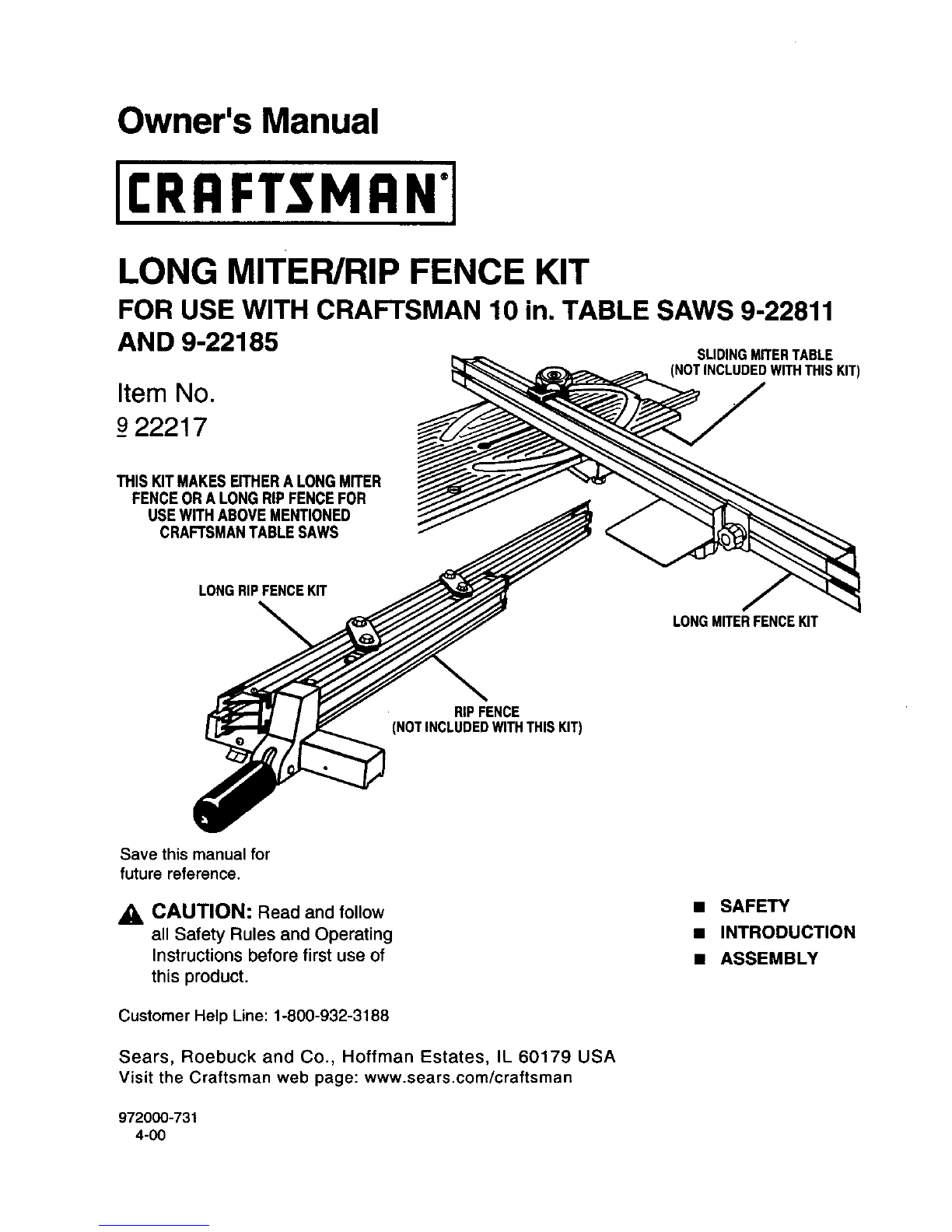

