2 P—MS2 Two Stage Electronic Control Installation Bulletin

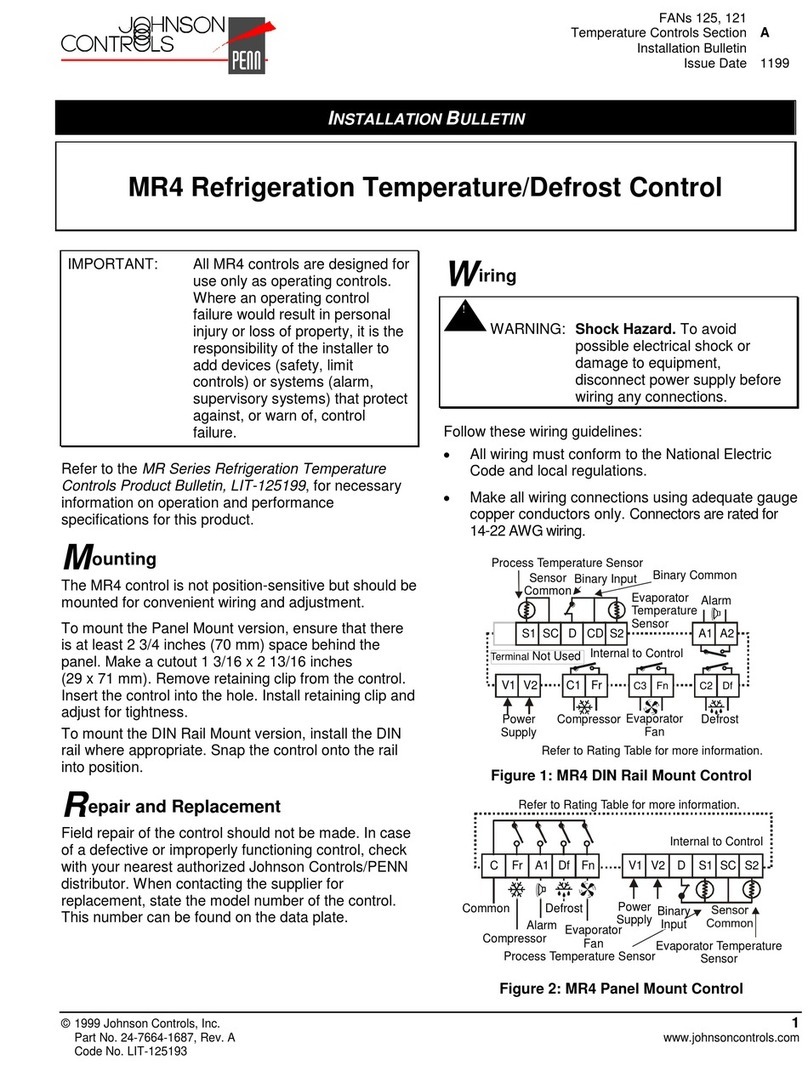

Table 1: Wiring

MS Series

Terminal

P99-1V

Wire Color

HE-6300 or

HE-6310

Terminal

VO Brown (+) PWR

SC Green (common) COM

S1 White (signal) OUT

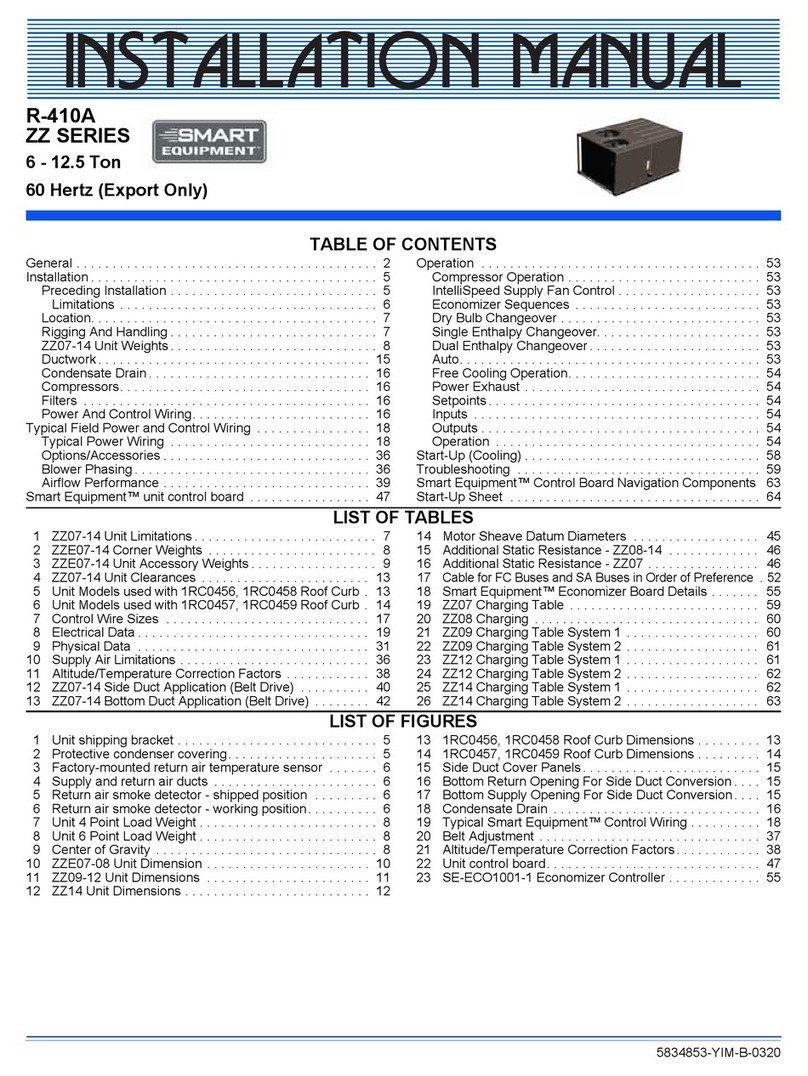

Table 2: Rating Table

Rating Category 120

VAC

240

VAC

24

VDC

Horsepower 1/4 1/2 -

Full Load Amperes 5.8 4.9 -

Locked Rotor Amperes 34.8 29.4 -

Inductive (non-motor)

Amperes

888

Pilot Duty VA 275 450 -

Power supply is 24 VAC.

Terminal VO output is 12-17 VDC.

FCC Compliance

This equipment has been tested and found to comply

with the limits for a Class A digital device pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the

instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in

a residential area is likely to cause harmful

interference, in which case the user will be required to

correct the interference at his/her own expense.

Canadian DOC Compliance

This digital apparatus does not exceed the Class A

limits for radio noise emissions from digital apparatus

set out in the Radio Interference Regulations of the

Canadian Department of Communications.

