Using the plus screwdriver

screw off 8pcs screws

Replace main PCB.

Unzip of the back pad

10

B:Please remove rear cover after removed power switch

C:You should be replaced if it was damaged

4:Disassembly of the front cover of back rest

If disfiguring damage or crack happened, or the inside

cloth is damaged, you can proceed as follow:

A:After removed the rear cover,

You can find 4pcs screws on the backrest with the front cover

B:Removed front cover after screw off the screws

C: You should be replace if it was damaged

5:Disassembly of the motors :

The voltage of this massage chair is high and the motors arerotating in high speed,

so make sure the power is OFF before disassembly.

For safety, you should remove plug from outlet.

Attention:Disassemble the rear cover of the back rest only, before disassembling the motors.

5.1 Kneading motor:

A :Disassembled the rear cover of the Back rest,

then take off the belt at the top massage mechanism

B :Find the wire of kneading motor,

Cut off the cable ties tightenin and contact nipple covering with wire,

Then disconnect the two wires

Take off the belt

Using plus screwdriver

screw off 4pcs screws

11

C :On the kneaking motor have 3PCS fixing screws

Just screw them that take off the motor,and replace it if you need

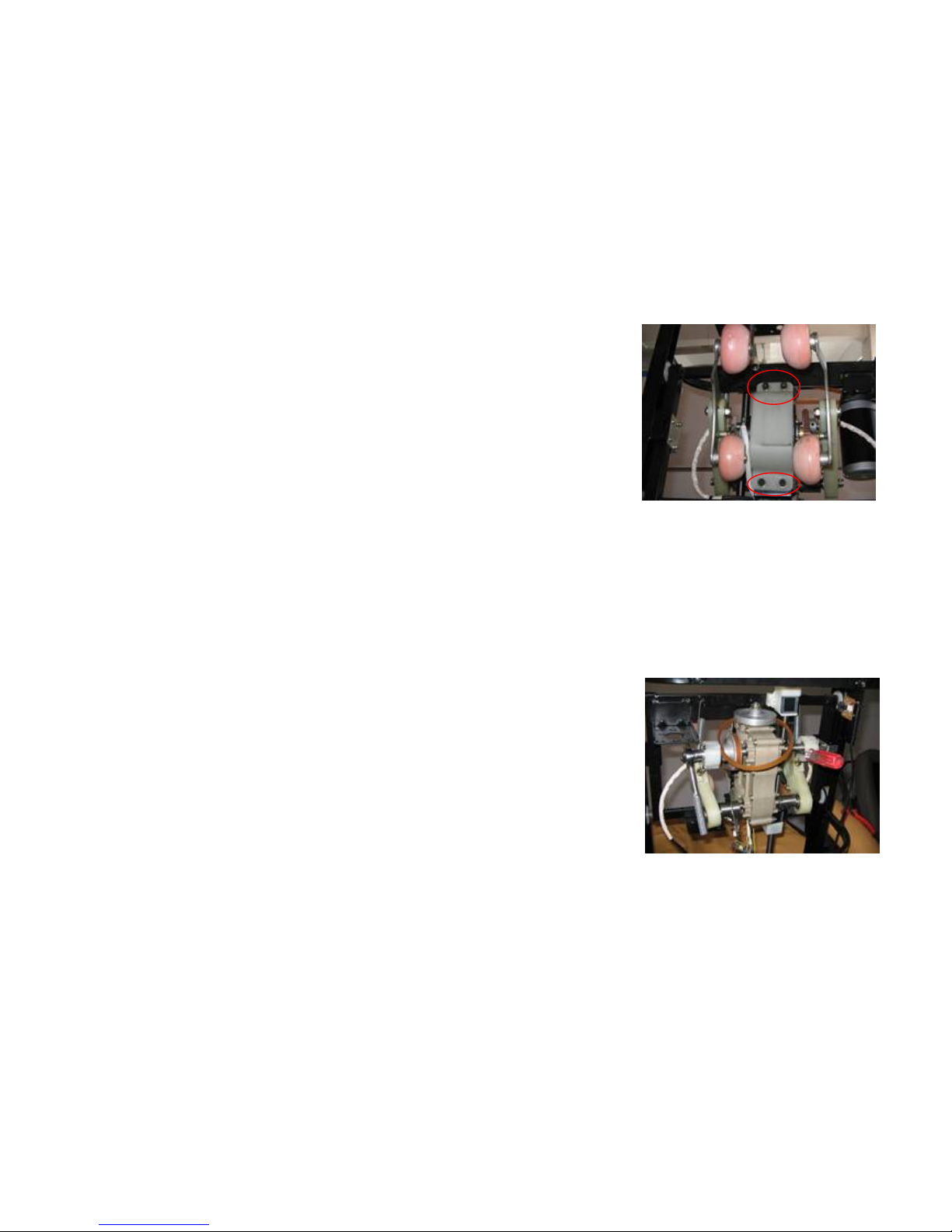

5.2 Rolling motor:

A :Release the stopper at the bottom of back rest,