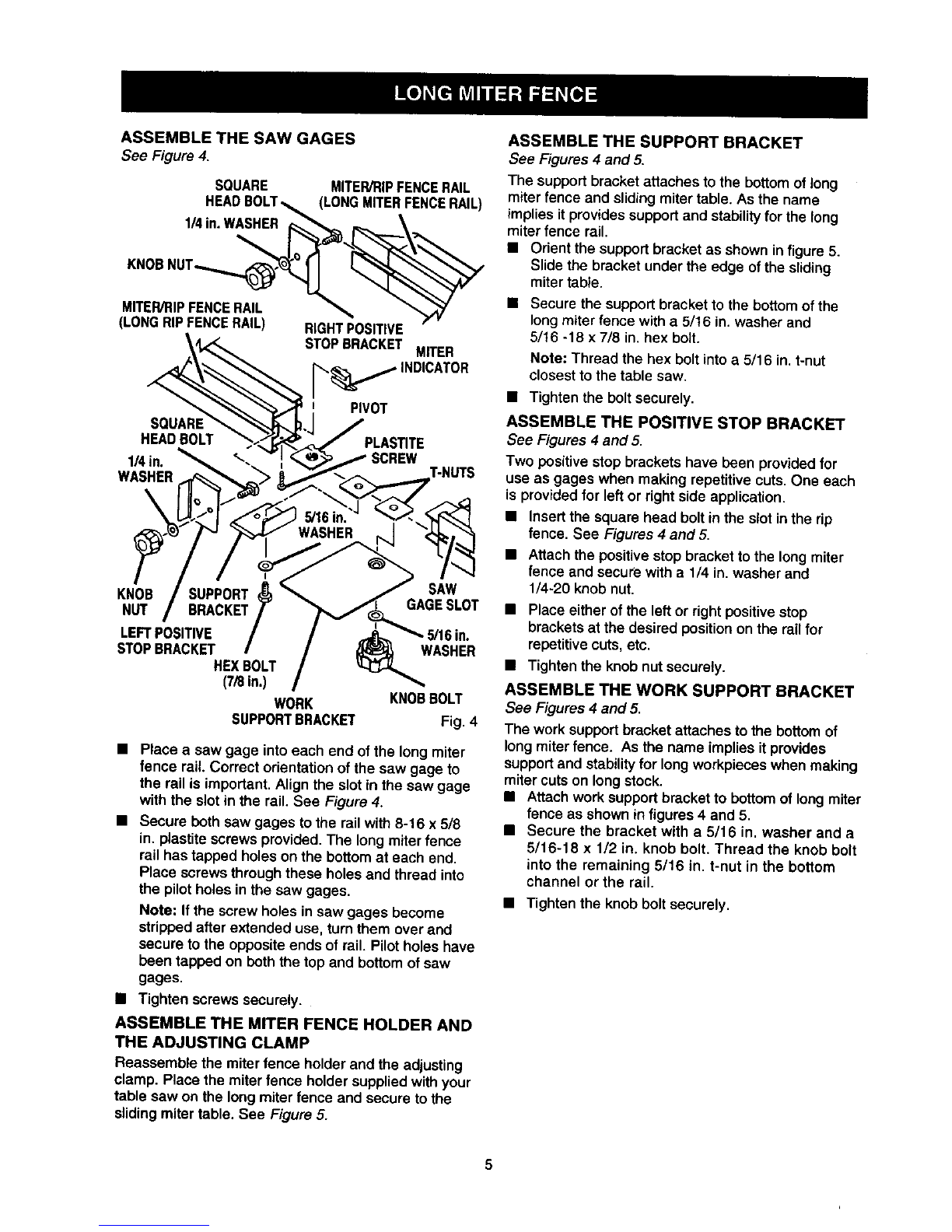

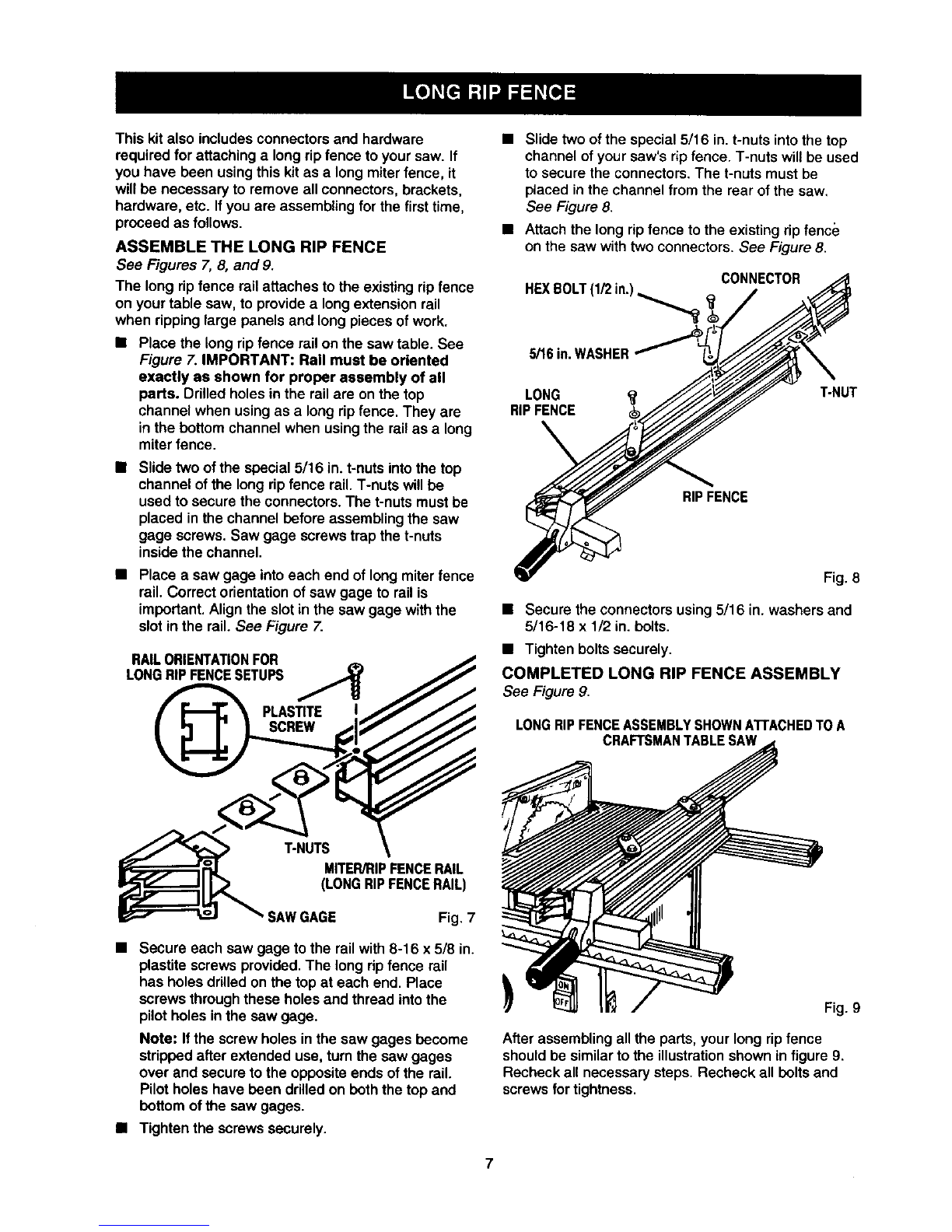

ASSEMBLETHESAWGAGES

See Figure 4.