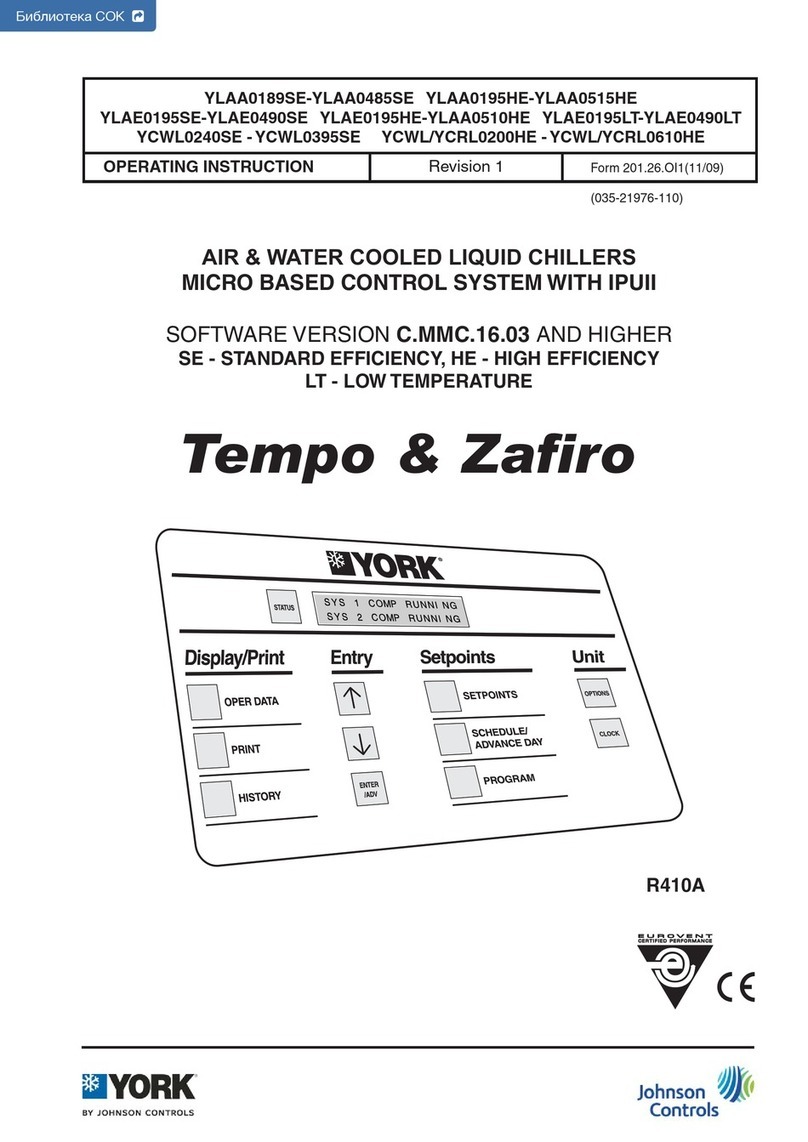

Display

Press Up and Down buttons to scroll through process

temperature and binary input status (On or OF). After

15 seconds of inactivity, the display shows the process

temperature.

Setting Up the Stage Control

To lock/unlock the unit for programming

Press the Enter, Up, and Down buttons

simultaneously and hold until “- - -” is displayed.

Hold for about 10 seconds until the current

condition value is displayed. This toggles the

keypad between locked and unlocked.

To run the self test procedure

IMPORTANT: Disconnect loads before beginning self-test

procedure. Cycle power to resume normal

operation.

Press the Up and Down buttons in sequence,

and hold for 5 seconds.

To select the mode of operation

1. Press and hold the Enter and Down buttons

simultaneously for approximately 7 seconds.

2. Press the Up or Down button until the desired

setting is shown.

2d =Direct

2r = Reverse

2b = Deadband

2i = Independent Setpoint

3. Press the Enter button to save the new mode

of operation.

To change the setpoint (modes b, d, and r only)

1. Hold the Enter button down for 3 seconds.

The display will change to show the setpoint.

2. Press the Up or Down button until you reach

the new setpoint.

3. Press the Enter button to save the new

setpoint.

Note: If you do not press the Enter button after selecting the new

setpoint, it is not saved. The control reverts to old setpoint.

To program other settings (modes b, d, r only) or to

program setpoints and settings (mode i only)

1. Hold the Enter button down for about

10 seconds. The display will change to HY.

(The display shows S1 if in Mode i.)

2. Press the Up or Down button until the

desired setting is shown.

3. Press the Enter button. The setting’s current

value is displayed.

4. Press the Up or Down button until the

desired value is shown.

5. Press the Enter button to save the new

value. After 10 seconds of inactivity, the

display will return to its normal function.

Note: If you do not press the Enter button after selecting the new

value, it is not saved. The control reverts to the old value.