Recline the back rest forward for disassembling the motor easily.

B:The rolling motor at the bottom of back rest.,

Take off the rolling belt at the bottom of motor

C: Disassemble ways as the same as the kneading motor

5.3 Tapping motor:

The tapping motor at behind the massage mechanism

Disassemble methods as the same as the kneading motor or rolling motor,

But you feel is difficult screw off screws,

please disassemble the swimming arm(a side of screws motor )

(If you need ,see disassemble the swimming arm part 6.2)

The rolling motor

Screw off the tapping

motor`s screws

Screw off the screws(3pcs)

Screw off the screws(3pcs)

12

6:Disassembly and replacement of massage mechanism

Disassemble the rear and front cover of the Back rest before disassembling the massage mechanism.

6.1 The belowe steps is the replace of massage mechanism

A. Remove the nipples tightening the wires of kneading and tapping

motors ,and disconnect the wires. Then cut off all the cable ties whith

this wires

B. Pull out the terminal of width inspection board.

C. Take off the belts of the kneading motor and tapping motor

Slacken and remove the 4 pieces of screws fixing the massage mechanism

to the frame with inner hexagon spanner(5mm).

D. You maybe don`t get it out because of the screw bolt.

So rotate the big belt wheel to adjust the width of swinging arms until you can get it out easily.

