6 of 6 LPN00513X0001A4_D

www.creelighting.com

© 2019 Cree Lighting, A company of IDEAL INDUSTRIES. All rights reserved. For informational purposes only. Content

is subject to change. See www.creelighting.com/warranty for warranty and specifications. Cree®and the Cree logo are

registered trademarks of Cree, Inc.

TROUBLESHOOTING

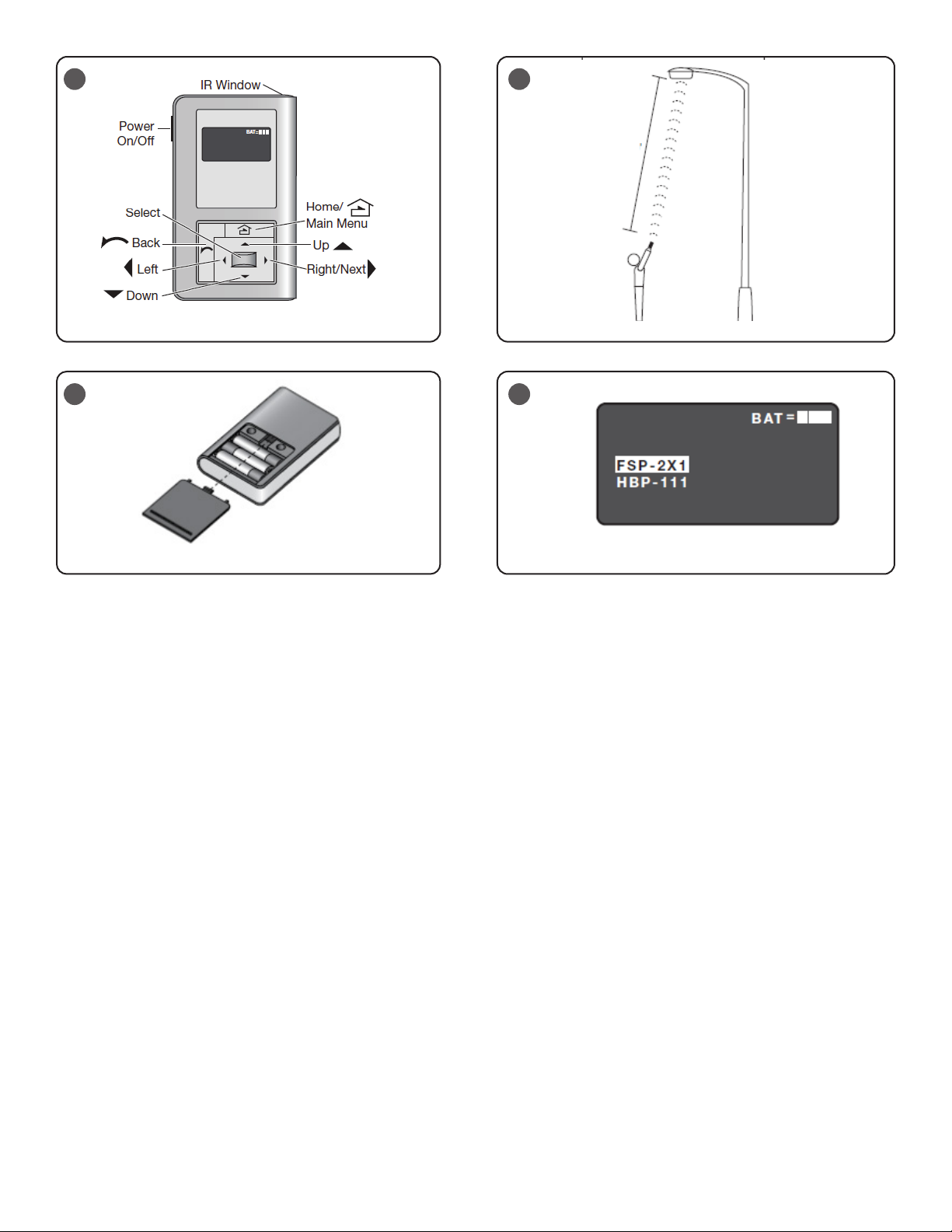

NO RESPONSE SCREEN APPEARS:

• Make sure that the sensor is not obstructed.

• Move closer to the sensor. A ladder or lift may be required.

• The angle may be too high, move closer so that you are directly

underneath the sensor.

• Make sure that multiple sensors are not in the range of the

transceiver. If this happens, then all of the luminaires will cycle.

• If still not successful, there may be too much IR interference from

other sources. Programming the unit at night may be the only way

to communicate with the sensor.

LIGHTS WILL NOT go to high mode:

• Make sure that the sensor is not obstructed. The sensor must

detect motion to switch to HIGH mode. The red LED indicator will

blink when motion is detected.

• Check the light level parameter, to find out the amount of light

that the sensor is detecting. Cover the sensor lens to simulate

darkness in the room. If the luminaire goes to high mode, then the

setpoint needs to be adjusted to a value greater than the detected

light level. See the new settings and current settings sections for

instructions.

• If the light level is higher than the setpoint value but less than

the photocell value, then the luminaire will remain in low mode.

Adjust the setpoint and photocell values as needed.

• Make sure that the high and low settings are correct by checking

the current settings.

Lights will not go into Low Mode:

The time delay can be set from a minimum of 30 seconds to a maximum

of 30 minutes. Ensure that the time delay is set to the desired value and

that there is no movement within the sensor’s view for that time period.

• To quickly test the unit operation, enable Test Mode and move out

of the sensor’s view. The luminaire should go to LOW mode after 5

seconds.

Lights will not turn OFF:

• Cut Off time may be set to “None.”

• Ensure that the Cut Off is set to the desired time and that there is

no movement within the sensor’s view for that time period when

the lights are in Low Mode.

• To quickly test the unit operation, enable test mode and move out

of the sensor’s view. The luminaire should switch to LOW mode

after 5 seconds and then turn OFF (if cut off is enabled) after 10

sec.

• If the luminaire does not turn off in daylight, check the ambient

light level. Adjust the photocell setting to a value lower than the

ambient light level. The setpoint may also need to be adjusted if

the difference is less than 10 fc.

• Make sure that the Sensitivity field is not set to On-Fix.

Lights will not turn ON:

• Check all wire connections and verify that the load and the ground

wires are tightly secured.

• Check the current settings. If the setpoint value is lower than the

ambient light level, the luminaire will be held OFF. Increase the

setpoint value.

• Disable the cut off function, if not desired.

• Make sure that the Sensitivity field is not set to Off-Fix.

OPERATION DURING POWER-UP

During the sensor warm-up period, which can last up to a minute after

initial power-up (or after a lengthy power outage), the load will remain

ON until the selected time delay expires.

TECHNICAL SUPPORT

If unable to successfully resolve problems with the sensor, contact Cree

Lighting at 800.236.6800 for technical support.

FEDERAL COMMUNICATION COMMISSION INTERFERENCE STATEMENT

CAUTION: Changes or modifications not expressly approved could void your authority to use this equipment.

This device complies with Part 15 of the FCC Rules. Operation to the following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause undesired operation.

This device has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the device is operated in a commercial environment. This device generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this device in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

INDUSTRY CANADA STATEMENT

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the device. In addition,

this device complies with ICES-003 of the Industry Canada (IC) Regulations.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation est autorisée aux deux

conditions suivantes : (1) l’appareil ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d’en compromettre le fonctionnement.