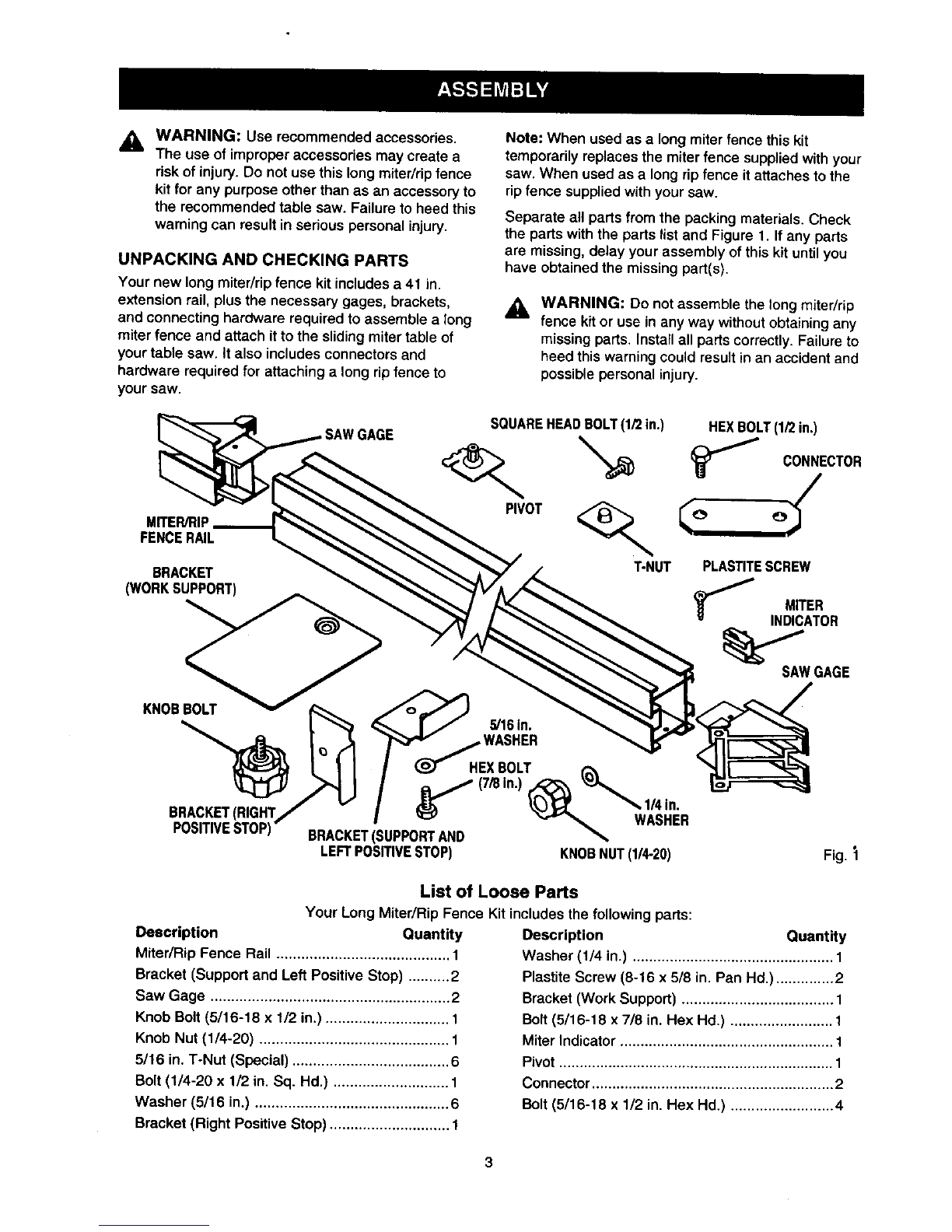

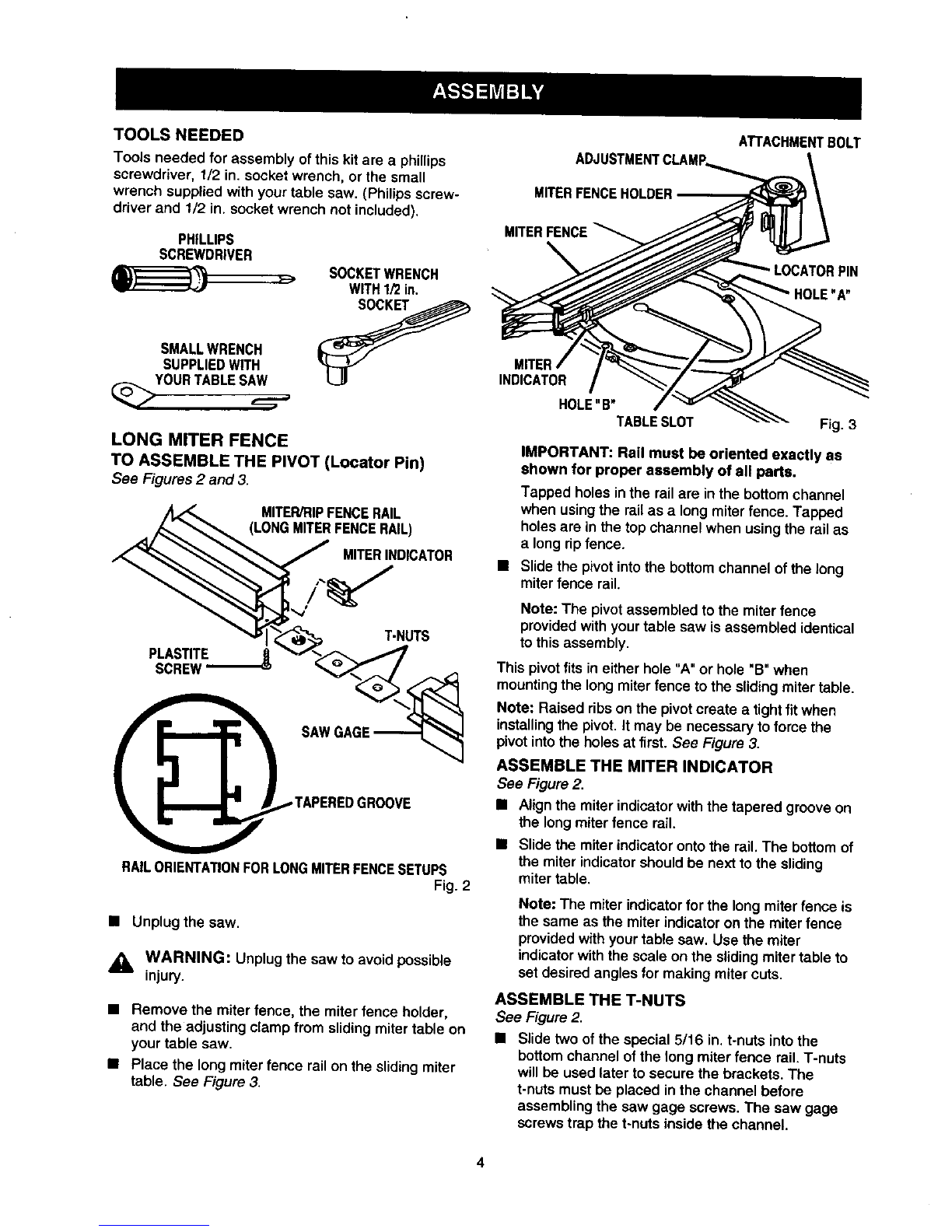

SOUARE MITER/RIPFENCERAIL

HEADBOLT_ (LONGMITERFENCERAIL)

1/4in.WASHER_,_ _., \

MITER/RIPFENCERAIL _

(LONGRIPFENCERAIL) RIGHTPOSITIVE

STOPBRACKET MITER

_._,_ INDICATOR

PIVOT

SOUARI

HEADBOLT PLAS_TE

l_in. SCREW

WASHER T-NUTS

t

KNOB SUPPORT SAW

NUT BRACKET/ GAGESLOT

LEFTPOSITIVE /

STOPBRACKET /WASHER

HEXBOLT

(7/8in.) WORK KNOBBOLT

SUPPORTBRACKET Fig. 4

•Place a saw gage intoeach end of the long miter

fence rail. Correct orientation ofthe saw gage to

the rail is important. Align the slot in the saw gage

with the slot in the rail. See Figure 4.

• Secure both saw gages to the rail with 8-16 x 5/8

in. plastite screwsprovided. The long miter fence

rail has tapped holes on the bottom at each end.

Place screws through these holes and thread into

the pilot holes in the saw gages.

Note: If the screw holes in saw gages become

strippedafter extended use, turn them over and

secure to the opposite ends of rail. Pilot holes have

been tapped on both the top and bottom of saw

gages.

• Tighten screws securely.