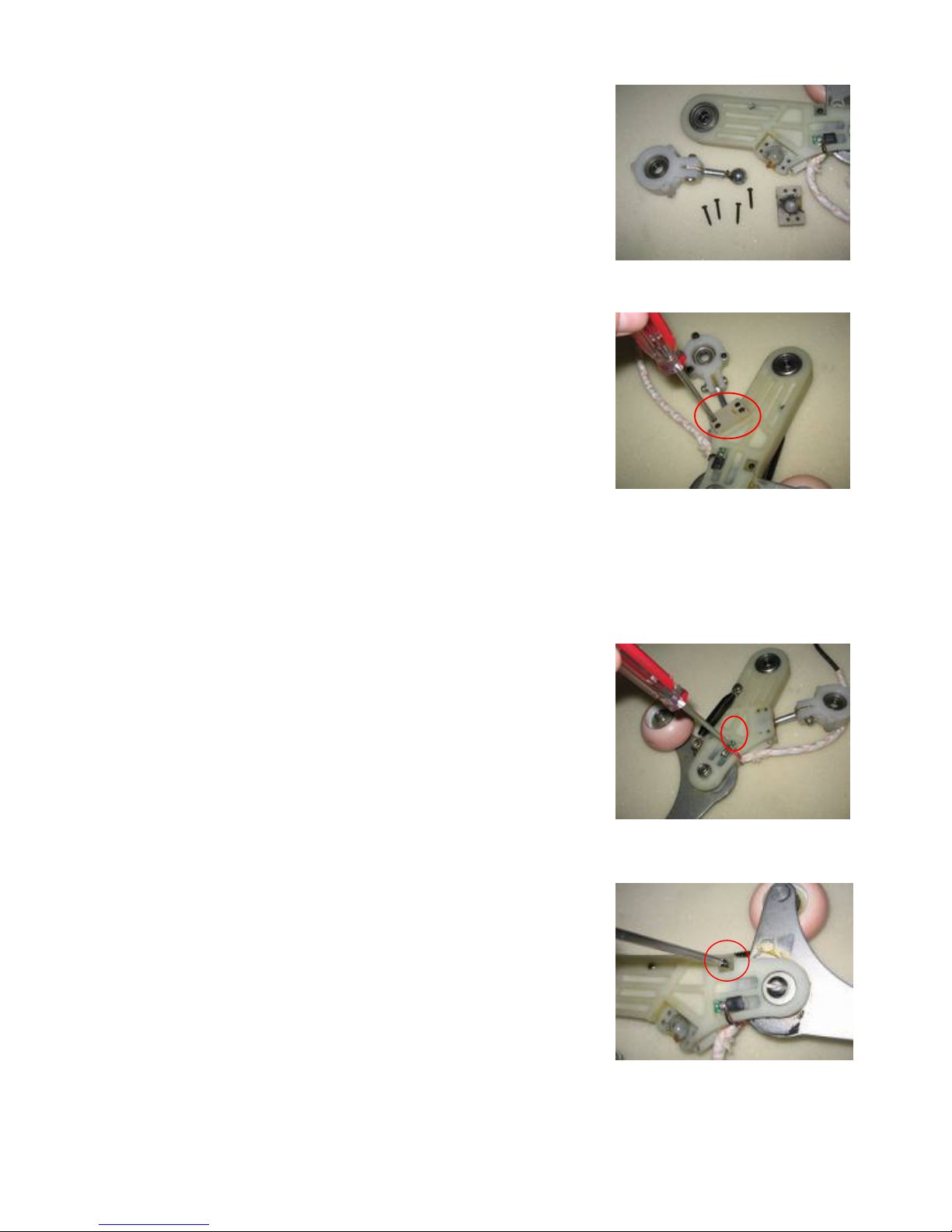

6.2 Disassemble the swinging arms and universal rods:

NOTE: You don’t have to disassemble the massage mechanism

If you just disassembling the swinging arms.

A.Slacken and remove the hexagon check nut tightening the universal

rod assembly to eccentric shaft with a hexagonal socket wrench(1/2).

B.Remove the hexagon check nut and washer, so you can

separate the swinging arm and universal rod from the massage mechanism.

C.Remove the tension spring, and further disassembly can be done

Attention:When slackening the hexagon check nut tightening the universal

rod assembly to eccentric shaft, you can’t loosen it for the rotating shaft.

So the eccentric shaft should be fixed. What you should do is inserting

an iron rod into the hole of the shaft to stop its rotating.

Remove the hexagon check

Screw off the inner hexagon(4pcs)

13

6.3 Disassembly of the universal rod:

A.Slacken and remove the screws tightening the plastic cover

to the winging arm with a plus screwdriver

if any parts need replacing.

B:Remove the plastic cover, so you can separate the universal rod

form the swimming arm.

C: Slacken and remove the screw bolt tightening the flat end to the plastic

bearing block with a shifting spanner and a plus screwdriver.

6.4 Replace the optocoupler of body type checkout

Note: You just disassemble the rear and front covers of the backrest

before disassembling the optocoupler of body type checkout.

A.Slacken and remove the screw tightening the optocoupler

to the swimming arm with a plus screwdriver

B: Disassemble the optocoupler on the other swinging arm

in the same way; Now ,you can replace it.

C: You can disassemble the optocouplers in the way mentioned

above if the wires need replacing.

6.5 Replacement of the shock pad

A: Find the screw tightening the shock pad to the swinging arm.

B: Slacken and remove the screw with a plus screwdriver, so you can replace it.

C: Proceed in the reverse order of disassembly when replacing a new one

Slacken the screws and take out

the ball top of rod

Take off the screws

and universal rod

Slacken the screws

Slacken the screws

14

6.6 Disassembly of the holder of knead balls

A:It is unnecessary to disassemble the massage mechanism to

replace the holder of knead balls, just disassemble the rear

cover of the Back rest.

B: Slacken and remove the screw bolt tightening the holder to

the swinging arm with a hexagonal socket wrench (10 mm)

and a minus screwdriver.

Pull the screw bolt out, and the holder can be removed.

C: Remove the tension spring and a new holder can be replaced if needed.

D: Proceed in the reverse order of disassembly when replacing a new one.

6.7.Disassembly of the knead balls

A: Slacken and remove the hexagon check nut tightening the knead balls

to the holder with a hexagonal socket wrench(1/2).

B: Replace a new knead ball and tighten the hexagon check nut.

Attention: There is a plastic washer between the wheel and the nut.

。

6.8.Disassembly of width inspection board

A:Pull out the terminal of width inspection board.

B:Disassemble the left swimming arm

C:Slacken and remove the screw bolt tightening the light barrier to

the eccentric shaft with shifting spanner and inner hexagon spanner,

then the eccentric shaft can be removed.

D: Slacken and remove the screws tightening the width inspection board

to the reduction gear box:

E: Proceed in the reverse order of disassembly if the width inspection board

Take off the ball

Drive the screw bolts and nuts

Tools and parts

Disassemble the holder of

knead balls

15

or light barrier needs replaced.

Attention:In order to operate conveniently,

you can disassemble the massage mechanism first,

then disassemble the width inspection board.

7.Disassembly of Photo-electricity Subassembly:

7.1. Disassembly of up /down stroke photo-electricity subassembly

A: Disassemble the Photo-electricity Subassembly is easier

Just slacken the screws(3pcs) and pull a terminal of the wire

B: There are on the backrest side

Attention: Generally speaking, the Stroke Photo-electricity

Subassembly is so stabile that it can’t be damaged easily.

7.2. Disassembly of the counting Photo-electricity Subassembly

A:Disassemble methods as the same as 7.1

B:There is at the bottom of backrest

width inspection board

and tools

Slacken the screws

Terminal of the wire and 3pcs screws

Terminal of the wire and 3pcs screws

16

8:Disassembly of bearings and bearing blocks

A:Disassemble the rear and front covers of the back rest.

B:Slacken and remove the screws tightening the sheet-metal to

the frame with a plus screwdriver.

C:Remove the sheet-metal, so you can pull out the bearing block. Turn the block clockwise and

counterclockwise alternately to pull it out easily.

9. Disassembly of the seat part

9.1 Replacement of the armrest

A:Slacken and remove the socket head screws tightening

the armrest with a inner hexagon spanner.

B:Replace a new one, and tighten the screw bolts.

9.2 . Replacement of the decorative board

A:Find the screws at the side of decorative board

There are 3pcs inner hexagon screws

B:Slacken and remove inner hexagon screws

Then you can take it down if need replace

9.3 Replacement of the seat pad

A:Raise seat pad begin behind of seat。

Raise seat pad

Slacken the screws(6pcs)

Slacken the screws(2pcs)

Slacken the screws(3pcs)

17

B:Pull out the Connector of air hose

and vibrational motor wires

then take off the fixing material

D:Now, you can replace new one if it need

9.4 Replacement of the side boards

A:disassemble the armrest above the side board

needing replacement

B:Find the inner hexagon screws (4pcs) ,then slacken them

And take down

C:Now,you can replace a new one.

9.5 Replacement of main PCB

A:Main PCB box Under the seat, just disassemble board and Raise it

B:Then,you can find 4pcs screws around box

Slacken these screws and take the cap

Inside board have 4pcs inner hexagon screws

Commector of air hose

and motor wires

Take off the fixing material

Slacken the screws(4pcs)

Slacken the screws(9pcs)

Take the box cap

18

C: Pull out all the terminal connecting to the main PCB,

unlock the plastic posts for the PCB. and a grounding screw

Then the PCB can be removed.