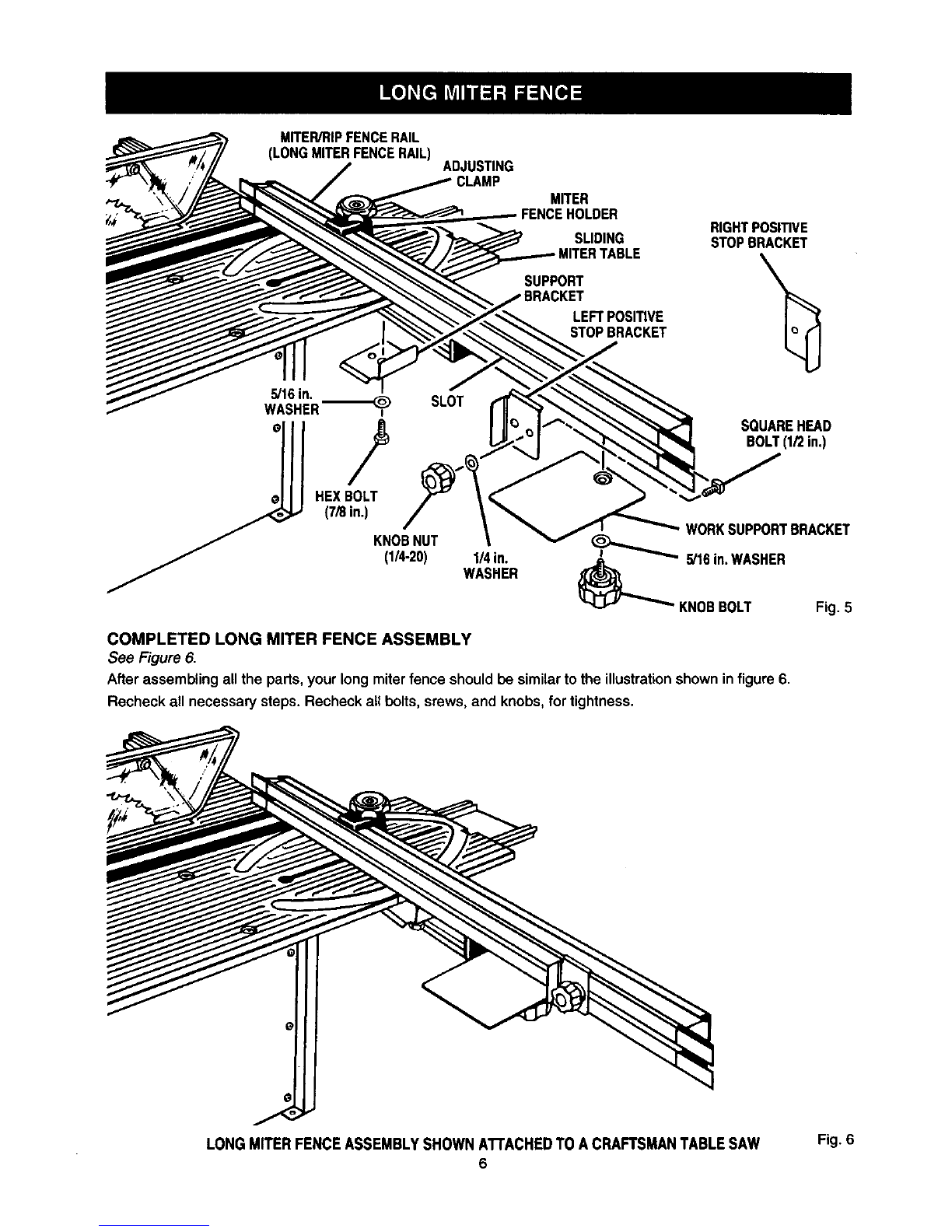

ASSEMBLE THE MITER FENCE HOLDER AND

THE ADJUSTING CLAMP

Reassemble the miterfence holderand the adjusting

clamp. Place the miter fence holdersuppliedwithyour

table saw on the long miterfence and secure to the

slidingmiter table, See Figure 5.

ASSEMBLE THE SUPPORT BRACKET

See Figures4 and 5.

The supportbracket attaches to the bottom of long

miter fence and slidingmitertable. As the name

impliesit provides support and stability for the long

miter fence rail.

• Orient the support bracket as shown in figure 5.

Slide the bracket under the edge of the sliding

miter table.

• Secure the supportbracket to the bottom of the

longmiter fence witha5/16 in.washer and

5/16 -18 x 7/8 in. hex bolt.

Note: Thread the hex bolt into a 5/16 in. t-nut

closest to the table saw.

• Tighten the bolt securely.

ASSEMBLE THE POSITIVE STOP BRACKET

See Figures 4 and 5.

Two positivestop brackets have been providedfor

use as gages when making repetitivecuts, One each

is providedfor left or rightside application,

•tnsert the squarehead boStinthe slotin the rip

fence. See Figures 4 and5.

• Attach the positive stop bracket to the long miter

fence and secure with a 1/4 in. washer and

1/4-20 knob nut.

• Place either of the leftor right positive stop

brackets at the desired position on the rail for

repetitive cuts, etc.

• Tighten the knob nut securely.

ASSEMBLE THE WORK SUPPORT BRACKET

See Figures4 and 5.

The work supportbracket attachesto the bottomof

longmiter fence. As the name implies itprovides

supportand stabilityfor longworkpieceswhen making

miter cutson longstock.

•Attachwork supportbracketto bottomof long miter

fenceas shownin figures4 and 5,

•Secure the bracket with a5/16 in. washer and a

5/16-18 x 1/2 in. knob bolt. Thread the knob bolt

into the remaining 5/16 in. t-nut in the bottom

channel or the rail.

•Tightenthe knob bolt securely.

5