F:Proceed in the reverse order of disassembly

when replacing a new PCB.

9.6 Replacement of the reclining actuator of the Back rest

A:Turn off the power and remove plug from outlet.

Lay the back rest forward on the Seat Pad.

Pull out the splint pin in the pin rollwhich connects the reclining actuator of

the Back rest and the turnover mechanism with a nipper pliers.

Then draw the pin roll to free one end of the actuator.

B: Release the other end of the actuator in the same way as”A”

C:Disassemble the upper cover of the box for the main PCB,

then pull out the terminal of the actuator.

D: First, fix both end of the actuator in the reverse order of Part A&B.

Don’t forget to assemble the bush rings in the both end of actuator as

you can see in disassembly.

The terminal of reclining actuator

Reclining actuator and the accessory

The screw is

grounding point”

The plastic posts

taken down

the another Pin roll

taken down the Pin roll

19

E:Then connect the terminal of the actuator to the main PCB.

Turn the power on and check the connection is right

or not by sitting up or reclining the Back rest.

If it’s not, just exchange the two pin of the terminal.

F:At last, assemble the box of the main PCB,

and tighten the wire of the actuator with cable ties.

9.7 Replacement of the foot rest actuator

A:Turn off the power and remove plug from outlet.

Lay the Back rest forward on the Seat Pad.

B:take off the splint pin in the pin roll which connects the

legrest actuator with a nipper pliers ,then separate the

actuator with legrest

Attention: When drawing the pin roll, you should hold the LegRest with

you leg or by another person. Because the LegRest maybe

fall down on your foot

C:Then.take off the splint pin of seat part,and separate the actuator with seatrest

D:Last, just you take off the terminal of actuator on main PCB

Now,you can take out the actuator and replace it

The terminal of the actuator

Tade out the actuator of legrest

Axis

Axis pin

Take off the splint pin

Separate the actuator with legrest

Take off the another pin

Separate the actuator

with seatrest

20

9.8 Replacement of the inflator pump and snuffle valves

A:Turn off the powe, then removed the seat pad and disassemble seat board

Now ,you can look at the inflator pump

B:Pull out the rubber poles fixing the inflator pump,

Take out the erminal of the inflator pump and

the terminal of the snuffle valves

10. Replacement of the LegRest

Please follow the steps below to disassemble the LegRest:

A:Turn on the power, Raise the legrest to the extreme position

for the easier disassembly.

Turn legrest back up and take the screws。

B:take out the side cover of legrest,then take off the splint pin(2pcs)

And legrest on the actuator of legrest(1pcs)

the rubber poles

Screws(3pcs)

The inflator pump

The terminal of

the inflator pump

The terminal of

the snuffle valves

Take off the splint pin

(another side has one also)

Take out the cover

Table of contents

Other Cozzia Massager manuals

Cozzia

Cozzia Renew Instruction Manual

Cozzia

Cozzia Revive OG357 User manual

Cozzia

Cozzia CZ-328 User manual

Cozzia

Cozzia CZ-710V User manual

Cozzia

Cozzia CZ-641 User manual

Cozzia

Cozzia EC-618 User manual

Cozzia

Cozzia Espree User manual

Cozzia

Cozzia EC-360D User manual

Cozzia

Cozzia CZ-357 User manual

Cozzia

Cozzia CZ-681 User manual

Cozzia

Cozzia CZ-357 User manual

Cozzia

Cozzia MC-520 User manual

Cozzia

Cozzia CZ-330 User manual

Cozzia

Cozzia ZEN CZ-641 User manual

Cozzia

Cozzia ergotec AG-6100 User manual

Cozzia

Cozzia 16027 User manual

Cozzia

Cozzia CZ-630 User manual

Cozzia

Cozzia EC-326G-CO Manual

Cozzia

Cozzia CZ-730/Qi User manual

Cozzia

Cozzia EC-362B User manual